|

- Team Associated B6.1D - Build Tips -

by Bruno Heremans

Associated's manual is very good, and there already are some online build reports filled with useful info. But here are a few more build tips:

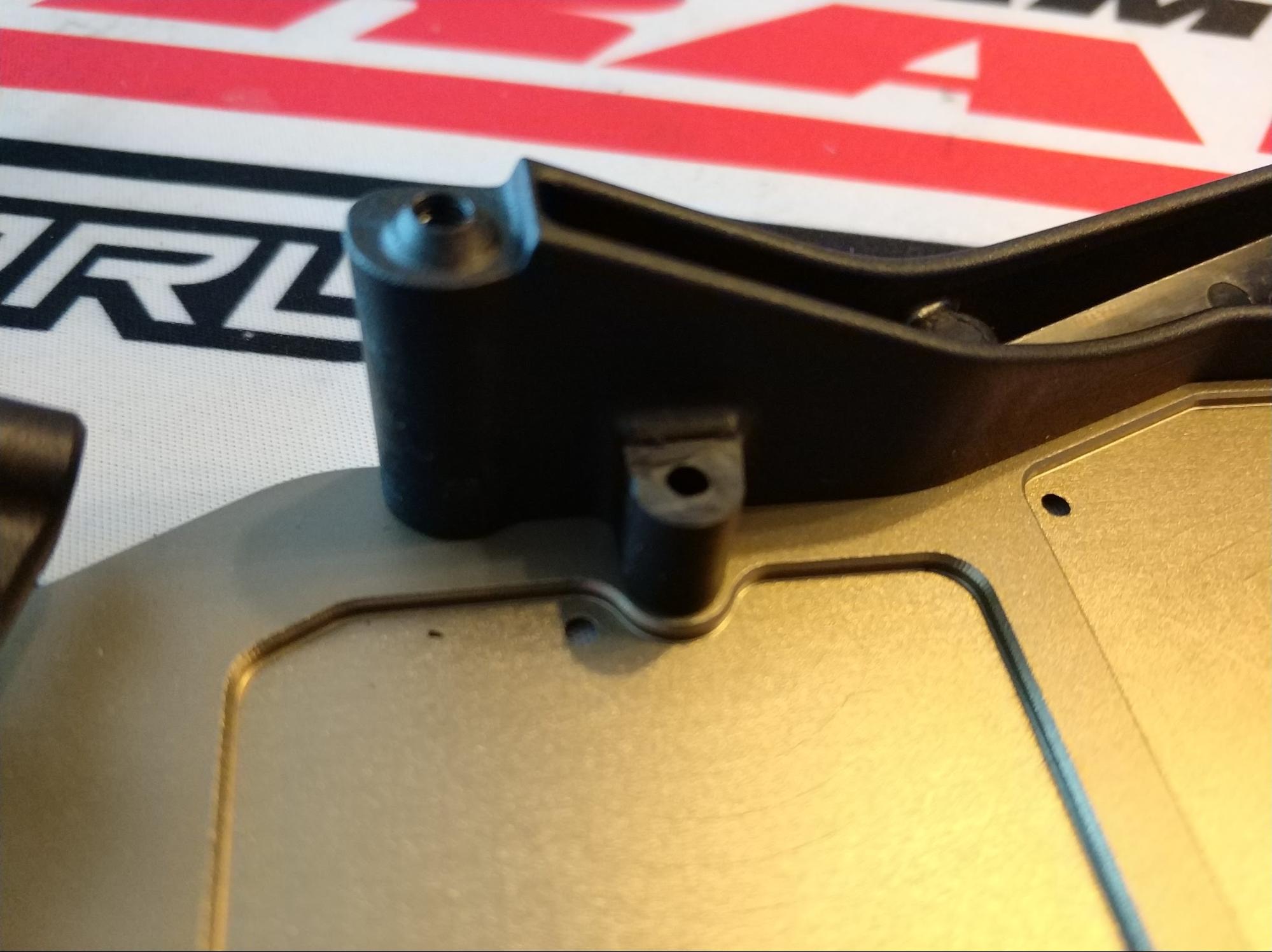

1: On the D car, I never use the servo weight. So the servo can be lowered by more than a mm. I cut 1mm off the servo mounts and then fiddle with the position of the aluminum mounts on the servo, to get it perfectly flat on the chassis. That way, the servo is supported better as well, it moves around less.

