|

Brand: Serpent

Product Type: Electric Cars > 1/10 offroad

Spyder SRX4 Buggy 4wd 1/10

High end Race level 1/10 scale 4wd buggy.

Ready for the racetracks in dirt, clay, grass, astro or carpet.

Vice European Champion 2015 : Joern Neumann

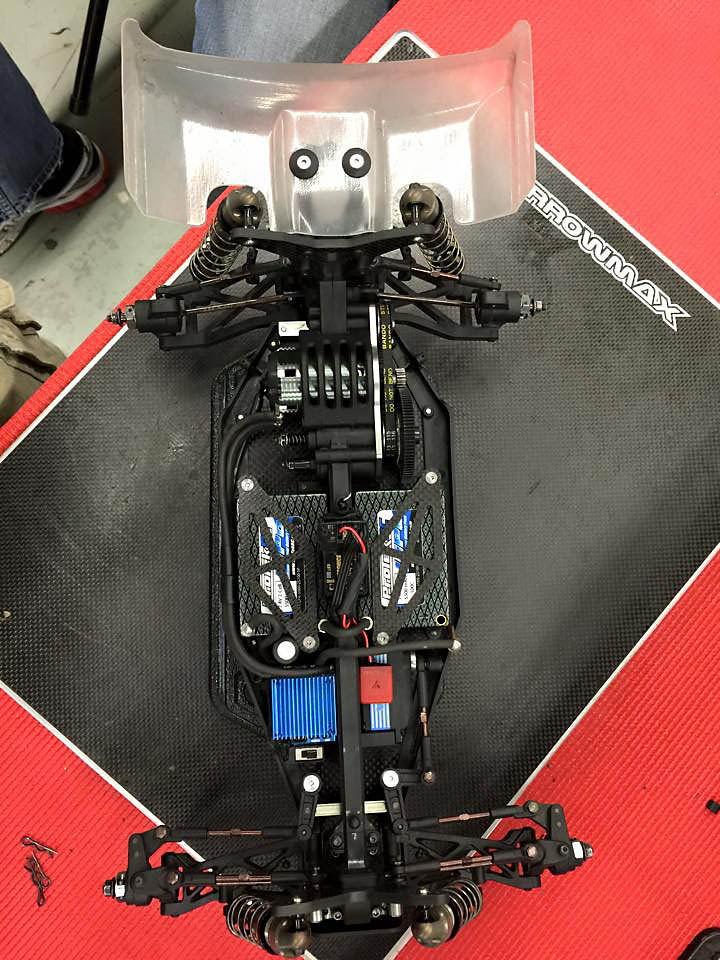

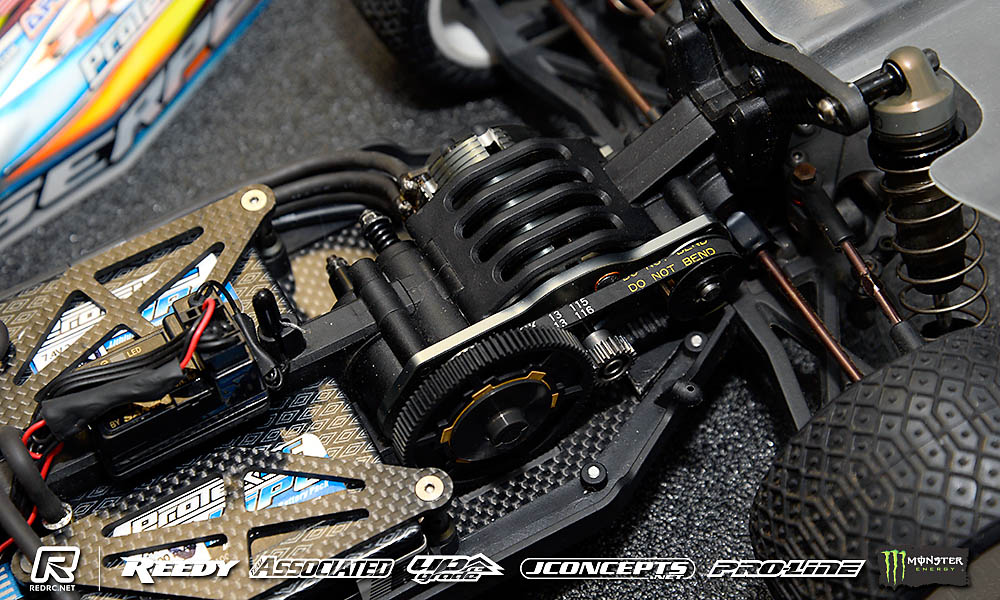

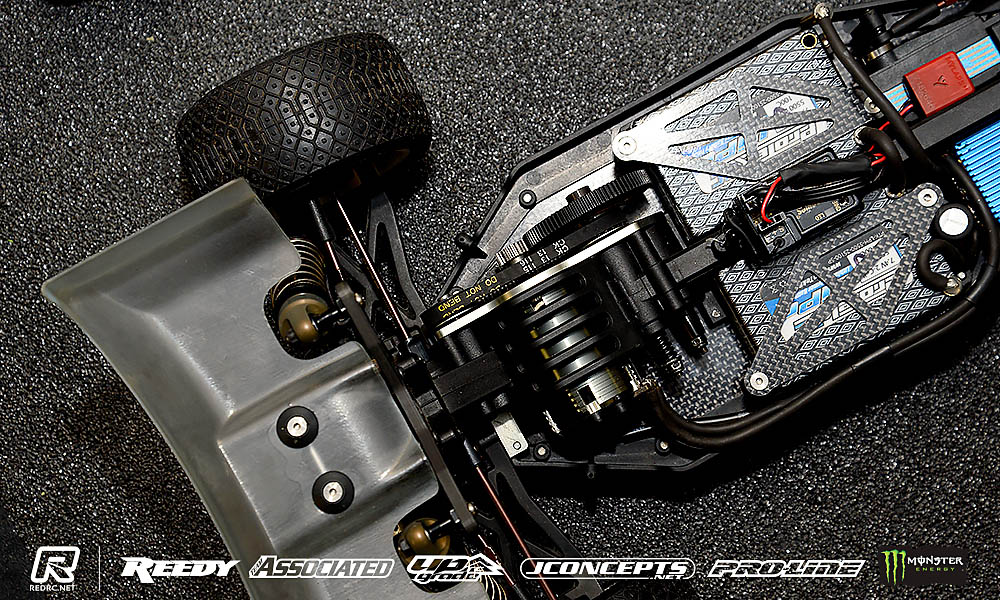

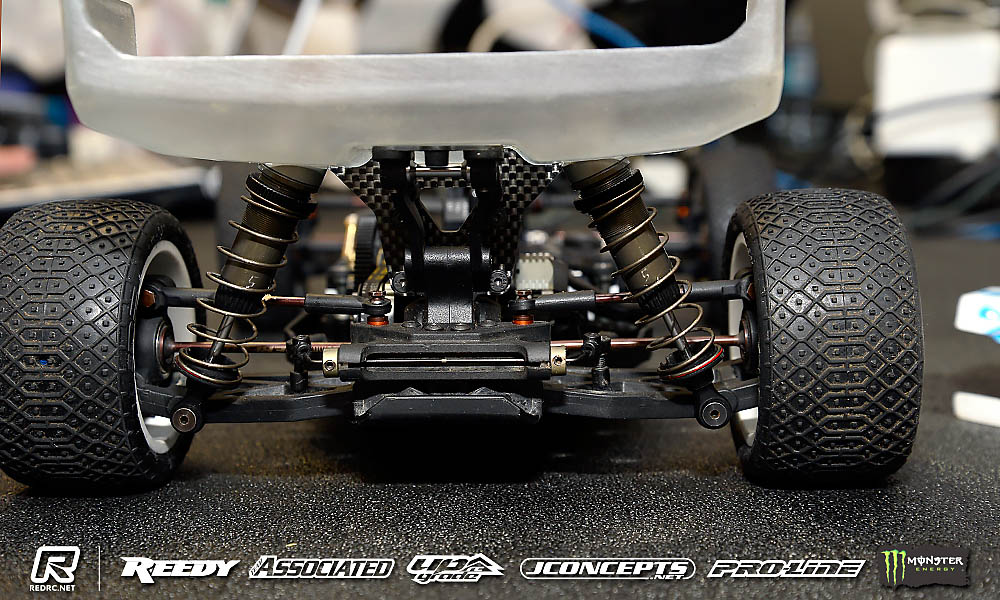

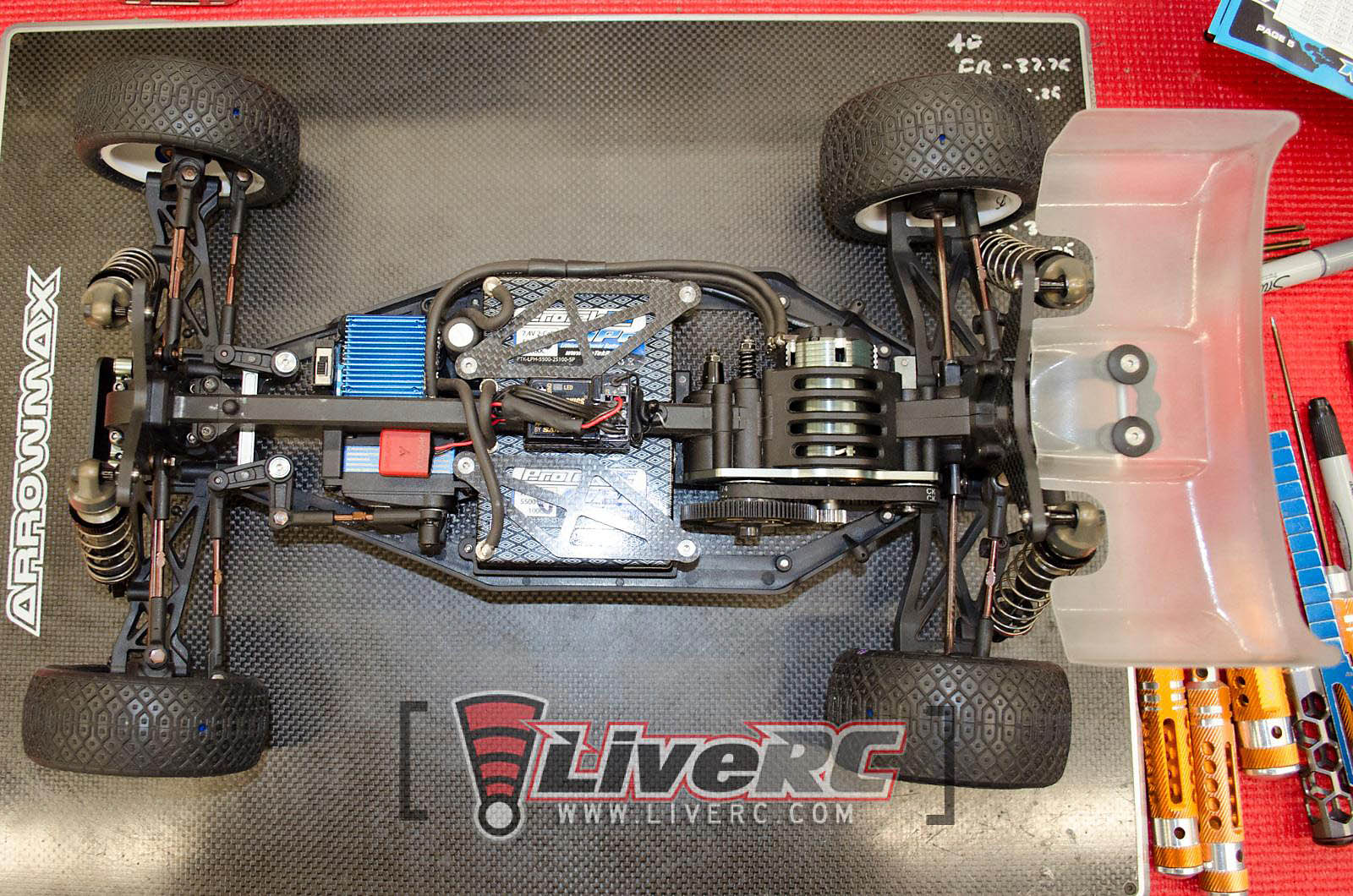

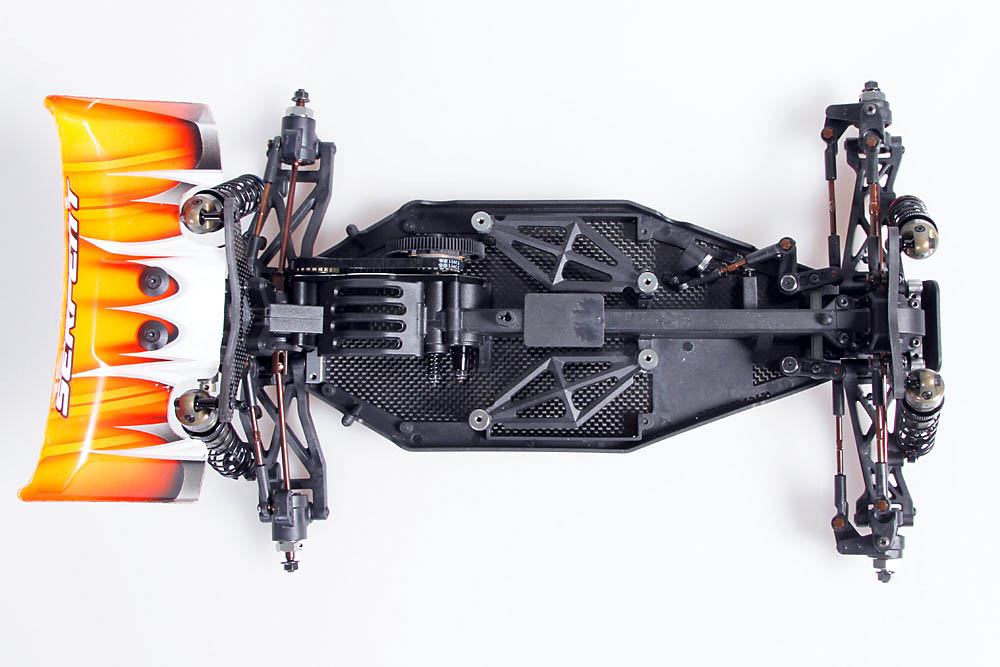

Carbon fiber 2.5mm chassis with composite side plates. Big bore 12mm hard coated shock-absorbers. Dual belt-driven drive system, with captured long front belt and open side belt. Compact and light front and rear gear differentials with composite front pulley and rear hard anodized aluminum diff gear. Slipper clutch with friction pads and solid aluminum front locked clicker. Durable spring steel drive shafts, wheel axles and drive cups. Carbon fiber shock towers front and rear.

