|

Particularly

invention-rich, concerning the designation of its chassis, was

Juraj Hudy actually never. And in such a way it also hardly

surprises that the first burning he route car was marked

directly with NT1 (Nitro-Touring-1). However the planning and

development of each chassis become clearly more aufwändiger.

So also those of the NT1, which found world-wide very much

Zuspruch at first attempt and since then on successful courses

steers.

The

first impression is called it, is the crucial, which is

confirmed also with the NT1. Times apart from the attractive

packing there is above all the worths those convinces. Before

with the assembly one begins, it is worthwhile itself to study

with a capuccino the documents printed usually on art paper.

Beside the current catalog, a detailed spare and

Tuningteileliste with exploded view as well as the Setupsheet,

above all the excellent colored assembly instruction and the

Setup Book are to be mentioned. The latter concerns itself in

detail with the meaning and effect of all adjustment

possibilities some route car chassis, in particular the NT1,

to offer has - fantastically.

NO

miracle

In order to take it in front, also Jurai Hudy no miracles know

to achieve or the wheel again to invent. But despite numerous

agreements with other makes the typical XRAY nuances are

unmistakable. The assembly begins, as with most chassis, with

the Differenzialen, in our case two classical Kegeldiffs.

Remarkably here the extremely compact dimensions and the

careful processing of all individual parts are - a fact, which

by the way like a red thread draws itself by the entire

sections. To the component system 80.000er-Öl for the

front Diff and 60.000er for in the back are attached. This

appears in the first moment too much, proves however in

practice as appropriate. The explanation for this are the

small Differenzialzahnräder, which less resistance develops

than with larger Diffs.

The sealing takes place via a

very thin and sensitive O-ring, which should be treated with

appropriate care. Alternatively the gear wheels can be

replaced in front also by a plastic right parallelepiped. Thus

one keeps and without auxiliary costs a Starrachse fast. The

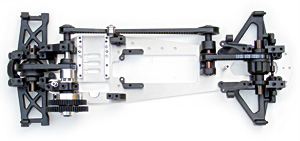

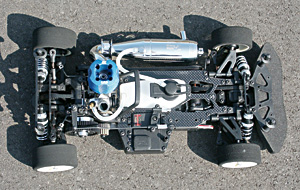

structure of the traditional three-belt drive effected on a 3

millimeter thick chassis from high-quality 7075-T6-Aluminium,

whose chamfered edges and ventilation openings stress the

quality of workmanship underneath the engine additionally. The

structure in principle of front and rear axle corresponds for

years to the unchanged system of all manufacturers whether 1:8

or 1:10. This means pivot ball hanging of the wheel and

steering arms at double wishbones, adjustable Messerstabi in

front and Drahtstabi in the back as well as eccentric

Differenzialaufnahmen for the adjustment of the tension of

belt and carbon fiber absorber bridges. Also the roll center

at both axles can of course be changed owing to different

plastic sleeves. However the NT1 differs in many small details

from the competition.

Components

There only once the choice of materials would be to be called.

Particularly with the plastic the Hudy team accomplished

innumerable tests, in order to find the correct composition.

The result are extremely form-stable and durable Composite

parts with a high glass fiber portion, whose Design and

dimensionings were carefully computed. With the metal parts

either Swiss becomes quality aluminum or, as however with the

drive shafts, wheel axles, the Differenzialausgängen or the

measurer stabilizer, which use notorious Hudy spring steel.

Points can the NT1 also in things operation smoothness. The

consequence from rubber-sealed light run ball bearings, narrow

belt, low-loss plastic gear wheels and the small mass (Differenziale),

are an all-wheel drive running easily from the component

system, which brings each viewer to being astonished. Apropos

small mass: Contrary to all other manufacturers XRAY

practically completely does when the assembling of the gear

wheels without the use of aluminum photographs. With the NT1

the gear wheels are locked simply with a steel pin and fixed

to a C-Klip on the wave.

On the part of the transmission

no way leads past the established two-cheek system for the

moment, which is used also in this case. Worth mentioning are

however again the good processing and fit as well as the

extremely sturdy gear wheels. So far singularly those are much

are enough two-piece engine supports, with which the lower

half with the chassis and the upper are firmly connected with

the engine. Both are united afterwards with two

M3-Inbusschrauben, whereby a steel pin takes over the guide

roller. This system makes simple and fast removement and

replacement possible of the engine, without having to concern

itself each mark with the adjustment of the pinion play.

During exact view it is noticeable that for this also no long

holes are present. Now, with the NT1 the distances between

pinions and gear wheels are practically always equivalent,

independently of which reduction is selected. This is reached

by different tooth profiles and so can, by the existing play

when assembly assembling of the engine, the fine tuning be

only settled.

Absolute

new fact

Which with electrical RC Cars since long time a topic is, so

far hardly attention found with verb racers. The speech is

from the Flex, thus the twisting ability of a chassis. Jurai

Hudy could be here completely inspired from the success model

T2 ´007 and the Flex principle to the NT1 to transfer. The

standard chassis has relatively much Flex. By means of an

optional mono engine support with additional attachment bars

the chassis in a first stage can be reinforced. Four small

carbon fiber props, two to the rear Bulkheads and two the

further direction the Empfängerakku lead, make a further

reinforcement possible of the chassis unit. Thus one achieves

a completely new set UP method for accurate adjustment to the

distance characteristic.

To the

2-Millimeter-CFK-Radioplatte are as usual installed the

RC-components and the tank. The latter convinces by the

perfect processing and the large high-speed tank lid.