2: I like to lightly sand the edges of the towers, and seal the laminations with glue. The current towers are made out of a very good carbon fiber, so this step might not be necessary, but rounded edges feel much nicer to touch. A car is often grabbed by the towers.

3: I pre-thread every hole. It's easier to do it while the screwdriver is in your hand anyway. I do it to all the holes, even the optional ones, even the ones in the extra pieces.

I have found that a tap removes material and makes the threads a little weaker. An electric screwdriver at high speed combined with a spare screw works best. The heat shapes the threads.

4: It doesn't matter, unless it matters to you, but you can install the steering blocks so the text '+1' reads correctly on both sides.

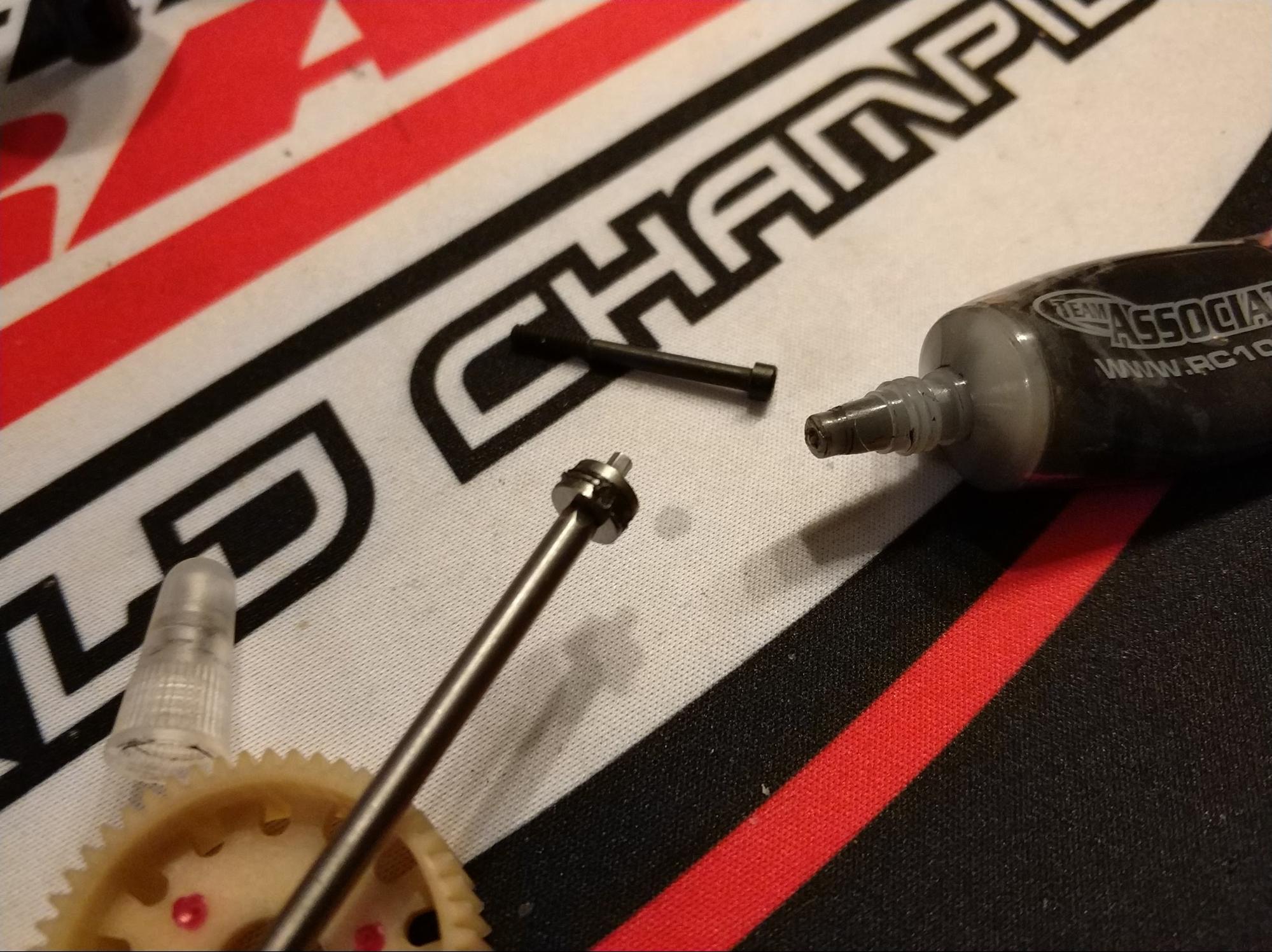

5: Polish your balls, gentlemen! Just a few seconds in an electric drill removes a lot of the surface roughness.

