|

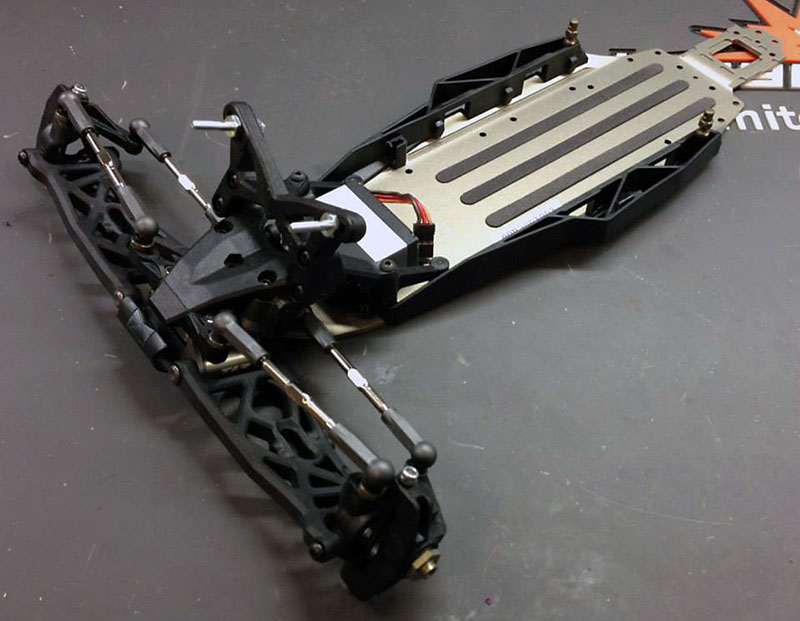

- Team Losi Racing 22 2.0 - Frank Root - Build -

Steering & front end

Previous - Page 2 - Next

Once Bag A is opened, bags A1, A2, A3 and the tool kit will all fall out.

Tool kit include TLR-Lok thread lock, the turnbuckle wrench and 4 way nut driver tool with 5.0, 5.5, and 7mm sizes all included.

Bag A1, all of the contents laid out, ready for step A1.

Step A1, assembling the servo link.

** Build Tip - Be sure put a small dab of black grease in the end of each ball cup. It will make threading the rod end in much easier.

Step A2 & A3, installing the servo link and servo horn onto the servo. Frank prefers the Spektrum S6040 for great speed and torque. He's been using the S6040 for over 4 years in all of his vehicles without a single issue to date.

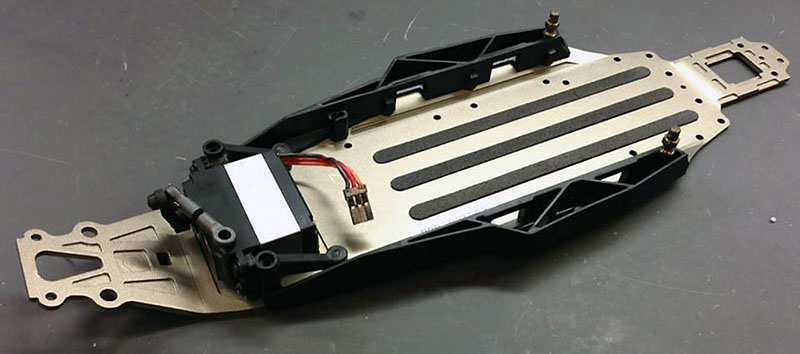

Step A4 & A5, installing the chassis foams, mud guards, and servo onto the chassis.

**Build tip - Use a body reamer to put a slight chamfer on the body post holes in the mud guards for an easier start for the first few threads.

