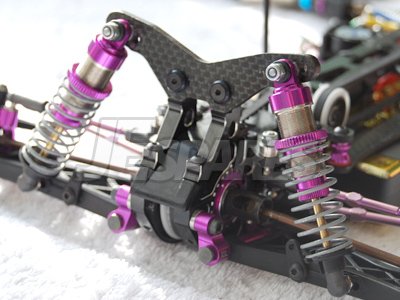

1. Remove shocks from car,

refit any nuts and bolts to retain any bushings, clean first if

necessary.

2. Remove spring retainer

and spring, clean if necessary.

3. Using a dry paintbrush

and paper tissue/rag, clean the shock.

4. Unscrew shock cap and clean, tip the

oil into a waste oil container. Tech Tip: Notice that the shock

cap has a cut bladder inside, I recommend this as the uncut bladder

can burst which is a failure and will lead to some strange handling

characteristics on the track. Cutting the bladder will ensure

consistency and reliability.

5. Unscrew shock rod end

and clean. Replace shock rod end if threads unwind too easily, this

should be tight. Pliers may be used for holding the shaft but ensure a

tight fit to ensure the shaft isn't damaged. Tech Tip: For easy

removal of shock rod ends and shock maintenance, we recommend a Shock

Shaft Vice.

Shock Shaft Vice

6. Push shaft and piston

out of shock body, wipe clean with paper tissue.

7. Open the o-ring

cartridge/lower cap, and remove o-rings & guides. Clean all parts

from cartridge, replace any damaged parts or any o-rings that look

worn, swollen or dirty.

8. Check over the shock

shaft for bends or damage. A shock shaft should be straight to avoid

damage to the seals and prevent dirt entering the shock, leading to

further damage. Replace the shaft if necessary. Clean the shock shaft

with paper tissue to absorb any old oil. Motor/Cleaning spray can be

used on the shaft to remove oil and clean, ensure that pistons and

o-rings do not get sprayed.

9. Lubricate the o-rings

and guides with a light shock oil or Green Slime, refit the parts into

the cartridge/lower cap taking care not to damage the parts. Tech

Tip: Using a 2mm hex wrench, slide the cartridge over the shaft,

pour in a small amount of light shock oil and fit the o-rings &

guides. The shock body can also be placed over the shaft and you can

screw the lower cap/cartridge onto the body with ease.

Green Slime

10. Lubricate the shock

shaft using shock oil as you did with the o-rings and insert the shaft

back into the shock body taking care not to damage the o-rings or

guides as you insert it.

11. Refit any external shock shims if

necessary and wind on the shock rod end. It is recommended to tighten

the rod end fully but it can be left slightly loose to achieve more

droop from the shock. Ensure that both shocks (front or rear) are the

same length with the rod tightened on.

12. With the shock shaft fully extended, fill the shock with your

desired weight of oil to just below the top. Slowly pump the shock

shaft up and down to remove any air bubbles, tap the shock and let it

sit for a couple of minutes to let any air bubbles rise to the

surface. Once the air has escaped, top up the shock with oil to the

top.

13. Refit the shock cap and point the

bleed hole on the cap upwards. Tighten the cap around half way on by

turning the shock body into the cap, ensuring that the bleed hole

points upwards. Air and excess oil will escape through the bleed hole.

Once the cap is screwed on half way you can set the rebound. For high

rebound, insert the shaft all the way into the shock body and for low

rebound, leave the shaft all the way out. Once you have this set,

finish off screwing the shock cap on. Excess oil and air may escape

through the bleed hole again, wipe this clean with tissue.

14. Repeat the steps for all the other

shocks. Test that the shocks have the same rebound by simply pushing

the shaft in, letting go and letting the shock shaft slide out. Match

up the left and right shocks to ensure they have equal rebound. Repeat

step 13 if the shocks do not match.

15. Re-fit the cleaned springs and

retainers onto the shock

16. Re-fit the shocks to

the car. Ensure that the top mount is not too tight as the shock needs

to hinge and move freely on the standoff. Fit the shock rod end to the

wishbone. Check the cars ride height and adjust the shock if required.

|