Depending upon assigned Empfängerakku, the height of the

tank positioned over it can be varied and the emphasis

additionally be optimized. Since we of emphasis to speak

should one also mention that the entire radio plate is below

installed already 8 to 10 millimeters than with most

comparable competition models.

Thus an accordingly low

situation of the Servos, which find steady stop by means of

the extensive adapters, results all the same which make it

concerns. To the scope of supply belong likewise an aluminum

Resorohr owner inclusive spring steel wire, different servo

horns for steering element and gas/brake as well as all

necessary small articles to the production of practical

controls. For a vehicle of this class rather unusually, but

quite meaningfully, the standard box is for the admission of

the receiver. A small rubber cap in the cover permits the fast

access to the quartz, without for this each mark the box must

be screwed on. The receiver should be rather kleinformatig,

since otherwise the installation, in particular in connection

with a switch, becomes to the challenge.

Without

diligence no price

The assembly of the NT1 as diligence work to designate borders

already on offense. In Ernst, the assembly on the basis the

first-class building guidance is a true joy and can easily on

one weekend be settled. Outstanding register accuracy and

quality place even inexperienced mechanics before no

difficulties and guarantee a chassis functional low-friction

at first attempt and. As used one should have appropriate

tools, which win particularly when screwing in into the quite

hard plastic at meaning. Up to a few little things (see

Montagetipps) no characteristics are to be considered to hold

except itself when the assembly and adjusting the clutch

exactly by the operating instructions and the chassis before

the first employment, preferably with a set UP system to

adjust.

Keep on

racing

After 5 litres muddled Sprit and three different distances one

can speak indeed of a test. Begun of Kirchhain over Lahn

valley until Luxembourg we tested the NT1 on heart and kidneys

and no change of set UP omitted. Whether obtained Differenzial,

Starrachse or free-wheel, roll center, stabilizer or absorber

position, the new Nitro chassis of XRAY always a feedback of

the modifications. After building guidance prepared the

Differenziale, in connection with the standard feathers/springs,

proved as outstanding basic adjustment, which serves even team

drivers as basis. The adjustable piston plates of the

absorbers one adjusted, therefore recommends all too easily we

from the beginning the 60's-oil from the component system with

the fixed four-perforated tiles in the back and for the

three-perforated tiles to in front use. Altogether the

performance of the NT1 on highest level moves.

On' s goes:

The body provides for sufficient aerodynamics, the tail

spoiler presses the rear axle on the soil

Particularly fell the precise

and durably evenly switching two-speed transmission and the

also problem-free working XCA clutch, which are based on the

well-known Centax principle. During the test of several days

there was not one defect or loss to deplore. Only three

missing teeth at the long belt witnessed from a carefully not

adjusted belt tension adjuster. Even the transmission gear

wheels, whose tooth loss is with some models true troubles,

did not give a reason after employment lasting several hours

and appropriate customs traces to the concern. Very pleasing

was likewise the condition of the small plastic gear wheels:

as new.

And completely

besides the plastic parts can be kept also still great clean,

which one wants more. All critics to the defiance, even with

thorough view we can certify the NT1 only good ones, partly

even Bestnoten. That CVD drive shafts were blocked in front

and aluminum wheel drivers not in series are unfortunate, but

usual practice and with the price performance ratio also okay.

Desirably it remains only that XRAY is concerned with the

construction of new absorbers. A statement on this topic finds

it in this booklet under the column scene

Words

and photo: Francois Legrand

|

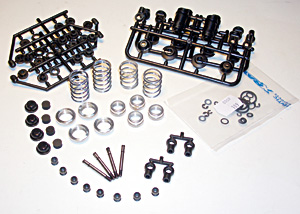

Front and rear axle are in series equipped with extremely

compact Kegeldifferenzialen. Replaces one the bevel gears of

the front Diffs by the small plastic right parallelepiped

receives one a Starrachse

Exclusively - the different metal parts from Hudy

Ferderstahl and rubber-sealed light run camps are expression

of the special one

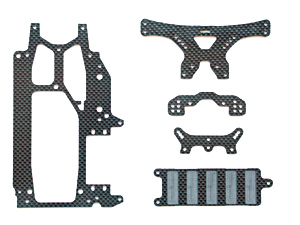

The CFK parts are carefully finished and in particular the

absorber bridges sufficiently dimensioned. The Akku mounting

plate is offered as option, in the component system is

selbige made of plastic

The later worked on brake eccentric cam was easily abgefeilt,

in order to prevent a sharpening of the brake disk

The XRAY XCA clutch which is based on the Centax principle

pleases by the quality of the components and the perfect

function. In the foreground the yellow Tuningbremsbelag is

to be seen

XRAY sets further on the long-proven absorbers with plastic

housing. Unfortunate, we had expected nevertheless finally

new models, which are worthy the XRAY requirement

The glass fiber portion of the Composite plastic parts

ensures a high rigidity.

The tension of belt can be adjusted at both drive units

problem-free.

The gear wheels are by means of a split pin and

C-Klipsen on the wave fixes

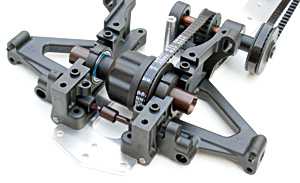

The two-piece engine supports are a new fact and make

possible fast removement and replacement of the engine,

without having to adjust the teeth profile play again each

mark. In addition with the optionally available Flex

Motorbock the rigidity of the chassis can be affected

The NT1 is pure competition equipment. The finished chassis

does not only work nobly, but is from highest quality

Winning combi nation: REX engine by MH-Tuning and the

Resorohre of Mielke

|