|

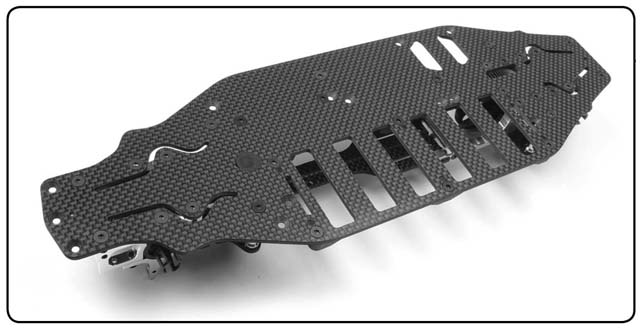

Quality assurance:

XRAY graphite parts are manufactured in-house on highly-accurate

German CNC-operated machinery using special production tools which

ensure that all correlative holes are drilled within the highest

tolerance and in the proper locations. Every T2 chassis is inspected

and controlled during production on a special checking tool that

ensures that all holes are manufactured correctly and in line. As

such, all holes on the chassis are perfectly straight and in line

with bulkheads. Additionally, flatness of each chassis is controlled

and inspected after the bulkheads are assembled to the chassis. With

the specific production process and several control and inspection

procedures being used, all chassis are correctly manufactured,

flatness is well within RC industry tolerance standards, and

bulkheads are mounted tweak-free.

Tweak inspection:

The chassis features the Multi-Flex Technology cut-outs which make

the chassis more flexible and thus more demanding for precise

installation of bulkheads to the chassis as well as to the top deck.

It is important to note that the screws have certain manufacturing

tolerances and the heads of screws may be slightly eccentric and

therefore after the bulkhead is assembled to the chassis may have

some tension in certain parts; however, this tension is very minor

and will not cause any tweak. If some excessive tweak is present,

check if some screw heads are significantly out-of-center, and

replace the screws as required.

Using XRAY

Products only:

For best performance, we strongly recommend using only unmodified

Authentic XRAY Products to avoid tweak, as all XRAY parts share the

same high production tolerances and are created to work together.

Non-countersunk

top deck:

The T2 platform is very different than previous T1 platforms, and a

non-countersunk top deck was determined to be the best and most

logical choice to achieve the intended results and performance. We

suggest not to modify the top deck. Also, use of an aftermarket

countersunk top deck may introduce undesired effects, including

tweak.

The non-countersunk top deck - after correct installation to the

bulkheads and after correct screw tightening - insures that the

chassis is tweak-free and provides the desired optimum flexibility.

REMOVING TWEAK

AFTER A CRASH

If you crash and your car becomes tweaked, follow this handy tip how

to remove the tweak:

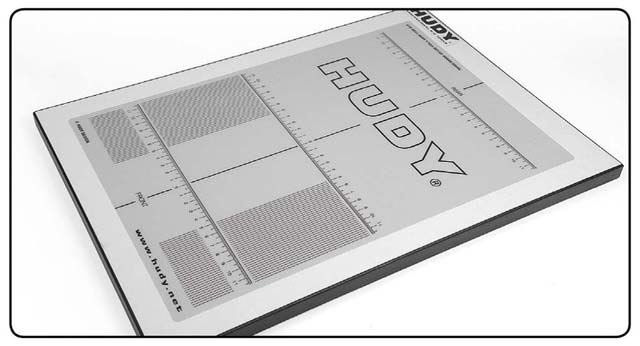

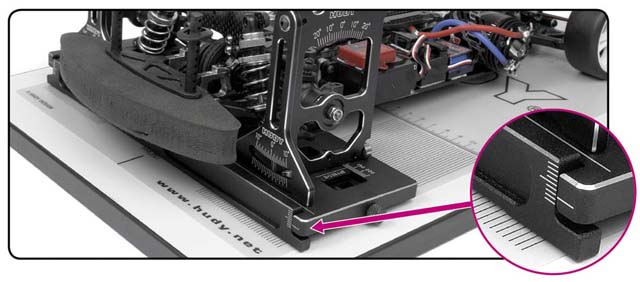

1. Use the

HUDY set-up board, which is ultimately flat and is a “must have”

basic environment for car setup. Checking for tweak on another

non-HUDY board may result that tweak will be checked on an uneven

surface which may show that the car is tweaked even if it is not.