Design by Billy Easton, USA

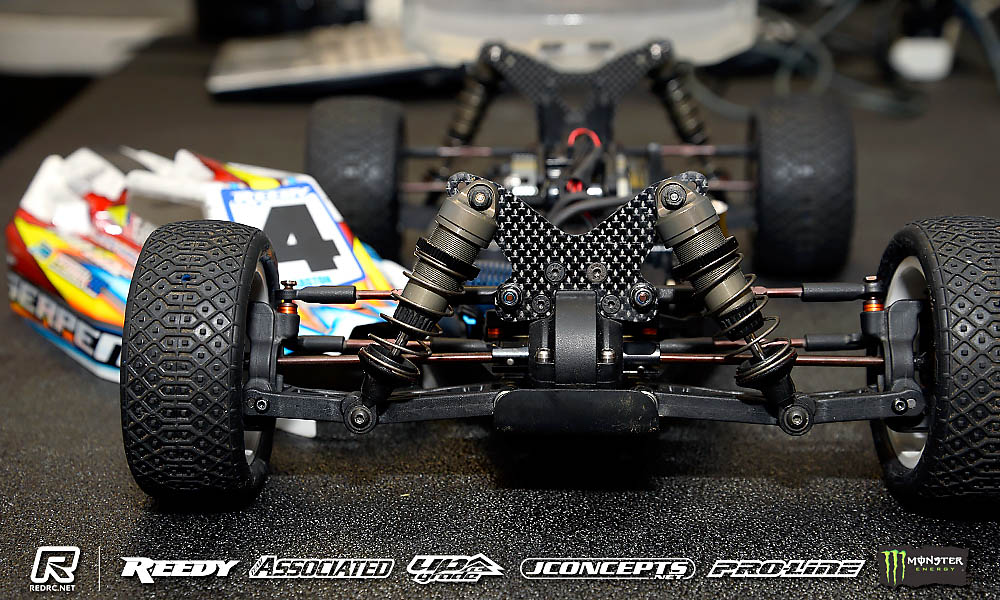

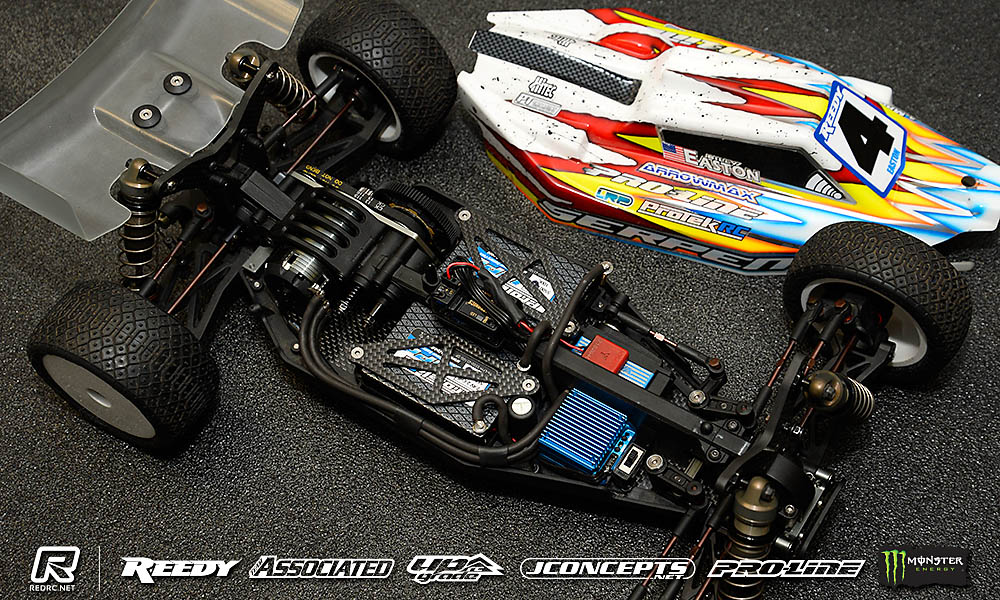

Serpent are debuting a pre release version of their all new SRX-4 1/10th 4wd buggy here at the Reedy Race. Being run by the carís designer Billy Easton it features a 2-belt configuration with a long centre belt and short side belt, which helps keep the centre of gravity low and the weight centralised. Positioning of the motor was a priority when designing the car, keeping it centralised and to the rear to help with rear traction which in turn allows you to run a more aggressive steering setup.

Utilising a saddle pack configuration, it still manages to be a very narrow and neat setup, similar in appearance to a 2wd buggy, something the carís designer was aiming for. Sporting a carbon fibre chassis plate, and shock towers, the steering uses a double bellcrank system which is actuated by the lay down servo and sports fully adjust ackermann on both the steering system and the steering arms.

Adjustable diff heights front and rear allow you to take away or create grip, while belt replacement is a breeze both for the short side belt and the main front belt, with the front belt needing 6 screws to remove the cover, the same process needed to change the front differential. Expect the car to be released in mid March.

For many years, the Serpent brand of cars encompassed only nitro on-road racing, and for good reason - thatís all they made. Not only has the dutch brand been at the forefront of 1:8 nitro on-road since the company began developing cars in the late 1970s, but Serpent can be credited with helping to create the 1:10 235mm and 200mm nitro touring car divisions as well. Serpent first began testing the waters of the off-road segment in the mid-2000s with cars designed by Gerd Strenge, who eventually produced his creations under the Team Durango name. Later in the decade, 2003 2WD IFMAR World Champion Billy Easton joined Serpent as a designer and helped put into production Serpentís first 1:8 nitro and electric off-road vehicles, then moved into 1:10 electric off-road with the SRX line that now includes rear- and mid-motor 2WD buggies, and a 2WD short course truck.

Amid rumors last year that the car was coming, Serpent recently announced the SRX-4 4WD buggy ahead of Easton making its international debut at the Reedy Race. Easton said that he finished the carís design around July of last year and started receiving samples in October and November. He was able to begin testing in earnest just before the start of the year, and both Easton and Serpent America CEO Joaquin de Soto suggested the car could be released to the public as early as March.

First and foremost, Easton said his objectives were to create a car that is balanced and generates grip at both ends. Billy felt that todayís current cars often lack rear grip, which means that they must be set up to reduce steering accordingly, and that a car with more traction can be set up more aggressively. It was also a prime concern that the car be balanced, and that required laying out the car with near-perfect symmetry as itís difficult to offset heavy components like the motor and batteries - even when using ballast to achieve left-right balance, that often throws off the front-rear balance and you end up with a car that is more weighted on opposite corners.

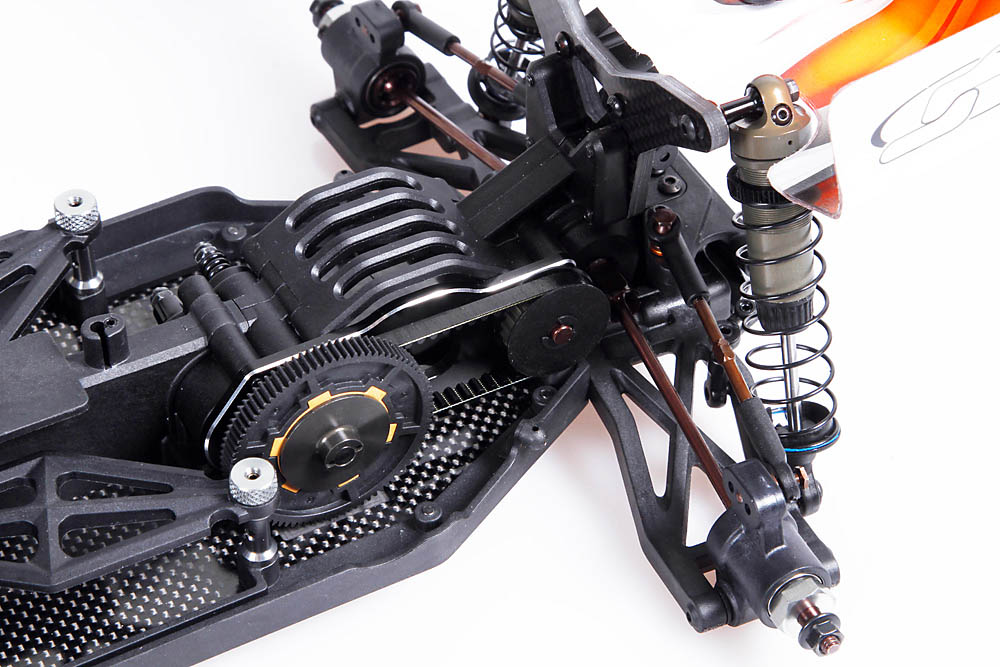

Achieving that symmetry was difficult, especially when trying to fit the motor into the center of the chassis. Easton found the answer by using a short belt to reach the gear differential and then building a transmission to offer the proper gear reduction to get the front drive ratio to match. Once Billy figured out that design, he said the rest was pretty easy - he wanted to use 3mm belts for a durable, low-maintenance drivetrain, and has been running the same belt for three months. Because of the gear ratios used to drive the front end, the front belt doesnít have to spin as fast - and that means longer belt life.

