|

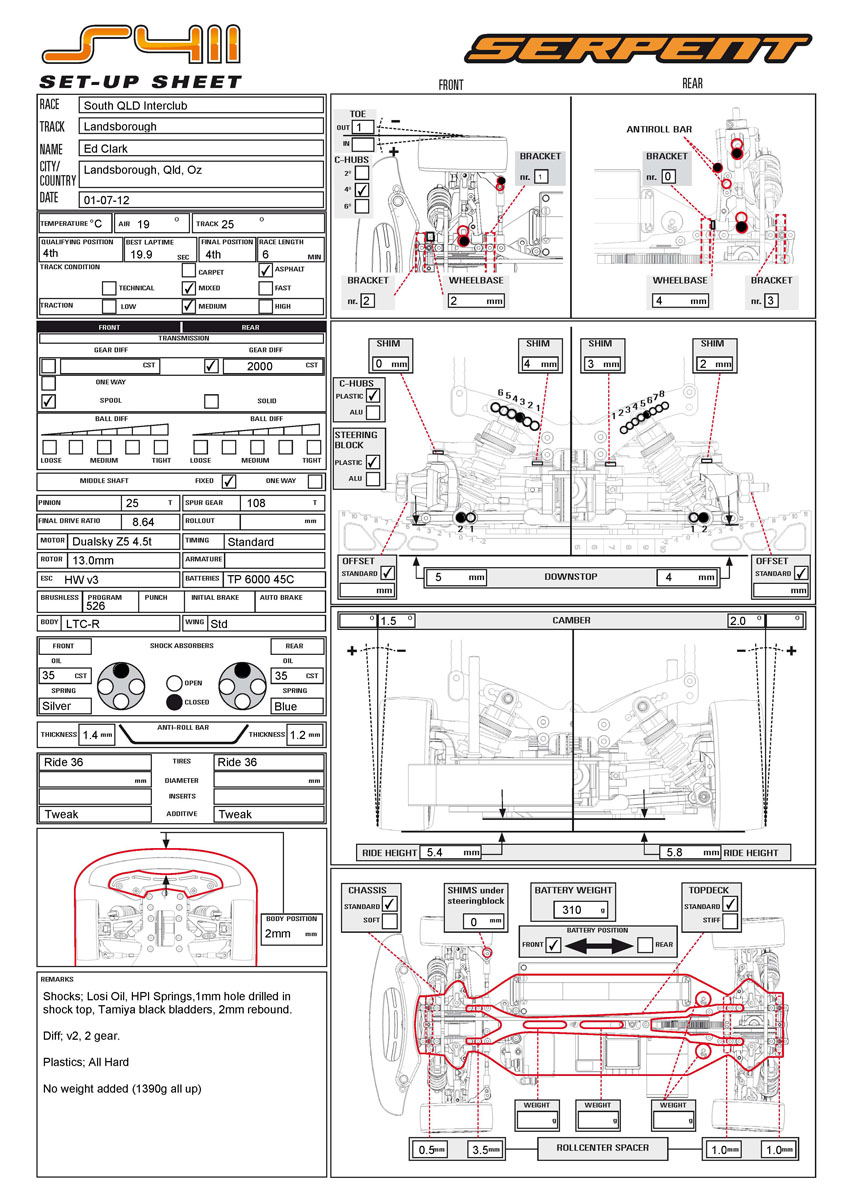

- Serpent S411 - Ed Clark - Landsborough - 01.07.2012 -

PDF File

Serpent Factory and working to fix this problem as we speak, they will be bringing out a ball stud that is 2-3mm longer.

With the bladders, the easiest way to build the shocks for me was to insert the bladder and screw the top on even with no oil. This beds the bladder into the shock top, then unscrew it and fill it with oil and screw it back on. If you put the bladder on top of the body then try and screw the top on - it's a nightmare.

I found the best feeling shock was when I drilled 1mm hole in the shock top. For some reason on our shocks you still get rebound - even with the hole. But you don't have to bleed as much oil out to get the desired rebound, hence better feeling and longer lasting shocks.

Hope this helps a bit, if anyone has any questions I'd be more than happy to help!

Ryan.

I got to run my car this past weekend, and I can't agree with Ryan more.

As I noted earlier, I had a real struggle building the shocks initially, and switched out the bladders before running. During the first run, I also drilled the top, and again that improved the car... quite a lot, with a very different (better!) feeling on track. Bladders are TAM53576 for those interested.

Anyway, back to the first run.... Having been pretty busy and not had a lot of opportunity to race recently, I headed into the weekend with limited preperation, and making it slightly harder by running mod, and at a new track too... deep end anyone

Anyway, I made up a list of stuff to run through during the day. This consisted mostly of major changes, and leaving the geometry alone, mainly as the geometry is something that doesn't seem to change too much over a number of setups.

First up was the V1 vs V2 (one-piece) motor mount.. felt that the car was more locked in and consistent with the V2, so left that on the car for the rest of the day.

Next up was a load of Diff changes, as I had built the diff as kit to start with (2gear, 1.2K), and felt this was a little soft, as the car was a bit unstable into the turns, and seemingly diffing out a bit on power. From those runs, I settled on 2gears with 2K oil as the prefered combo. The 4gear diff I also tried with 1.2K, but this was very hard and inconsistent to drive, very snappy on low throttle. Maybe 1000wt would have been better with the four gear, but it didn't feel great on the bench, so maybe needs a bit of work still.

Last on the list (well, not quite, as the shock change was last of all as I didn't have time to do that between rounds!) was playing with the rear roll bar positions. Having started out with kit (1.4mm, inside mount), feeling that the car was a bit too unstable during quick direction changes, I tried the 1.2mm bar on the outside mount to make it more linear and generally softer. This worked well to settle the rear down, too well in fact as the car then started to generate a on power push. To resolve this, moved the rear shock up one hole to 5 from 4. One thing nice to feel was that even this small change was felt on track, and did make a difference.

Overall, the day went really well, very happy with were the car ended up. Plenty still to come from it (and the driver), but every run learnt something, and every change I could feel on track. Also very impressed with the durability of the car, only issue I had all day was a rear CVD pin falling out after the grub screw came loose. Replaced both the rear's with TOP pins, that have a ground flat on them, and loctite, and that was the sum of the days problems. No issues with losing settings, no loose bits, no tweak issues... just a solid, easy and relaxing days racing. Just great really

Looking forward to running the car some more.

1mm hole?

Drilling from above or from below?

Drilling in the middle or next to the shock cap mount?

Here you go, pretty easy to do, doesn't matter how you do it, just as long as it goes into the area above the bladder. I even did mine with the shock assembled... just be careful not to drill the bladder!!

Source:

|