1. Remove the differential

from your model.

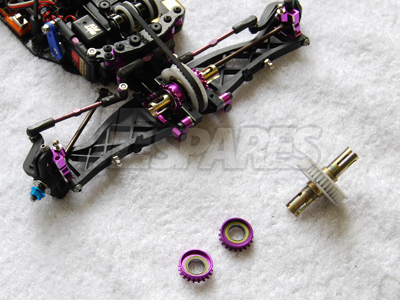

2. Disassemble your

differential completely and place all the parts on your work surface

ready for maintenance. In the photo you can see that we have used a

pair of tweezers for removing the c-clip (model specific). These are

modified tweezers that have been sharpened on the ends to fit into the

c-clip holes and then bent slightly to reach inside the diff cup.

3. Clean all the parts of

your differential. Wipe clean all oil, grease and dirt from the parts,

a stiff brush comes in handy for the gear.

4. Once all of the parts have been

cleaned, you can now begin rebuilding the differential. Follow your

manual for the rebuild process as it varies from car to car. Tech

Tip: On the Schumacher CAT SX, the 2 thrust washers on the diff

screw are marginally different in size so check them with some

calipers or an accurate measuring device.

Team Associated's Black Grease for

thrust bearing

5. While rebuilding the

diff, remember the modified tweezers tip we showed you earlier in the

guide.

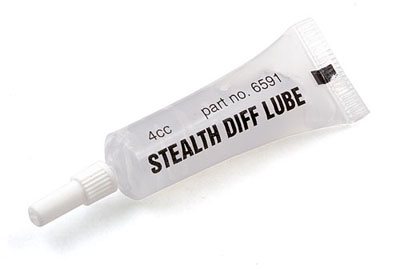

6. Team Associated's

Stealth grease works well on the diff plates. Use a similar amount as

shown in the photos below.

Team Associated's Stealth for diff

plates

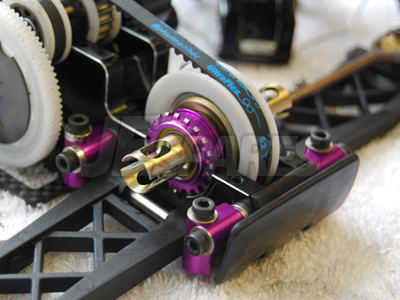

7. Once the diff has been

assembled, you can use two tools as shown in the photo below to check

the tightness of the differential by turning each driver in a

different direction.

8. Re-install the

differential into your car and you're done!

|