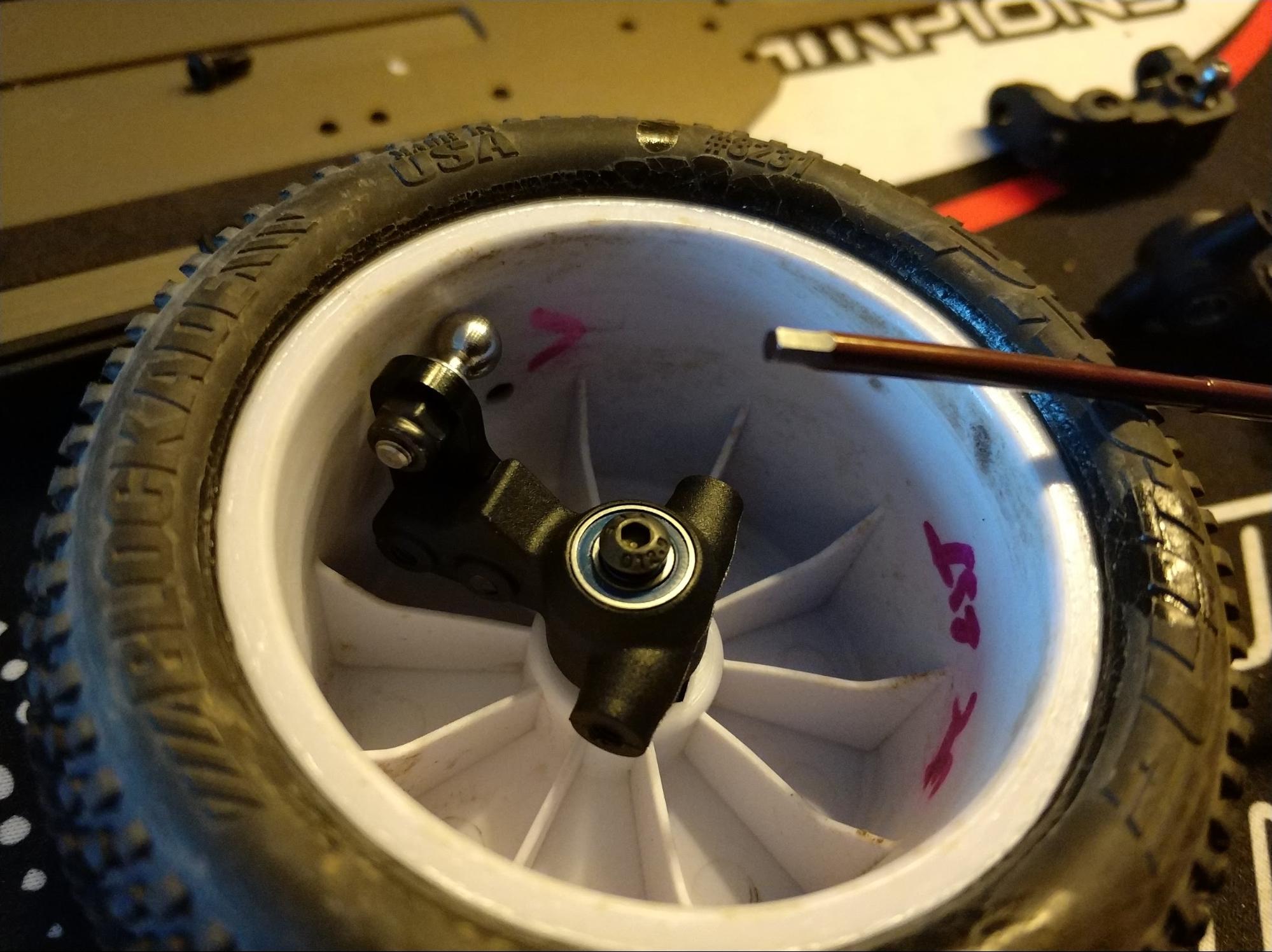

6: When installing the axle screw, you don't need to get a 12mm wrench. Just use a wheel. It's plastic, so it won't damage the hex.

