As many of you may know, X Factory President and Engineer Paul Sinclair had most of his RC equipment stolen in February, just two weeks before the

2014 Cactus Classic. With much help from sponsors and friends, Paul was able to piece together equipment, tools, and electronics to build a new

X - 6 Cubed during the first day of practice.

Chazz, ever-present with his camera, decided to snap pictures as the build progressed, including some of the small details Paul puts into his cars. We

decided to throw up these pics and Paul's capftions in a gallery for you to enjoy! Paul took his time with the build, spending most of the day working

on his Cubed and finishing it up the next morning. Paul learned from some of the best mechanics in RC; it's all about attention to details!

You can find Paul's latest set-up sheet, good on a variety of low- to medium-bite indoors and outdoor tracks,

here.

It's always a great idea to use threadlock on screws going into aluminum components. "Even with threadlock, I check the screws that hold the front carbon fiber stack together

every couple of race days," Paul says.

Paul uses the standard sanding drum attachment to smooth out any minor bumps in the front CF stack. "This is more of an aesthetic thing; it'll also help the velcro I use

to mount the body with to stick and be flat."

A little more minor trim work. The center post on the nose piece has a little vertical lip of flashing - it takes just a second to trim it flat.

Paul made a mistake building his new Cubed. "I forgot I had specially-made black anodized posts. If you look at the earlier pics, you'll see I assembled the front with stock

clear-anodized parts. Then I found my black parts and was like, 'Doh!'"

Paul likes to trim the flashing from the wingmounts. The XF-3500 wing mounts are one of the oldest parts X Factory has, and the mold has admittedly seen better days. "The wing mounts

are still plenty strong though. We've gone through a few different evolutions in the plastic they're made from, and the latest ones are nearly indestructable."

Slightly different than the instructions, Paul likes to install longer screws in the top of the rear ballstud lands, and use a locknut on the backside of the bulkhead. "I've had the

top screw work loose occasionally, especially on the left side of the car it seems, and a locknut just keeps everything secured nicely."

