| |

Article ID: 472 |

Pit Pass » Archives

|

[Pit Pass] Revo Performance Set-Up Guide (part 2) |

|

Revo Performance

Set-Up Guide

Steering System & Chassis Attachments |

Welcome

to the second installment of my Revo performance guide. This time, it's

about chassis set-up. I'm going to show you the little tricks that I do

to my Revos involving chassis attachments and radio boxes for better

weight transfer and ease of use. You'll also find simple mods to

greatly improve steering performance and chassis balance.

It's important to remember that paying attention to every little detail on your Revo

Important:

Some of the following procedures require the use of a rotary power tool

for cutting and grinding. Always wear eye protection when using a

rotary power tool.

Steering Mods

Trimming specific areas to attain "full-lock" steering

1. Remove the steering bump stops

This

is a very important step in achieving maximum steering angle from the

wheels. There are two molded bump-stops designed into the Revo lower

hinge pin retainer (part #5343) that straddles the steering

bellcrank. These bump stops limit the travel of the bellcrank, which

was intended to keep newer drivers from over-steering the truck.

With the bump stops ground down (shown above),

and the bellcrank arm beveled (shown below), the steering angle of the

wheels is significantly increased for more overall steering.

2. Bevel the bellcrank

Once

the steering stops are ground down on the hinge pin retainer, the

bellcrank can now travel to the body of the retainer. But, even more

range can be gained by beveling the edges of the bellcrank that touch

the retainer (see photo).

| |

| Left - Grinding the edges indicated in the photo can easily be accomplished with a Dremel™ tool. Right - This photo shows how the bellcrank and the hinge pin retainer meet after the mod. |

3. Make room for the steering arm

After

substantially increasing the range of the steering bellcrank, the part

of the arm that connects to the servo will now interfere with the

outside of the hinge pin retainer, where it mounts to the bulkhead (See

photo). Remove material, as needed, to get full range from the

bellcrank (left to right). You shouldn't need to remove any more

material than what is shown in the photo.

4. Eliminate the interference between the rod ends and the bulkhead

When

the suspension is fully extended, the inner rod ends on the steering

links may rub against the bulkhead halves in the areas indicated below.

This can slow steering response and limit range when under

acceleration. Be careful not to over-grind this area because this is

where the two rear suspension pins are captured for the front

suspension arms. Use the photos as a guide.

5. Remove the pivot ball dust boots

This

is very minor, and normally doesn't need to be done. But, if you've

completed all of the steps above correctly, then chances are the boots

are now keeping the hub carriers from bottoming out against the ball

shafts.

To get maximum angle from the hub

carriers, the boots must be removed. Make sure to check the pivot balls

and hub carriers regularly for dirt or binding. There should be no

problems with the operation of the pivot balls when routine maintenance

is performed.

6. Install a longer steering arm

After

all of the above modifications are performed, the steering system will

allow an extra-long servo arm to be mounted onto the steering servo.

The longer servo arm will provide the extra range needed.

I

recommend the use of a heavy-duty servo arm. Check with your local

hobby shop or your radio manufacturer for what's recommended for your

particular servo.

7. Traxxas heavy-duty servo saver spring (part #5344x) / Pro-Line™ aluminum steering arm

I

use the heavy-duty servo saver spring in all of my Revos. The HD spring

provides more steering authority and keeps up with the higher demands

of track surfaces that offer extreme traction. It's also best if the HD

spring is used with a strong high-quality servo. The stronger spring

may not give enough for weaker servos. This may lead to servo failure. |

| |

| You

can also check out the Pro-Line #6037-00 aluminum steering arm for the

Revo (right). I haven't actually broken the stock steering arm, but

this Pro-Line aluminum steering arm will ensure that nothing like that

will happen when using the extra-stout servo saver spring and a

high-powered steering servo. |

8. Upgrade the steering servo

| The

twin stock servo set-up is great for bashing and novice-level racing,

but when facing the demands of competitive off-road racing, a

high-powered/high-speed servo is what you'll need to transition from

left to right-hand corners quickly. I use the Hitec HSC-5997TG servo. |

I

recommend using a servo with at least 110oz. of torque, so only one

servo can be used. This will save a little bit of weight and will leave

you the choice of mounting the servo on the left or the right-hand side

of the chassis.

