|

May 11th 1977, Tamiya releases their first

Formula 1 radio controlled model car, the Tyrrell P34 Six Wheeler. 32

years later, interest in Formula 1 continues to be as strong as ever and

Tamiya releases their latest Formula 1 chassis, the F104 Pro.

The

successor to the popular F103 chassis, the F104 Pro brings more features

and realistic dimensions of the modern Formula 1 car. Complete with a new

late generation Formula 1 body, the F104 Pro is well equipped with the

most desirable components and features. The

successor to the popular F103 chassis, the F104 Pro brings more features

and realistic dimensions of the modern Formula 1 car. Complete with a new

late generation Formula 1 body, the F104 Pro is well equipped with the

most desirable components and features.

Key Features:

3.2mm carbon fiber main chassis

2mm carbon fiber upper deck

Carbon fiber drive axle

Adjustable front and rear ride height

Adjustable front camber

Machined aluminum ball differential

assembly

TRF aluminum threaded body shock

Integrated rear diffuser

Carbon reinforced steering knuckles

Detailed 3 piece polycarbonate modern

Formula 1 body

As

well equipped as the F104 Pro is, there is still an excellent selection of

Hop-Up parts to further elevate the performance of the F104. These Hop-Up

options offer a variety of benefits, such as increase durability, reduce

wear, improve tuning potential and enhance performance. The following are

just a few examples. As

well equipped as the F104 Pro is, there is still an excellent selection of

Hop-Up parts to further elevate the performance of the F104. These Hop-Up

options offer a variety of benefits, such as increase durability, reduce

wear, improve tuning potential and enhance performance. The following are

just a few examples.

F104 Hop-Up Options:

54176

- Formula-Tuned Motor (32 turn)

54169

- F104 Aluminum Pivot Post

54168

- F104 Sponge Tires Type B Rear

54167

- F104 Sponge Tires Type B Front

54166

- F104 Aluminum Motor Mount

54165

- F104 Soft T-Bar

54160

- F104 Titanium Nitride Coated King Pins

54159

- F104 Hi Torque Servo Saver Horn

54157

- F104 Titanium Screw Set

54138

- F103 Low Friction Pads

53918

- TRF Damper Low Friction V-Parts

53906

- 5x5mm Aluminum Ball Connector

Building the F104

Because it's easier to add Hop-Up parts to a car during the build, have

any additional Hop-Up items you've selected on hand prior to assembly. If

you're unsure of which additional Hop-Ups should be considered, I

recommend the soft T-Bar (54165), the Aluminum Motor Mount (54166) and a

softer rear shock spring. I found the M04 front shock spring (9805921) to

be a noticeable improvement over the kit spring under medium to low

traction surfaces. The soft T-Bar and the M04 spring improves the cars

compliancy and stability over bumps while the aluminum motor mount

maintains cooler motor temperatures. One final item I recommend is a

Kimbrough servo saver (standard size). In addition to protecting the servo

gears from impacts, the servo saver effects ackerman and bump steer. With

all the additional Hop-Ups and parts on hand, assembling the F104 is very

easy. In fact, there are only a few areas that can benefit from extra

attention during the build process.

Rear Pod

The rear pod of the F104 consists of 4 pieces, so it's important that they

are aligned properly to avoid any twisting. Start by assembling all 4

components together as per instructions but do not completely tighten the

screws. The screws should be just loose enough for the 4 pieces to move

around a little. Place the rear pod assembly on a flat surface such as a

set-up board and hold down only the left and right portions of the pod.

While maintaining moderate pressure, gently begin tightening the 8 screws.

Rather than completely tightening one screw at a time, tighten each screw

slightly in equal increments and repeat this process until they're all

completely tight. Lightly tap on the corners of the pod periodically to

check alignment during the gradual tightening process to insure the pod

isn't twisting.

Steering / Servo Position

The

length of the servo saver arm and the angle of the steering links will

directly affect the amount of Ackerman and bump steer the steering will

have. I settled on the Kimbrough servo saver because it provided the

steering characteristics I was looking for. On the Kimbrough servo saver,

the two 5x5mm ball ends should be installed on the farthest row of holes

(end of the servo arm). The

length of the servo saver arm and the angle of the steering links will

directly affect the amount of Ackerman and bump steer the steering will

have. I settled on the Kimbrough servo saver because it provided the

steering characteristics I was looking for. On the Kimbrough servo saver,

the two 5x5mm ball ends should be installed on the farthest row of holes

(end of the servo arm).