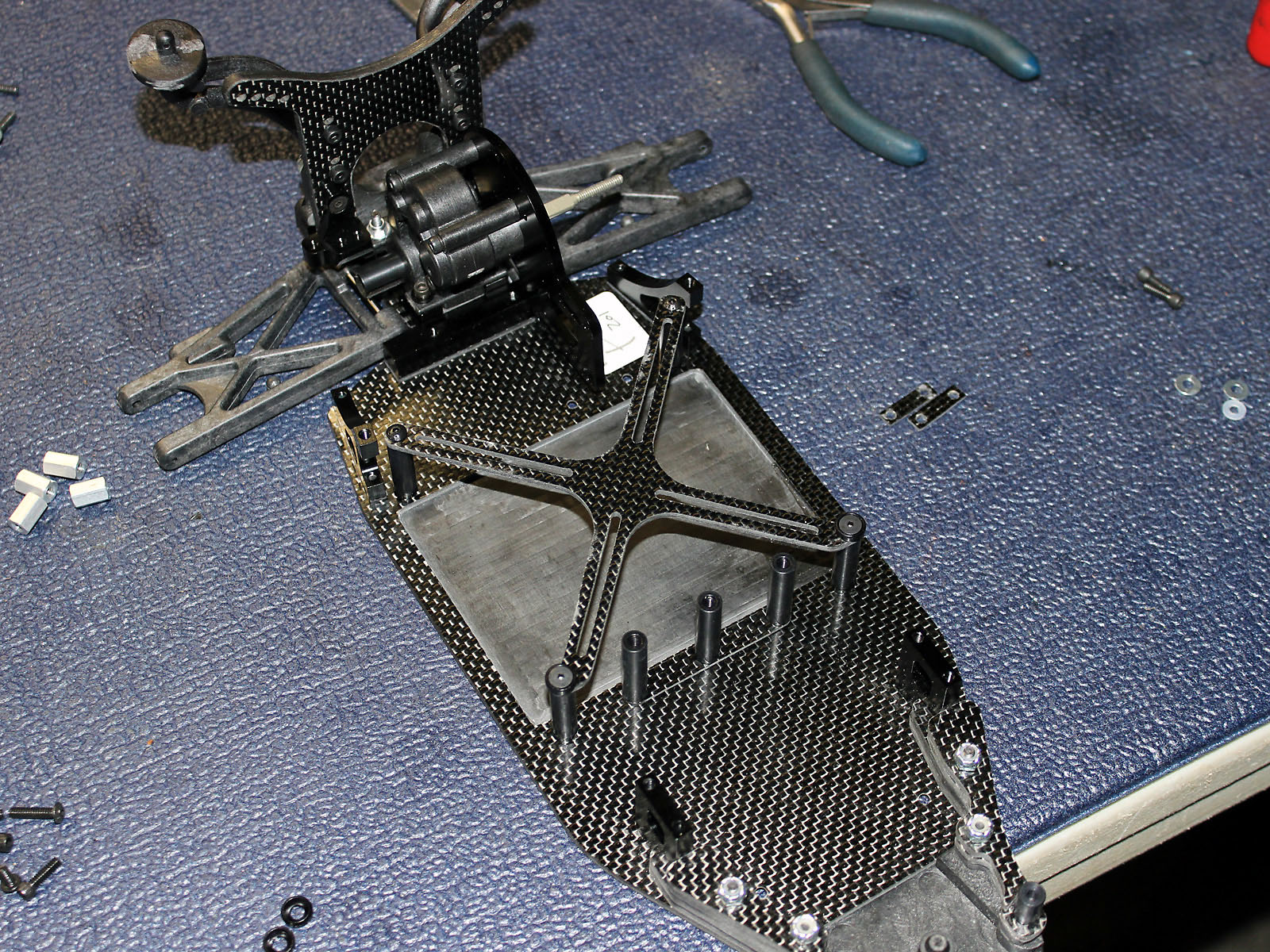

Paul's car about half-way through the build. As you would expect, Paul is using all the Real Men Wear Black parts.