I place my steering servo on the left side

(drivers side). This helps balance the chassis after removing the

EZ-Start electric starting system from the engine.

Weight balance

Removing

weight is common for making a more responsive race truck. Sometimes,

removing too much weight can cause the truck to be unstable. I've found

that 7.5 to 8.0 pounds is a great range for the Revo. This weight range

offers a good balance between response and stability.

Most

everyone knows that removing unnecessary items such as the starting

system, and the reverse components will knock off the ounces. However,

when you get down to less than eight pounds, you may try moving some of

the weight around to different areas of the truck. This will change the

feel of the truck, and better suit your driving style or track

conditions.

I measure the front to rear weight bias on all of my race vehicles. So much can be gained from correct balance.

Removing weight from specific areas

There

are different ways to achieve desired results. There are many items

that can be removed or swapped with lighter versions of the same item.

You may choose to replace steel components with aluminum counterparts,

like the pivot ball (#4933X) in this photo. It's a good way to shed

some weight in a specific area. For example, if you want to reduce the

weight at the rear of the chassis, but not at the front, you can

replace just the rear pivot balls with a set of aluminum pivot balls.

This also works for items like toe links and push rods.

Strategic weight placement

Sometimes

you need to get just a little bit more out of your chassis. Adding

weight to specific areas can help. This photo shows where I mounted two

ounces. of lead (tire weight tabs) to the front skid plate. This helped

with steering and improved handling when using engines that generated a

lot of torque. This also helped keep the chassis flat off of high-speed

jumps.

Weigh your truck

Keeping

track of your truck's weight will give you a good idea of what needs to

be done to get your chassis where it needs to be. The scale set (below)

is an elaborate one and not totally necessary to get the information

you need. Multiple digital scales like these can be pretty pricey. All

you really need is one scale.

When only using one

scale, place the scale under one corner at a time, while the other

three wheels are propped up by a solid object of the same height as the

scale. This way you can measure one corner at a time, and then total up

your readings.

A

good starting point for weight bias (front to rear) is 47%-front bias,

and 53%-rear bias. My truck in the picture totals out at just over

eight pounds, with a front weight bias of 47.8%, and rear bias of

52.2%. The more you increase the front bias number, the more steering

you will find.

Calculating weight bias (front to rear)

(total of both front corners) = total front weight (F)

(total of both rear corners) = total rear weight (R)

(F) + (R) = total truck weight (T)

(T) = 100%

(F) = n (front weight bias)

cross multiply (T)n = (F)100

n = (F)100/(T)

Now, let's do this using a sample scenario with actual numbers from an 8 pound truck:

weight of front = 61oz.

weight of rear = 68oz.

61 + 68 = 129oz. total weight

129 = 100%

61 = n

cross multiply 129n = 6100

n = 6100/129

n = 47.29% (front weight bias)

Once

you start recording changes to your truck's weight bias, you can use

those results as reference for when you decide to make a change in

set-up, or install aftermarket components onto your truck. You can see

what affect the changes made to your bias, and better understand why

your truck may have felt different on the track.

Radio installation and RX box mods

Here are few things you can do to better secure your radio boxes and to make working with them a little easier.

Zip tie radio the box hinges

I

made hinges for my lower and upper covers for my receiver box. This

allows the covers to be opened to access the receiver, battery, switch,

and etc. without having to separate them from the box.

They

also secure their respective ends to the radio box, so you don't have

to worry about the covers popping off from a hard crash or jump

landing.

RX cover |

|  |

Drill

the holes close to the pivot points of the covers (click on photos for

larger view). Use small zip ties for the hinges and be sure to make the

holes large enough for the ties being used. After drilling the holes,

insert the zip ties through the holes, and cinch them up (not too tight

at first). Make sure the lids close securely, and open all the way to

access equipment.

Extra antenna tube security

Here's

a little trick that I use to keep the antenna tube from loosening and

pulling out. Cut a slot (yellow arrow) right next to the groove that

the tube slides into. Now, drill a small hole (red arrow) to the other

side of the antenna slot about a 1/4-inch down from the top of the tube

entrance.

Insert the tie through the hole and around the tube

slot. After inserting the antenna tube into the slot, cinch down on the

zip tie. This will tighten the slot around the tube, making it much

more difficult for the tube to come out.