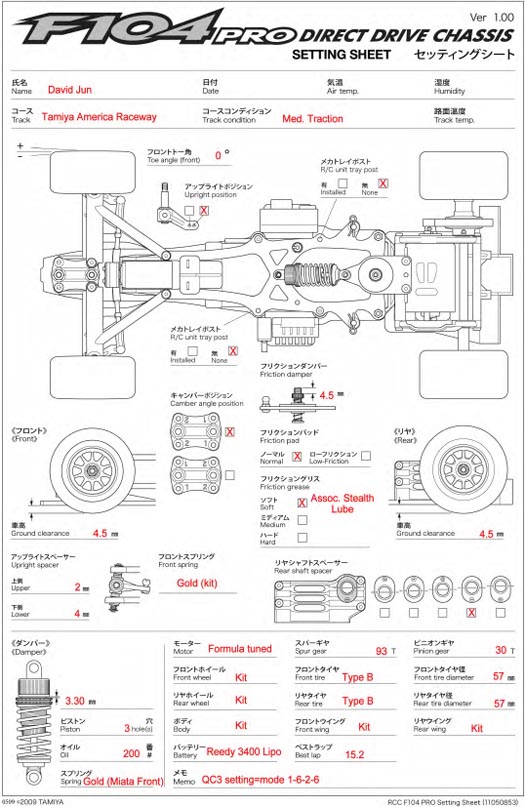

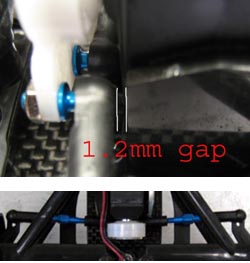

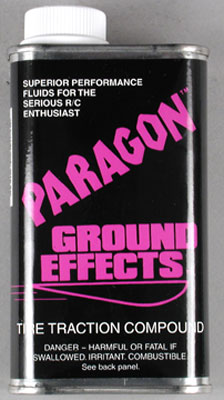

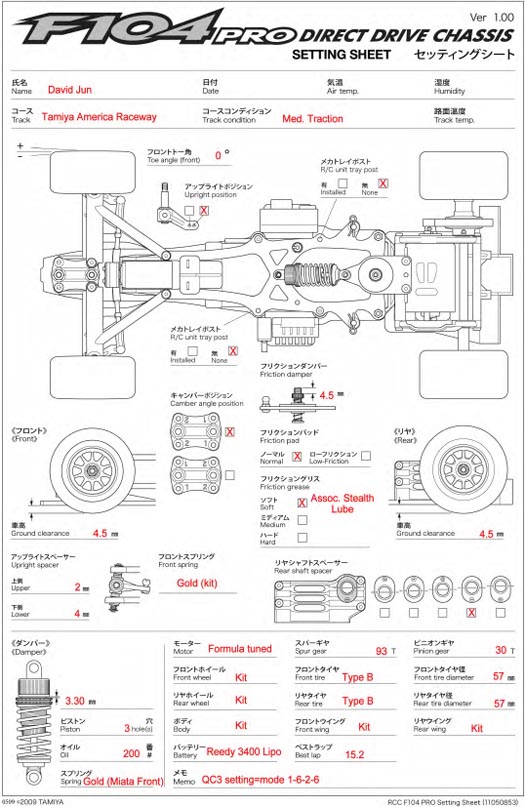

When installing the servo, the instructions

illustrate that the center of the servo output shaft should be 30mm from

the chassis. I used a Futaba 9602 mini servo and raised the height to 32mm

to reduce bump steer a little and this also affects the Ackerman slightly

as well. The fore and aft position of the servo also effects Ackerman. For

reference, I set a 1.2mm gap between the plastic ball end and the front of

the servo mount. This is roughly a 5 deg. angle in the steering linkages.

(Your potential range in servo position

will vary depending on the size of the servo used.)

When installing the servo, the instructions

illustrate that the center of the servo output shaft should be 30mm from

the chassis. I used a Futaba 9602 mini servo and raised the height to 32mm

to reduce bump steer a little and this also affects the ackerman slightly

as well. The fore and aft position of the servo also effects ackerman. For

reference, I set a 1.2mm gap between the plastic ball end and the front of

the servo mount. This is roughly a 5 deg. angle in the steering linkages.

