-

Schumacher Cougar SV -

Words & Pictures: Arn0

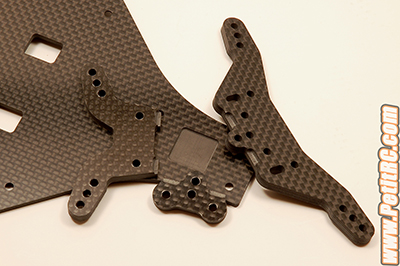

Steering

With

the first part of the build-up, it is time to discover a bit more about

the car's parts and especially the carbon fiber ones which include the

chassis, both front and rear shock towers and upper links mounts, a

bracket as well as the top desk-battery holder. This last component and

its teammate the low desk, are both made from 2.5mm carbon fiber while

as the upper link mounts are a bit bigger machined in a 3mm thick plate. With

the first part of the build-up, it is time to discover a bit more about

the car's parts and especially the carbon fiber ones which include the

chassis, both front and rear shock towers and upper links mounts, a

bracket as well as the top desk-battery holder. This last component and

its teammate the low desk, are both made from 2.5mm carbon fiber while

as the upper link mounts are a bit bigger machined in a 3mm thick plate.

These upper mounts are the

39mm wide ones for the front end and 40.5mm located on the rear of the

car. Some optional parts are available with 34mm, 44mm and 49mm for the

front ones and 45.5mm and 50.5mm for the rear. There is potential to get

some more value in between each but if you count the number of

possibilities to set up the car, well, that might be enough.

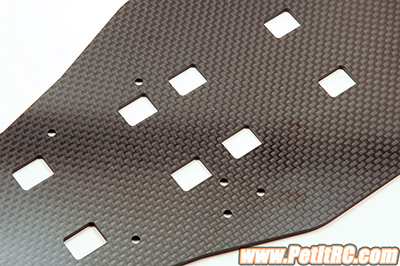

The shock towers and the

bracket are the thickest carbon fiber parts at 4mm. The chassis and the

towers have machined areas to obtain some specific clearances to install

the gearbox and set the towers on their dedicated supports.

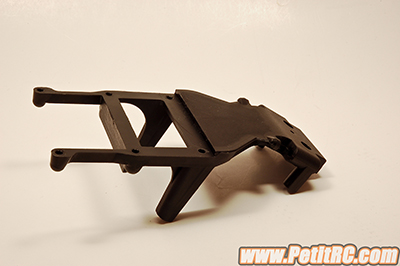

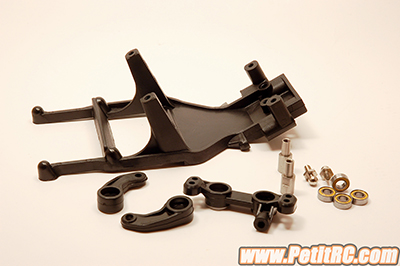

On the other side, there is

also some plastic parts as a well designed and molded front bottom

plate. This bottom plate has a step that, once linked with the low desk,

makes a completely flat assembly with the low desk. Some steering

components get a bit of flash but nothing major and a quick cut with an

x-acto will allow the removal of this excess of material.

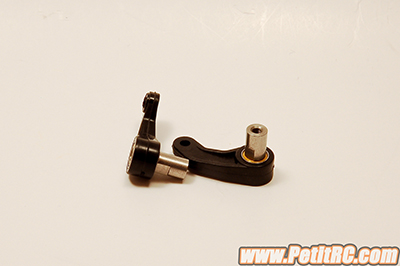

As this is a competition

car, the steering is equipped with four rubber sealed ball bearings to

guide around two small metallic posts, the little arms supporting a

rack. The ball bearings are not tight mounted as there will be some load

applied and no high revolution. The metallic posts are secured with two

long screws and two thin washers, make sure of a sufficient clearance

with the bulkhead. There is no mention of thread lock here, a little

drop won't hurt to avoid any loss of parts within in the assembly while

the car goes around the track.