Experience has shown that some other aftermarket boards (for

example, those made from Plexiglas or aluminum) are not flat and

checking the car on these boards may show a tweaked car even if it

is not tweaked. Therefore it is suggested to use only the

ultimately flat HUDY set-up board #108201.

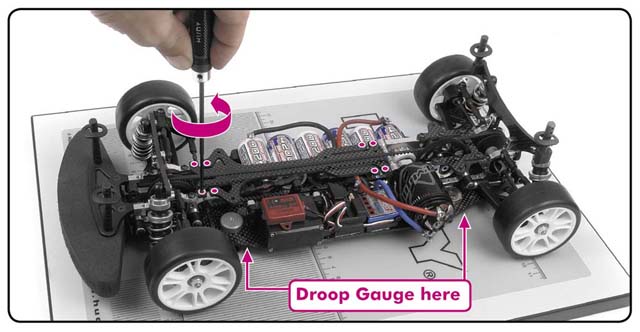

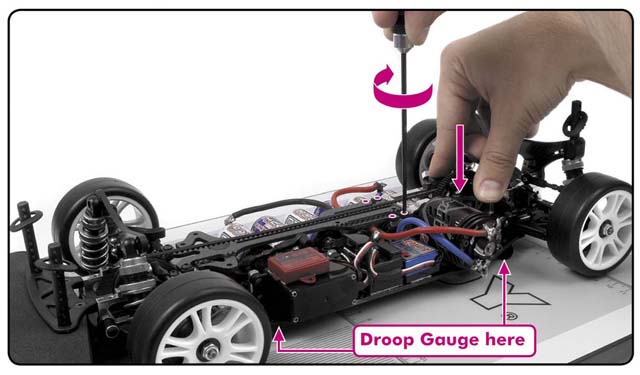

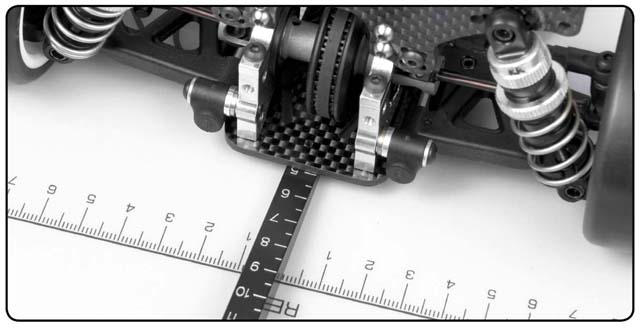

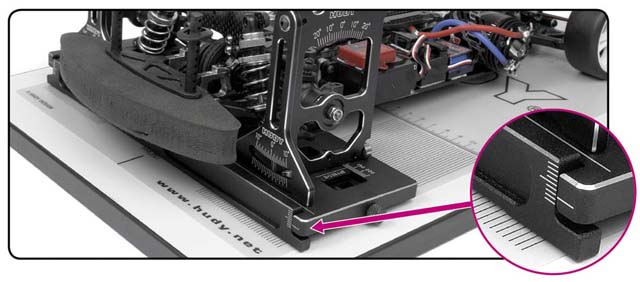

2. Place the

T2 on the Hudy Droop Gauges (#107702) in the place where front and

rear bulkheads are. Verify that your droop gauges are clean and

smooth. If any debris (CA glue, etc) is on the gauges, this may

result in uneven results.

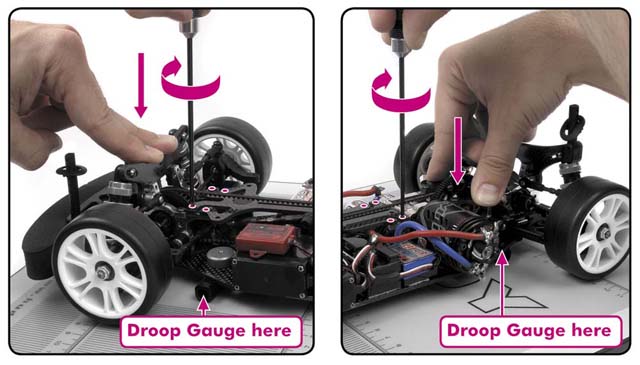

3. Release

the screws of the top deck. The released tension will allow the

chassis and top deck to return to their normal standard flat

position.

4. Retighten

the screws only slightly, not fully.

