THE PROCESS

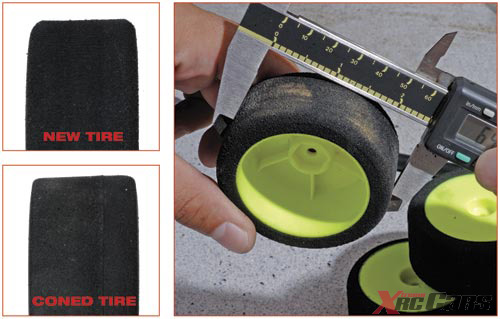

1 Before you even think about firing up your tire truer you have to

determine what you are trying to do with your foams. Whether you are

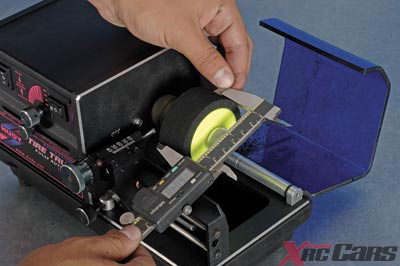

starting with a fresh set or just cleaning up an older set you must

determine your desired tire diameter. If you are working with a used

set of tires and want to match sizes or flatten out a few coned tires,

you are best to start working with the smallest diameter tire and match

the rest to that one so you are removing the least amount of material.

This offers you the longest tire life when you are finished with the

truing process.

2Assuming that you are working with brand new tires that are usually

way oversized, you first need to rough them down so you are close to

the size you want before you do the precision truing to the actual race

size. Make sure there is no flashing on the rim or debris on the tire

truer hub to ensure that the wheel assembly mounts flat to the machine

and provides an even cut. Also be careful not to over-tighten the

mounting nut or you may warp the wheel, causing an untrue finished

wheel. Some truing machines have an option as to what direction you

want the truer to rotate the tire. If you have the option, rotate the

tire towards you for this step. Rough cut all of the tires down to

about 1mm bigger than you want, and set them aside in the order you cut

them. Temperature can affect the final size of the tire, so to ensure

accurate tire diameter you want to let the tires fully cool down before

you make the final cut to size. After you rough down the last tire,

mount up the first tire you worked with (which should be cooled down)

before you move onto the next step.

3 With your first tire mounted to the machine, you are ready to do the

final cut. Most tire truers have some sort of a measuring device and

lock, so the cut diameter stays consistent. It is recommended that you

use a set of calipers to verify the tire diameter of your first tire,

but once you know the size is accurate, lock the machine for the other

three tires. It is a wise idea to pass the cutter over the face of the

tire a few times to ensure all of the material has been removed and to

create the smoothest finish possible.

ROUND OR SQUARE?

Rounded tire edges with a radius between 1/16" and 1/8" is the most

common setup for foam tire racing. This setup offers the most

consistency when it comes to on-track performance, but Josh says you

can round the edges even further if the track is super high-bite but

really rough. This offers you a more controlled slide without losing

too much grip. A rounded tire edge will keep the tire on its contact

patch better and you'll have fewer worries of the tire rolling over

onto the side wall which will break the car loose through a turn.

Rounded edges will also help to reduce foam tire chunking, which can

become a huge issue, especially during longer nitro main events.

The least common cut when it comes to foam tires is a

square edge. A tire with a square edge will always be riding on that

edge, thus taking side grip away from that area. If you run a square

edge on the front tires you will get less steering. A square edge at

the rear causes your car to be very inconsistent--it offers increased

forward grip but much less side traction. The track surface has to be

very smooth for square edges to work on the rear tires.

Josh will usually run the same type of edge cut front and

rear except in 1/12 scale where it's common to run a square edge at the

front and a rounded edge on the rear tires. Josh also used a mixed cut

when he raced at the Gas Nationals in Texas. The track was really rough

with very little grip, so he ran square fronts but rounded rear tires

with an excessive amount of radius cut into the edge. The square cut on

the front prevented his car from over-steering while the rounded rears

stayed consistent over the bumps, making his car easier to drive.