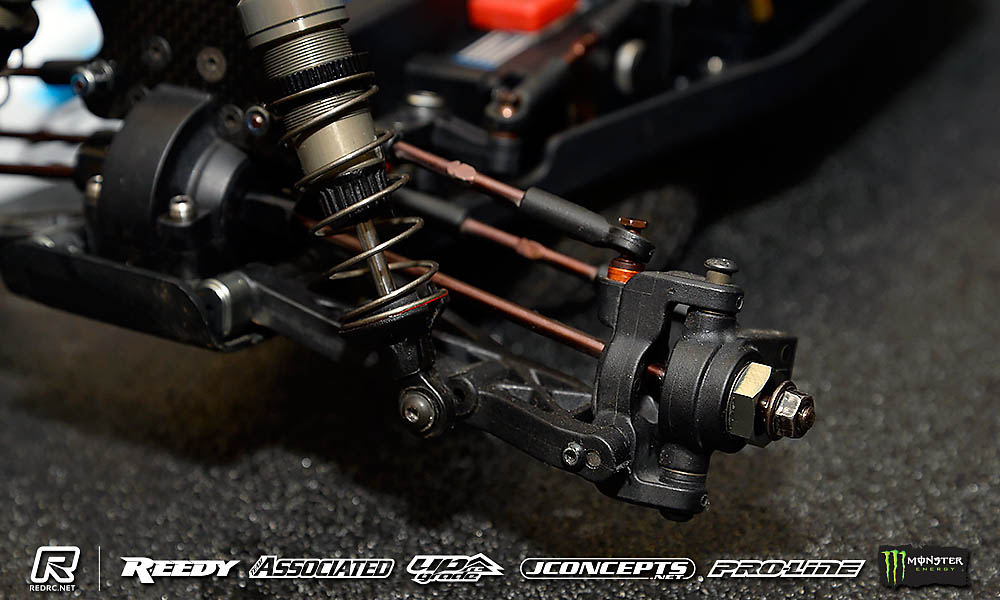

When it came time to configure the suspension, Billy looked at other cars to see the direction of todayís current 4-wheelers. He designed a new front spindle design with a different offset to help the SRX-4 achieve the feel and stability of a 2WD, but still maintain the aggressive cornering behavior of a 4WD buggy. The balance of the chassis means that the car reacts similarly when turning in both directions, and it flies flat through the air as well. Knowing that the SRX-4 would be competing on both dirt tracks in the U.S. as well as carpet and astroturf tracks everywhere else, Easton said it was imperative that the car have the adjustability options to be able to cope with either condition. In particular, he needed to make sure the roll centers and diff heights were right. In addition to his running test car in the U.S., two of Serpentís drivers in Europe have been running the car as well.

Billy will be the first to admit that he doesnít get to practice and run as much as heíd like, so his performance in his return to the Reedy Race of Champions after over a decade doesnít showcase what the car is truly capable of doing on the track. But the World Champ says he is happy with how the project has turned out, and is excited to see what the world thinks when it hits the track.

Serpent is introducing the long awaited 1/10 scale 4wd buggy, designed by Billy Easton.

The 2-belt-driven 1/10 4wd buggy is a high end racing buggy with carbon chassis and carbon shocktowers, springsteel transmission, smooth geardiffs, solid slipper, clicker, hardcoated big bore shocks with pre-oiled x-rings, and a large variety of set-up options to fine-tune your SRX4 car. The SRX4 car is designed as saddle pack version, but with some small mods a shorty can be fitted too. The kit comes complete with wheels, a very sleek, low, narrow body and large rear wing.

Shipping starts 25th of august, so kits will arrive at dealers last week august and 1st week September. # 500010

Designer Billy Easton has shown great pace at tracks across Florida, USA and Joern Neumann and Hupo Honigl showed good results at the recent EC in the UK, where Neumann took the Vice Championship title in 4wd buggy.

Spyder program

Serpent now offers a superb 1/10 offroad program with the Spyder RM 2wd buggy, the MM 2wd buggy, the ShortCourse RM 2wd and now the SRX4 1/10 4wd buggy. In case you run multiple classes its good to know that the Spyder MM 2wd and SRX4 share quite a few parts.

Spyder SRX4: How it developed

A pre production version was already shown on the Nurnberg Toyfair earlier this year, and Team Serpent drivers as Joern Neumann, Billy Easton, Hupo Honigl, and distributor-driver Tony Evdoka have been running the prototype car in various races, both dirt and astro.

While we were happy with the performance on loose dirt and hardpacked high grip clay, where this belt-driven SRX4 buggy is working superwell, we were not happy enough with the cars high grip carpet / astro performance initially.

We have taken our time to run the cars more on astro and carpet tracks and improved the cars performance by making small but significant changes, and we are now happy with how the car works also on these higher grip astro and carpet tracks.

Worlds Japan test

Team Serpent also joined the Worlds test-week after the warm-up to learn more about racing the 2wd and 4wd buggies on this super high grip carpet. For testing we tested 2wd and 4wd cars with some different layouts. These prototypes, partially retro-fitted with parts from other brand cars as well to allow for such short term and quick track-testing. Maybe none of the cars tested was the optimal one, but we have gathered lots of data and believe we know now whats needed Ö.. !

The WC track-surface is a very special one, with extreme grip levels, which you will hardly find anywhere else on this planet. However we will take part in the WC and want to do well. We are currently working on some special design cars which we feel may work even better on this specific track, but which may also work well after the WC on other type tracks. There is only one way to find out ! Design, make, test and race !

In the end Serpents goal is to supply our customers with the best Serpent cars possible, for the specific surface you may be racing on. If that needs more different version cars, or specific optionals then we will make them for you ! Development never stops Ö.

Team Serpent

--------------------------------------------------------------------------

Description

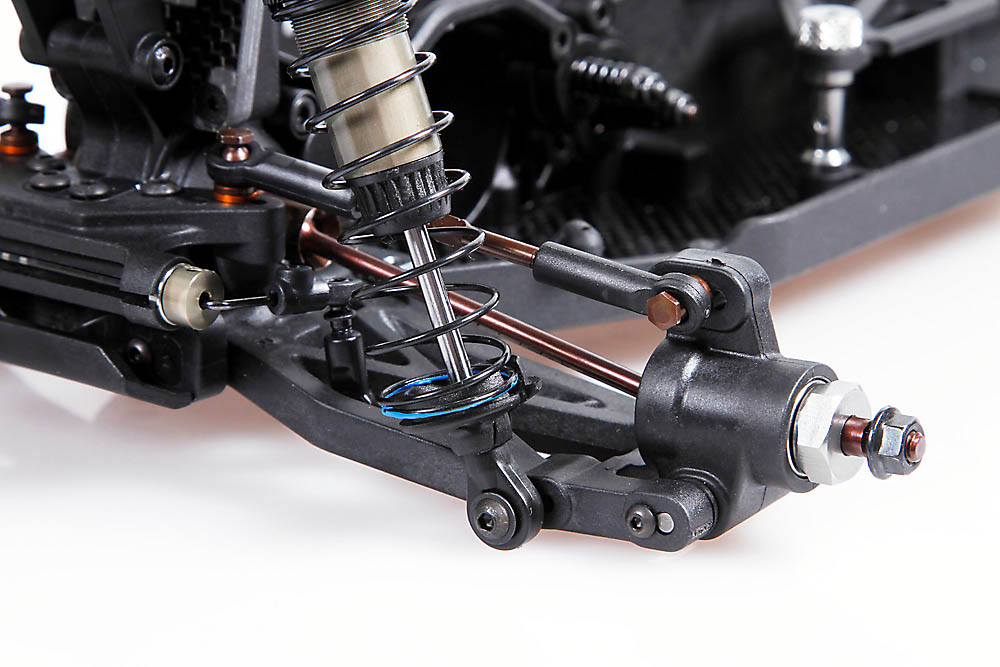

Front suspension Front suspension

Strong composite lower suspension arms with mounting spots for the optional anti-roll bar. Aluminum suspension brackets with inserts to change set-up. Small but effective composite front bumper to protect the front end. The angled front built in kick up allows for smoother landings. The composite front diff case is a very strong affair to mount the diffs, front shock tower, central spline and chassis too.

