|

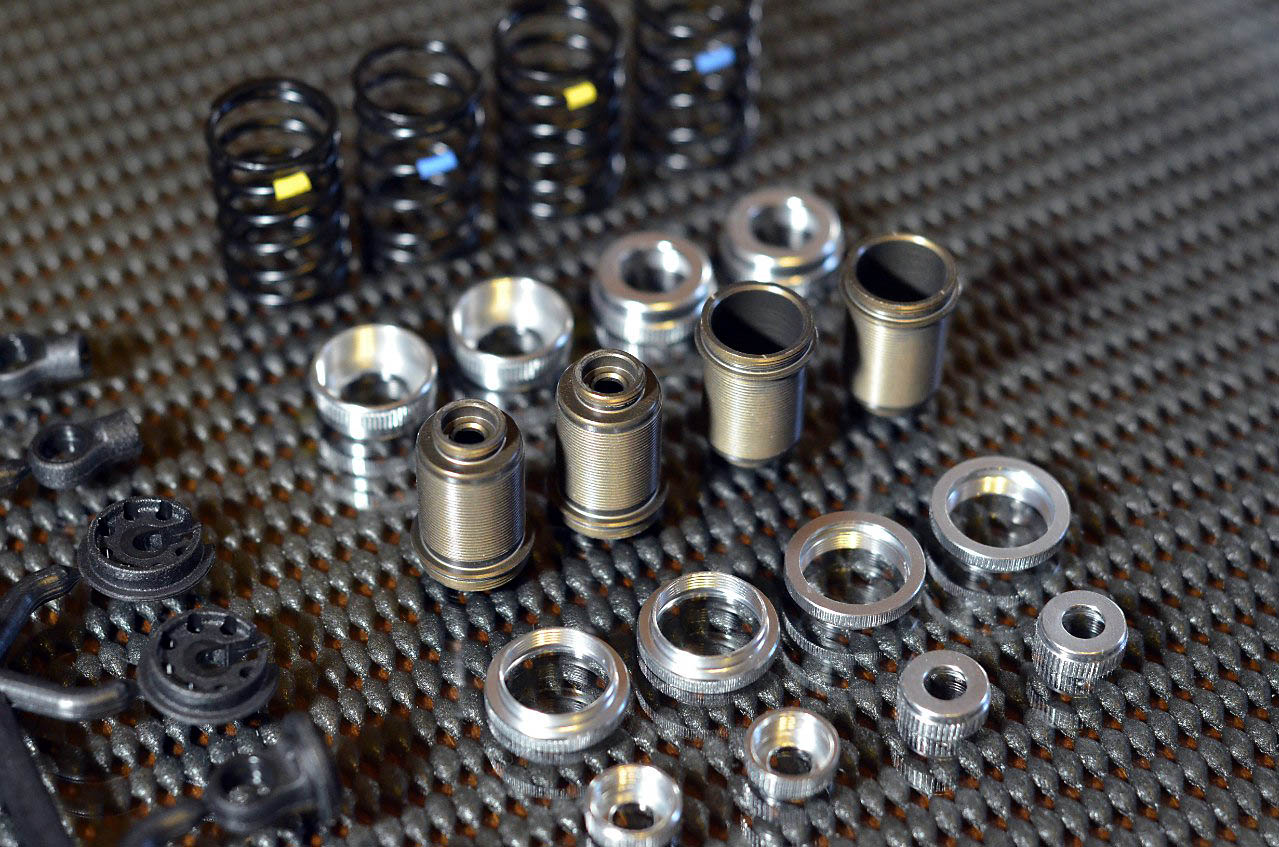

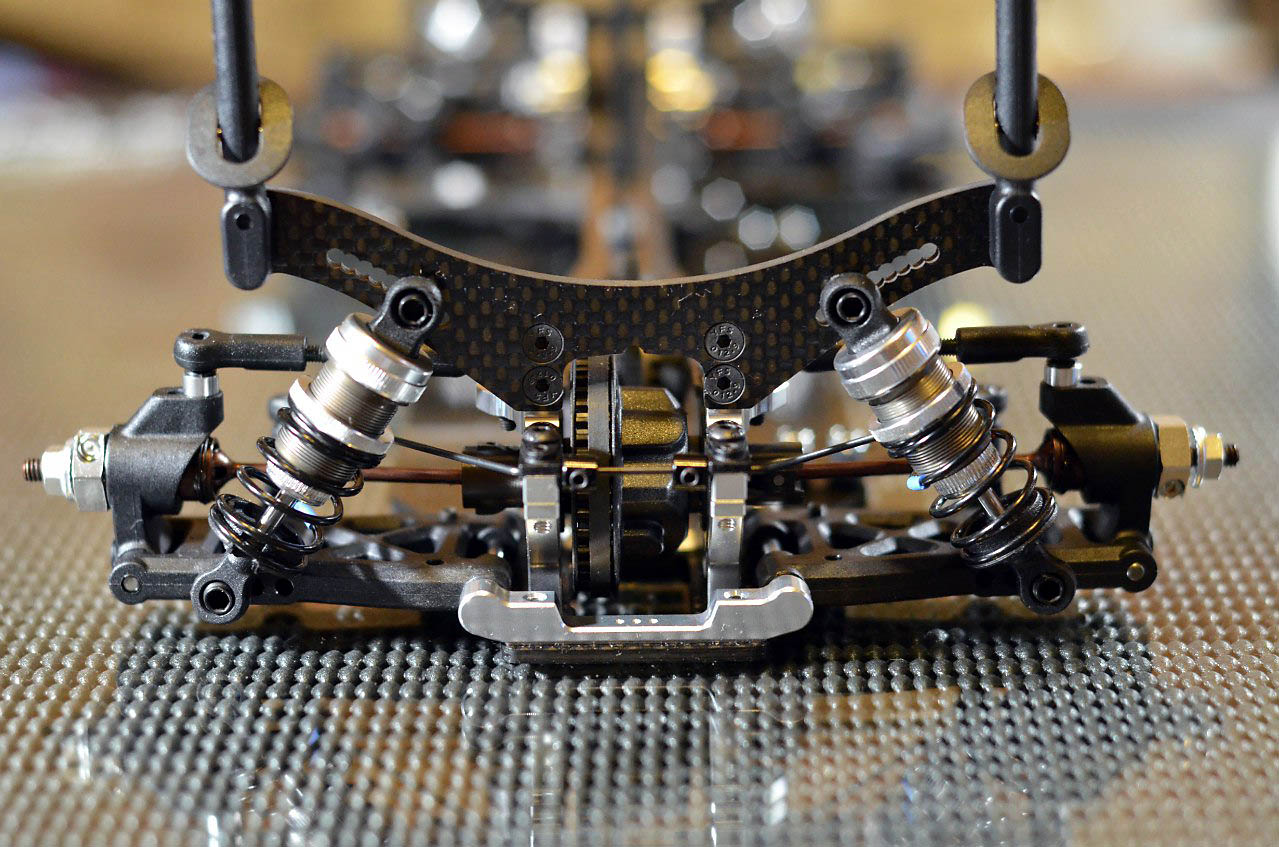

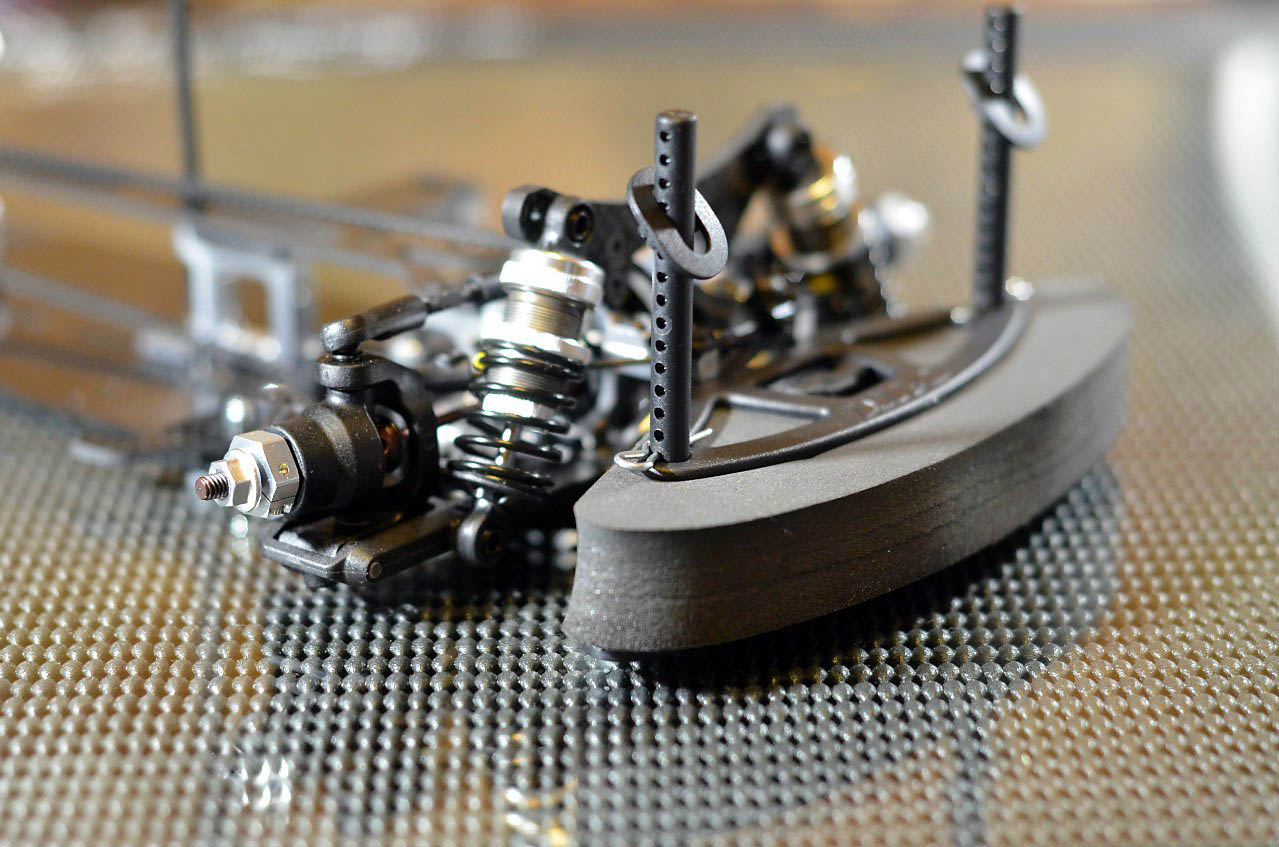

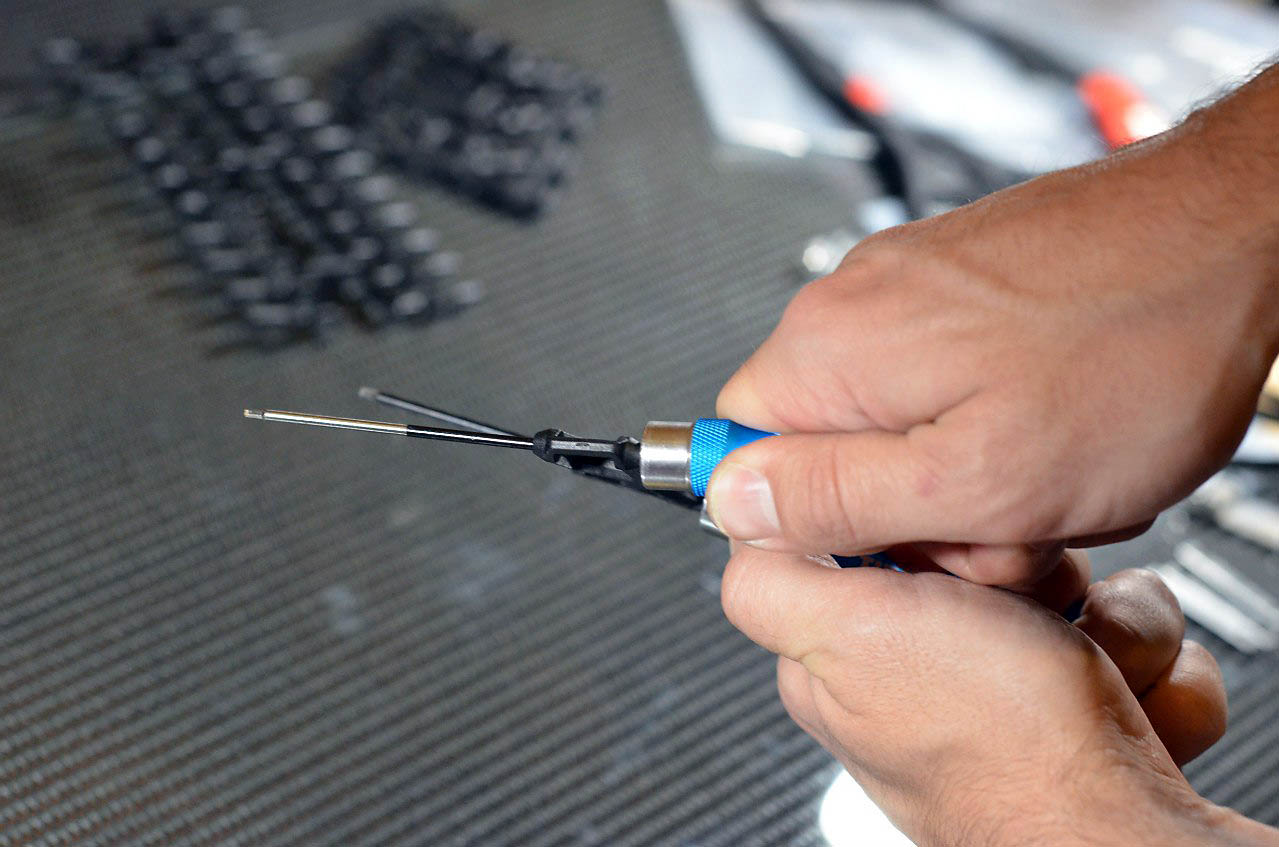

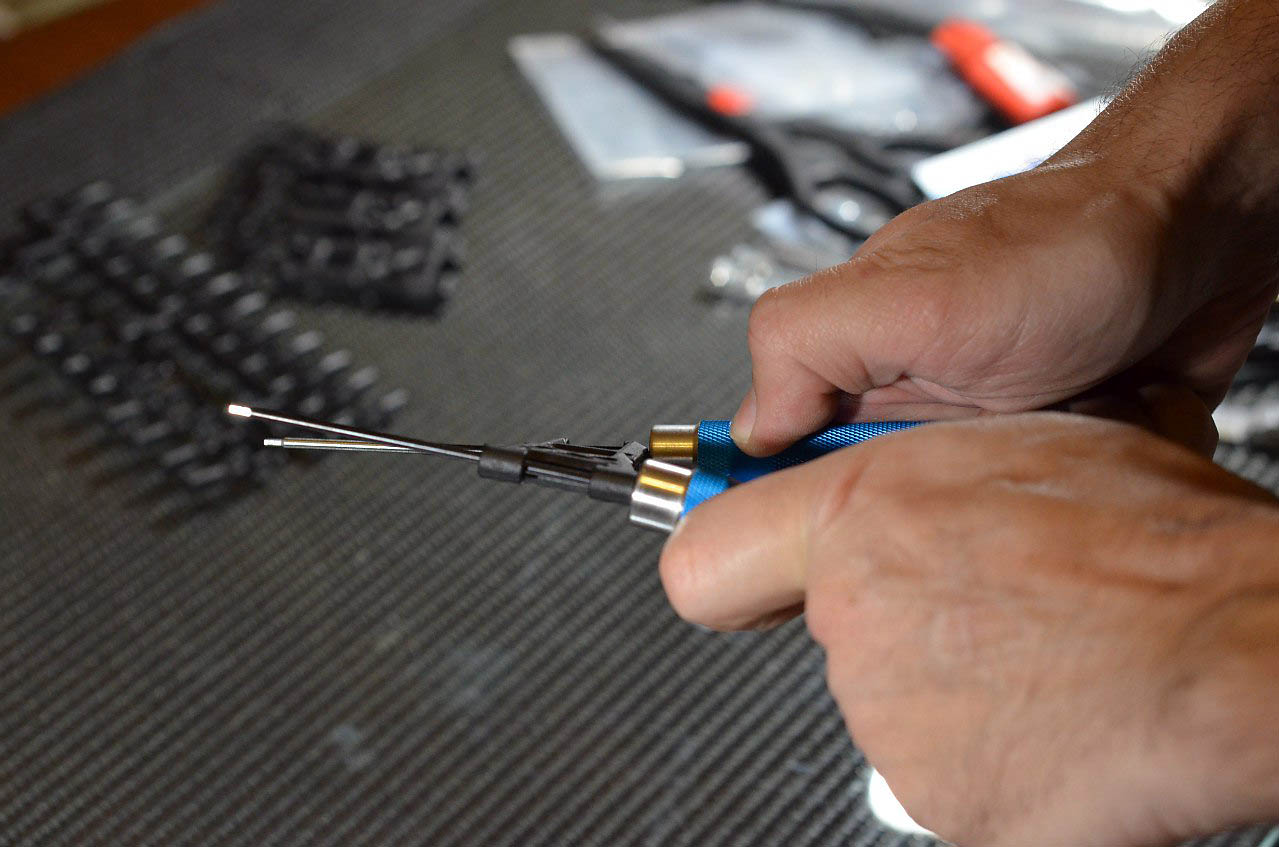

Finally - the shocks. There will be a lot of photos, because shocks are the most critical details in any RC chassis. Proper cornering, accelerating, braking - all of it depends on how good your shocks are. Shocks must keep oil from air long time, be as smooth as possible, free from any play and easy rebuildable.

