|

Kyosho announces

the new Ultima RB5 electric racing buggy. It's a virtually

all-new design that is the result of years of R&D and

includes the collective experience of the world's most

experienced RC racing drivers and engineers from the world's

most experienced RC racing company. The main goal of the new

Ultima RB5 is simple - to win the next IFMAR World Championship.

The new Ultima

RB5 only shares rear hubs with the Lazer ZX-5 and a few common

hardware items, but the essential and distinguishing components

of the car, such as the chassis, transmission, bulkheads, shock

towers, suspension and the sleek aerodynamic body, are all new.

Each aspect of the car is specially designed and tested to

produce maximum performance. Likewise, the materials chosen for

this new Ultima are exhaustively tested - all with the goal to

create the ultimate no-nonsense competition car that's ready to

take on the world.

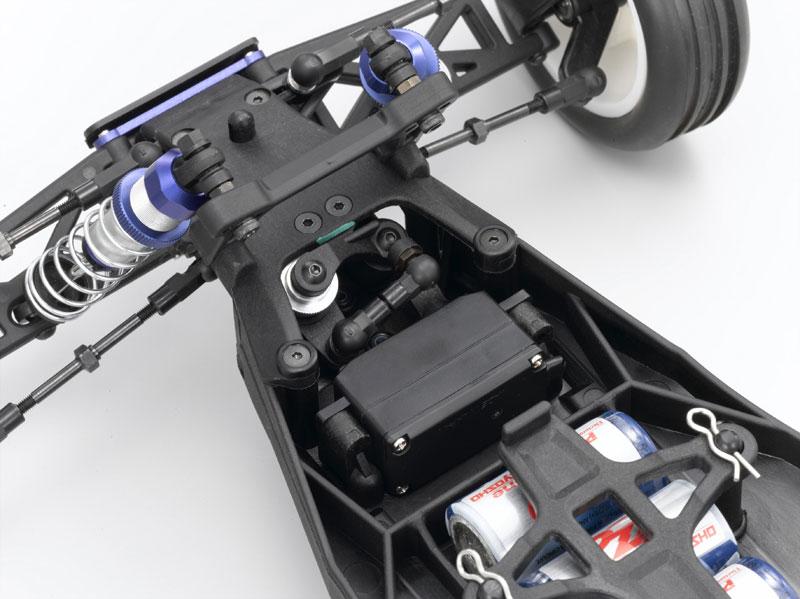

Chassis

- The chassis plate is light and strong, featuring a specially

formulated carbon fiber composite for the best balance of

performance and durability. Strategic braces molded into the

chassis enhance the stiffness without adding any unnecessary

weight. Separate front and rear "clips" allow fast and

easy removal of the front or rear end of the car, which makes

maintenance and repair much easier. Designed to accept stick

packs and racing-style 6-cell matched packs, the RB5 chassis

features an adjustable battery mounting position that allows you

to shift weight bias to suit track conditions and your driving

style.

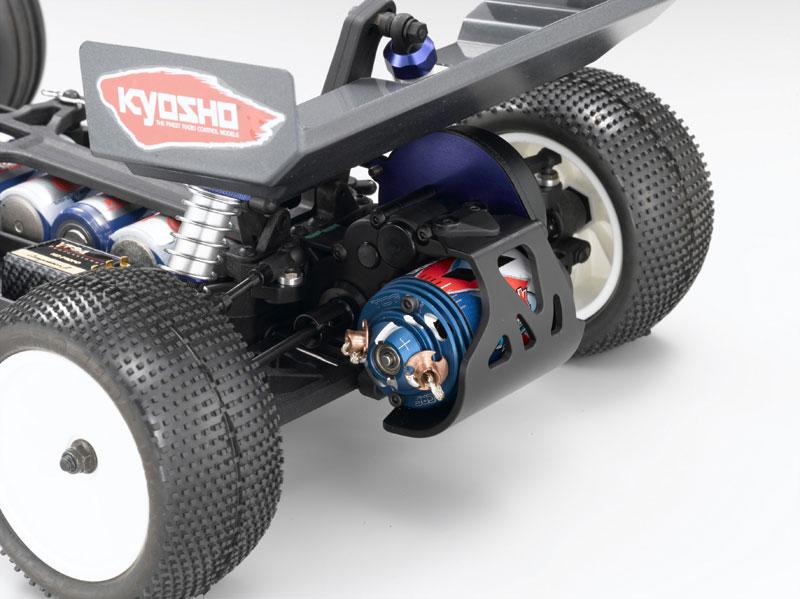

Transmission

- The new transmission features a smaller, more compact housing

that keeps the motor as low and close to the transmission as

possible, which reduces CG and improves bump handing. The

three-gear transmission features an internal ball differential

that uses standard 3/32-inch diff balls and 1/16-inch thrust

balls. The differential is also externally adjustable, and a

dust cover fits over the adjustment holes so the thrust bearing

lasts much longer. An injection molded gear cover is included,

which better fits the motor plate to minimize dust and debris

for longer gear life.