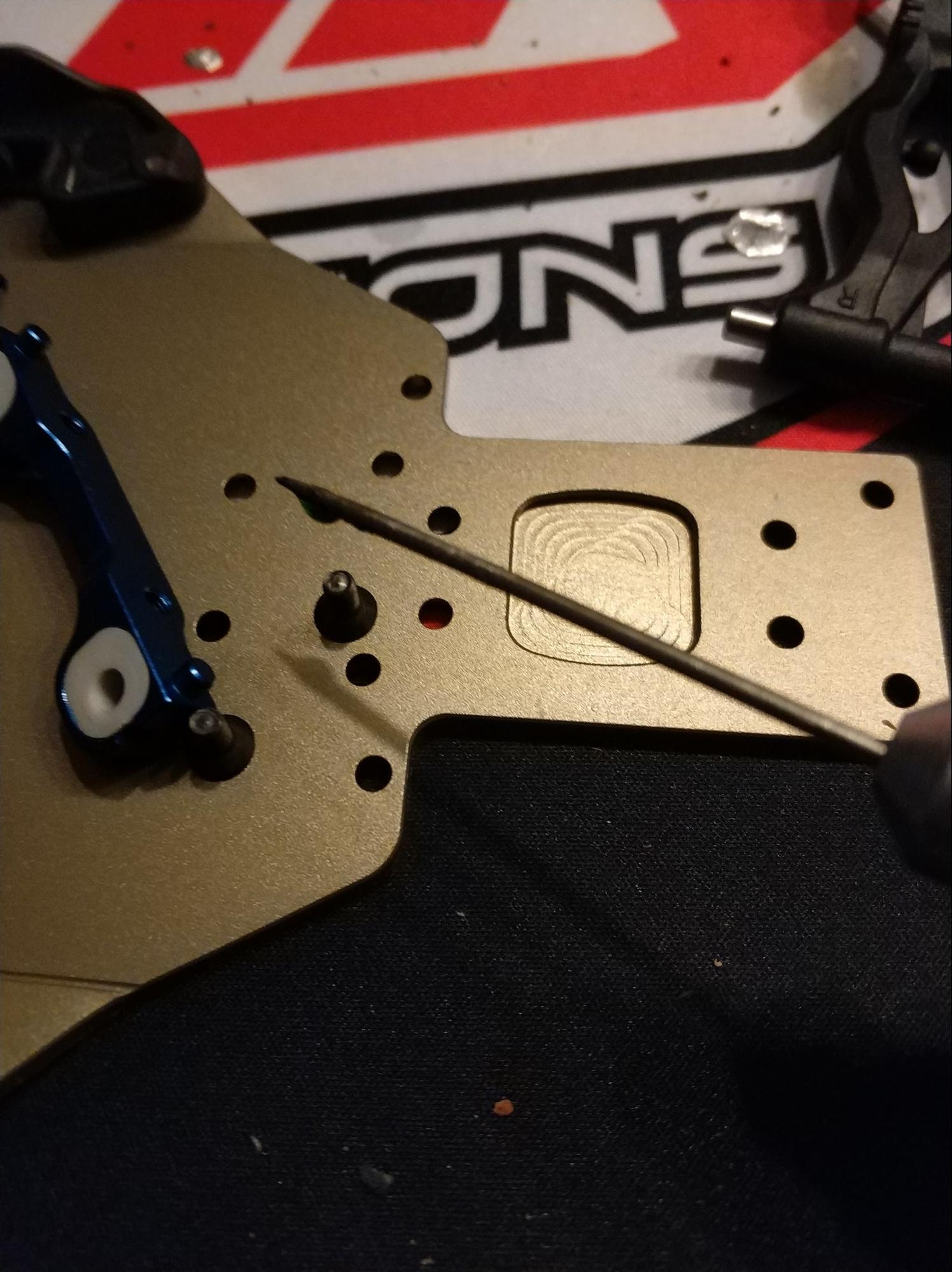

7: Those are the screws which I think need loctite. Just the tiniest drop will do.