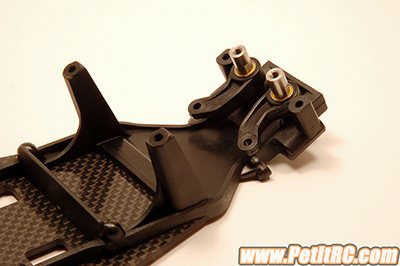

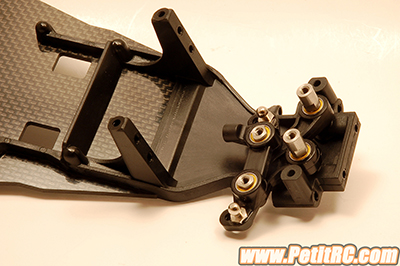

The rack itself is set with

another four sealed ball bearings, the exact same as the arms, and again

two posts support this item. The Ackerman effect can be adjusted by

moving forward or backward the ball studs on the rack. Once all

together, the steering system sits very low on the car, that's pretty

impressive. And it is smooth, super smooth! Well done!

|

The steering rack in position

|

Three horns to match all brands of servo but no servo saver

|

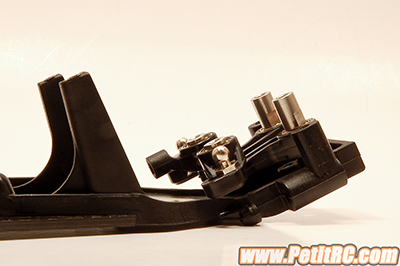

To get the steering fully

done, you may install a servo and some additional linkages. You must set

the servo to neutral when setting the horn as it won't be possible once

the front end is completed. The manual is well detailed for this section

and various horns are provided depending on which servo you use.

Strangely, there is no servo-saver in the kit. As a measure of

precaution, you'd better purchase one.

Front suspension

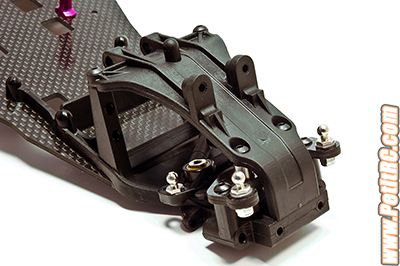

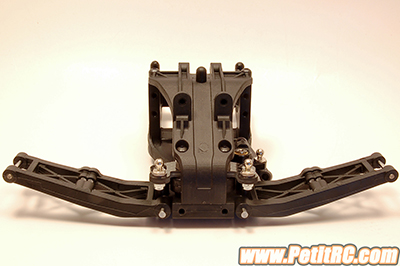

Once

the steering is done, the following and logical step is the front

suspension. Some nice features are part of this car's extremity but as

is standard, this front end is a double wishbone type, as the SV is a

racing car. Once

the steering is done, the following and logical step is the front

suspension. Some nice features are part of this car's extremity but as

is standard, this front end is a double wishbone type, as the SV is a

racing car.

The front link mount sits on

top of the steering posts, evidence here that every part was fully

considered in the design to move components as forward as possible. The

front bulkhead finishes the car nose with two pairs of screws. All parts

need a little clean up once they have been removed from their molding

support. The link mount receives two ball studs adjustable with some

shims, one on each side is included in the kit so be sure to get some

more to raise the ball studs. This setting will affect both the roll

center and the camber change.