Electronics

LRP QC3 Speed control

Futaba R603FF Receiver

Futaba S9602 Servo

Reedy 3400mah Lipo Battery

Tamiya "Silver Can"/Tamiya Formula Tuned 32T

Although

installation of the electronics is easy on the F104, special attention

should be placed on the motor wiring because it can affect the handling of

the car. To begin, there are two areas to mount the receiver and speed

control on the F104. The logical position of the speed control is on the

left because the motor leads come off the left side of the rear pod.

Rather than placing the speed control in a typical bottom down position, I

placed it on its side with the wires pointing back. This enabled the

battery and motor wires to travel in a more direct path. Although

installation of the electronics is easy on the F104, special attention

should be placed on the motor wiring because it can affect the handling of

the car. To begin, there are two areas to mount the receiver and speed

control on the F104. The logical position of the speed control is on the

left because the motor leads come off the left side of the rear pod.

Rather than placing the speed control in a typical bottom down position, I

placed it on its side with the wires pointing back. This enabled the

battery and motor wires to travel in a more direct path.

Regarding

wires, it's not necessary to have excessively thick gauge wire because it

can limit free movement of the motor pod resulting in handling problems.

To avoid this, I used 16 gauge wire to insure the motor pod moved with

minimal interference. The receiver installation is straight forward. To

allow plenty of clearance for the body, it was also placed on its side

with the antenna pointing rearward. This creates a clean path for the

speed control and servo wires to reach the receiver ports. Regarding

wires, it's not necessary to have excessively thick gauge wire because it

can limit free movement of the motor pod resulting in handling problems.

To avoid this, I used 16 gauge wire to insure the motor pod moved with

minimal interference. The receiver installation is straight forward. To

allow plenty of clearance for the body, it was also placed on its side

with the antenna pointing rearward. This creates a clean path for the

speed control and servo wires to reach the receiver ports.

Due

to the very scale nature of the F104 Pro's body, the receiver sits on the

opposite side of the speed control with the battery running down the

center. This doesn't make installation of the electronics difficult but

the speed control wire typically goes over the upper deck to reach the

receiver. I prefer to have this wire less visible so I routed it under the

battery. Due

to the very scale nature of the F104 Pro's body, the receiver sits on the

opposite side of the speed control with the battery running down the

center. This doesn't make installation of the electronics difficult but

the speed control wire typically goes over the upper deck to reach the

receiver. I prefer to have this wire less visible so I routed it under the

battery. Start by adding shrink tubing around the area that will be under the

battery. This will avoid wear on the wire from installation and removal of

the battery. Make sure to have enough slack in the wire next to the speed

control to account for movement during battery installation/removal. Most

Lipo batteries have slots on the bottom to lock into a chassis design for

Sub C packs so with the heat shrink in place; use Shoe Goo to mount the

wire on the chassis so that it sits between these slots. I also used heat

shrink on the servo wire and used Shoe Goo to secure it down the right

side of the chassis. The end result will be not only a clean appearance

but a functional one.

Start by adding shrink tubing around the area that will be under the

battery. This will avoid wear on the wire from installation and removal of

the battery. Make sure to have enough slack in the wire next to the speed

control to account for movement during battery installation/removal. Most

Lipo batteries have slots on the bottom to lock into a chassis design for

Sub C packs so with the heat shrink in place; use Shoe Goo to mount the

wire on the chassis so that it sits between these slots. I also used heat

shrink on the servo wire and used Shoe Goo to secure it down the right

side of the chassis. The end result will be not only a clean appearance

but a functional one.