Steering blocks and c-hubs Steering blocks and c-hubs

The composite steering blocks and c-hubs offer a variety of set-ups with inserts and shaped changeable Ackermann plates of which all 3 composite ones are included.

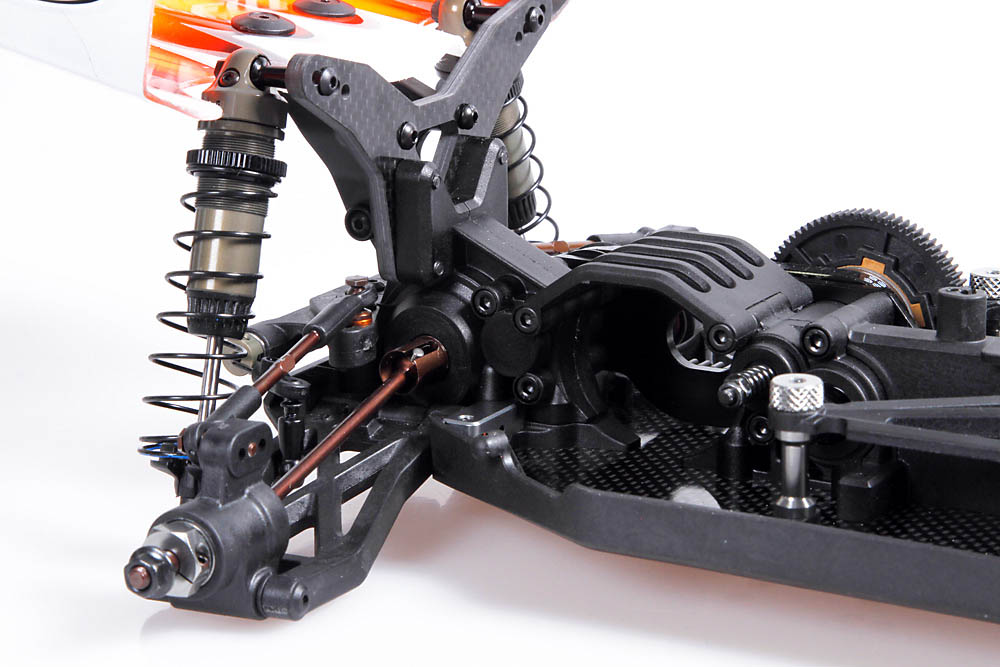

Rear suspension Rear suspension

The rear end shares many parts with the 2wd MM Spyder, which is nice if you also run 2wd. Also here a very sturdy structure with the diff-case as base to mount diffs, shock tower, chassis and motor mount to. Strong composite lower arms. Suspension brackets in aluminum also here with inserts to play with set-up. The beefy composite uprights offer 3 setup position in the top and inserts in the bottom.

Rear wing and wing holder Rear wing and wing holder

The strong clear polycarbonate wing is mounted to the nylon rear wing holder. The wing angle can be changed by using the included wing angle spacers: 0, 2, 4, 6, and 8 angle are all included.

Anti-roll bar Anti-roll bar

Both the front and rear allow mounting anti-roll bars. As default Serpent only supplies the rear ball-raced anti-roll bar, as that is used more commonly.

Motor mount Motor mount

The motor is mounted securely to the thick 3mm cnc machined 7075 T6 alu motor plate, which doubles as cooler. Machined slots allow movement of the motor to fine-tune the pinion/spur gap. The motor holder also holds the shafts of the side belt system, and allows mounting.

Body mounts Body mounts

The strong composite body mounts are easily located in case used. As alternative velcro can be added to the side of the chassis stiffeners.

Body Body

The body is made in the same Avenger style as the 2wd buggy and shares its looks and compact shape. Top quality clear polycarbonate is used. The body comes with a masking sheet.

Rear wing and wing holder

The strong clear polycarbonate wing is mounted to the nylon rear wing holder. The wing angle can be changed by using the included wing angle spacers: 0, 2, 4, 6, and 8 angle are all included.

Rims Rims

Durable Serpent designed wheel are included in white color for front and rear (tires and inserts are not included).

Clicker system Clicker system

Standard in the car the ďsolid clickerĒ is used for permanent 4wd, which for high grip conditions is best to use. The optional clicker system requires few extra parts only and can be used well in medium and lower grip conditions, to allow the front wheels to spin more free and create more corner entry speed as needed.

Slipper clutch Slipper clutch

This light slipper-clutch unit, is a spring loaded 3 pad version, allow to control the power distribution.

Shock towers Shock towers

Very durable 4mm thick carbon fiber front and rear shock towers with 4 positions for shock angle.

Shock stays

Very durable aluminum shock stays combined with a small bushing and nylon flanged nuts.

