Team Associated 12L4 Setup Tips - Lufaso

|

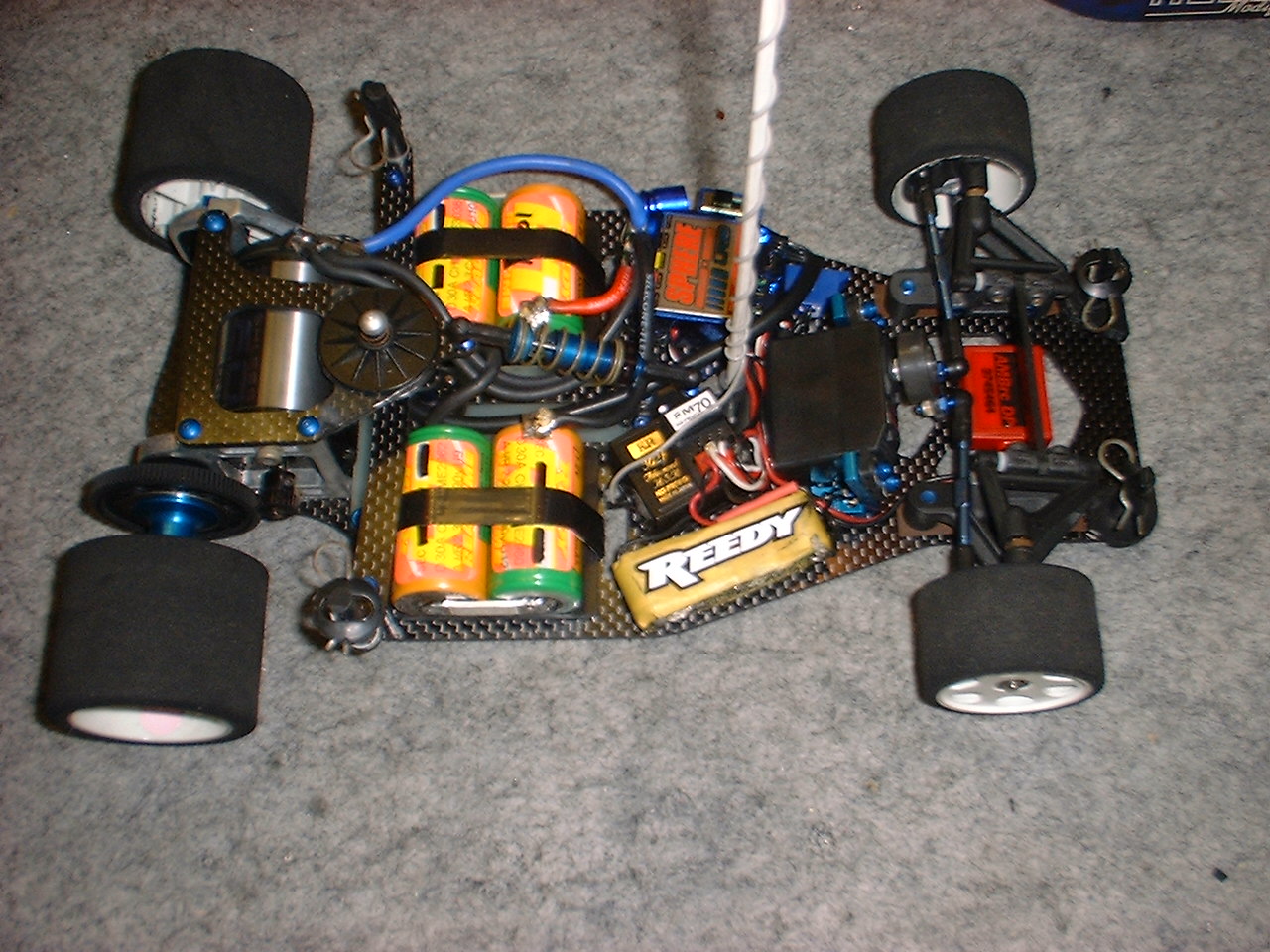

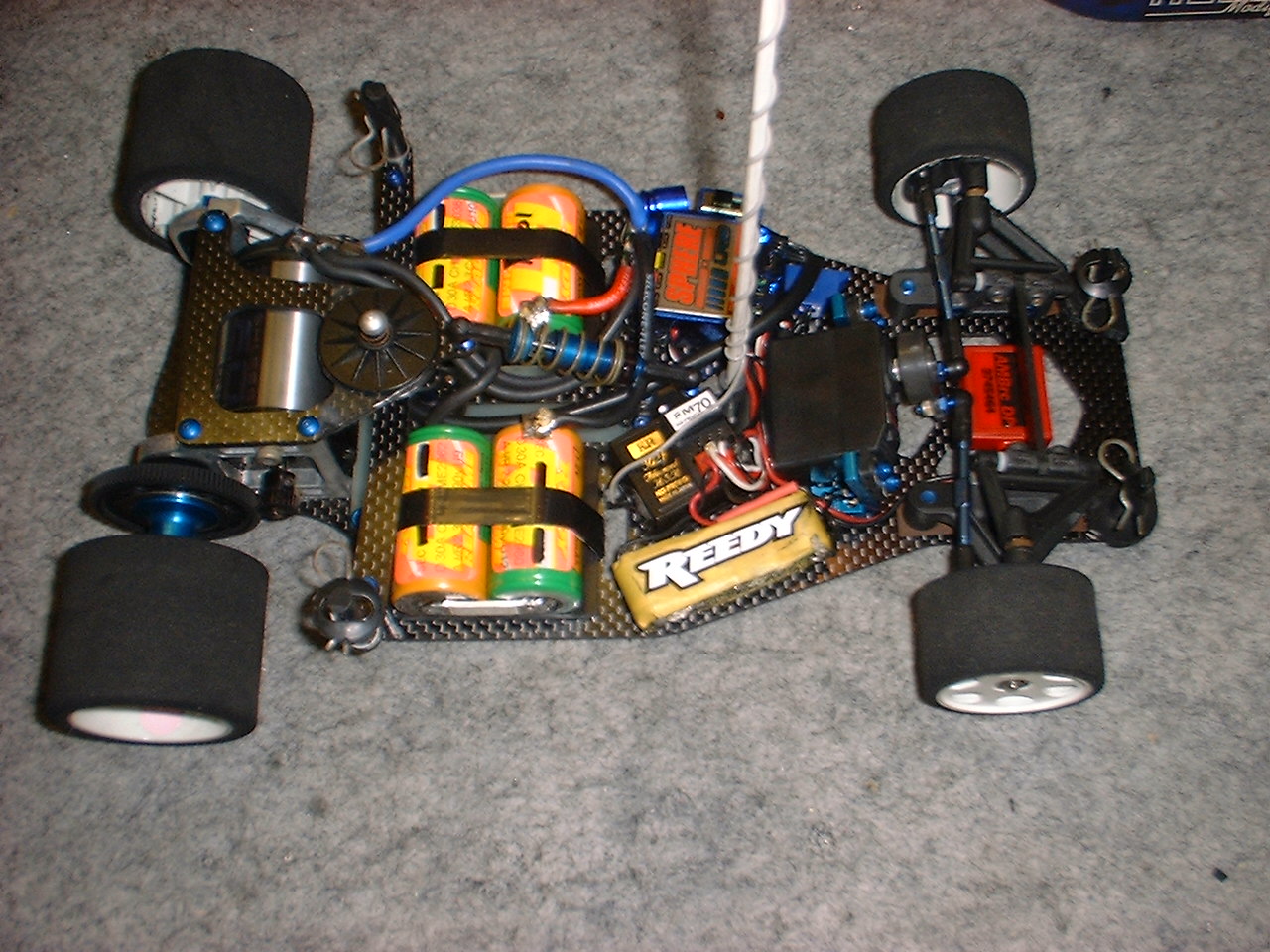

There are many

variables involved in setting up 12L4 radio controlled racing car that

it is nearly impossible to give a setup that will work with all tracks

and driving styles. Starting points for the various parameters involved

in building and setting up the Team Associated12L4

are shown below. Try the car in its box stock form first, before you

make any changes. At the 2005 ROAR Nationals in Tampa, FL, except for

lowered rear pod, I used the car in the box stock form (damping

discs, etc.) to win the A-main modified. At the IFMAR worlds (5th

place), I used the stock chassis and front end, with Yokomo option

parts (rear pod) to allow the use of smaller rear tires.