Bag 2, all of the contents laid out and ready for step A6

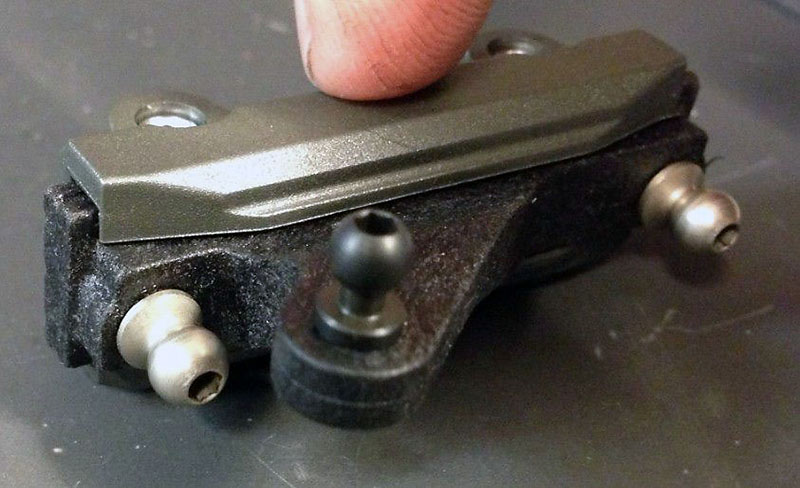

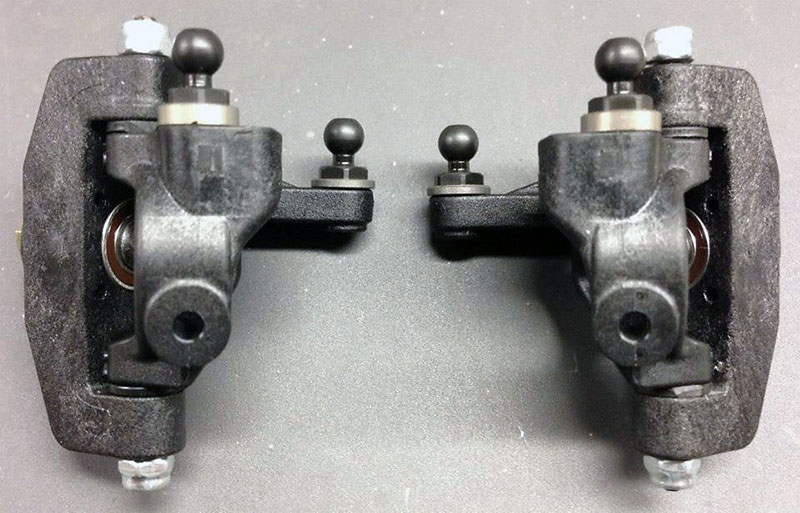

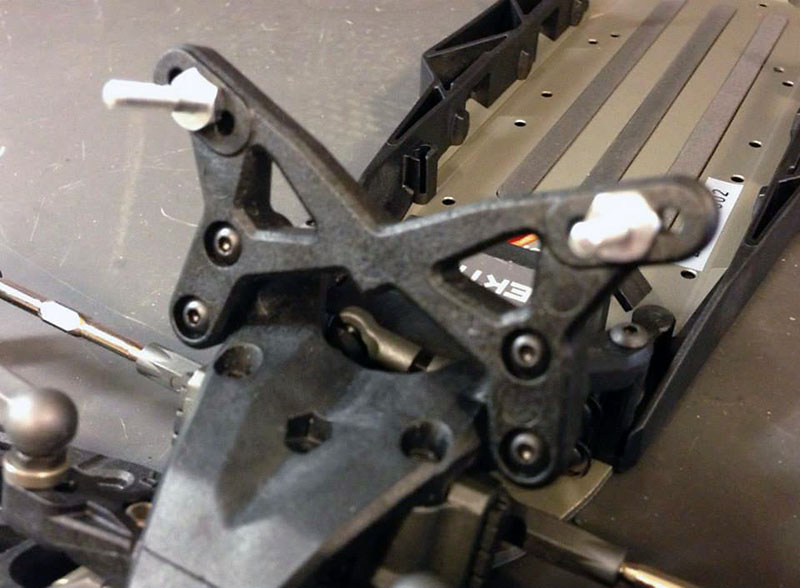

Step A6, the all new 22 2.0 steering rack and housing. Notice the steering link ball studs are now horizontal which gives the ability to make ackermann adjustments.

On the 22 2.0 build, I have one quick note guy. On one of the sample kits, we saw an issue that when the rack housing was tightened down well in the chassis between the chassis, front pivot and front bulkhead, the slider rack could be a little on the snug side. We didn't see this during any of the testing or samples, so it was a surprise to see it in the production kits. Since the fix literally takes only 30 seconds, we didn't feel it was worth holding back the kits to do a full inspection, or possibly rework the kits with new parts.