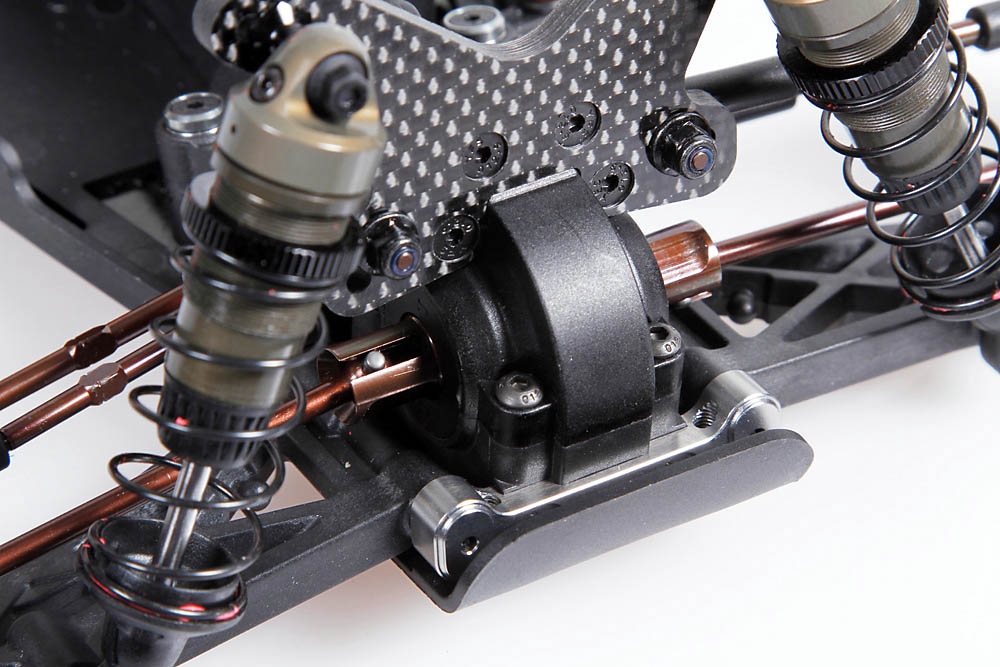

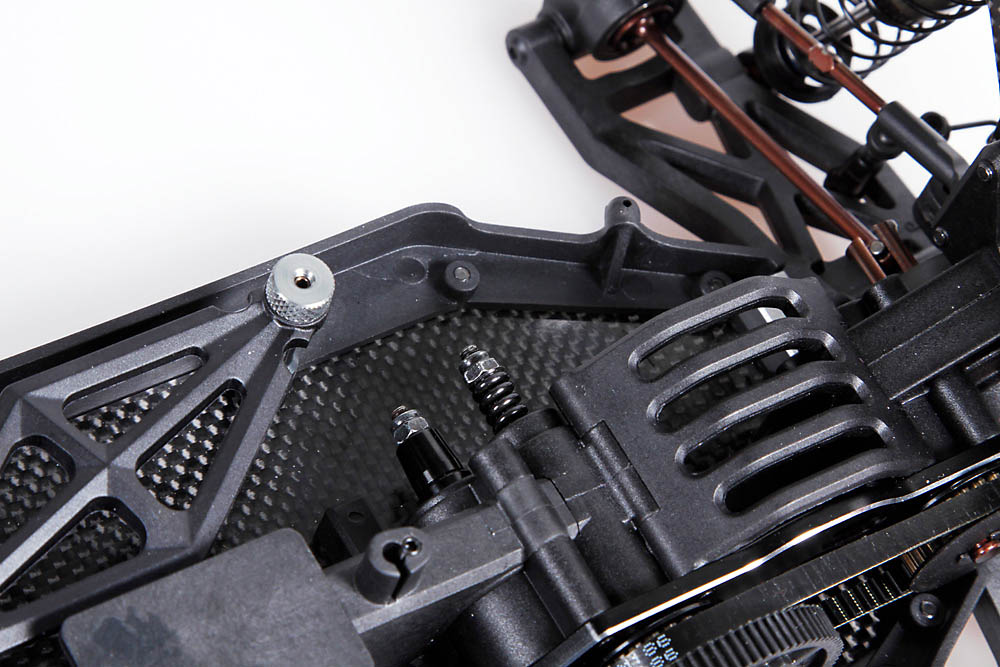

Central spline Central spline

The composite central spline in which the front belt runs, creates a very strong chassis stiffener, right in the center of the car. It also protects the front belt very well against debris and insures no belt can skip.

Battery and stays Battery and stays

The saddle pack battery (not included) is kept in place by 2 easy to use composite battery-covers. Small machined aluminum nuts are included to keep them in place.

Electronics Electronics

The center of the car allows plenty of space to mount the most popular speedo and receivers, as well as the transponder. The car also allows enough space to enable nice routing of your cables. The shorty type servo is mounted on integrated composite stands. Various spacers and horns are included to suit the most popular servo brands.

Drivetrain Drivetrain

The dual belt system is very durable and light. The Kevlar reinforced front belt is fully captured, so well protected against debris which increases life. The Kevlar reinforced side belt is open due to its location, and the closely fitted body will prevent debris from coming in contact with the belt. The belts run on precision machined pulleys. The front belt tension can be changed with eccentric inserts.

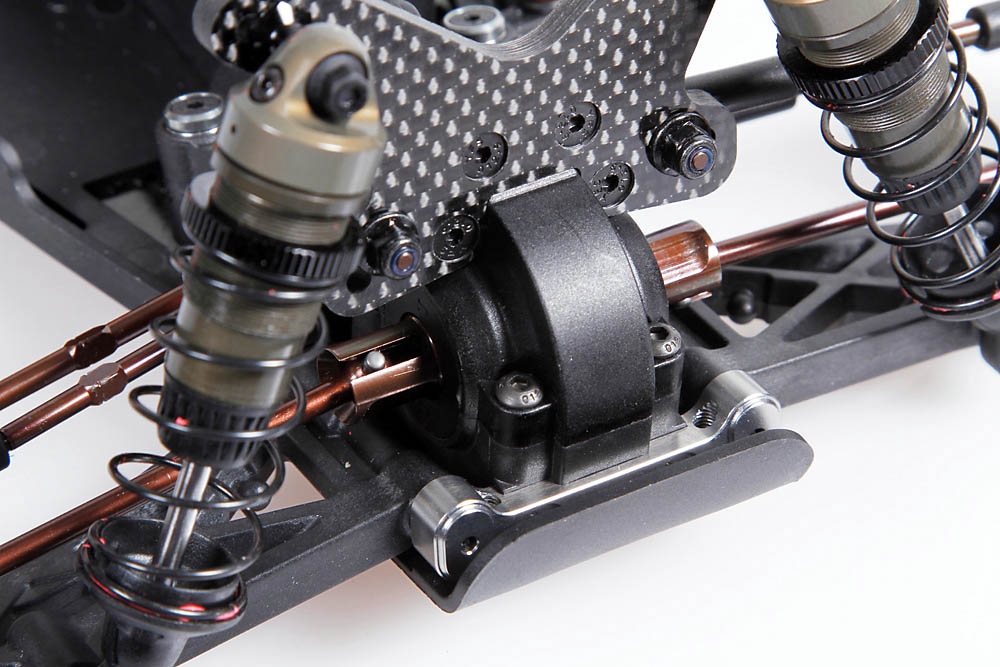

Gear-diffs Gear-diffs

The 2 compact oil-filled gear differentials front and rear. These super smooth units are light and compact and very durable. The differentials are also very easy to build and are very low maintenance. The diff-inserts in the cases allow to you run a low, mid or high position which alters grip.

The rear gear diff has a hard coated aluminum gear for durability.

Drive shafts Drive shafts

Serpent spring steel CVD drive shafts and wheel axles for durability. Also the lightened differential drive cups are in spring steel.

Suspension pins Suspension pins

Made in durable and strong Serpent hardened steel. Captured units with rounded end which rotate in small ball-cups inside the suspension brackets, so itís super free.

Shocks Shocks

Serpent hard coated shock bodies and shock tops for super smooth operation and durability. 3.2mm shafts with new X-ring package and molded pistons. The shocks can be used either emulsion or membrane configuration. The shock springs have ground ends, checked and matched for perfect equal operation. Ride height can be easy set with the threaded collars which have o-rings inside to stay in position.

