-

Schumacher Cougar SV -

Words & Pictures: Arn0

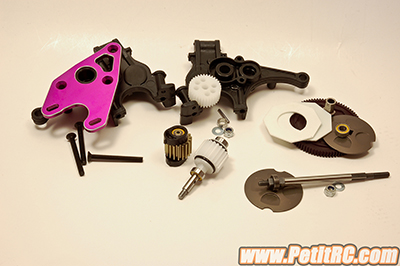

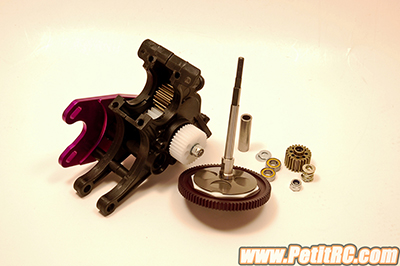

Transmission

Only for the second time, Schumacher

does not use a belt transmission on his two wheel drive buggy, the

previous one being the Cougar 2000. So the SV owns a brand new

transmission with four gears plus the usual spur-pinion, without

taking in consideration the differential spur. At the end of the day,

that makes five gears, impressive for a two wheel drive.

To get it done, seven bags need to be

opened!! Here are the components of this transmission:

- 3 pins

- 6 bearing

- 2 seals

- 2 eccentrics

- 4 gears

- 2 housings

- 1 motor plate

- 3 screws

- 3 shafts

- 3 spacers

- 4 washers

- 2 nuts

- 1 spring

- 2 slipper plate

- 2 slipper pad

- 1 machined spur

That makes a total of forty

one items. There are this many components because this transmission is

adjustable in different ways. Letís have a quick overview of the four

major assemblies detailed below:

1

- the transfer shaft with the slipper clutch already seen on the Cat

SX

2

- the layshaft with itís gear

3

- the height-adjustable idle gear

4

- the differential

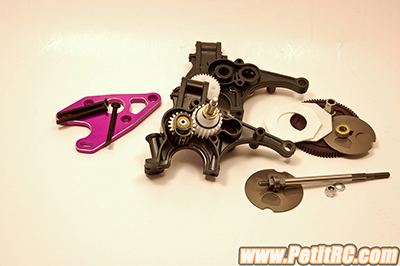

By default, the internal

ratio is 2.6:1, kind of a magic number in 2wd, and it is defined as

'medium internal ratio'. 'Medium internal ratio', that means there is a

'high internal ratio' and a 'low internal ratio'. This can be achieved

but replacing a set of pinions: the ones on the outside of the gearbox.

Per kit, you have a 23 tooth and a 33 tooth, but you may switch for

22/34 to get the 'high internal ratio' for hi rev motors. 'Low internal

ratio' is established by combining a 24 tooth gear with a 32 tooth

one which is a better fit for low rev motors such as those dedicated to

the stock class. In every case, fine tuning of the final drive ratio is

still achieved with the inseparable spur-pinion.

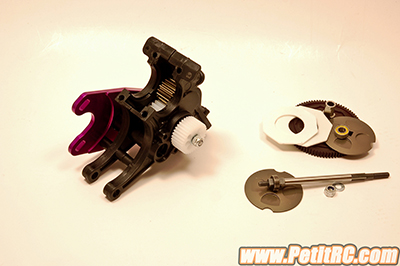

It is possible to set the

transmission height, a setting that appeared some years back but is very

useful to increase or reduce traction of the rear end. In the present

case, the casing will always stay in the same position, meaning some

eccentrics located around the differential will allow the adjustment of

this parameter. But to do so, one gear - and consequently a shaft -

needs to move up or down, which is done by the eccentrics inside the

gearbox.

Before pushing forward, letís

have a better view of the layshaft gear inside the gearbox. This gear is

mounted on a shaft with two pins; these two pins are held on by two

o-rings. Fresh mounted, that looks good. But projecting ourselves into

the future, the o-ring may dry, the pins may push on those o-rings and

at one moment, one of the pins might escape and have a nice and

devastating journey inside the casing. You get the point: bye-bye

internal gears. So, while mounting this gear, you can either replace the

pins by roll pins or use a tiny drop of glue to avoid any pin movement.