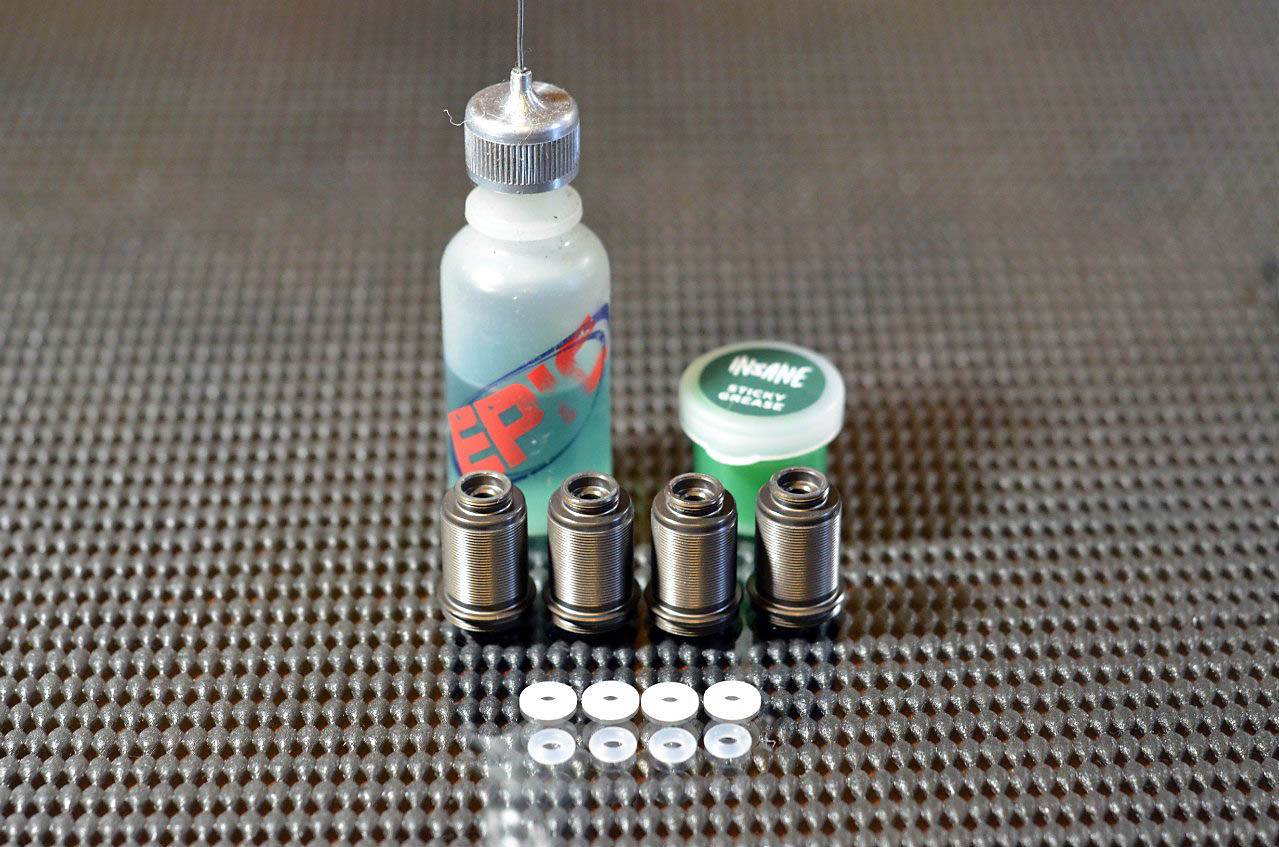

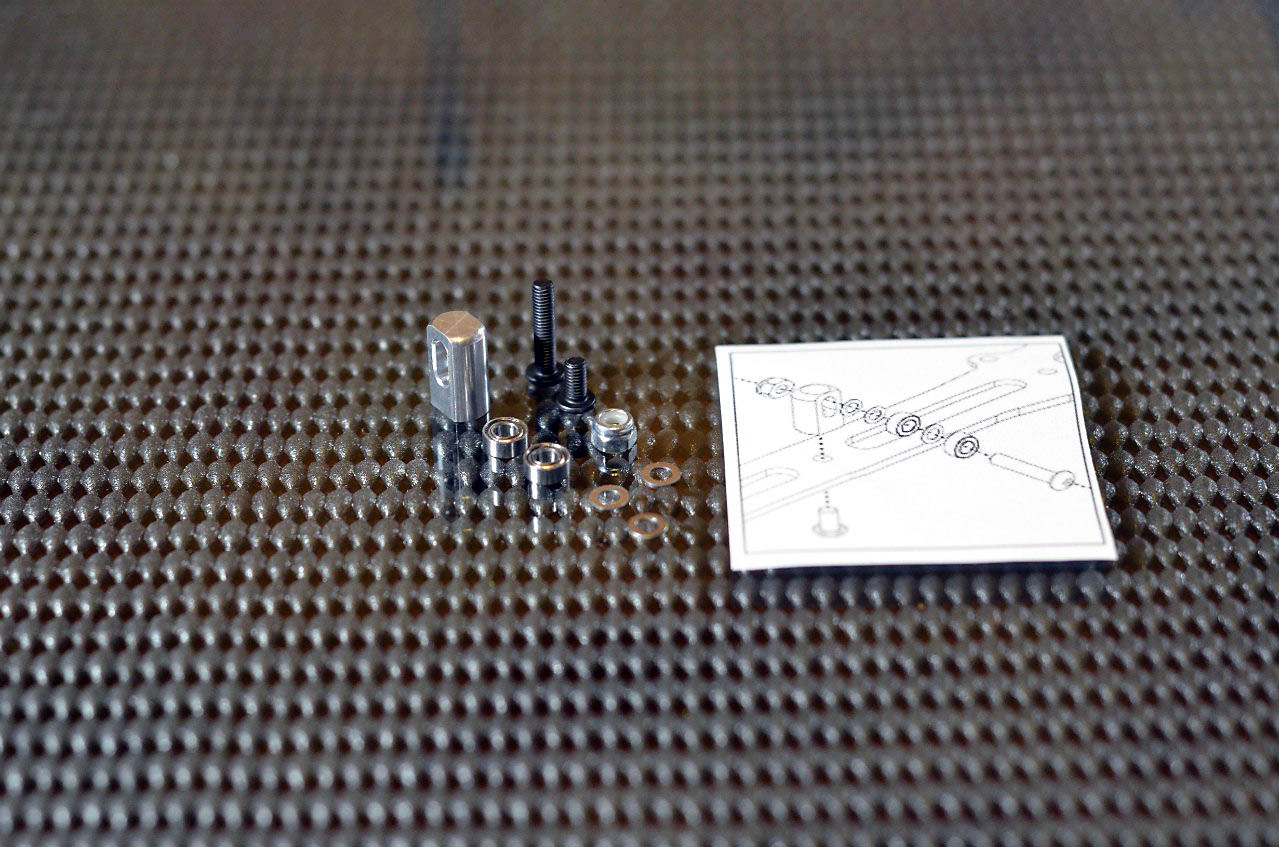

Top cap and rod end have oversized 5.8mm balls, which are made from steel. Rod bushings and piston - CNC machined from derlin straight from the box. This makes shocks as durable as some offroad shocks. Also, keep in mind, that shocks have oversized inner diameter and pretty long body (means much more oil volume). All this made for better consistency, temperature stability and overall damping.