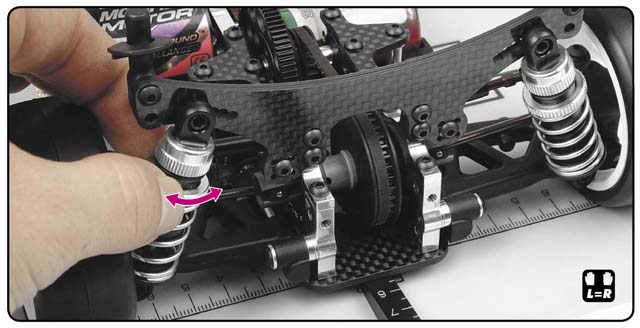

5. To tighten the screws slightly, start with the screws at

the front v of the top deck. When tightening the screws in the

front of the top deck, push on the chassis through the front shock

tower. Tighten the screws lightly.

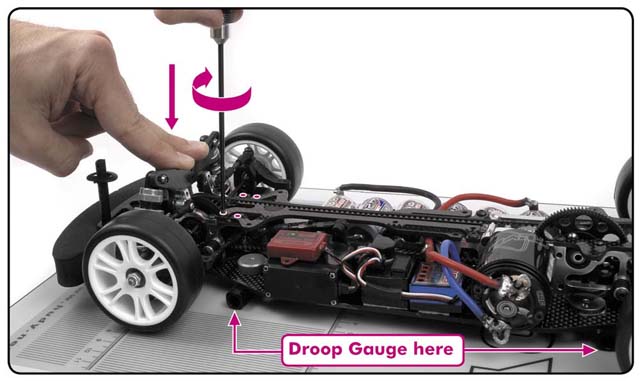

6. When

tightening the screws in the rear, push on the top of the rear

bulkheads so you push the car against the droop gauges.

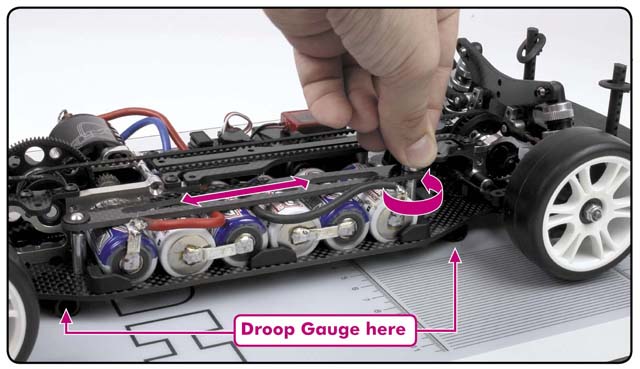

7. If the

chassis is flat and lays flatly on the droop gauges, then it is

correct. Now tighten all screws fully. Again follow the same

proccedure.

When tightening the screws fully in the front of the top deck,

push on the chassis through the front shock tower.

When tightening the screws fully in the rear, push on the top of

the rear bulkheads so you push the car against the droop gauges.

If the chassis is not

flat then repeat this procedure again.

REMOVING TWEAK

FROM OTHER SOURCES

After you set the

chassis flat on the droop gauges but it still seems tweaked use the

HUDY Tweak Station which will instantly discover any tweak. If you

have the chassis flat on the droop gauges then the tweak comes from

some other source. There are other factors which can influence and

create tweak.

TIP: To fully understand the theory, how to identify and how

to adjust the Tweak using HUDY Tweak Station, read the XRAY T2

Set-up Book pages 20~23.

Here are typical factors that can create tweak:

SHOCK ABSORBERS

The most important factor for a tweak-free car is to have left

with right shocks set up perfectly equal with springs. Both pairs

of shocks must have:

• same rebound

• same compression of springs

• same oil viscosity

• same amount of holes open

• same shock mounting position on arm and shock tower

TIP: To fully understand the theory about shocks, read the

XRAY T2 Set-up Book pages 30~32.

BATTERY ASSEMBLY

TWEAK

Problem: The batteries are overtightened and are

deforming the chassis.

Solution: If you use the optional Graphite Battery Strap

release the locking wheel slightly, so the battery strap sits

freely and can slightly move.

If you use the tape, reinstall it again.

Problem: There is insufficient play between the batteries

and battery strap (when used as an optional part).

Solution: In this case, file the battery slots to allow

more play of the batteries when placed on the chassis.