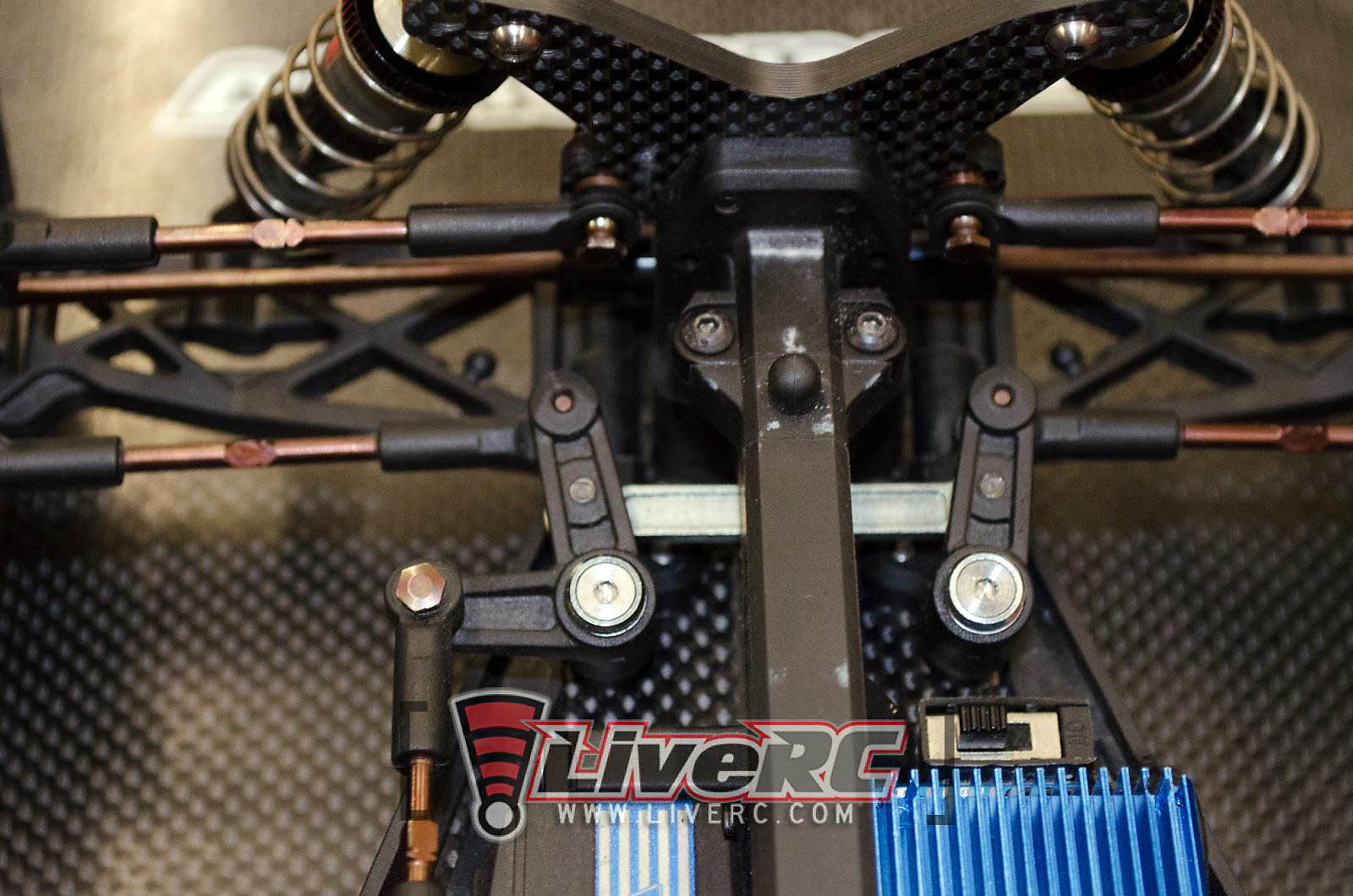

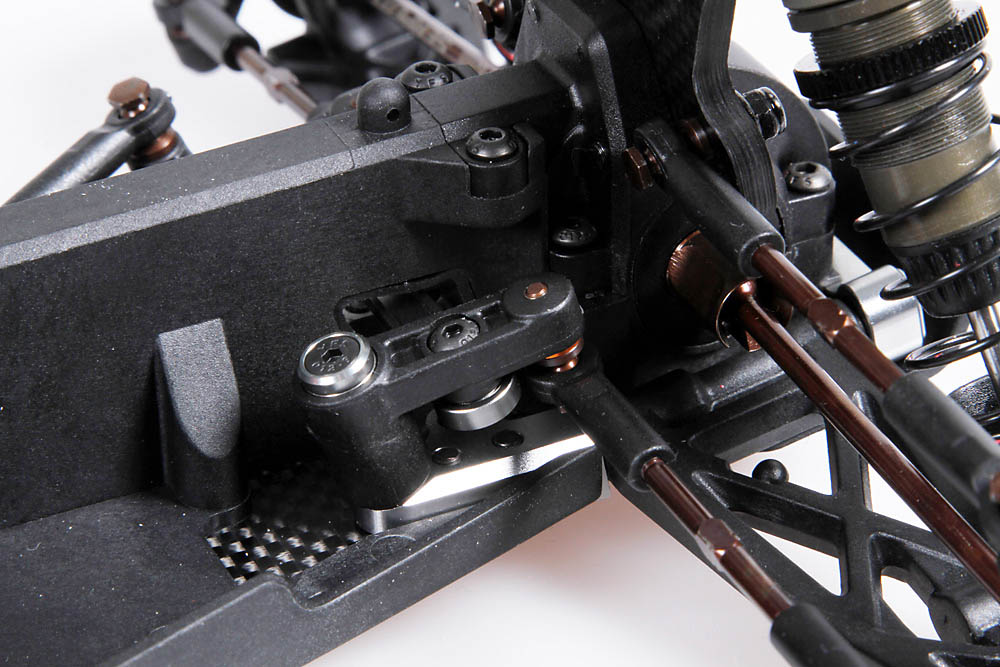

Steering Steering

The fully ball raced angled dual axis steering system with integrated servo saver function, offers an almost perfect Ackermann effect. Ackermann can be set with small plates which mount to the steering arms. 3 types included to play with. The angled system will prevent bump steer.

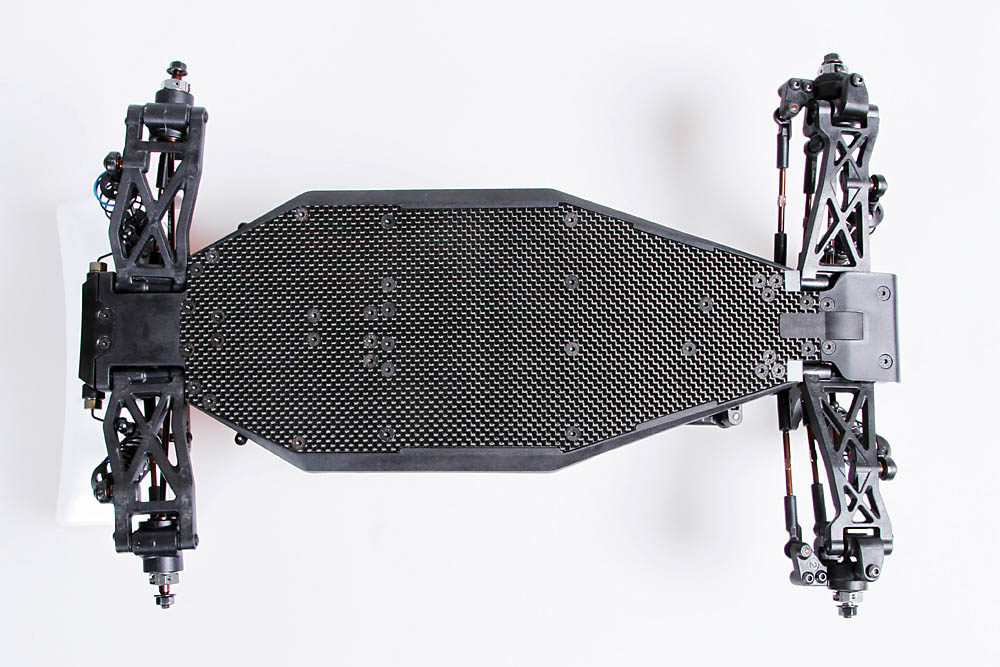

Chassis Chassis

The light 2.5mm carbon fiber chassis has the right flex combined with the composite side-guards / chassis stiffeners and center spline. All holes are countersunk to have a fully flat bottom surface. Holes are centered and symmetrical for even flex.

The overall layout gives a 42/58 Ė 44/56 weight balance. Optional weights and brass parts can be used to influence that.

Manual / setup sheet / decals

Manual / setup sheet / decals

The Spyder SRX4 comes with a printed full color manual which shows the assembly process in steps following the packed bags. The manual also encloses the exploded views and a ref-guide to make it easy to find the part numbers you may need of spares and optional parts. A latest version of the manual can always be found on our website as PDF.

A default set-up sheet is included, but more set-ups can be found on our product page under set-ups.

A Spyder decal sheet and a Serpent decal sheet are included.

Designer interview Spyder SRX-4 buggy 1/10

Hello Billy

I like to ask you some questions on the new Spyder 4wd buggy that is released last week.

Q: You have been creating a really nice line of 1/8 and 1/10 offroad cars in just a few years time, and even a GT car in 4 versions in the process too; how many cars did you design for Serpent till now?

A: Although this seems like a simple question, I have to really think about that one. I have done somewhere in the range of 15-30 different models. This would include the originals nitro and electric updated versions, and RTR variants. I actually also helped design our original link 1.12 car as well as the 1.10 GT version.. I would like to consider myself a jack of all trades for Serpent.

Q: Which of these cars was the most challenging?

A: Honestly, I donít think that any car is easier than another. The end goals are all equally difficult to achieve. Since we are in a very competitive industry where racing at a high level is considered the standard, itís always very challenging to make a car, which out of the box is competitive. I think, if we had to pick a class, in which the design has the most challenges, I would actually say 1/10 2wd buggies. 2wd buggies seem to be extremely critical of things that you would otherwise consider un-important. In all fairness though anything 1/10 scale seems to carry more challenges, due to the competitive nature of the industry in that scale size.