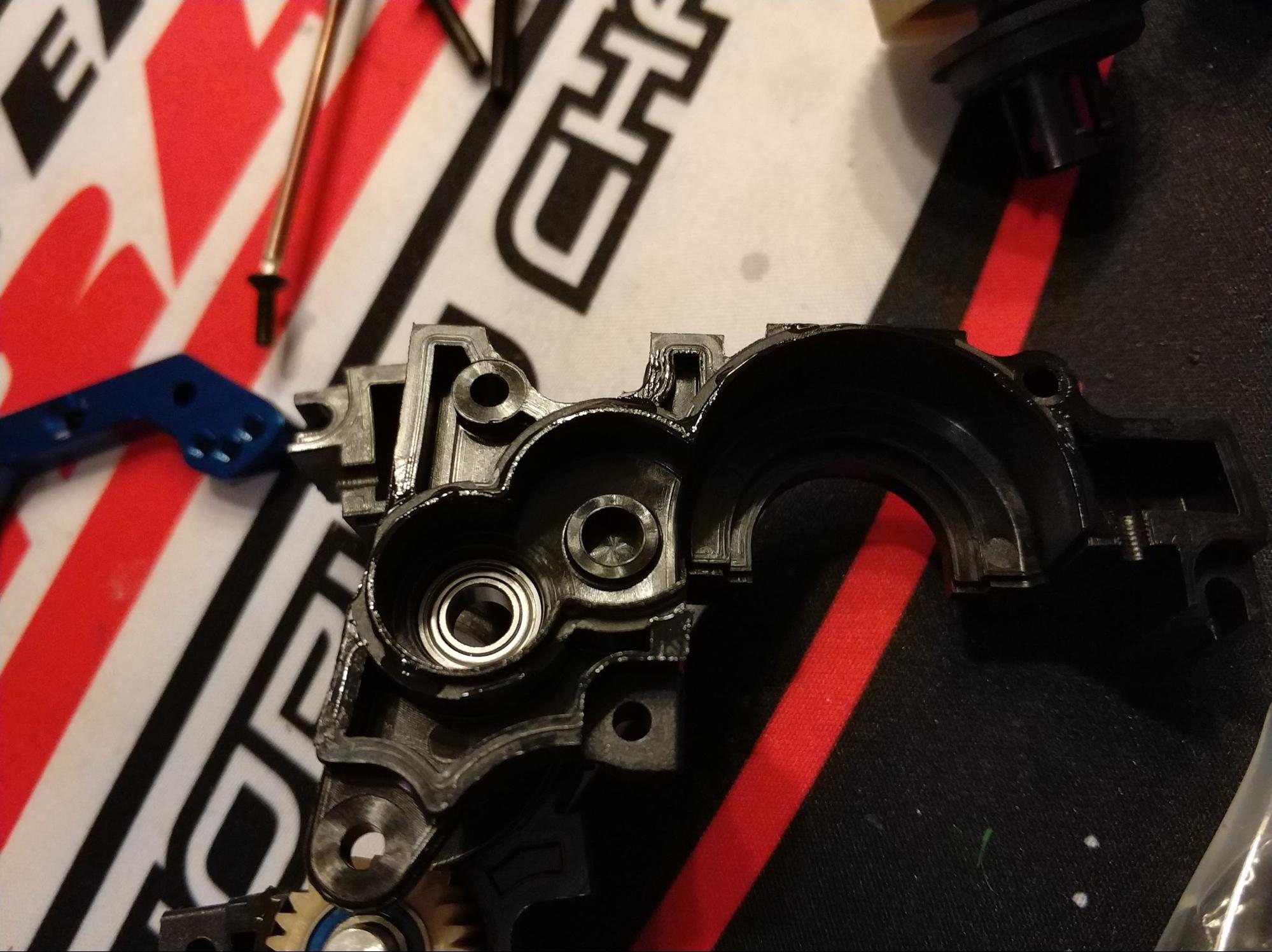

8: RDRP sell captured thrust bearings. They're awesome. Ceramic, even.

9: I mark one side of the gears, so I can always put them back in the same orientation. Keeps the gearbox quiet.