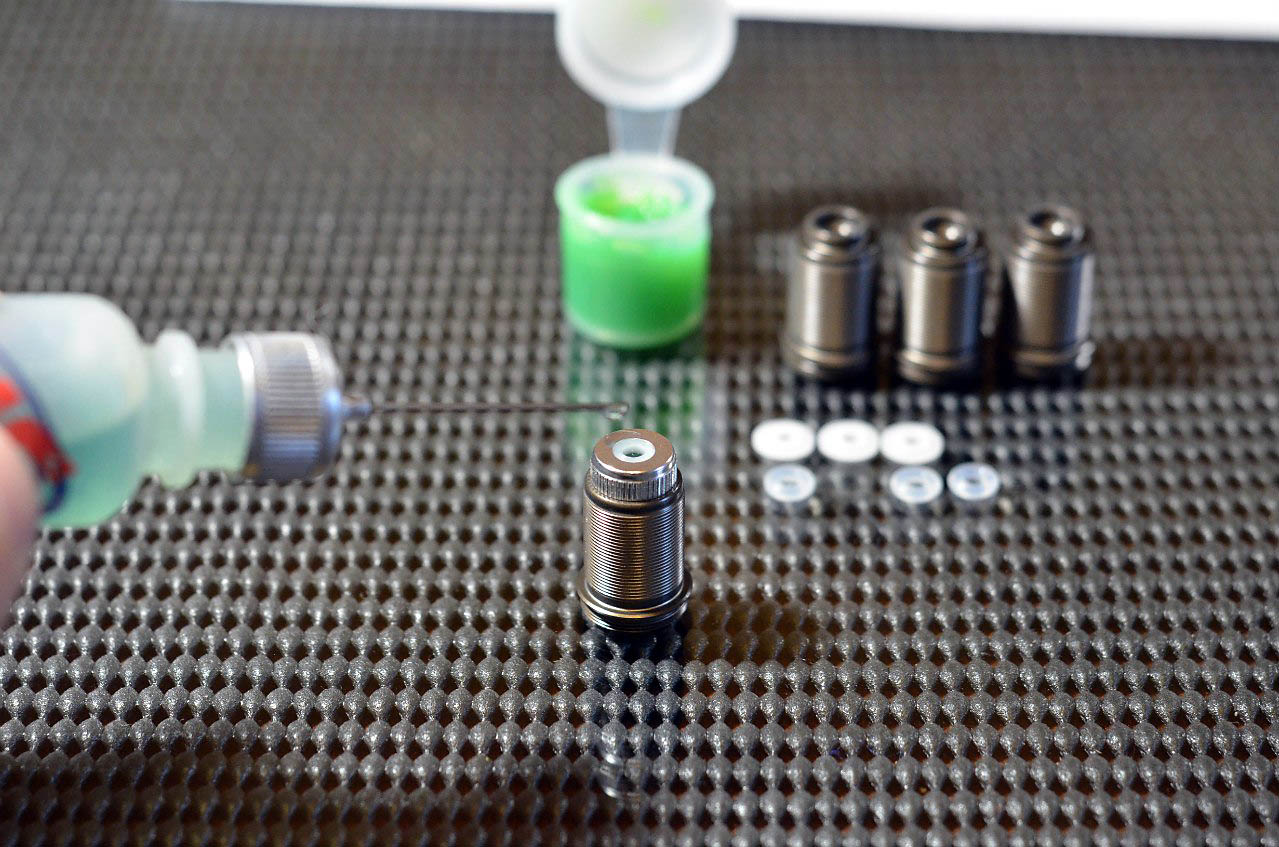

TIP: To reach close to zero initial drag between oil seal and shock shaft lube o-ring with grease and then place one drop of super thin bearing oil into assembled shock. You can use any grease - key is bearing oil. You will be surprised how smooth the shaft will move.

Be attentive - front and rear rod ends have different length. Longer one is on the rear shocks.

