|

Rock crawling

is becoming increasingly popular, and many crawling enthusiasts

build custom creations by using parts from several vehicles or by

making new parts. If ya donít think ya have the skills to build

a custom rig, donít be discouraged. You can start rock crawling

easily, and you donít have to spend a lot of cash to do it. The

budget-build rock crawler featured here is based on a Tamiya

TXT-1. Out of the box, the truck is a pretty good rock crawler,

but you can cheaply make many easy mods that will allow it to

crawl with the best of them. Youíll need a few parts, the basic

tools and time. Letís rip!

|

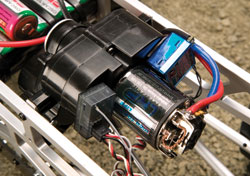

Rock-crawling-specific lathe motors

or truck-specific ones such as this one from LRP

are perfect for the job because they produce tons

of torque. The motor is attached to a Tamiya

gear-reduction unit. Itís from their Monster

Drop truck.

|

Low-turn

motor

For rock

crawling, torque is king, and one way to get that torque

is by using a high-turn motor like the LRP Truck Puller II

I used in my truck. The more turns it has, the stronger

its magnetic field will be, and the truck will have more

power. If you donít want to spend any money, the motor

that comes with the TXT-1 will work for you. But if you

have a few bucks, you can pick up a lathe motor thatís

designed for rock crawling. These suckers have winds in

the 55-turn rangeóway more than any stock motor, and

they arenít too expensive.

|

|

You donít need a lot of J-B Weld

epoxy hereójust enough to coat the gears.

|

Gear

reduction

Another way

to turn this truck into a torque monster is to reduce the

gear ratio as much as you can. You can install a smaller

pinion gear, but that takes you only so far. Your best bet

is to install a gear-reduction unit. This basically adds

to the number of gears in the transmission and reduces the

gear ratio. You can fine-tune it by changing the size of

the pinion gear that drives it and the pinion gear inside

the transmission, depending on which gear reduction you

use. Tamiya produced a dump truck based on the Juggernaut

2, which uses the same transmission as the TXT-1, and it

came with its own gear-reduction unit. You can use this

gear reduction if you canít find another unit like the

two offered by RC4WD. To make that happen, youíll need

these Tamiya parts: nos. 0225092, 9335344, 9415714.

|

|

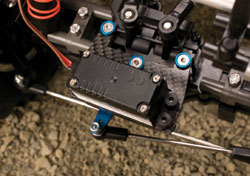

My Blue Bird servoís 150 oz.-in.

of torque is plenty for rock crawling. Donít use

a servo-saver here. You need total control of the

tires at all times.

|

Get a

high-torque servo

Torque is

important for steering, too. Buy a strong, high-torque

servo for the job. Donít install a servo-saver; it will

make the steering spongy, and you need it to be as tight

as possible here. You donít have to worry about

stripping a servo because the truck moves so slowly that

most hits that the servo takes wonít damage it.

|

|

Lock

the diff

Traction is

very important for getting over rocks, and your truckís

stock diff isnít up to the job. The stock diff will

allow the tires with the least traction to spin, and if

this happens, your truck wonít go very far. The front

and rear tires should pull the truck equally at all times,

so you have to lock the front and rear diffs. This is a

simple mod. Remove the diffs from the axles, and clean all

the grease off the gears. Put the gears back in the diff

and coat them with an epoxy to set them in place and lock

the diff. I use J-B Weld because it holds up well to

abuse. Assemble the diff and turn it to coat all the gears

with the epoxy before you set the diff aside to let the

epoxy cure overnight. You donít need much epoxyójust

enough to coat the gears.

|

|

Get rid of the lower front bumpers

and skidplates. Theyíll get hung up on the

rocks. Cut bumper at dotted line and remove

forward section.

|

Ditch

the lower bumpers & skidplates

The lower

front bumper and skidplate do a good job of protecting the

axles but will get hung up on the rocks and limit the

TXT-1ís maneuverability, so weíll have to remove themóbut

not entirely. Youíll need the upper mounts for your

shocks and suspension links. Remove the front and rear

bumpers and skidplates from the axle. Ditch the skidplates,

and cut the front bumpers off at the points where they

just meet the axles. You basically want to save the upper

and lower mounts used for the shocks and lower links.

|

|

Mounting the shocks upside-down

lowers the truck and its CG. Mount them directly

from the axle to the chassis, and use lighter

springs for better articulation.

|

Shock

mods

Remove the

shocks, the shock mounts, the cantilevers and cantilever

links, and set them aside. The shocks are what youíre

after here. Now ditch the shock-shaft spacers and the

springs. Removing the spacers will give the shocks more

travel, and youíll need that for better axle

articulation. The stock springs are way too stiff, so

replace them; softer springs are ideal here. I used a set

of Losi orange springs on my truck. Losi offers springs in

several rates, and they will allow you to fine-tune your

suspension. Now mount your shocks directly on the axle to

eliminate the cantilevers. Thread the pivot ball from the

shock side of the cantilever into your chassis, as shown

in the photos. Youíll mount the shock-shaft side of the

shock here and screw the other end to the upper mount on

the front bumper. You want to mount the shock body as low

as it can go to lower the truckís center of gravity

(CG). Youíll have to cut the chassis to make room for

the shock.

|

|

Swaybars help the TXT to corner but

are worthless on a rock crawler. You can ditch

them.

|

Remove

the swaybars

The

swaybars on the lower links allow you to increase or

decrease the TXT-1ís axle articulation. For rock

crawling, you want maximum axle articulation, so remove

the front and rear bars from the links and toss them.

|

|

A lot of unnecessary material can

be removed from the chassis to lighten it. The

front and rear bumpers, battery tray and some

cross-members can go.

|

Lose

the weight

To trim

fat, I removed the front and rear bumpers. I also removed

the lower front and rear cross-members for axle clearance.