Set-Up sheets in Adobe PDF format

| Blank Setup Sheet |

Construction

Chassis and front armsChassis

preparation is very important. The chassis should have smooth edges

around all of the outside edges of the chassis. Fine grit (600)

sandpaper is an easy way to accomplish this. Each screw that is on the

bottom of the chassis should be mounted flush with the chassis, check

by sliding a straght edge across the assembled chassis. If the straight

edge contacts any of the screw heads, then that hole must be

counter-sunk more or the screw machined down. I prefer countersinking

the carbon fiber chassis more than removing material from the screw as

the screw may have to be replaced at some point. (Option: To the rear

outside edges of the chassis, add telflon tape to ride smoother against

the carpet in hard cornering.).

Lower and upperplate

Smooth out these pieces similarly to the chassis described above,

spending more time with the upper plate at the location the dampener

disks ride. If you have access to a mill, these pieces can be milled

slightly to reduce weight. On the upper plate use teflon tape to ride

against the dampener disk for smoother rear suspension action. On the

upper plate, replace the two button head screws on the back with blue

anodized flat head aluminum bolts and countersink the plate bolts. This

lightens the plate slightly, and allows the body to be mounted slightly

lower before the body hits the pod.

Pivot Balls

For weight savings, try CRC blue anodized aluminum pivot balls

replacing the steel pivot balls. Replace the steel screws for the pivot

sockets with light blue anodized aluminum screws (Trinity). If the

pivot ball is slightly loose, then the top of the bottom socket can be

sanded to tighten the tolerances between the two sockets. The pivot

balls should smoothly rotate in the pivot ball sockets. I use the stock

steel pivot balls, but polish the steel pivot balls to a mirror-like

finish. Periodically repolish the steel pivot ball to make the T-plate

twisting actions smoother.

Front Suspension

The back of the front arms should be filed at an angle. This will allow

smoother steering, without the steering block binding with the arm.

This will also allow you to use smaller front tires for lower

rotational weight. The front suspension should be free and smooth. The

pivotballs should be free and not loose or binding. Use polished

titanium kingpins and stub axles. One may also drill out the steel

upper suspension turnbuckle to save weight. The top pins are also made

out of titanium. Add a thin teflon shim or thin steel washer to tighten

the tolerances between the upper suspension arm mount and the upper

suspension arm. Check each side for caster, about 2-4 degrees.

Generally, if the car has high speed push, add more caster. A total of

5 degrees is the maximum that should normally be used. Note that the

same number of spacers will not necessarily result in the same degree

of caster on each side on some older pieces, but should not be a

problem with the 12L4. Use a camber/caster gauge (Team Associated or

RPM) to measure and make sure each side is the same. Use about -1.5 to

1.0 degrees of camber, which allows the tire to wear evenly. Adjust the

camber until the tire wears evenly and otherwise do not use this as a

tuning parameter.

Rear PodUsethe

Team Associated Magnesium motor plate, saving weight compared to the

stock alumimum motor plate. If you are a stock race you could use IRS

or Yokomo lowered pod blocks to use smaller rear tires. Depending on

the t-plate thickness, adjust the 2 or 3 spacers so that the chassis is

level with the rear pod, or the chassis is slightly higher that the pod

- so the chassis does not rub.

Axle Use

the Team Associated stock axle and it should fits moothly into the rear

bearing. The bearing bracket may fit too tightly into the magnesium or

aluminum motor mount. Excess material on the bearing ride height block

should be removed until the fit is not too tight. This will make the

rear axle spin much more freely, resulting in higher efficiency. This

is very important for run time.

DifferentialA

smooth and free differential is a vital component in constructing a

good handling 1/12 car. The stock Associated components create a smooth

differential. Use the stock Associated Differential grease on the diff

balls in Kimbrough gears. Typically a 100 tooth is used for modified

and in stock a smaller spur. Generally use the largest spur gear

possible possible in which you can still get proper gear mesh. Setting

the gear mesh is very important, there should be some play at the

tightest spot on the gear, but not too much play. The outside ball

bearing used as a thrust bearing will quickly wear out. I used thick

oil in the bearing, usually 5-20 weight shock oil. This prevents the

bearing from wearing out as rapidly. When finished racing for the day,

I loosen the differential so a constant side load is not placed on the

bearing. These bearings were not designed for the side loads in a

differential and wear out quickly. Consider using a slightly worn

bearing for practice, then change to a newer bearing for the races and

observe the difference in the handling of the car.