Shock and Damper Plate

The

rear dampening system on the F104 Pro consists of an oil filled coil

spring shock for perpendicular dampening and a dual disk damper plate

assembly for 360 degree dampening of the rear pod. Because the damper

plate and the shock both control perpendicular damping and the T-plate is

firm in this direction, I went with the softest oil and spring combination

on the shock and light damper grease for the damper plate. Using the

3-hole piston, I used 200 weight oil in the shock and the front spring

from the M04 M-Chassis (gold color). This improved the overall compliance

over bumps. To control lateral movement of the pod, loosen or tighten the

adjustment screw on the T-plate. A loose setting will generally provide

more stability but reduce steering (good for low traction surfaces). A

tighter setting will increase response and provide more steering (good for

high traction surfaces). The

rear dampening system on the F104 Pro consists of an oil filled coil

spring shock for perpendicular dampening and a dual disk damper plate

assembly for 360 degree dampening of the rear pod. Because the damper

plate and the shock both control perpendicular damping and the T-plate is

firm in this direction, I went with the softest oil and spring combination

on the shock and light damper grease for the damper plate. Using the

3-hole piston, I used 200 weight oil in the shock and the front spring

from the M04 M-Chassis (gold color). This improved the overall compliance

over bumps. To control lateral movement of the pod, loosen or tighten the

adjustment screw on the T-plate. A loose setting will generally provide

more stability but reduce steering (good for low traction surfaces). A

tighter setting will increase response and provide more steering (good for

high traction surfaces).

On the rear friction damper, add a 3mm

o-ring above the preload collar after assembly. This keeps the preload

setting from moving. In rare cases, the preload collar can completely

unthread itself without the added o-ring, so it's a good way to avoid this

from happening.

Tires & Gearing

The

F104 Pro is equipped with the Tamiya Type A foam tires. These are a

relatively soft compound with a moderate amount of rubber content. The

optional Type B is a bit harder but with more rubber and this typically

generates more traction. For medium to low traction surfaces, the Type B

will most likely be the best choice between the two. The

F104 Pro is equipped with the Tamiya Type A foam tires. These are a

relatively soft compound with a moderate amount of rubber content. The

optional Type B is a bit harder but with more rubber and this typically

generates more traction. For medium to low traction surfaces, the Type B

will most likely be the best choice between the two.

For carpet or high traction surfaces, the

Type A may be better. Once you've selected your compound, the diameter is

very important because it affects your ride height, gearing (rear tires),

and overall handling. A smaller diameter tire tends to be more responsive

due to less sidewall flex but can have less overall grip than a larger

tire. In general, try a larger tire for low traction surfaces and a

smaller tire for high traction surfaces. A good starting diameter for low

grip surfaces is 60mm and 57mm for medium and higher grip. For very high

grip such as carpet, 55mm would be a good starting point.

Deciding on the gearing for your F104 will

depend on the motor you'll be using, the size of the track and the

diameter of your rear tires. The F104 Pro includes two spur gears sizes, a

104 tooth and a 93 tooth. For motors such as a "silver can" and

the Formula Tuned, the 93 tooth spur will be ideal in most cases. For high

powered motors, the 104 tooth spur may give you the proper gearing range.

With your tire diameter determined, you can select your gearing. The best

way to calculate gearing is by "roll out". This is the distance

the car will move per one rotation of the motor armature/rotor.

Roll Out Formula:

Pinion x Tire Diameter x 3.142 / Spur = Roll Out

Example - 27 tooth pinion x 60mm tire x 3.142 / 93 tooth Spur = 54.7mm

Roll Out

General Roll Out Range:

"Silver Can" - 53mm to 56mm

Formula Tuned - 57mm to 60mm

Chassis

The F104 includes two optional chassis posts. If used, they must be

installed after the battery is installed and removed before the battery

can be removed. The purpose is to make the chassis flex characteristics

symmetrical. I found that on medium to low traction surfaces, the benefit

is marginal. However, a high traction surface may justify the use of the

optional posts.

Differential

The differential is a very important component of any direct drive car so

it's important to use the right differential grease. Differential grease

has a unique characteristic in relation to typical grease. It lubricates

the differential yet resists slipping on the differential rings. This

allows for a free rotating differential that is resistant to slipping. If

conventional grease is used, the balls will slip on the rings requiring

and excessively tight setting resulting in a poor handling car. For this

reason, you shouldn't use just any kind of grease. My personal preference

is Associated Stealth Lube.

The setting of the differential will also

be determined by grip level and the power of the motor. The higher the

grip level and or powerful motors, the tighter the differential may need

to be to avoid slipping. In general, a differential that is too tight can

cause sudden loss of traction on a low grip surface yet in some cases,

under steer on high grip surfaces. A setting that is too loose will slip

excessively reducing drive exiting corners and will also create

inconsistent handling. For this reason, the setting will need to be tuned

to each condition. Typically, you want the differential to spin relatively

freely but not loose enough to cause slipping while exiting corners.