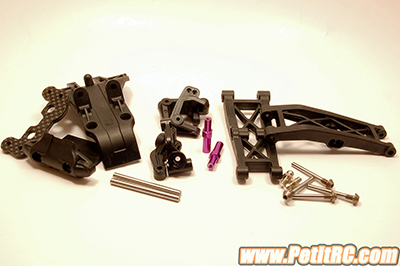

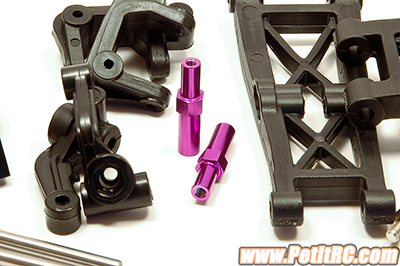

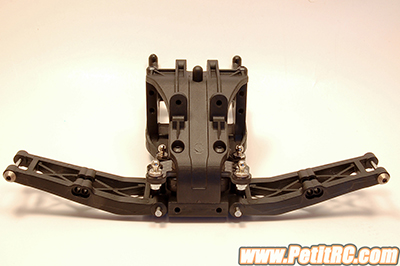

The following step is

related to the front end's mobile components such as wishbones, hub

carriers and turnbuckles. Interestingly, the front wishbones can be

mounted on either side as a tuning option. As others cars on the market,

switching A-arms has an effect on the geometry of the vehicle by

increasing the wheelbase of 1.5mm and hence changes the weight

distribution slightly but also affects the Ackerman effect, giving an

easier car to drive.

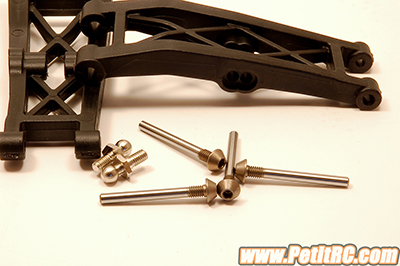

The threaded hinge pins

to mount hub carriers with A-arms |

The front axles allows

you to use different brands of rims |

|

|

Front wishbones as per kit |

Front wishbones flipped |

As a standard advice, make

sure suspension moves freely under gravity; mounted per the manual, one

of the wishbones was slightly tight, but when flipping the A-arms,

everything what perfect. So use a file or fine sandpaper if needed to

remove some material from both wishbones and from the bottom plate to

obtain a free suspension. A small bumper will secure the hinge pins in

position and will also protect part of the bottom from impact.

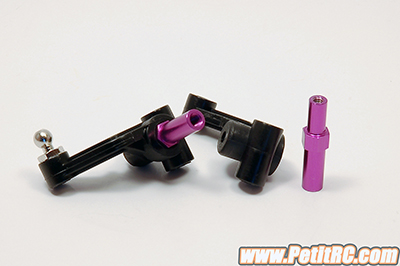

The outer hinge pins

connecting A-arms with yokes are threaded near the head screw - this

item is already used on the Cat SX but it is always nice to get them

instead of those e-clips that tend to get loose at one moment or

another.

Here the assembly is fully

secured and easy to remove in case of necessity. The exact same

procedure applies for the hub carriers and the yoke as one was a bit

tight but that was really minor.

The

hub carriers are fairly common which is good and are featured with two

possible height adjustments (high and low), allowing to change the roll

center and the bumper steer, so remember every time to properly set the

shim under the ball stud. For racers who have spare rims other than

Schumacherís, those will fit on the axle as long as you can use the

screw and not a nut. The

hub carriers are fairly common which is good and are featured with two

possible height adjustments (high and low), allowing to change the roll

center and the bumper steer, so remember every time to properly set the

shim under the ball stud. For racers who have spare rims other than

Schumacherís, those will fit on the axle as long as you can use the

screw and not a nut.

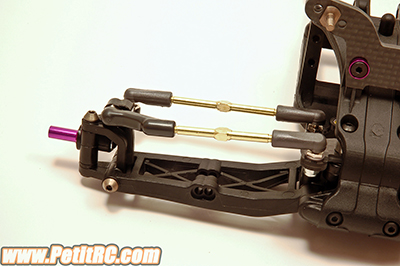

The last two items to have a completed

front suspension are the turnbuckles and the shock tower. The latter

have been already mentioned and will be maintained using two 12mm long

screws. There are three top damper positions, a regular feature stronger

than a screw. Regarding the turnbuckles, they are made from steel and

are gold plated. As many racers switch them for titanium components,

thatís not really a matter, they will do the job for the first runs

Once together, this front end is real

specific, open spaced, with a servo located more forward than standard.

|