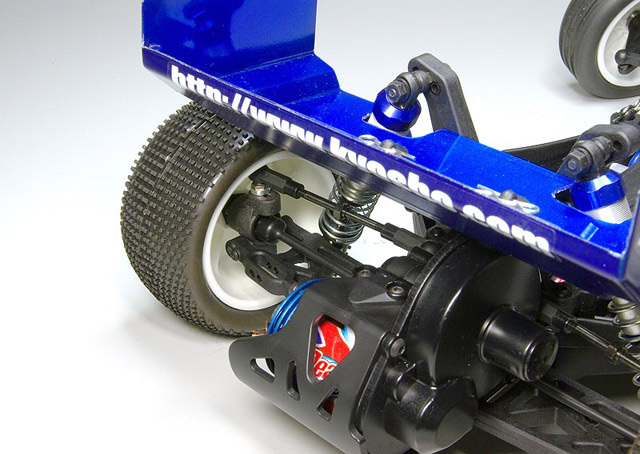

Rear

Suspension - The rear suspension arms are symmetrical

so a single replacement arm can be used on either side of the

car, saving money and space inside your pit box because you

don't need to carry as many replacement parts. The inside of the

arms are attached to the chassis using separate suspension

mounts, which will allows anti-squat adjustment. The rear wheel

hubs feature three lower hinge-pin holes, which allow

modification of the ride height with minimal disturbance of the

suspension geometry. Vertical ball studs for the both the inner

and out rod ends of the upper link mean the rear suspension

geometry can be fine-tuned with shims.

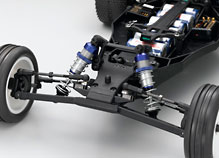

Front

Suspension - Longer, straighter and symmetrical

suspension arms connect to a narrow front bulkhead. The bumper/skid

plate, suspension block, nose plate and front bulkhead all come

together to form a very rigid assembly, to which the front

suspension arms mount. The standard position of the suspension

mount produces 25 degrees of hinge pin angle in the front

suspension arms, but simply flipping the suspension mount

increases the hinge pin angle to 30 degrees. The added

flexibility of having adjustable hinge pin angles means you have

more options when it comes to setting up your car. Like the rear

arms, a single replacement arm can be used on either side of the

car.

Offset steering

hubs make high-speed handling a dream, while floating axles ride

in bearings that are mounted in the hub instead of the wheel

This moves the weight of the bearings inboard for more

responsive suspension, the bearings are under less stress, and

they're better shielded from the elements. This means the front

wheel bearings last longer and run smoother. The front track

width is also easily adjusted, which means the amount of

steering response is easily increased or decreased for track

conditions and driver preference.

Steering

Assembly - Ball bearings provide smooth movement of the

steering bellcranks, which are mounted on the chassis at the

same angle as the suspension arms. This eliminates bump steer

and produces more accurate Ackerman geometry throughout the

entire range of steering motion. The steering plate (center link)

features horizontally mounted ball studs, which mean Ackerman

can be fine tuned using shims behind the ball studs, offering a

nearing infinite range of adjustment.

Captured

Hinge Pins - A simple button head screw captures all

the outer hinge pins of the Ultima RB5. The rear inner hinge

pins are truly captured between the suspension mounts, and the

notched inner front pins are secured with a setscrew through the

front suspension mount. This means that the hinge pins are much

more secure and less likely to come loose.