Of course, some other alternative solutions may appear.

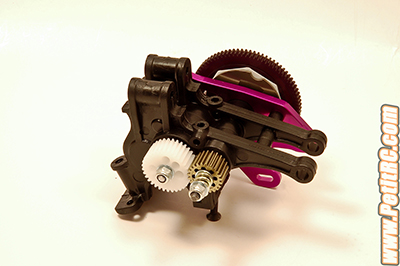

Done with the rotational

parts, letís have a look at the fixed parts. The motor mount is a

one-sided chamfered purple anodized 4mm aluminum plate, a nice look

piece to cool down the motor. The two others fixed parts are the

housings. Complex molded items with a lot of recesses and details, the

twins may have cost Schumacher some effort. The internal shape is well

made, no play between gears, shaft distances are good with the provided

external gears and no doubt will work great with the optional ones

described above. But strangely enough, there is no lip all around one of

the housings to provide sealing. Look deeply at the shape, it is

impossible to get this lip done as the casings are almost symmetrical

and molding processes do not allow the fabrication of this lip. To get

it in place, the housing should have been asymmetrical or with an

additional piece, but would probably be even more complex to produce.

Here, only the design team gets the answer and the final decision was a

compromise between various parameters, as always in engineering.

The assembly is in fact

pretty straight forward. Be sure to install one eccentric on each

housing and in the same position. As recommended, the differential will

be set low to get the highest traction possible so the idle gear must be

positioned low, otherwise you won't have mesh contact and consequent

motion while accelerating.

As standard equipment, the

transmission is loaded with a slipper, the basic system designed years

back. The components are the same as the ones from the Cat SX, so no

surprise. And as the 4wd, the setting will be realized from the other

side of the spur location.

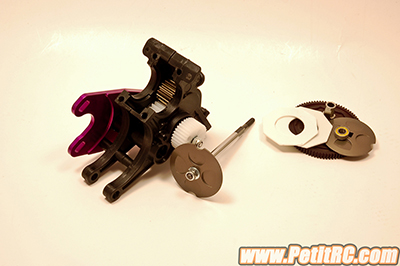

Once together, the whole

transmission runs smoo... almost smooth, there is one spot where you can

feel some resistance, a hard spot most probably due to a tiny something

on the nylon gear located before the metal one. That will disappear

after a little break-in.

One advice that will be

useful while putting the transmission into place, do not tighten the

three screws holding the motor plate and so, do not install the spur and

the related items.

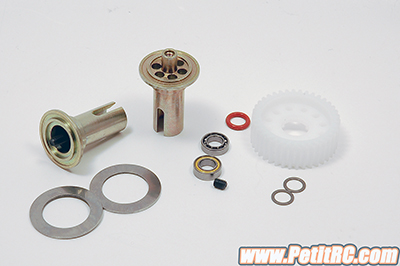

Differential

To get the transmission

fully done, the differential is the next step.

First point to note, an

additional sheet giving some advice on a specific point of this part of

the car's assembly; the mounting of a circlip with dedicated pliers,

provides advice for this procedure.

The design is the same as

the one for the Cat SX, just to note a thrust bearing and four

Belleville type disc springs are fitted on a fully threaded screw. The

use of a fully threaded screw is weird as one of the thrust bearing

washers will come in contact with the thread at one point. In the first

instance, itís worth the try as is works fine on the 4wd but switching

for a partly threaded screw would be a good idea. This assembly sits

inside one output once installed from the inside of the differential and

not from the outside.

Others designs are based on

the use of a spring and nut, both located on the opposite output where

the thrust bearing is located. The Schumacher design makes the screw

tightening directly on the opposite output, meaning no nut, and a

headless screw secures the whole package.

The assembly is pretty

straight forward. The thrust bearing discs are not the same thickness,

the difference is minimal so be careful. Also be patient while putting

on the circlip, it can be twisted slightly to avoid any freedom and take

care how you insert it as the additional sheet is very clear about that.

You may add a spot of glue to make sure this circlip wonít move. The

differential will be adjusted once the car is done, tightened enough to

be borderline loose.

|