|

- Team Losi Racing 22 2.0 - Review -

TEXT BY AARON WALDRON

PHOTOS BY JOEL NAVARRO

The bar to measure the success of Team Losi Racing’s new 22 2.0 buggy was set almost unrealistically high before the car ever existed – its predecessor, the TLR 22, won the prestigious Reedy Race of Champions and ROAR National Championship in its first year – but the TLR engineers and race team drivers started searching for ways to refine the vehicle’s on-track prowess and overall user experience the day the original car was released. Hours of testing on a wide variety of tracks, taking meticulous notes that accounted for the feedback of both team drivers and customers, and creating new prototype parts in order to learn more about the potential direction of a refined model led to the race-winning 22 being replaced after two seasons at the top of its game. In the summer leading up to the IFMAR Worlds, TLR chose to unveil the new buggy at an event pitting the fastest racers in the country against one another and was rewarded immediately, as Dakotah Phend won the ROAR National Championship in the car’s debut. How well do the changes trickle down to the local level?

INCLUDED UPGRADES AND REFINEMENTS

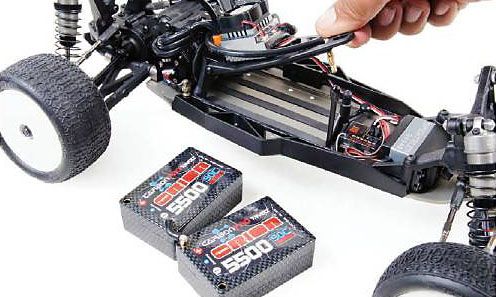

Removing the transmission no longer requires dismantling the rear suspension, as the forward rear pivot is now secured to the chassis using a tiny flathead screw. The Velcro battery straps of the original 22 are replaced by a hard brace that holds the battery more securely and makes for easier installation of a saddle pack. The brace also holds the front foam spacer in place for a wider range of adjustment. Additional hop-ups used by TLR team drivers that were previously sold as an optional parts are now included, such as aluminum ball stud spacers, aluminum clamping rear hexes, aluminum front pivot, aluminum rear camber block, 3.0 degree LRC (low roll center) rear toe plate, serrated wheel nuts, and threaded kingpins and rear outer hinge pins. The hinge pins and shock shafts are finished with titanium-carbonitride, which was first seen on the 8IGHT 3.0 and is said to be smoother and more durable than TLR’s previous titanium-nitride treatment. Like the original 22, a full set of both yellow and white wheels are included, while a new and more symmetrical body, with more clearance for saddle pack batteries and the buggy’s rear body clips, is matched by a new 6.5-inch wide Medium Downforce wing. The wing is made of thicker Lexan with raised end plates for extra tire clearance.

Removing and inserting the battery is much easier with this battery bar than the Velcro straps of the 2.0’s predecessor.

DRIVETRAIN UPDATES

Many racers had their favorite differential parts that they used to replace the original 22’s internals, sourcing the hardware from aftermarket manufacturers and other vehicles alike. TLR now includes tungsten carbide balls for the diff and thrust assemblies, diff rings with a larger outer diameter and a tumbled finish, thrust washers that have been heat treated, and a Gen II one-piece diff nut. The diff gear has extra centering pins, and the outdrives have a flatter diff ring surface thanks to being machined after the heat-treating process. Those new outdrives key into CV-style drive shafts with new axles that can be adjusted to change their offset: removing a 1mm spacer pushes the axle farther into the hub, which reduces the drive shafts’ support of the rear suspension and increases forward traction. Finally, an all-new Heavy Duty Slipper (HDS) uses larger octagonal pads that increase the surface area between the pads and plates for more consistency and a higher adjustment resolution. While the new pads will fit the included 78-tooth spur gear used for modified racing, the included set of older-style pads must be used if installing the smaller 70-tooth spur gear. This is necessary in order to obtain the proper gear ratio for 17.5-spec class competition.

The 2.0’s adjustable-offset axles are a go-to adjustment for loose conditions.

The new HDS slipper is better equipped for modified class horsepower.

SECOND GENERATION SHOCKS

TLR’s new Gen II 12mm front and rear shocks are made entirely of machined components for improved fit and finish. The bladders of the original 22’s dampers are gone in favor of bleeder caps, which the TLR team drivers favored in all conditions, and new X-ring seals lessen the chance of oil leaks and reduce friction on the new titanium-carbonitride shock shafts. TLR’s previously optional low-frequency springs are now used in the front and rear.

The 2.0’s dampers benefit from updates that enhance build quality, durability, and performance.

REVISED FRONT SUSPENSION

Giving a 2WD racing buggy an ample amount of steering while still maintaining stability is a tall order, and one of the most monumental changes to the 2.0 is in the front suspension geometry. Redesigned front caster blocks and spindles feature less scrub offset (the distance from the kingpin to the wheel), the front axle itself trails the kingpin by 4mm, and there’s a new outer camber link position that allows for an extra tuning option. The steering rack is also new, with ball studs that are horizontal to the plane of the kickup rather than vertically mounted so that Ackerman adjustments can be made by adding or removing spacers. The ball studs themselves are mounted 2mm higher, which allows for the front end to be built with zero bump steer, and the ball cups used for the steering servo link are now an open design, which increases clearance when a low-profile servo is installed.

The new steering rack provides better alignment for the whole linkage for smoother response.

Small changes to the geometry of the front caster blocks pay huge dividends in drivability.