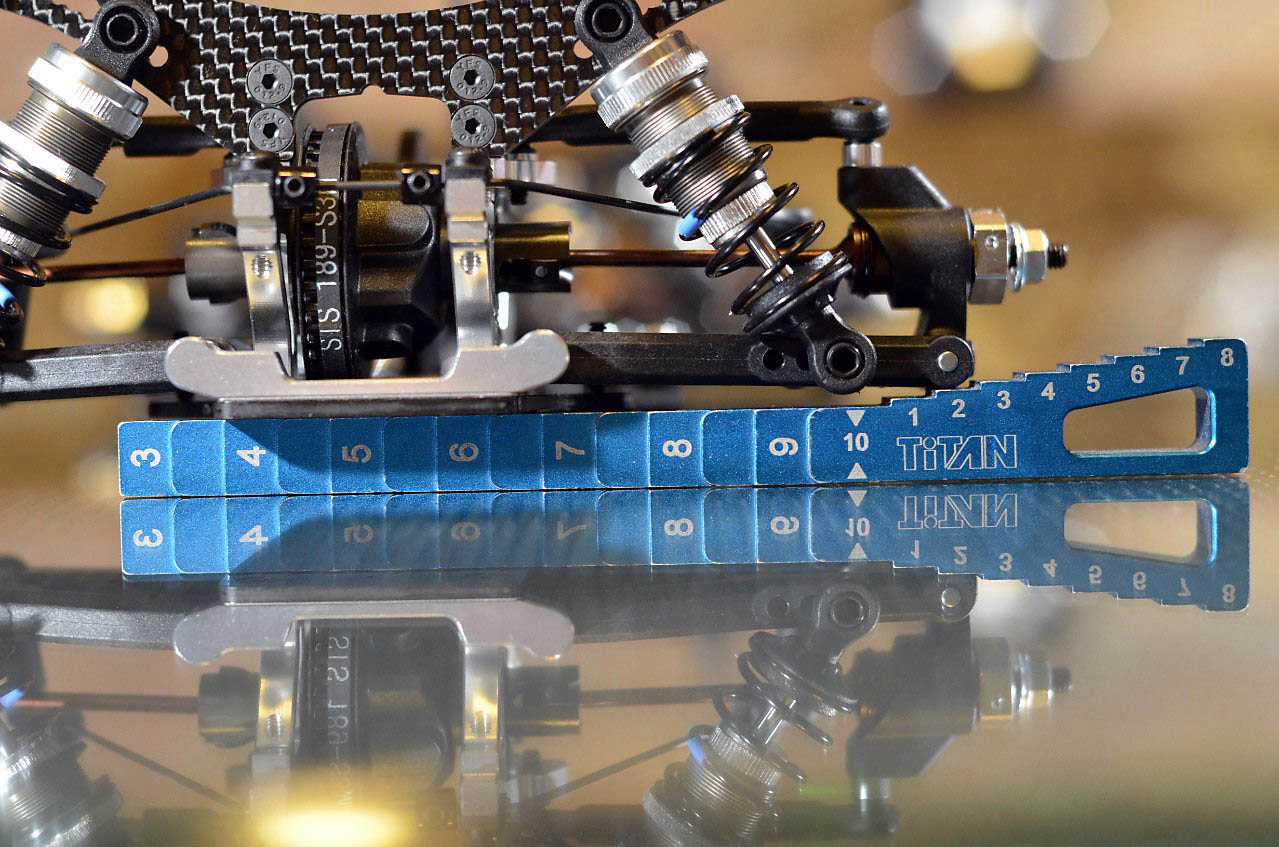

TIP: For easier tuning of ride high I mark spring preload rings with permanent pen.

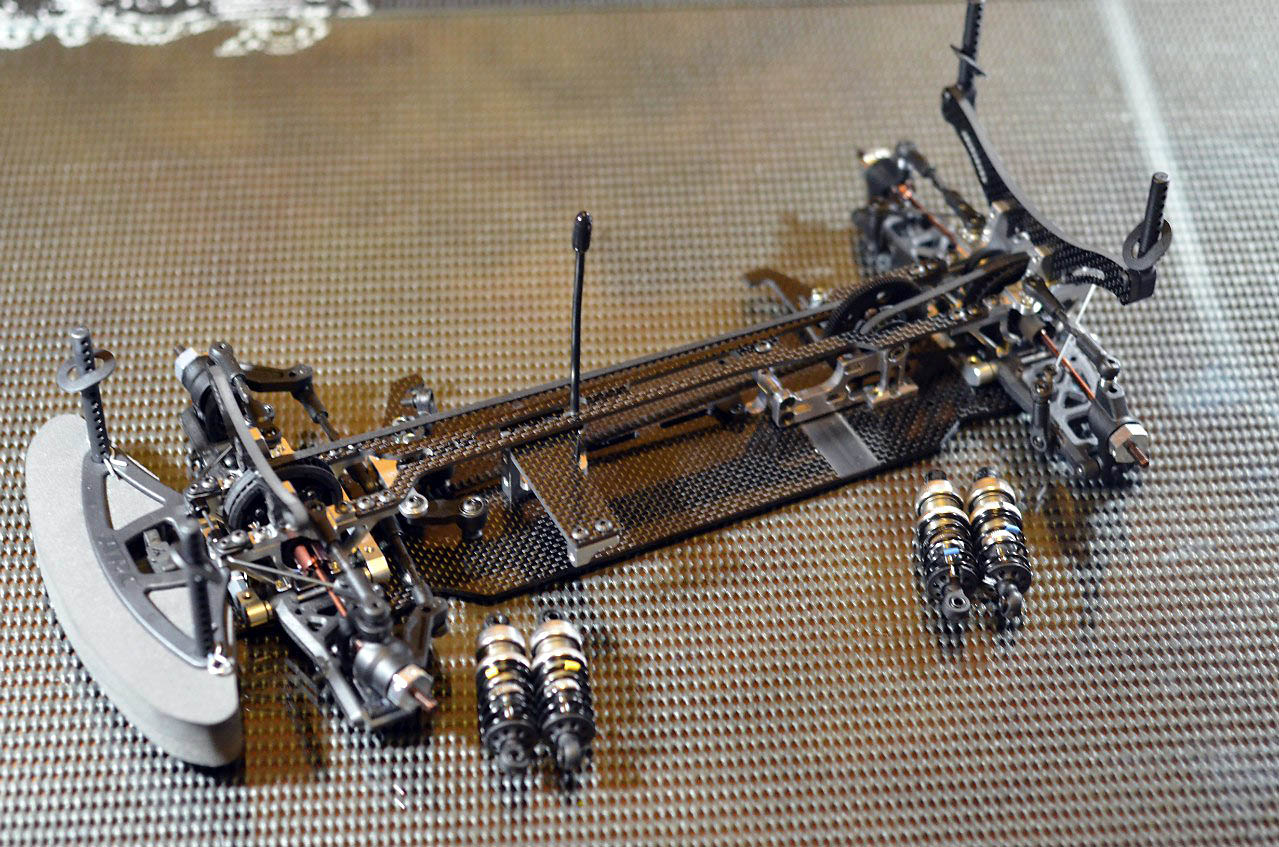

Assembled shocks with springs.