The middle third of the chassis also has two cross-members

that hold the chassis plates together. You can remove both

of them because the transmission does the same job, and

removing the cross-members will give the upper links more

room to move when the suspension is compressed. Remove the

stock battery holder. It weighs a lot, and you wonít

need it because youíll mount the battery pack much lower

on the chassis.

|

|

Stick lead weight to the front rims

to help lower the CG and increase front traction.

Reverse the direction of the tiresí treads for

even more traction.

|

Reverse

tires & weighted wheels

Keeping the

CG as low as it can go is the key to having a crawler that

handles well. An easy way to do this is to stick lead

weights around the front rims. Cut off the plastic support

pieces from the center along the rimís outside diameter.

Clean the rim with motor spray to remove any mold-release

agent or oil from your fingers. Now wrap the stick-on lead

weight around the center of the rim. Some think that for

better traction, you should reverse the direction of the

tire treads when you put them back on the rims. Remember

to glue the tires to the front and rear rims.

|

|

Custom-build a side-by-side pack

that you can mount wherever you want. I mounted my

Orion pack on the inside of the chassis.

|

Side-by-side

battery pack

A truck

like this doesnít have enough room for a typical stick

pack. Build a side-by-side pack to fit a lower mounting

position. People usually mount them on the axles, the

upper links, or the chassis. I went with the chassis. I

used two of the cross-members that I had removed, drilled

the chassis in a new place and mounted the pack on them.

Secure the pack with Velcro or wire ties.

|

|

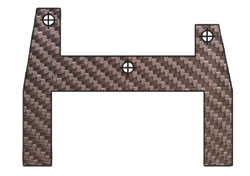

Since you cut the only servo mounts

off the axle, youíll have to make new mounts. A

piece of carbon fiber or aluminum plate will do

the trick.

|

Steering-servo

mount

You removed

the lower front bumpers and skidplates, so thereís

nowhere to mount the steering servo. You can easily make a

mount out of carbon-fiber plate or sheet aluminum. Follow

the template provided to cut your mount out. Cut out the

template, glue it to your material, and follow it to drill

your holes and cut the plate to the correct size. Attach

the servo to its mount using screws and nuts, and youíll

be able to attach the assembly to the top of the axle

using screws to hold the top cover down. Do the same at

the rear. If you only plan to use 2-wheel steering, use

the servo plate as a place to attach the rear links to

lock the rear wheels. Removing the washers from between

the hubs and axles will strengthen the rear lock because

the tabs will pinch the hubs when you tighten the screws,

and they wonít be able to move.

|

|

The full-size servo-mount template.

You can copy it and use it as a template to make

your mount. When youíve finished cutting the

mount out, position your servo on it, mark the

mounting-hole locations, and drill the holes.

|

There

you have it!

Now youíre

armed with everything you need to know to turn your TXT-1

into a rock crawler without spending a lot of money. I

took my TXT-1 to a local rock-crawling comp, and it

actually did pretty well against some high-tech and

high-dollar machines. This is just the beginning. You can

make many other mods to take it to another level, but thatís

another article. As you run your truck, youíll probably

make further tweaks, and before you know it, youíll have

a new truck. Enjoy!

|

Sources

Blue Bird

distributed by BP Hobbies and Nitro House; bphobbies.com;

nitrohouse.com

LRP distributed by Team Associated; RC10.com

Tamiya America Inc. tamiyausa.com

Team Orion Inc. teamorion.com

|

BEFORE

|

|

AFTER

|

|

This modification is easy to

make. Take your time and pay attention to where you drill and cut

because you only have one shot at getting it right. Take a look at

the after photo and youíll see that the lower links are level

and the center of the chassis has been cut.

Increase ground

clearance

Until now, the mods I

describe have been easy. This next mod gives your TXT-1 truck more

ground clearance, and itís more difficult because you have to

cut the chassis, but it greatly improves ground clearance. Remove

the transmission mounting screws so you can move the transmissionís

upper mount to the hole above the stock location. Before you do

that, drill a new hole for the lower mount. Measure the distance

between the centers of the stock top mounting hole and the new top

mounting hole. Use that measurement to find how far the center of

the new lower mounting hole is from the center of the old hole,

and drill an 1ľ8-inch hole there. Modify each chassis plate in

this way. Now draw a straight line on the chassis from front to

back and about 1ľ4 inch below the new lower hole. Use the line

you drew as a guide to cut off the lower part of the chassis.

These modifications are easier to make with the chassis plates

removed from the truck. Having made these mods, put the chassis

plates back together. Mount the lower links in the upper to the

top mount on the axle as shown in the photos. Cut a strip of

carbon fiber or aluminum plate, and attach it to the bottom of the

chassis to give you somewhere to mount the lower links. Swing the

free side of the link up to the chassis while keeping the axle

level. Mark the chassis where the link contacts it, and drill an

1ľ8-inch hole. Do this for all four links. If you want, you can

finish the bottom of the chassis with an aluminum skidplate.

|