Tire Additive

Tire

additive helps enhance the grip level of the tires. There are a variety of

options made specifically for hobby use. If you are unsure of which

additive to get, the most commonly used additive is Paragon Ground

Effects. This additive works by softening the foam and is suitable for

tarmac or carpet tracks. Tire

additive helps enhance the grip level of the tires. There are a variety of

options made specifically for hobby use. If you are unsure of which

additive to get, the most commonly used additive is Paragon Ground

Effects. This additive works by softening the foam and is suitable for

tarmac or carpet tracks.

The other recommended additive is sun

block. This may sound unusual but sun block has been used for outdoor foam

tire racing for as long as I can remember. Of course, there are a lot of

brands of sun block out there so I would suggest starting with Coppertone

SPF 30. Sun block tends to be used mostly on low to medium grip conditions

and is applied after the primary additive such as Paragon has been

applied. When using additive, the amount of time it is left on the tire

determines the level of effect. Apply additive to the full surface of the

rear tire for maximum rear grip but only the inside 1/4 of the front

tires. The amount of additive applied to the front can be increased or

decreased depending on the amount of steering desired. Also, experiment

with the duration you let the additive sit before wiping it off and

running. The longer the additive is left on the tire, the softer the tire

will become and the depth of absorption will also increase. |

Tire

additive helps enhance the grip level of the tires. There are a variety of

options made specifically for hobby use. If you are unsure of which

additive to get, the most commonly used additive is Paragon Ground

Effects. This additive works by softening the foam and is suitable for

tarmac or carpet tracks.

Tire

additive helps enhance the grip level of the tires. There are a variety of

options made specifically for hobby use. If you are unsure of which

additive to get, the most commonly used additive is Paragon Ground

Effects. This additive works by softening the foam and is suitable for

tarmac or carpet tracks.

The

successor to the popular F103 chassis, the F104 Pro brings more features

and realistic dimensions of the modern Formula 1 car. Complete with a new

late generation Formula 1 body, the F104 Pro is well equipped with the

most desirable components and features.

The

successor to the popular F103 chassis, the F104 Pro brings more features

and realistic dimensions of the modern Formula 1 car. Complete with a new

late generation Formula 1 body, the F104 Pro is well equipped with the

most desirable components and features. As

well equipped as the F104 Pro is, there is still an excellent selection of

Hop-Up parts to further elevate the performance of the F104. These Hop-Up

options offer a variety of benefits, such as increase durability, reduce

wear, improve tuning potential and enhance performance. The following are

just a few examples.

As

well equipped as the F104 Pro is, there is still an excellent selection of

Hop-Up parts to further elevate the performance of the F104. These Hop-Up

options offer a variety of benefits, such as increase durability, reduce

wear, improve tuning potential and enhance performance. The following are

just a few examples. The

length of the servo saver arm and the angle of the steering links will

directly affect the amount of Ackerman and bump steer the steering will

have. I settled on the Kimbrough servo saver because it provided the

steering characteristics I was looking for. On the Kimbrough servo saver,

the two 5x5mm ball ends should be installed on the farthest row of holes

(end of the servo arm).

The

length of the servo saver arm and the angle of the steering links will

directly affect the amount of Ackerman and bump steer the steering will

have. I settled on the Kimbrough servo saver because it provided the

steering characteristics I was looking for. On the Kimbrough servo saver,

the two 5x5mm ball ends should be installed on the farthest row of holes

(end of the servo arm).

Although

installation of the electronics is easy on the F104, special attention

should be placed on the motor wiring because it can affect the handling of

the car. To begin, there are two areas to mount the receiver and speed

control on the F104. The logical position of the speed control is on the

left because the motor leads come off the left side of the rear pod.

Rather than placing the speed control in a typical bottom down position, I

placed it on its side with the wires pointing back. This enabled the

battery and motor wires to travel in a more direct path.

Although

installation of the electronics is easy on the F104, special attention

should be placed on the motor wiring because it can affect the handling of

the car. To begin, there are two areas to mount the receiver and speed

control on the F104. The logical position of the speed control is on the

left because the motor leads come off the left side of the rear pod.

Rather than placing the speed control in a typical bottom down position, I

placed it on its side with the wires pointing back. This enabled the

battery and motor wires to travel in a more direct path. Regarding

wires, it's not necessary to have excessively thick gauge wire because it

can limit free movement of the motor pod resulting in handling problems.