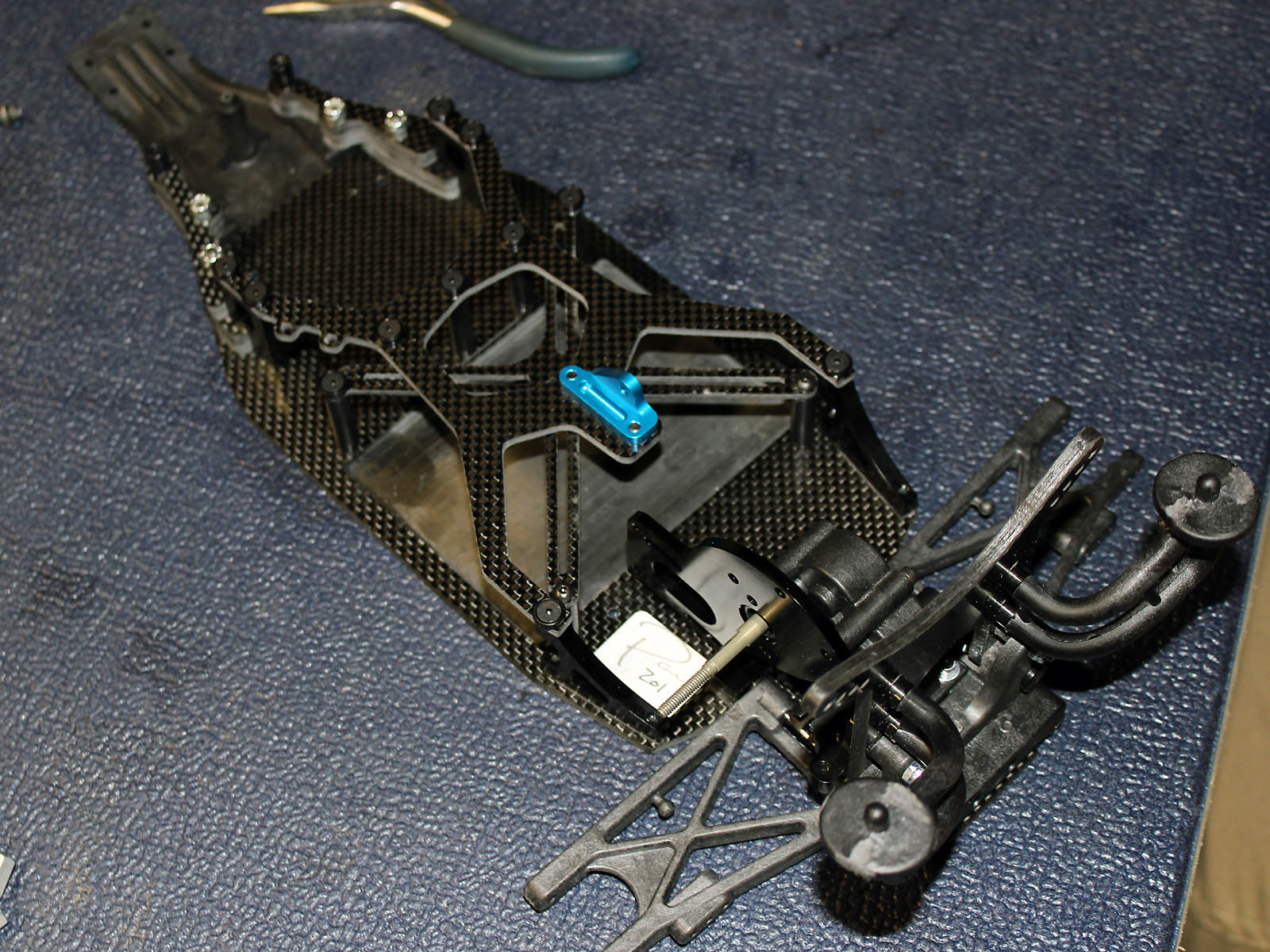

A few more minutes later....

Top deck installed. Paul forgoes the kit's cap head screws for flatheads with black countersunk washers for a cleaner look.

And now the rear hub carriers. Several tips to note in this picture: First, Paul dremels the top of the aluminum hub carrier down, giving more clearance for the camberlink to be mounted

on the backside. Second, he secures the CF hub camber plates (XF 9501) with two black mini-nuts (XF 6076). Finally, rather than just 1 plate, Paul uses two per side for extra beef and security.