Q: Which software do you use to design?

A: I actually use a variety of software. The main software for Serpent would be Pro-e. However, I use Solidworks for bodies and misc. items, Gear trax for making most drivetrain components and MathCAD for all the calculating. Aside from those programs/software, we use a lot of Microsoft products to keep things in order and for other smaller calculations.

Q: When did you start on the 1/10 4wd Buggy design?

A: I started working on the concept, if I remember correctly sometime in April of 2014.

Q: What were the key goals to achieve?

A: Well the primary goal was to create a car that I felt would potentially be competitive out of the box. I had to do a ton of research for that. Aside from that goal, I wanted to innovate the class. So many companies talk about innovating things, but they really fall short when it comes down to it. I wanted to give the customers a car that could produce more grip than anything they had ever had before. More rear grip and steering to match, along with having a perfect balance. In the highest grip condition would be extremely stable, easy to drive and fast. So far it has proven to achieve most of those goals.

Q: What are the 5 main specific elements why a driver should consider the Spyder SRX-4 1/10 buggy?

A: If I were to sell you 5 good ideas:

1) It shares over 50% of the parts from your existing mm Buggy

2) The drivetrain weight is significantly reduced over what is on the market. This translates into more acceleration and lap time.

3) The car comes out of the box with every tuning tool you need to win your local race and save your wallet

4) The rear grip, steering and overall driving feel is the same as a 2wd, only with the ability to handle more power and brake later and simply go a whole lot faster.

5) The body is devilishly sexy. Your friends will not even know you are driving a 4wd.:)

Q: Why did you decide to use the belt-drive system?

A: With the belt system, itís actually smoother, and you do not need to make as many steel, heavy parts to make it effective. In the case of our design, the weight of the car is distributed perfectly left to right as well as the overall weight of the drivetrain is significantly reduced over a shaft driven variant. Balance is the key to any winning race car.

Q: When using belts drivers may pop the questions: do they last? how much time to replace? what about belt tension? What about debris inside the car? What is your reply to that?

A:Its really funny, people seem to have this perception that belt driven cars will skip belts. In some case, they are correct, that is if you are using the wrong pulleys , too little belt tension or the wrong pitch belts. The width of the belt also plays into that. Offroad cars are not onroad cars and you can not have the same super free transmission. You have to have tension on the belts, and there can not be as much deflection as you would use in eptc. With the jumps, uneven terrain and all the other variables, picking the right pulleys, pitch and belt width are extremely critical. In the case of our car, our smallest pulley is 20t, the belt is 3mm pitch and they are 4 plus mm wide. I have been running the same belts now for 3 months and they are still in remarkable shape. As for the debris, that also is not an issue. When I design the bodies for the cars, they are a perfect fit so that you can use the clips and no additional debris will get in the car than necessary. Any of our current customers will attest to that. Aside from that, the front belt is 100% enclosed and the rear belt is elevated off the chassis and partly covered. Even if you did have an issue with the rear belt, you can actually change that in less than 2 minutes time. I did not actually time it, you probably can do it in less than a minute if you are really in a bind. Its that simple.. In my opinion, being belt, or the worry of wearing out belts, itís a past time.

Q: Which batteries fit the SRX-4?

A: You have to use saddle pack batteries with the SRX-4. A variety of brands fit in there, if not most. A shorty can be fitted, but requires some mods by the driver.

Q: Why did you choose to use a carbon chassis and will there be other options?

A: I actually like the Carbon chassis as it allows me more options with weight. Its lighter, so if I wanted to add weight it opens up freedoms for me. Other than that we will offer an aluminum light weight chassis that customers can use.

Q: how do the slipper, clicker and diffs work together?

A: The slipper,clicker and diffs are actually all three different entities all together. We have a couple of different slipper options..1 you have a thrust driven slipper, which basically is an improved gear diff concept in my opinion. With the thrust driven slipper, you can control the amount of power to the front wheels with a spring and slipper pads. It does not change during the run or if it gets hot or cold. Its an extremely consistent concept. A gear diff center for instance, will start off thick, and by the end of your run will be thin, so you have to account for that. Having your fluid viscosity change through your run is never a good thing. The second slipper choice would be our full time 4wd option, where the front and rear wheels are connected. The slipper then works like a normal 2wd. The slipper controls both wheels. The clicker, now, that is more like an adjustable front one way. The idea behind it is you can control the breaking bias as well as it allows the drivetrain to be separated during cornering. It actually can serve two purposes there. We have 3 spring options and we also have a locker to lock it out. Finally the diffs in the SRX-4 are both gear diff, but we also have ball diffs too. I think gear diffs are more suited for higher grip whereas I like ball diffs in lower grip. Everyone though has their opinions of that. We have some other options as well, that include overdrive and a front one way differential. Either way, all the parts are the same as the Srx-2 rm and mm. So you can reuse and share most if not all the parts. We have pretty much every base you could cover, coveredÖ?

Q: are the wheels industry standard in offset and size?

A: The rear wheels are industry offset and size. They are also the same ones you would use from your Srx-2 rm or mm buggies. As for the front, when I redesigned all the front end geometry, which is very unique and different than the other cars, I wanted to have the wheels look the same as the rear. There is something about having a car that is uniform that is very appealing to me. In doing this, it also will allow us if we ever had to(etc. world championships) we can adapt any other brand of wheel to our car. The spindle design and offset are in our favor. So, our front wheels are specific to our car,but with a couple optional parts, anything other brands wheels can be made to fit. We are also making 61mm wheels for our 1/10 buggies.

Q: Will the car come with a ball differential or gear differential?

A: The car is slated to come with Gear differentials as standard equipment.

Q: What is the approx ready to race weight when using saddle packs?

A: The car ready to race is in the high 1700ís. I would say the weight is comparable to some of the other cars even using a shorty.

Q: The low, narrow body makes it look like a 2wd almost , is that intentional, and what about fitting a fan and electronics?

A: One of the main ideas when I was designing the car was to make them look almost identical. So many of the cars these days look like shoe boxís.. When you go from your 2wd to your 4wd, the appearance is quite different. I wanted to eliminate that for all the Serpent customers. Give them something that was or seemed like the same car. I think that goal was achieve quite nicely and it really sets our cars appearance apart from the rest of the cars. I have added scoops for ducting air into the motor and also I have improved the area around the speed control to allow most if not all speedos to have a fan installed.

Q: Did you try to run the car as 2wd as well, and if yes whats the feeling and performance?

A: I actually have not tried it yet. When I designed this car, I had a plan to spin the design off a few different ways. I designed many of the parts to be able to attach to different chassis so that making more cars out of this design would be really easy for me to do. The design is very modular capable. I simply have not had as much time as I would have like to start tinkering with ideas on this project.

Q: Does the 4wd buggy share many parts with the 2wd car?

A: I would say about 50% or more of the parts are carried over from the 2wd. This car is probably one of the cheapest entirely new cars we have actually ever made. Thanks to being able to carry over so many parts.

Q: Will you run the 4wd at some bigger events in near future?

A: I plan to attend as many races as I can. I have other responsibilities though at work that can make that really tough on me. I try my best to prioritize work and racing. I will most likely attend the nationals, an EOS race and the world championships later this year. I am sure there are other events in between, but those are the major ones I would like to be at.

Q: Now that the 4wd design is finished, what is your next project?

A: Right now, I am working on a new 1.8th Nitro buggy for release early 2016. I have only had the chance to update our old car a couple times. However, I have never had the chance to take everything I have learned the last 6 or more years and apply it to something I could call new. I really want to turn the market upside down, with something that every customer would want to race. I also want to make a product that can bear the Serpent brand name, and have the respect of all the other industry partners. I am very excited about what I have so far, and I think all of our racers, future racers and customers will be overjoyed with what Iím going to bring to the table. Its going to be a contender straight out of the box..:)

Thanks for the answers !

Team Serpent

|