Servo MountsThe

servo mounts depends on the choice of a position of the servo, tilted

or flat on the chassis. I prefer using the tilted servo positions, use

stock adjustable aluminum servo mounts. A flat mounted servo results in

increased bumpsteer. Ball studs require spacers underneath, or an

offset ball stud to eliminate some of the bump steer.

Tires

are one of the most important aspects of the car. As a general rule for

1/12 carpet, good tires to use are Jaco Purple or Double Pink for the

front and Jaco Pink for the rear (for modified). One could try Jaco

White or Gray in stock for more efficiency. The pink dot tires are

softer and tend to wear more quickly. The outside sidewall of the tire

should be glued to the wheel with CA glue to keep it from tearing away

from the wheel. This also need to be checked after each run. If the

tire is starting to tear away from the wheel, clean up the outside edge

from with a tire trued and reglue the wheel. A tire durometer (e.g.

Maxmod) helps eliminate production tolerances inherent in the synthesis

of foam rubber. At important races, it may be useful to "match" tires.

A durometer reading can vary over 6 unit on the same compound of tire.

Tire Size

is another important aspect. The 'best' tire size is generally the

smallest in which enough traction is available for the entire 8 minute

run,and maintains enough ride height to meet ROAR rules 0.125" and not

drag or rub on track. A smaller tire generally has less rotational

mass. Typical tire size ranges are 1.78" to 1.69" on the front for a

smooth track. The rears range from 1.77" to 1.89" I typically run the

ride height near 0.150" The ride height should be high enough that the

chassis is not black after the race.

Tire Rotation

A typical road course always has more right turns than left turns if

the track run clockwise. This results in the left side tires wearing

more than the right side. I always put the larger tire on the left

side, because it will wear quicker. This should be checked after every

race. I have observed racers with as much as 0.100" difference in right

to left tire size. That makes for a car that can not possibly turn the

same left to right. Invest in a set of calipers and check tire size after every race, rotating the tires as necessary.

Ride Height

The car is riding too low when the front of the chassis/body mount

screws are blackened after a run - or the strapping tape used to hold

the cells in is blackened. There are several solutions to this,

including using the #4 offset ride height adaptors and no spacers

underneath the front blocks. Use shim stock or cut out lexan to adjust

front ride height.

Tire TractionThe

standard traction compound foruse on ozite based carpet is Paragon

Ground Effects. There are many important factors in it's use - which

can be quite an art form. The length of time the traction stays on is

important. For tracks with low traction, it should be allowed to soak

in for a longer period of time. On high traction track, a few minutes

may be all that is necessary. The amount applied is also considered -

in most cases I see racers putting on much more than necessary for the

track conditions. This can actually slow the car down as the softer

tire tend to scrub more speed - slowing the car down and reducing run

time and efficiency. The width of the application is important. The

inside 1/4 to 3/4 of the front tires shouldbe done and most often full

width on the rear tires. It is also beneficial to change tires each run

to prevent traction build up. I usually run only one set of tires twice

a day, once in practice and one in a qualifier or main.

Front Springs

Most commonly used front springs are 0.022",0.020" and 0.018" depending

on the amount of steering needed, bumps on the track, and

responsiveness desired. Various combinations of oil or grease can be

used as dampening on the kingpins. Note that using lube will require

more frequent cleaning and reapplication of dampening. In many cases,

it is more convenient to just use the polished kingpins with no

lubrication.

T-PlateThe

thick T-plate - which can vary from 0.070" to 0.080" thick is a good

place to begin for carpet. There is nearly 0.010" production tolerance

in fiberglass, so measure the T-plate to ensure what thickness you are

using. The thin T-plate is generally used for asphalt Note the thin

t-plate is more susceptible to failure and requires replacement more

often. The T-plate has the option to use 2 washers or 3 washers between

the T-plate and the rear pod. In general, the 2 washers makes the front

the back softer, making it better for the bumps and increasing rear

traction. Three washers stiffens front toback and decreases traction.