With the said, the rack top to bottom, just needs a little shaving. I don't have one in front of me, so I don't have the exact dimensions, but you should be able to sand about .15mm (almost nothing) off the top and/or bottom of the rack to solve the issue. I used an emory board (nail file) and it only took a few swipes, so don't go crazy with it. If you already have the rack housing installed in the front end, just do a little at a time and keep checking to see if the rack is 100% free. If it is, you are done and move on. If not, sand just a little more.

Guys, I am really sorry I had to throw this build tip out there. We worked really hard to do everything in our power to be sure the kit build was perfect, but sometimes the production parts from longer runs are just a tab bit off. Again, we never saw this problem until we got a production kit to check when the shipment arrive in CA. When you are working with tolerances as tight as we are you take this risk, and this time it bit us a little, but at least the fix is easy. We'll work to be sure the fit is improved moving forward,

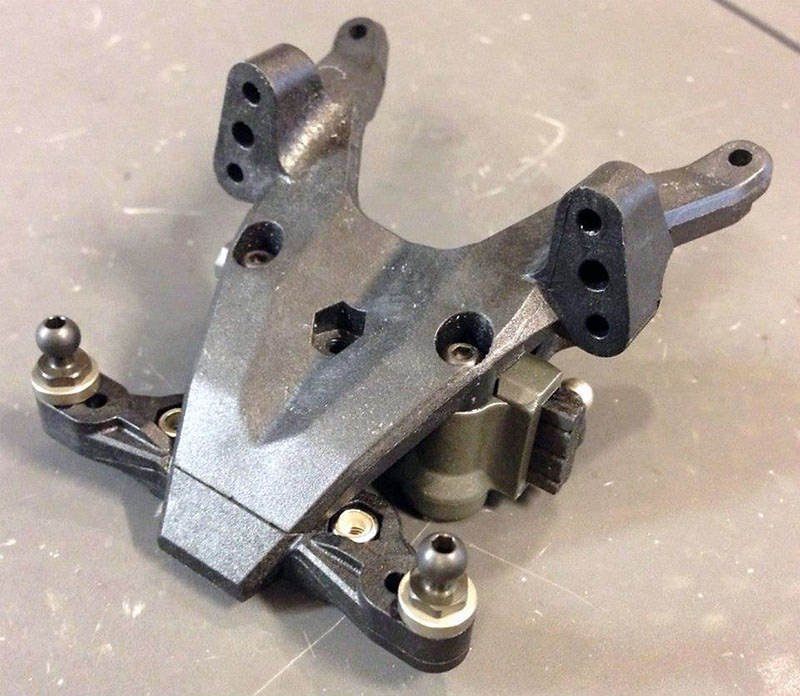

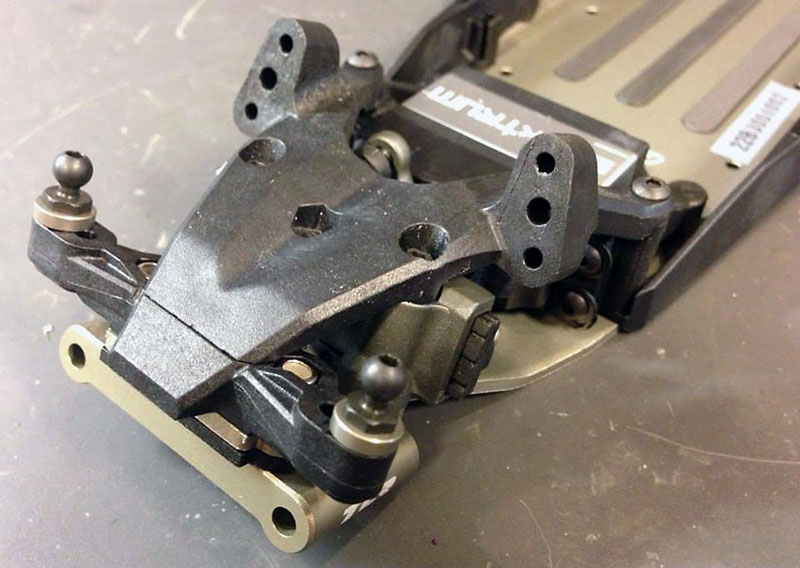

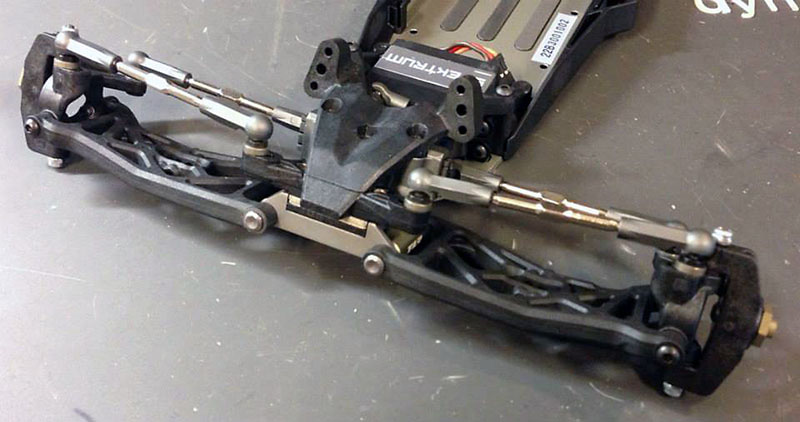

Step A7 & A8, the steering rack assembly and front camber block assembly are both installed onto the front bulkhead.

Step A9, the front bulkhead assembly, 25 degree kick shim, and TLR Aluminum Front Pivot are installed to the chassis. Do not forget to pop the steering link onto the rack.