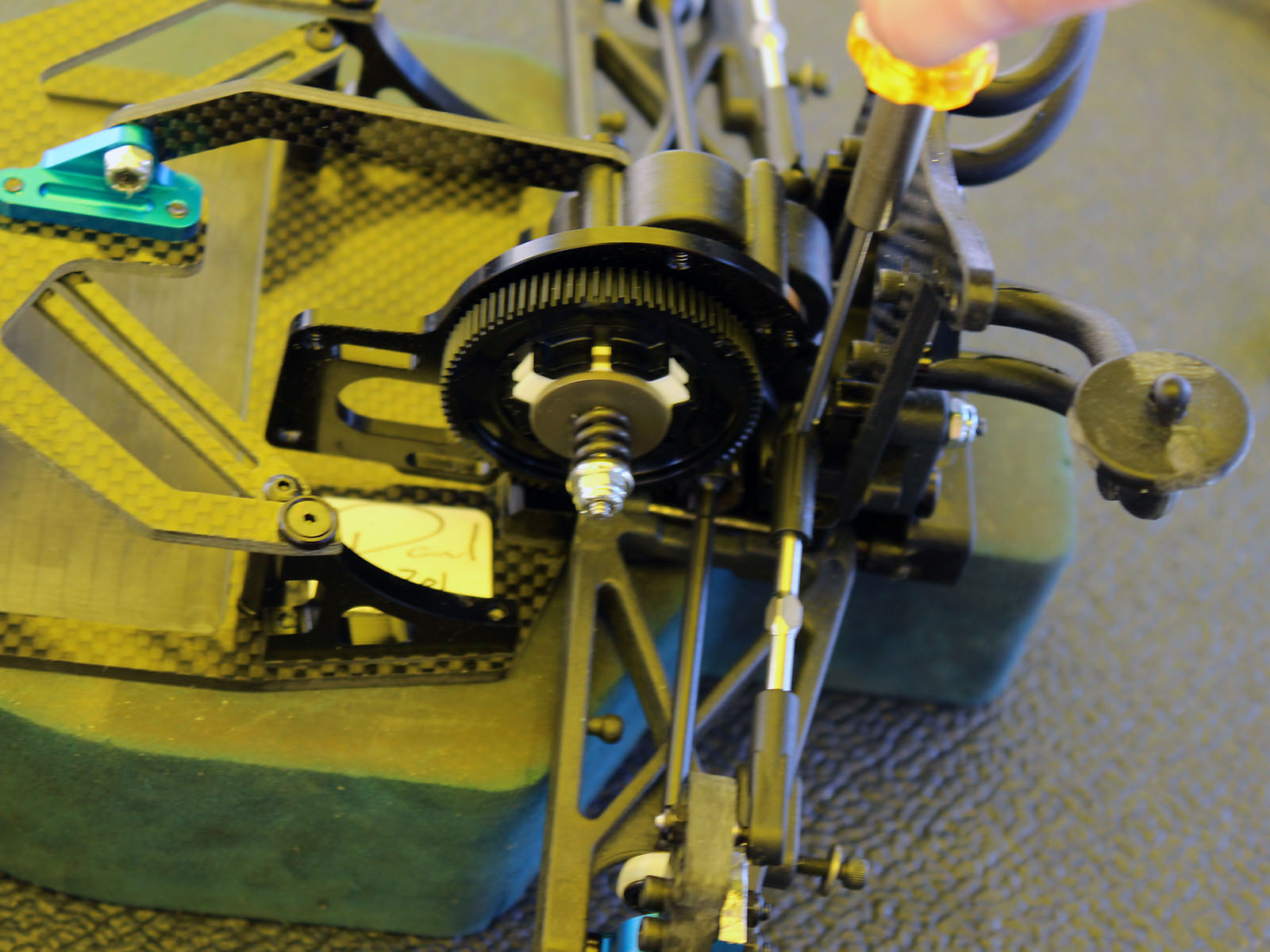

JConcepts Ballcups are pretty neat - they come with a hole molded in so you can use broached ballstuds without having to pop off the ballcup. "The Avid slipper clutch is a must-have, in

my opinion - one of the best drivetrain upgrades available, for stock or modified racing," Paul says.

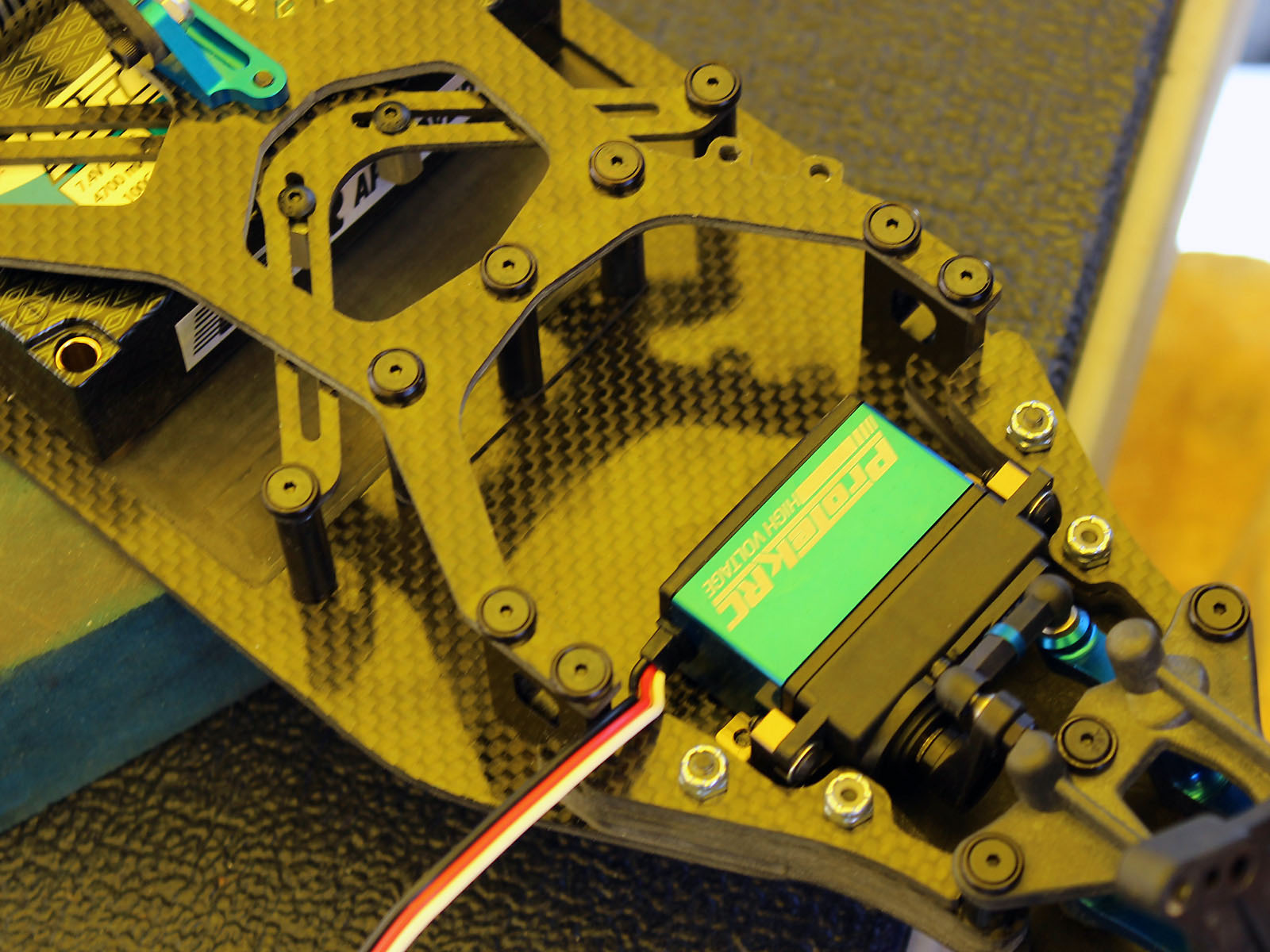

ProTek Supreme Power Lipo's power all of Paul's cars - but you may not know they offer a great line of performance servos, too. Paul uses the 130T servo in all his vehicles, which offers

a .10s/60º transit time with a massive 288 oz-in of torque at 6V. "Servo speed isn't worth much if you don't have the torque to hold the steering at the end of a high-speed

sweeper."