+

Easier to drive hard and turn faster lap times

Added hop-ups provide additional value

Additional options allow for finer tuning

Requires less maintenance and is easier to work on

-

Doesn’t include TLR’s new cab-forward body

SOURCES

Fatty Grafx

Pro-Line Racing

Spektrum

Team Losi Racing

Team Orion

VEHICLE SPECS

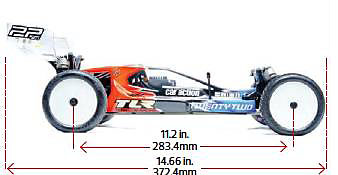

Type: Electric 2WD buggy kit

Item no.: TLR03002

Scale: 1/10

Price*: $350

Width: 9.6 in. (245mm)

Height: 7.87 in. (200mm)

Ground clearance: .95 in. (24mm)

Length: 14.66 in. (372.4mm)

Wheelbase: 11.2 in. (283.4mm)

Weight, as tested: 3 lb. 11.7 oz. (1,692g)

Chassis: Hard-anodized machined aluminum plate

SUSPENSION

Type: Lower H-arm with upper camber link

Inboard camber link positions (F/R): 2/2

Outboard camber link positions (F/R): 3/4

Shock positions, towers (F/R): 3/3

Shock positions, arms (F/R): 2/3

Shocks: Threaded aluminum coilover shocks

DRIVETRAIN

Type/ratio: Three-gear transmission/2.43:1

Spur gear/pinion: 78/not included

Slipper clutch: Adjustable dual-disk slipper

Differential: Adjustable ball differential

Driveshafts: CV-style

Bearings: Rubber-sealed

WHEELS & TIRES

Wheels: TLR dish wheels (full set each of yellow and white included)

Tires: None

Body: TLR 22 2.0 body and medium downforce wing included (painted by Fatty Grafx)

When testing TLR’s newest factory ride, why not use factory-level gear? Spektrum’s DX3R Pro and S6040 servo work together flawlessly, as do the Team Orion combo of Vortex R10 Pro speed control, VST2 Pro 8.5 motor, and Carbon Pro saddle pack.

TEST GEAR (NOT INCLUDED)

Transmitter: Spektrum DX3R Pro 2.4GHz (Part no. SPM3200, $270)

Receiver: Spektrum SR3100 DSM2 3-channel receiver (Part no. SPMSR3100, $70)

Speed control: Team Orion Vortex R10 Pro Brushless ESC 160A (Part no. ORI65102, $210)

Motor: Team Orion Vortex VST 2 Pro Brushless Motor 8.5T (Part no. ORI28260, $140)

Steering servo: Spektrum S6040 Digital High-Speed (Part no. SPMSS6040, $70)

Battery: Team Orion 2S “Carbon Pro” 7.4V 5500mAh 90C LiPo Saddle Pack with Tubes (Part no. ORI14048, $115)

Tires (F/R): Pro-Line ION Front 2WD tires, MC compound (Part no. 8224-17, $13)/Pro-Line ION 2.2” Rear tires, MC compound (#8222-17)

*Varies by dealer

CRASH COURSE - WHAT’S A WICKERBILL?

The new rear wing on the 22 2.0 has three different trim lines along its rear surface that set the height of the vertical flap at the back of the wing, known as a wickerbill or Gurney flap. While not a true gurney flap because it’s not completely perpendicular to the pressure surface of the wing, the wickerbill creates additional downforce that can pay huge dividends on loose track surfaces and also make the car easier to drive in any condition. A taller wickerbill will create more grip, while trimming it shorter will give the buggy more steering and a smoother drive. Because it’s only possible to trim the wing shorter rather than add to it, many racers will keep a spare wing or two with different wicker bill heights as tuning options.

BEHIND THE WHEEL

I decided to build our test buggy in mid-motor configuration, which has been all the rage in 2WD buggy racing over the last year, and I was eager to head to SDRC Raceway to see how it worked. The first words I uttered to myself during my first test-drive with the TLR 22 2.0, while jubilantly positive, are not fit for print in this magazine. I drove an original 22 as my personal race car for a long time and never felt as comfortable driving it at the limit as I did by the end of the first battery pack with the new 2.0. It carved through the track’s many tricky cornering sections with corner speed that felt almost like an on-road car, rewarding me for sweeping through the apex and picking up the throttle early for more speed toward the next corner – it felt like the longer I drove, the faster I was going. The 2.0 turned in smoothly but with razor-sharp accuracy, stepped out of line only when commanded, and launched toward the following obstacle like a house cat chasing a laser pointer. The buggy’s wide stance and almost undetectable weight transfer of the narrow chassis made it look as though the car was simply unfazed by anything going on beneath it, simply breezing through each lap like I was Dustin Evans on a TQ run. It took just a few laps for me to pinpoint the center tabletop, which had a step-down landing that could be cleared in one leap, as my favorite section of the track. I could clench the trigger exiting the preceding 180, and the car would glide off of the takeoff, stay flat, and settle smoothly on the backside as though it was a Boeing airliner on autopilot. The buggy’s long-arm suspension molded compliantly over every elevation change and bump without influencing the car’s direction, making the track feel relatively flat as I sped from corner to corner. Not even the track’s final double-double section, which seemed to kick the cars and trucks in every class at a weird angle, tripped up the 22 2.0 – it just soaked up the landing and begged for me to get back on the throttle.

FINAL WORD

From radio control to Formula One cars, one thing is constant across all forms of motorsport – those who quit looking for an advantage not only struggle to keep up, they get left behind. The track record of the original TLR 22 showed its potential to be competitive in any environment, but that didn’t stop the engineers and team drivers from looking for ways to make the buggy easier to both drive and maintain – and it worked. Research and development, after all, are fueled by the spirit of racing and the drive to keep improving. In an industry where relatively few sport-level vehicles ever see radical changes throughout their production run, the new TLR 22 2.0 is the benefactor of several revisions that enhance its performance in every aspect, from the racetrack to the pit table.

Source:

|