Truing Camber Into Tires

Truing camber into your rear foam tires is a trick used for longer

nitro mains. It is almost unheard of in electric classes where race

lengths are much shorter, so if you're racing electric you are best to

stick with the good old fashioned flat tire true. With nitro racing, if

you don't run enough negative camber at the rear your tires will wear

flat or cone to the outside. This greatly increases your risk of

chunking a tire during your hour long main, so to combat this Josh

usually trues his rear foams with about 1 degree of camber into them so

the diameter of the outside of the tire is larger than the diameter of

the inside of the tire. Nitro front tires are always cut flat. The rear

camber is set within the chassis to maintain the 1 degree of coning

towards the center of the car within the tire. In some rare cases where

traction is "stupid high," Josh says he'll cut a bit more camber into

the rear tires to a maximum of 2 degrees.

4 Your tire now has square edges that need to be addressed. Use a file

or sandpaper to round the edges slightly both on the inside and outside

of the tire, and smooth the face of the tire even further to help it

break-in quicker on the track. You can hold a piece of sandpaper in

your hand, but it is usually better to get some adhesive sandpaper and

adhere it to a stick to give you better grip and keep your hands away

from the moving tire. 120-grit sandpaper is usually good, but you can

go coarser for harder tires or finer for soft tires or to smooth the

face of your tire even further by removing most of the tire grain left

by the truing machine. If possible, the direction of the truer rotation

should now be away from you, but if you are using a directional file

you want to hold it backwards so the tire is rotating into the cutting

edge of the file. This will prevent you from having the tire rotate

towards you, which could cause the file to fly in your direction if it

catches on the tire.

5 Repeat the above steps for the other three tires after ensuring that

they've had enough time to cool so their diameters are in check. After

you've done all four tires let them cool down, and verify their

diameters one last time before you mount them onto your chassis and hit

the track.

Multiple Tire Sizes

Foam tires mounted at the front and rear and left to right of your

chassis won't always wear at the same rate during a race, so Josh likes

to experiment with varying tire diameters around his car to match wear

as best he can. For indoor carpet racing Josh will estimate wear

patterns and set up a stagger with his foams, run three or four

practice races to scuff his tires in and bring them to equal sizes,

then set them aside for a big race. This ensures that all of his tires

are the same diameter for the shorter electric races while still

scuffing them in on the track. Once he starts racing with these perfect

tires he'll swap the left and right tires back and forth after each

battery pack run. Josh will only practice with his electric car on

different tire diameters to match them; he will never start an actual

electric race on staggered tires.

Racing nitro cars on foam tires is an entirely different

game. Josh will sometimes run multiple tire diameters during qualifying

but always for the longer mains. You'll have to do some experimenting

to determine tire wear characteristics for your chassis on your

specific track and then use some common sense to estimate starting

diameters. Josh says that with a track that runs clockwise he'll

usually start with the left side of the car with tires that are 0.5mm

larger than the right side on both the front and rear. If his rear

tires are wearing more than his fronts then he'll run both rears

another 0.5mm larger than the fronts. Here is an example of a starting

tire diameter setup that Josh would try for a longer nitro race. Let's

say he wants to run a 60mm tire. He'll experiment with the front right

tire cut to 60mm, the front left tire to 60.5mm, the right rear tire to

61mm, and the left rear tire to 61.5mm. After this initial setup he'll

do some testing on the track and alter his stagger from there.

Track direction for this type of setup would be clockwise. You'll need

to experiment with different diameters that suit your chassis and track

layout or conditions.

CLOSING

As most racers will tell you, if your tires aren't right it doesn't

matter how good your chassis setup is; you aren't winning. With that in

mind the perfect prep of your foam tires is crucial to success on the

track, so read this article carefully to ensure you carve your tires to

perfection every time. Don't forget to experiment with some of these

tips from Josh Cyrul and you'll see why he's got more National Titles

than most people have sets of tires. |