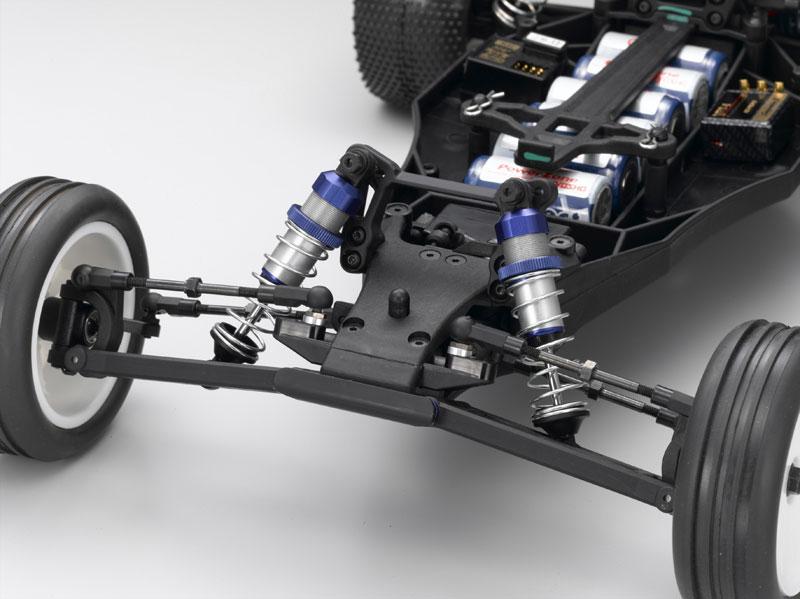

Low-Profile

Shock Towers - The front shock tower is mounted as far

back on the chassis as possibly, as are the shocks, to keep the

mass as low as possible. Likewise, the rear shock tower is also

designed to keep a low profile, yet allow enough suspension

travel to ensure the best possible handling. The shock towers

are molded from an exhaustively tested composite, which is much

more costly to produce than shock towers made from woven

graphite, but will also provide greater durability.

Threaded

Aluminum "Triple" Shocks - Kyosho is well

known for silky smooth shocks and the new "Triple"

shocks included with the Ultima RB5 are no exception. The shock

body consists of three major components - a top cap, threaded

body, and a lower cap. The aluminum shock bodies feature a

threaded spring pre-load collar for quick and easy adjustment.

The threaded adjuster features an O-ring that prevents the

preload settings from moving, which ensures consistent

performance from start to finish. The lower shock cap allows

quick and easy maintenance of the double O-ring seals.

Low-Profile

Body - no less than ten versions of the new body for

the RB5 were thoroughly tested to maximize performance and to

ensure that you have the best-looking car on the track. The

entire R&D team as well as the factory drivers were involved

in the development, and the finished product is the

best-performing body ever used on a 2WD buggy according to the

team.

|

It is

hard with the bulkhead of the material of the [me] and

the suspension mount of the soft and others pot,

compatibility gap absorptivity and the steering wheel

where the rigid impression is high. In addition in the

wheel design which installs the bearing in hub side,

tire exchange at brief is possible.

|

|

The foot

which moves well (the suspension) with, being smooth,

the oil damper of 3 block constructions which do not

have the being off-center of the shaft, low actualizing

the running which at ~ high-speed all catches the land.

The roll doing securely even with the corner, grip it

does, promising the maneuverability which is superior.

|

|

You

adhere to center shaft position, the mission which makes

the motor and the axle approach, acquiring high

maneuverability. Furthermore you adopt teflon sealed

type for all bearing, actualizing high durability and

dustproof characteristic.

|

|

|

|

|

|

|

The

private body in order all the speed limits and the

aerodynamic effect which is made securely the various

behavior times to show, throwing the original device.

The dent before the front screen actualizing the high

result e.g., the down fourth which is effective to the

front is offered.

|

|

You

install in the doubles ripper clutch, combining this car

private shoe. Going hand in hand with the setting which

makes secondary reduction gear ratio high, while the

sharp pickup the tripod kettle, actualizing smooth

traction transmission. Showing the maneuverability which

is superior in all scenes.

|

|

The

maintenance characteristic which can be accessed

important place directly with the chassis which was

divided into 3 parts, actualizing the doing easiness of

setting. With combination with the 12T class which is

the recommendation motor, the controller bull announcing

running highest.

|

|

Specifications

|

| Wheelbase: |

10.63 in.

(270mm) |

| Track

Width: |

9.84 in.

(250mm) |

| Chassis: |

Molded Carbon Composite

|

| Transmission: |

Compact

3-Gear |

| Differential: |

Externally

adjustable ball diff |

| Transmission

Ratio: |

2.6:1 |

| Bearings: |

Teflon

Seales (Trans), metal shielded |

| Suspension: |

Lower H-arm

w/steel turnbuckles |

| Shocks: |

3 piece

threaded aluminum, oil damped |

| Driveshafts |

Steel, CV

type |

| Gears: |

48 Pitch |

| Slipper: |

Double Disk,

spring loaded |

| Weight: |

57.2 oz.

(1620g) |

| Motor: |

540 size (Sold

Separately) |

|