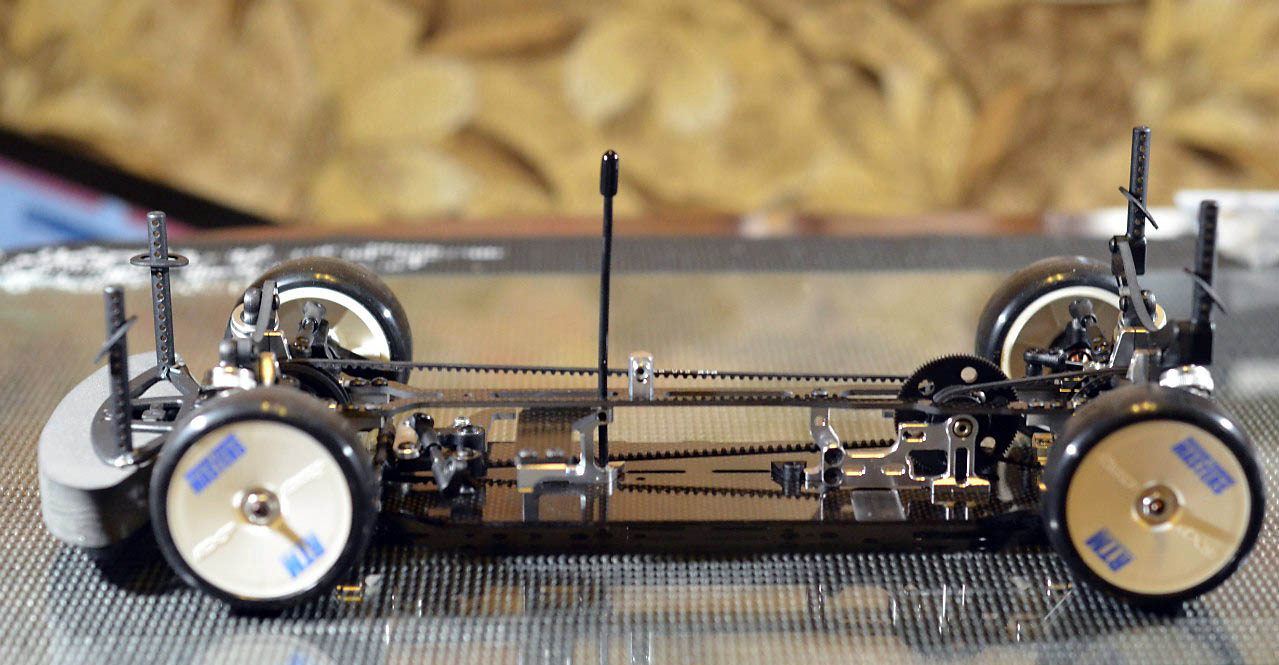

That's what I was talking about previously. Roll center shim under pivot block is 0.5mm. Even with it you still can adjust droop down to 2mm! Just imagine, what value can be reached with 1mm shims. No doubt - it's overkill, but this is a good illustration of overall length of the shocks and tuning potential.