Bag A3 contents all laid out and ready for Step A10.

Step A10, the front spindles are assembled with the steering link ball stud and axles. The 22 2.0 spindles are one of the biggest improvement to the geometry and handling of the 22 2.0, so this is one of my favorite steps.

Step A11, the spindle assembly is installed to the spindle carrier/caster block. The kit caster blocks are 5 degree, while the stock spindles have 4mm of trail; this is the setup the team has preferred during testing. Notice the new "B" hole on the 2.0 caster block, this has worked great for the team!

** Build Tip - Be sure not to over tighten the threaded kingpin nuts. You should be able to move the kingpin up and down just a touch in the assembly.

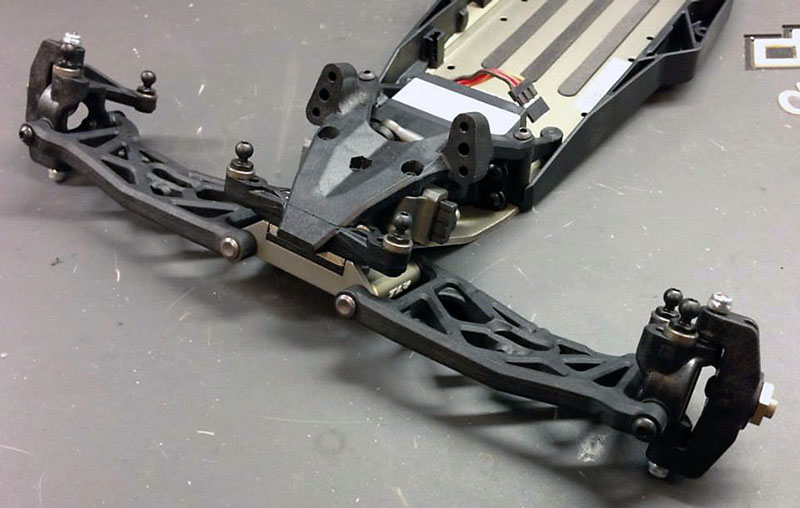

Step A12, installing the caster block and spindle assembly to the front arms, and the front arms onto the chassis.

Step A13 & A15, assembly of the front turnbuckles. Since the front camber link is a little longer on the 22 2.0, we included 4 of the 55mm long turnbuckles for improved durability.

** Build Tip - Make sure to put a dab of black grease in the end of each ball cup for smoother and easier assembly and adjustment of the turnbuckles.

Step A14 & A16 ,the camber link and steering turnbuckles are installed onto the the front suspension.

A17, the front tower installation. Nothing new here, same tower as the original 22.

A18, front bumper installation.

A19, Bag A and the front end of Frank's 22 2.0 is complete! Let's move onto Bag B.

Previous - Page 2 - Next

Source:

|