To avoid this, I used 16 gauge wire to insure the motor pod moved with

minimal interference. The receiver installation is straight forward. To

allow plenty of clearance for the body, it was also placed on its side

with the antenna pointing rearward. This creates a clean path for the

speed control and servo wires to reach the receiver ports.

Regarding

wires, it's not necessary to have excessively thick gauge wire because it

can limit free movement of the motor pod resulting in handling problems.

To avoid this, I used 16 gauge wire to insure the motor pod moved with

minimal interference. The receiver installation is straight forward. To

allow plenty of clearance for the body, it was also placed on its side

with the antenna pointing rearward. This creates a clean path for the

speed control and servo wires to reach the receiver ports. Due

to the very scale nature of the F104 Pro's body, the receiver sits on the

opposite side of the speed control with the battery running down the

center. This doesn't make installation of the electronics difficult but

the speed control wire typically goes over the upper deck to reach the

receiver. I prefer to have this wire less visible so I routed it under the

battery.

Due

to the very scale nature of the F104 Pro's body, the receiver sits on the

opposite side of the speed control with the battery running down the

center. This doesn't make installation of the electronics difficult but

the speed control wire typically goes over the upper deck to reach the

receiver. I prefer to have this wire less visible so I routed it under the

battery. Start by adding shrink tubing around the area that will be under the

battery. This will avoid wear on the wire from installation and removal of

the battery. Make sure to have enough slack in the wire next to the speed

control to account for movement during battery installation/removal. Most

Lipo batteries have slots on the bottom to lock into a chassis design for

Sub C packs so with the heat shrink in place; use Shoe Goo to mount the

wire on the chassis so that it sits between these slots. I also used heat

shrink on the servo wire and used Shoe Goo to secure it down the right

side of the chassis. The end result will be not only a clean appearance

but a functional one.

Start by adding shrink tubing around the area that will be under the

battery. This will avoid wear on the wire from installation and removal of

the battery. Make sure to have enough slack in the wire next to the speed

control to account for movement during battery installation/removal. Most

Lipo batteries have slots on the bottom to lock into a chassis design for

Sub C packs so with the heat shrink in place; use Shoe Goo to mount the

wire on the chassis so that it sits between these slots. I also used heat

shrink on the servo wire and used Shoe Goo to secure it down the right

side of the chassis. The end result will be not only a clean appearance

but a functional one.  The

rear dampening system on the F104 Pro consists of an oil filled coil

spring shock for perpendicular dampening and a dual disk damper plate

assembly for 360 degree dampening of the rear pod. Because the damper

plate and the shock both control perpendicular damping and the T-plate is

firm in this direction, I went with the softest oil and spring combination

on the shock and light damper grease for the damper plate. Using the

3-hole piston, I used 200 weight oil in the shock and the front spring

from the M04 M-Chassis (gold color). This improved the overall compliance

over bumps. To control lateral movement of the pod, loosen or tighten the

adjustment screw on the T-plate. A loose setting will generally provide

more stability but reduce steering (good for low traction surfaces). A

tighter setting will increase response and provide more steering (good for

high traction surfaces).

The

rear dampening system on the F104 Pro consists of an oil filled coil

spring shock for perpendicular dampening and a dual disk damper plate

assembly for 360 degree dampening of the rear pod. Because the damper

plate and the shock both control perpendicular damping and the T-plate is

firm in this direction, I went with the softest oil and spring combination

on the shock and light damper grease for the damper plate. Using the

3-hole piston, I used 200 weight oil in the shock and the front spring

from the M04 M-Chassis (gold color). This improved the overall compliance

over bumps. To control lateral movement of the pod, loosen or tighten the

adjustment screw on the T-plate. A loose setting will generally provide

more stability but reduce steering (good for low traction surfaces). A

tighter setting will increase response and provide more steering (good for

high traction surfaces). The

F104 Pro is equipped with the Tamiya Type A foam tires. These are a

relatively soft compound with a moderate amount of rubber content. The

optional Type B is a bit harder but with more rubber and this typically

generates more traction. For medium to low traction surfaces, the Type B

will most likely be the best choice between the two.

The

F104 Pro is equipped with the Tamiya Type A foam tires. These are a

relatively soft compound with a moderate amount of rubber content. The

optional Type B is a bit harder but with more rubber and this typically

generates more traction. For medium to low traction surfaces, the Type B

will most likely be the best choice between the two.