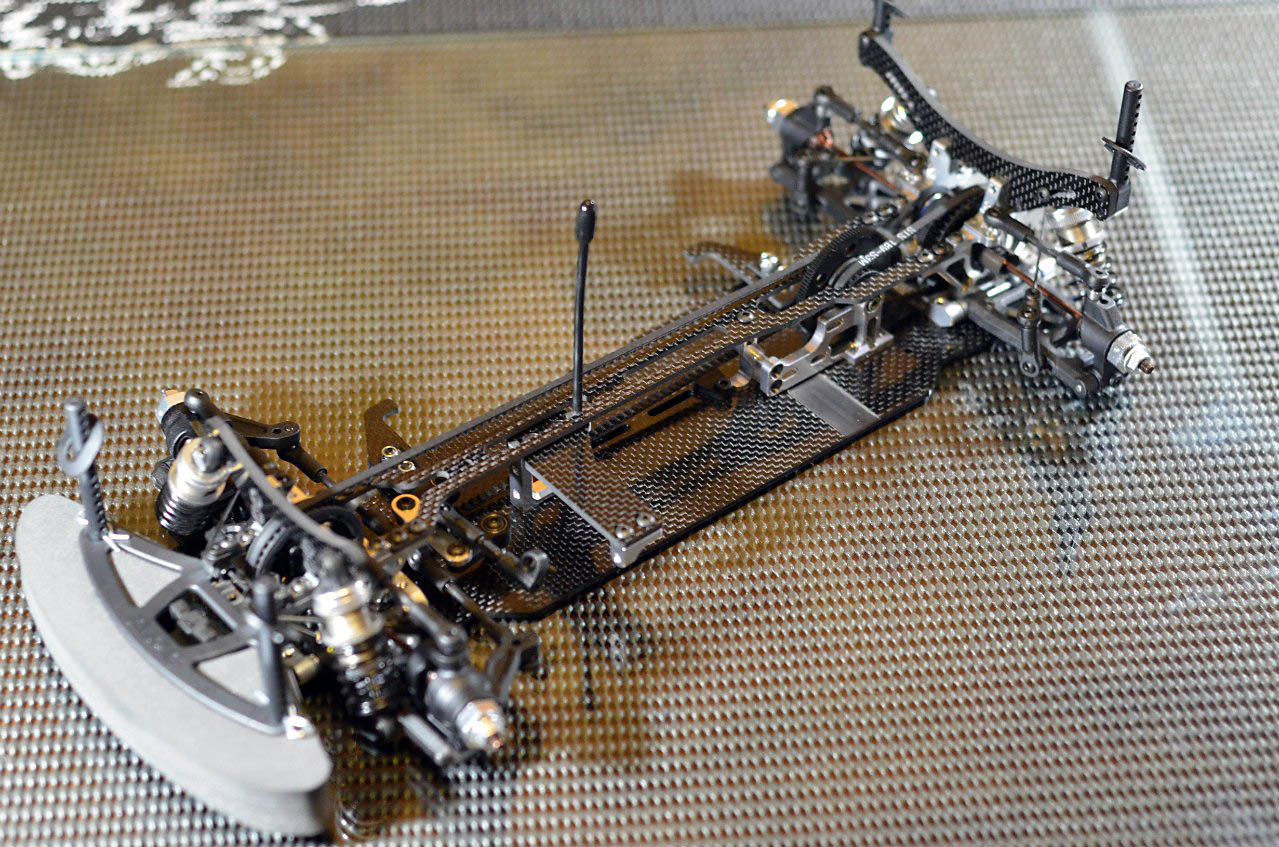

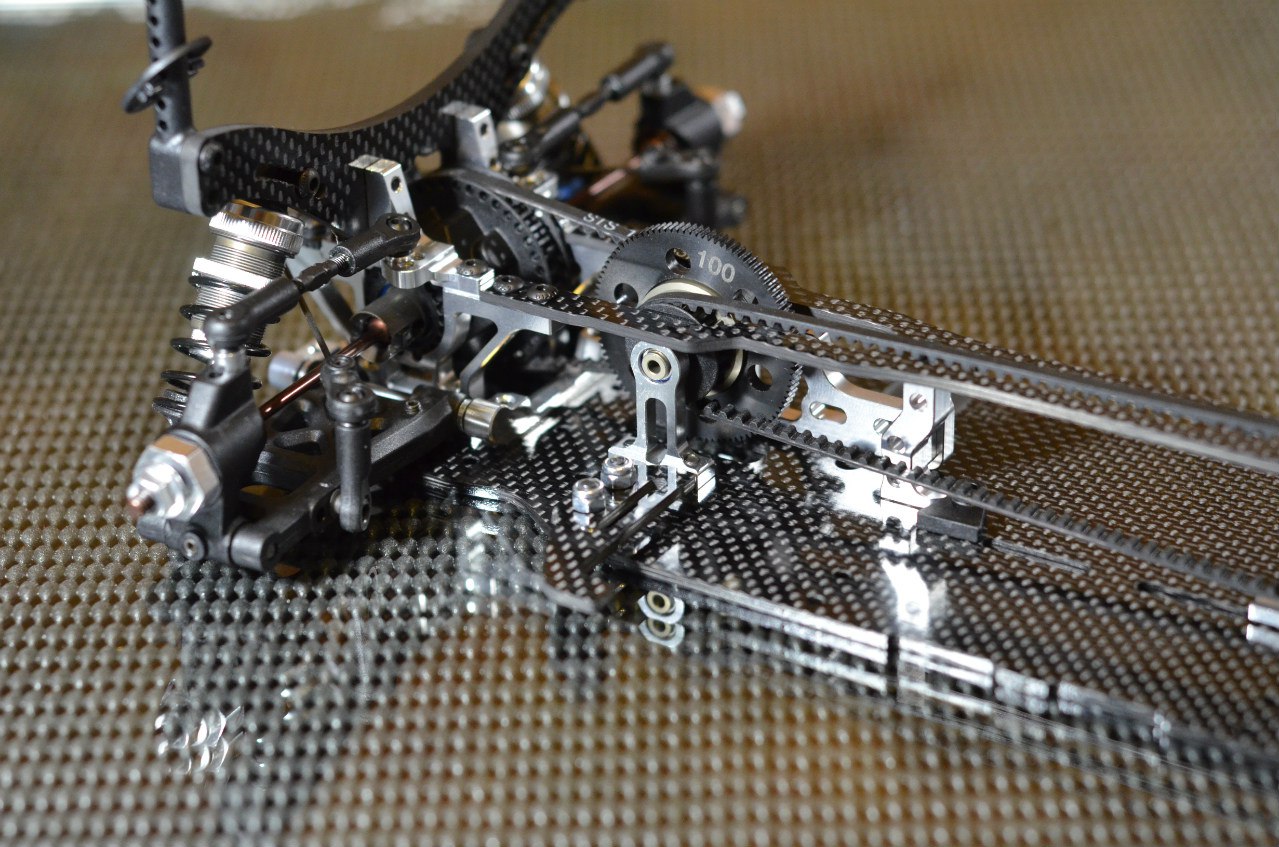

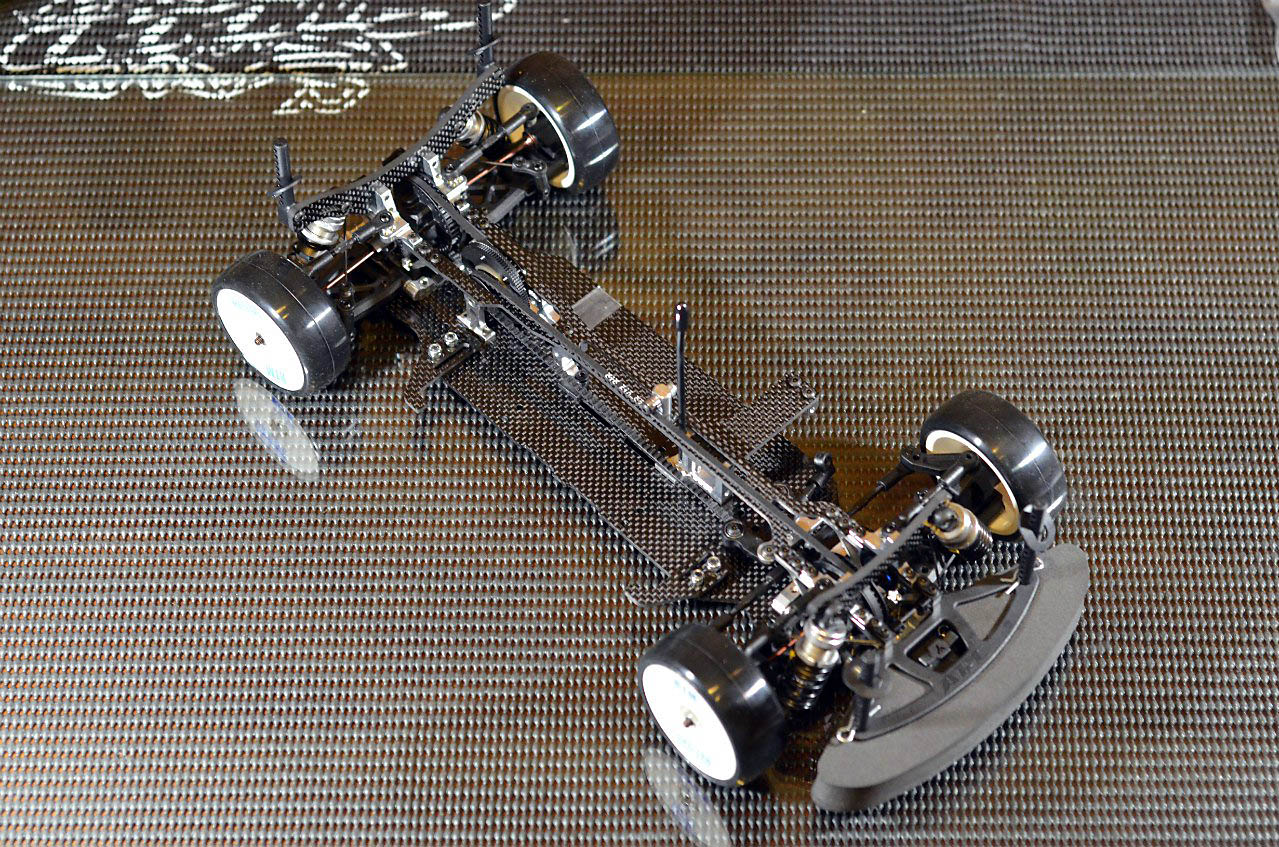

All details on their places.

Battery stop and belt tensioner. Nothing special. Battery position can be adjusted front or rear for some millimeters.