Extreme radio box mods

Left

- Here is an example of removing all excess material from the throttle

servo box. This is pretty extreme, but it does clean things up a little

bit, and makes getting to the throttle servo and linkage much easier. Below - This is an extreme modification to the RX box. All but the battery compartment was trimmed off to reduce weight and lower CG.

Left

- Here is an example of removing all excess material from the throttle

servo box. This is pretty extreme, but it does clean things up a little

bit, and makes getting to the throttle servo and linkage much easier. Below - This is an extreme modification to the RX box. All but the battery compartment was trimmed off to reduce weight and lower CG.  The receiver is placed inside of the battery compartment area, while the battery was moved up front for more front weight bias. Important:

This photo is to show what can be removed from the box only. It's very

important to cover all areas of the receiver box to prevent moisture

and dirt from entering. This set-up is fine for dry conditions, but I

don't recommend this mod to be run in wet conditions.

The receiver is placed inside of the battery compartment area, while the battery was moved up front for more front weight bias. Important:

This photo is to show what can be removed from the box only. It's very

important to cover all areas of the receiver box to prevent moisture

and dirt from entering. This set-up is fine for dry conditions, but I

don't recommend this mod to be run in wet conditions.

Body mounting

Here's

two of my favorite body styles for the Revo: The Traxxas S-Maxx body

(#5112X), and the Pro-Line Crowd Pleazer body (#3144-00). I'll use

these two bodies to show you a few things that I believe are important

for racing.

|

| Here's

both the S-Maxx (above), and the Crowd Pleazer (below) in action. These

are the two most commonly used body styles on my Revos. I prefer a

"fastback" style not only because I think they look more "racy", but

they also offer extra protection to the engine and exhaust system vs.

standard bed designs. |

|

Windshield cutout

This

one should go without saying, but I can't stress enough how important

it is to provide a good amount of airflow to the cooling head of your

engine. Cut out about a 2-inch hole (round or square) into the

windshield on the same side that the engine is located. It doesn't hurt

to cut a little out of the drivers side window as well, to allow even

more cooling.

Tank cutout

Making

the opening for the filler cap large and easy to use is the most

important part of this mod. A larger opening allows easier access,

which will speed up your pit times and cut down on the chances of a

mistake from your pitman. Make sure the hole is cut high enough to open

the tank lid fully, and so you'll be able to fuel accurately even at

extreme angles.

Roll bar trimming

Many

Revo owners are unaware of what the two little lines are at the bottom

of the roll bar are for. These lines are actually there to show where

to cut when lowering the body. Each mark is an equal distance from one

another, just as each screw pin hole is on the body mounts.

This

means for each mark cut off of the bar, the body can be lowered one

hole to match. This keeps the top of the bar up against the inside of

the cab, where it needs to be. I generally run mine in the stock

position for extra protection against damaging the engine and exhaust

system, but the adjustment is there for those who want to lower CG, or

to just get that slammed look.

Cross-drill rear body mounts

Tired

of losing rear body clips? Cross-drill the body pin holes in the rear

body posts. This will allow you to insert the body clips into the posts

sideways, like the front end. This will help prevent the clips from

popping out during a crash or rollover.

Miscellaneous tricks

Trim the bumpers

| |

| Trim off the sidebars from the bumpers to "clean-up" the appearance and to make caster clips easier to access. |

Tank strap

Attach

an extra-long Zip-tie to the fuel cap on the tank for easier pitting.

The longer strap is much easier to grab quickly for fast pit stops.

Fuel tank cap mod

Cut

off the material indicated by the red line in the photo. Remove

material from both sides of the cap to allow the cap to open further.

Be very careful not to cut into the tank.

Uncut Cut

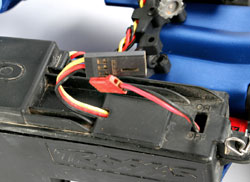

Eliminate the On/Off switch

Switches are vulnerable to dirt and moisture. This can lead to failure from worn out contacts, or from shorting the circuit.

This

failure can't be detected beforehand, so you risk the chance of the

switch failing during a very important race. A failed switch could not

only end your main prematurely, but it can also cause a runaway, which

can be very damaging to your engine and chassis.

Using a servo

extention wire to directly connect the battery to the receiver will

eliminate that from being possible. Just plug-in when you're ready to

race.

Stayed tuned to Traxxas for more information..

Article ID: 472 |

|

| Last update: 2006-01-23 10:31 |