10: I assemble the thrust bearing on the tip of a screwdriver instead of on the diff screw. Less schmutz that way. It will attract less dirt afterwards.

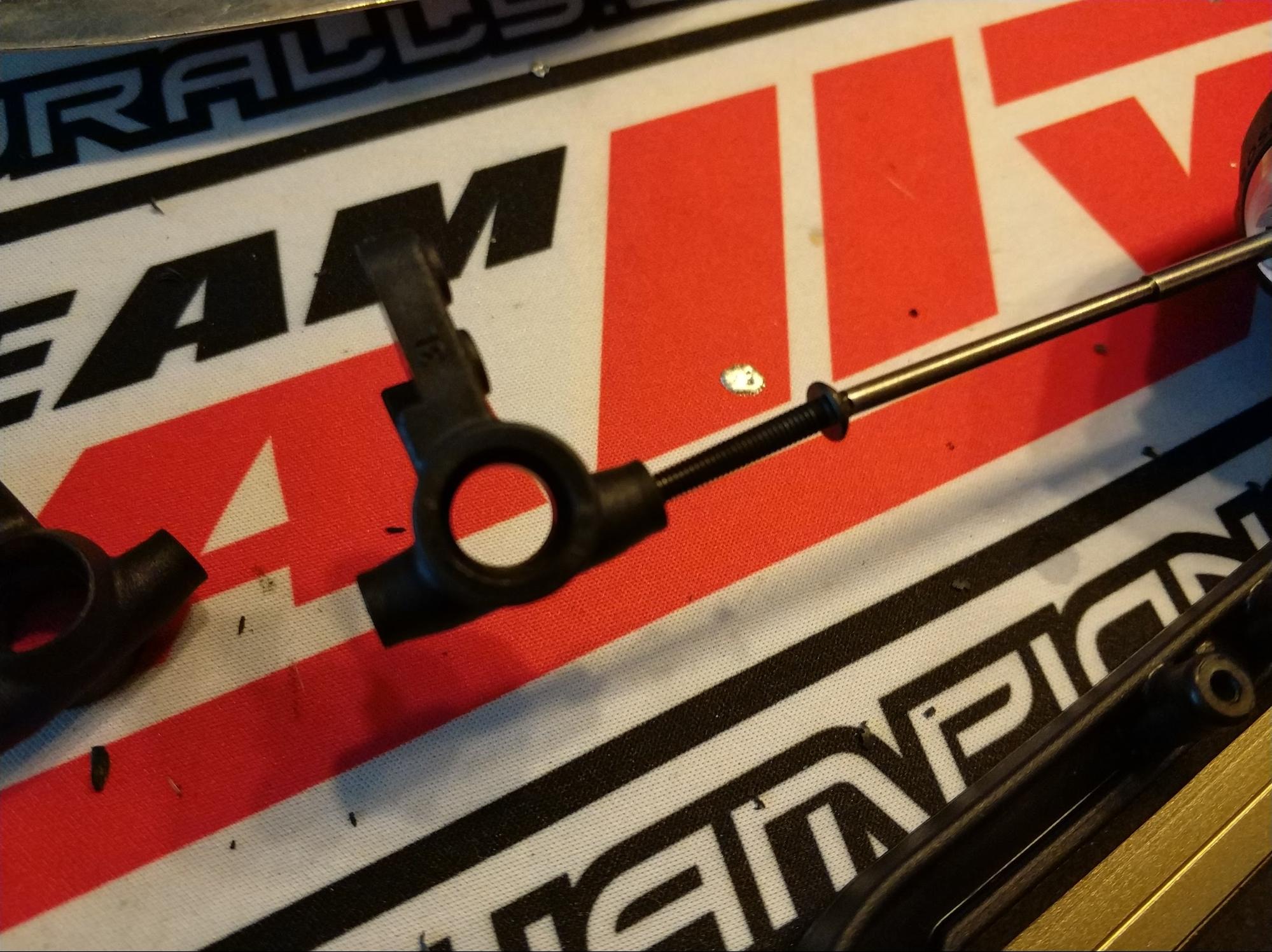

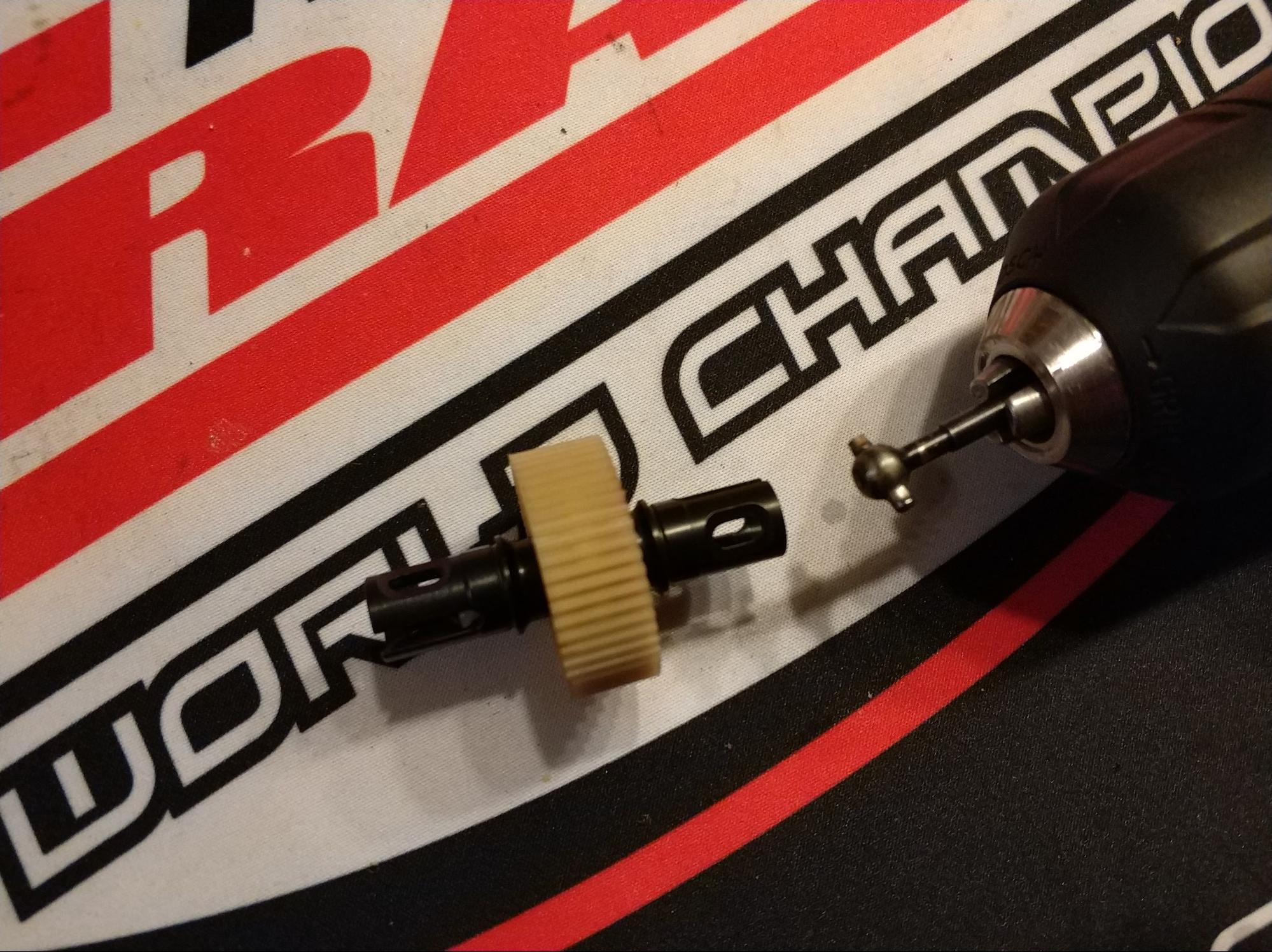

11: This is how I break in a diff. With half of an old CVD shaft and an electric screwdriver.

12: I like to seal the diff cases with grease. Keeps fine dust out. What a marvellous piece of engineering by the way.

13: There is a special tool to hold ball cups, but this is how I thread turnbuckles. It's fast and it saves the wrists.

14: Before snapping the ball cups on, dip them in your hot tea. They will expand and the plastic will be softer. The ball cup will less easily be damaged, especially the small ones on the steering arm.

You can use hot water as well.

|