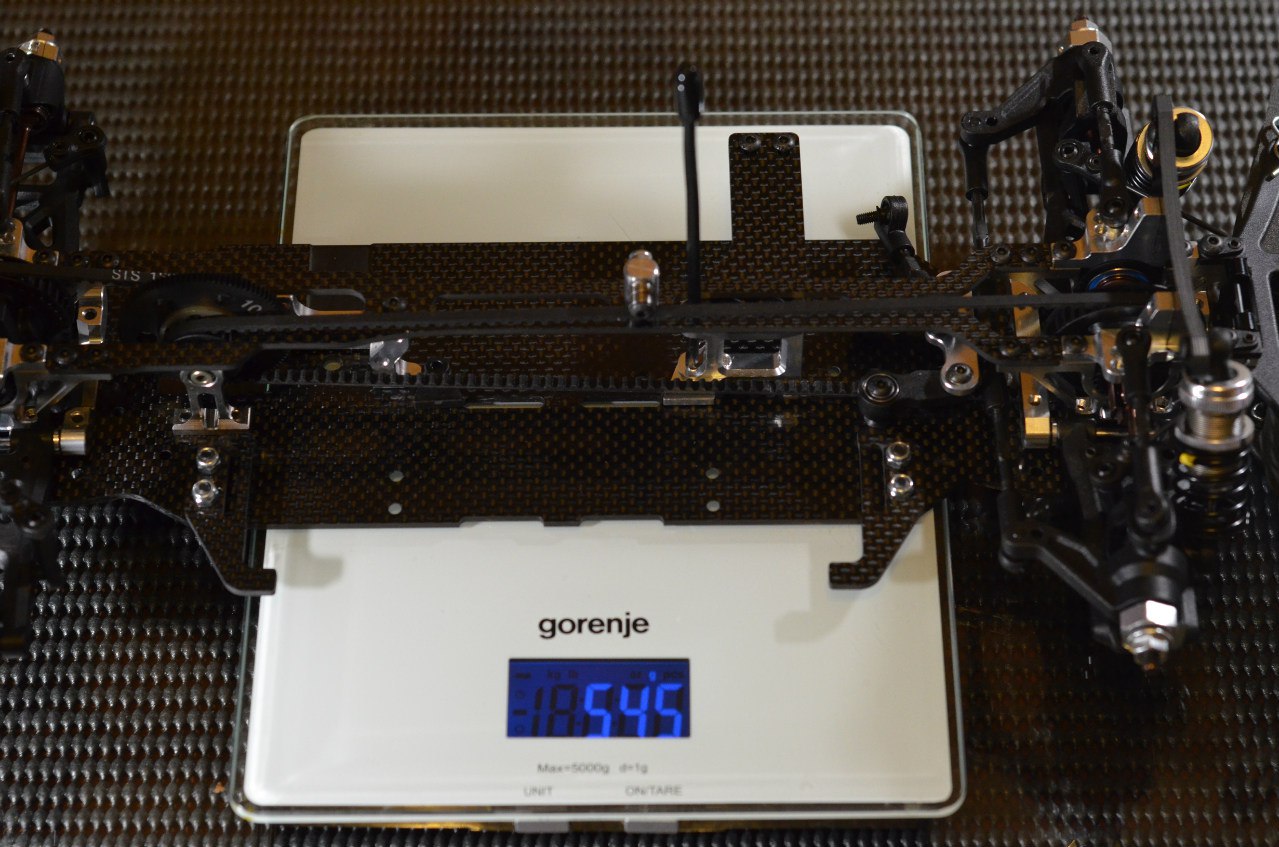

Total weight of assembled chassis. All parts from the box, except: 0.5mm roll center shims vs. 1mm.

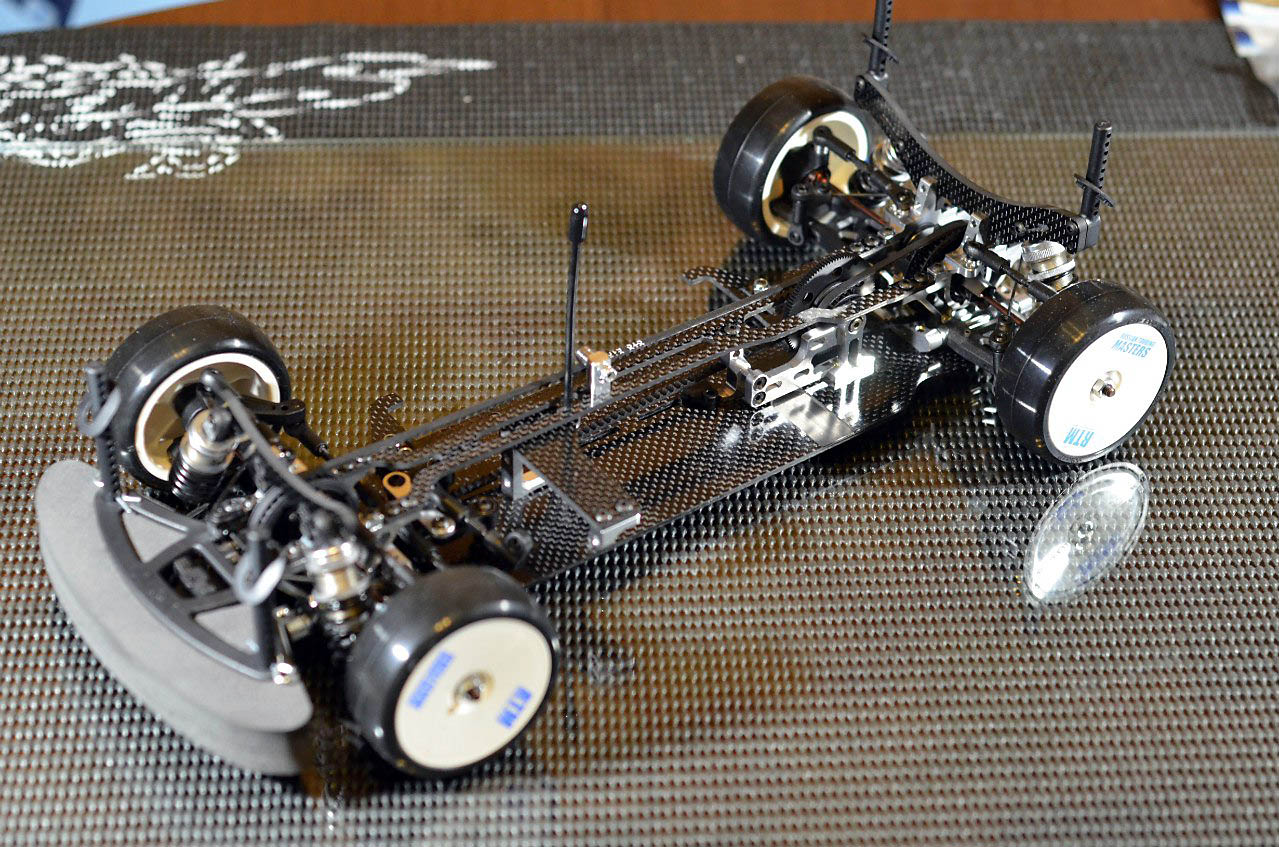

Finished chassis on the wheels.

You can ask me, how plastic strength is compared to other cars. I see only one brand, which produce this kind of plastic, that is very strong and still have possibility to bend without breaking. Just look at the next photo and make your own decision.

And this plastic used for all parts, not only for arms.

TEST

So, building is done and now time for testing and making some conclusions.

Track is medium size (30x14m) indoor circuit with low grip carpet. Mostly, I run 13.5t blinky against other top club driver's. I test many of BLITZ bodies (GSF, WRX, TSX) and stops with LSF as a most consistent and with good initial steering.

I quickly switch to different setup in case of the specifics of my local track. Blue springs and 1.2mm anti-roll bars both sides, lower roll center, thinner oil in shocks. It's common idea for any chassis on our track to get fast cornering and stable rear end. What I first noted, how precisely the car was steering and fast in corners. The test was in race conditions on one of the stages of club Cup. After qualifying I was as close to top drivers as never before - I shave about 0.5 sec from my best time without changing best/average gap. Third after Finals, that's good for me. Very predictable, consistent and fast.

OVERALL

My assumption about car, that I said in the beginning of the article, was fully confirmed. ARC R10 2015 ATS is solid, good engineered chassis, that can race on one level with Top Brands latest models. Quality of plastic (molding accuracy and strength), CNC machining - flawless. Assembling process is easy and straightforward. Suspension parts have zero play, but still extremely free move. Buttery smooth shocks. Plastic hold hard crashes without breaks and appearance of additional play.

I want to make a point of CNC machined spur gear, double joint front drive shafts, CNC machined shock parts, belt tensioner and ATS option (basically, second rear end), that you get straight from the box. Not many of top brands have such rich equipment of their kits.

Here are Pro's and cons:

Pro's

- Strong, reliable race chassis

- Smooth and free of play suspension

- Free drive train

- Amazing fit and finish of all parts

- Many option parts included in the kit with spare screws and plastic

Cons

- Manual have some mistakes and misprints, but it doesn’t affect the construction

- Too big gap between piston and shock body

- All fasteners are steel and heavy. Many of them can be aluminum without sacrificing overall strength. But from the box car is truly bulletproof.

The ARC R10 2015 is amazing chassis, that can compete on top level with any modern top brands models. Doesn't matter if you are on club race or in National Championship. I'm waiting for summer to try R10 on asphalt - it's homeland.

Page 5

|