Using two washers also increases the chances that the T-plate will

become stressed. Look at the T-plate by holding it to the light. If a

noticeable color difference is present at the corners, the t-plate

needs replaced. I usually prefer to use 3 washers on carpet. I

sometimes place a small motor shim (0.010") under the font of the

T-plate, which tends to increase rear traction and is often helpful for

1/12 modified.

Damping

Very little damping is used initially when I start at a track. Add

damping to the rear end to add more steering. I have tried many types

of grease, including various oils and diff lubes (the type of diff lube

is not important, I use and try many types on the discs). The tension

on the damping discs should be very light in most cases (cut the spring

to reduce tension if necessary). Remove damping fluid to obtain more

rear traction. If a lot of damping is used then a thin T-bar may handle

better in extreme situations, but I do not typically like this setup.

Chassis Rake is

the single most under-checked parameter in setting up a 12L4 or any

onroad car for that matter. The chassis height off of the ground should

be measured at 3 distinct locations - the front end between the body

posts, the middle nearthe chassis brace, and the middle rear. The

chassis should bevery nearly level - to within 0.030" and this is

another way to tune the handling. By having the front end lower than

the rear,more steering can be obtained and conversely having the rear

end lower the the front will create less steering. Note that is valid

only toa point.

Equipment

Body

Good body choices for 1/12 are the Parma/PSE EXP Speed 8 and Protoform Speed 12. Overall downforce is good in front and rear, which results in better and more consistent handling.

PaintParma/PSE Faskolor

is a great nearly odorless paint for Lexan bodies. A wide variety of

colors is available. Airbrushing and cleanup is simple with the

non-toxic aqueous based paint.

Speed Control LRP Quantum 2is

very lightweight and highly efficient. I use setting #4 for throttle,

#0 for brake and 0 drag brake. The throttle curve is extremely linear

and easy to be smooth with. It is convenient to change wires with the

tabs outside the case. The setup is simple, and there are several

choices of throttle curves.

Servo & Receiver

1/12 racing needs a very fast servo, but does not need high torque. I currently use a KO Propo PDS-949 ICS, which has a good combination of lightweight and fast rotation speed.

Receiver Pack

A 5 or 6 cell receiver pack made of of N-cells is useful in trying to

extract the last few seconds of runtime from the main pack. The Rx pack

powers the servo and receiver, instead of draining the main pack. Note

this may only gain ~5 seconds of runtime, which can easily be lost in

one crash. Use a Rx pack to extract more performance, but only use one

if your driving/crashing is not the limiting factor (then focus on

practice). Mount the receiver so the plugs are near the center of the

chassis, so the body can be lowered even more.

TransmitterKO

Propo EX-10 Helios with the wheel drop down extension. I use tennis

wrap around the grip to make the radio more comfortable to use. A few

layers of tape attached to the brake trigger helps provide more

sensitivity for braking, which is very seldom used in 1/12 racing.

Setting up the transmitter is arguably the most important tuning aids,

and often an incorrectly setup radio is the cause of problems. When

setting up the speed control, set the throttle Hipoint to 150

(maximum), then set brake to 100. Set steering travel and EPA to 100.

Setup the speedo, then adjust the braking down to 80% as a stopping

point. Then use the steering balance to adjust the right and left end

points to the stopping point on the steering knuckles. Do a turning

circle, and reduce steering on the side with a shorter turning radius

until both sides are of equal radius. Then reduce the travel to 75%.

Adjust the braking feel and steering travel to your needs.

CellsThere

are many companies that sell NiMH, but if you are a beginner you do not

need awesome cells and can get good performance by buying lower

runtime/IR/voltage cells. The key is to learn to

mechanically/technically setup the car. When you are driving perfect

lines and not crashing for the entire 8 minute race then the better

cells will be beneficial. Try the Reedy GP 3700, or better yet, the

VTEC 3800 and you will not be disappointed with the performance.

Battery Charger The LRP Pulsar 2

is an excellent choice with a adjustable current and peak detection

limit. Try betwen 5.0 and 6.0 A with 0.005 or 0.010 mV detection. Peak

until heat reaches about 130 F.

Performance Enhancement PartsParagon

floating damping post - although it is not sold anymore. The stock

damper disks function just as well. I sometimes use the shortened

aluminum damping post by Yokomo, so I can mount the body lower.

Created October 18,1998

Modified June 21, 2006

Back to main page