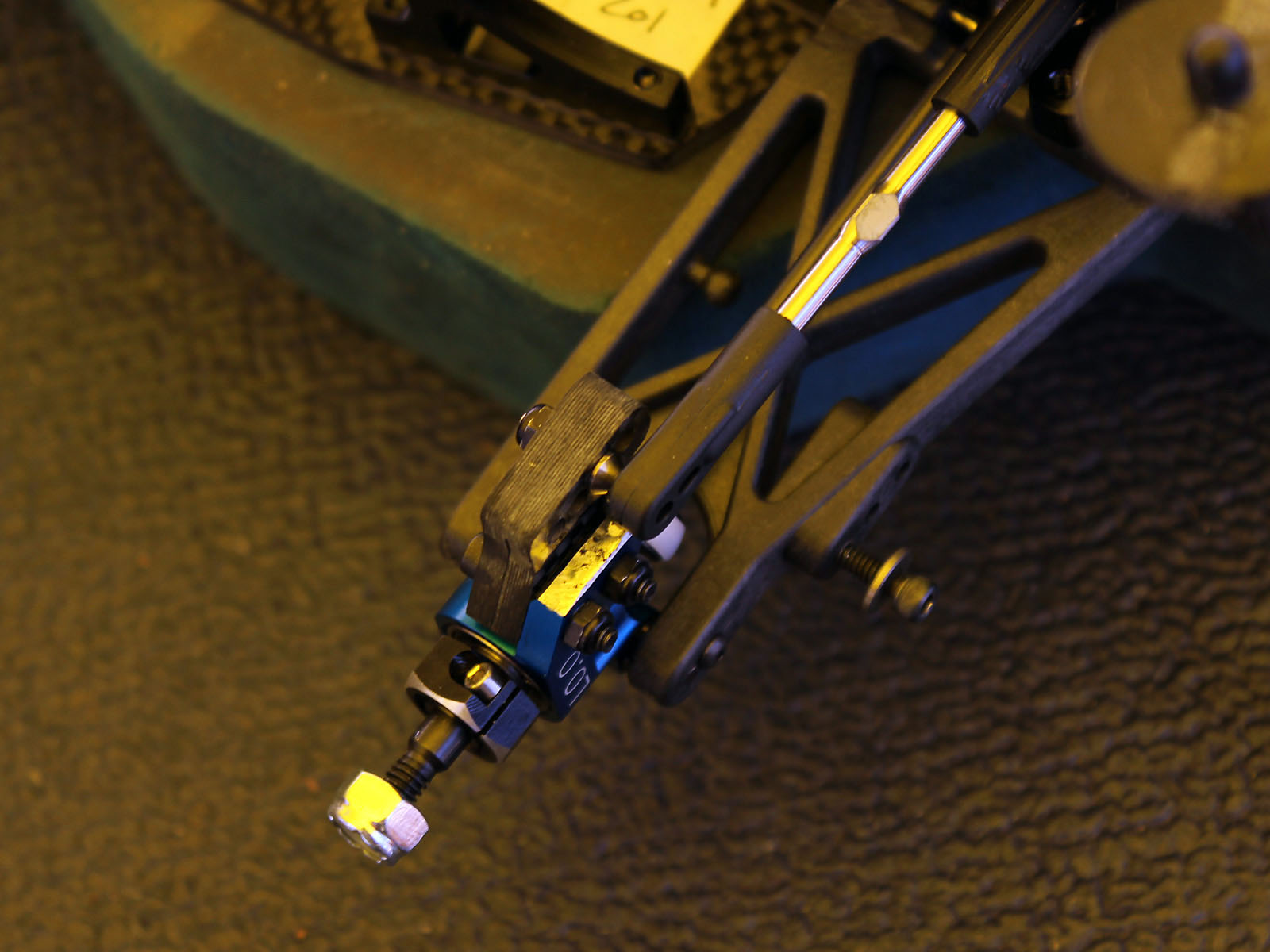

Paul's set-ups often include "dremeling the caster blocks forward." Here you can see how Paul achieves that, along with some dialed Schelle Racing washers.

Paul's freshly-built cubed climbing onto the straightaway at the 2014 Cactus Classic!