TWEAKED

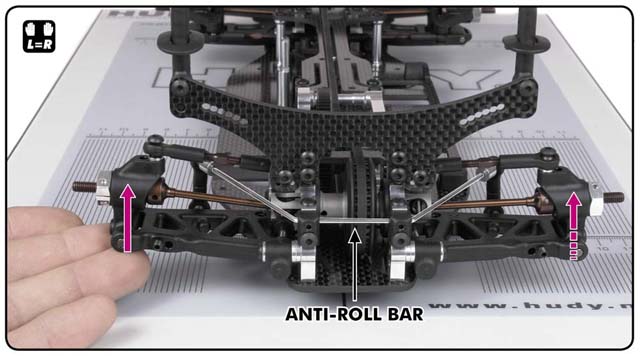

ANTI-ROLL BAR

Problem: Your front and/or rear anti-roll bars are tweaked

(when used as an optional part). To check if an anti-roll bar is

tweaked, first remove the wheels, and then put the car on the flat

setup board so the suspension is not in contact with the board (you

may have to use downstop blocks). Slowly lift the left suspension

and note how high you have to lift it before the right suspension

starts to lift. Repeat this for the right side. If the left and

right suspensions do not start to lift at the same height, the

anti-roll bar is tweaked.

Solution: Change the length of one or both anti-roll bar

linkages. The side that reacts the slowest (that is, the side that

has to be raised the most before the other side comes up) needs a

longer linkage, or the other side needs a shorter linkage.

TIP: To fully understand the theory and how to adjust the

Tweak through anti-roll b ars, read the XRAY T2 Set-up Book page 23.

UNEVEN DOWNSTOPS

Problem: Your left and right downstops are not equal. This

makes the car handle like it is tweaked and the HUDY Tweak Station

will evaluate this unevenness as tweak.

Solution: Set the downstops on both left and right side

equally in front and/or rear through the downstop screws. Typical

downstop setting is 5 or 6. For measuring and adjusting the

downstops use the HUDY Droop Gauge #107712.

TIP: To fully understand the theory and how to adjust the

Droop, read the XRAY T2 Set-up Book pages 10~11.

ADJUSTING TWEAK

USING SPRING PRELOAD

Problem: Incorrectly adjusted springs can result in one

side of the car being firmer or higher than the other, causing

difference when turning left or right.

Solution: Adjusting tweak using spring preload should be

done only after all other items have been checked and corrected.

!!! Adjusting tweak using spring preload is an advanced

set-up procedure and therefore it is strongly suggested that you

read and fully understand the details on this set-up procedure in

the XRAY T2 Set-up Book on page 22.

UNEQUAL RIDE

HEIGHT

Problem: Unequally adjusted ride height may result in a

tweaked car. To check your current setting of the ride height use

the HUDY Ride Height Tool #107715.

Solution: Adjust the ride height through shock preloads so

it is equal on left and right side under the chassis.

TIP: To fully understand the theory and how to adjust the

Ride Height, read the XRAY T2 Set-up Book pages 8~9.

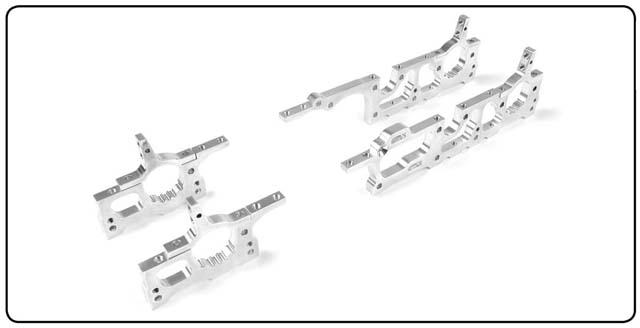

BENT BULKHEADS

Problem: In the event of a very serious crash the bulkheads

may bend slightly and this may result in tweak.

Solution: Replace any bulkheads which seem to be bent.

TIP: CHASSIS

SCREW TIGHTENING

When tightening screws from the bottom of the chassis, initially

you should only tighten them slightly. Afterwards, tighten all

screws fully.

UN-TWEAKED CAR

After you set the chassis flat on the droop gauges and check for

the other sources of tweak and remove any present tweak, your car

should be perfectly tweak-free. To verify your tweak-free car, use

a Tweak Station.

Check for tweak after each run.

Source:

|