|

Ticks a lot of boxes for me:

- It's a kit

- A 4wd that takes stick packs

- Clever motor mount

- Compatible with a lot of the D4 drivetrain.

A few negatives:

- No slipper

- Rear wheels use regular dogbones

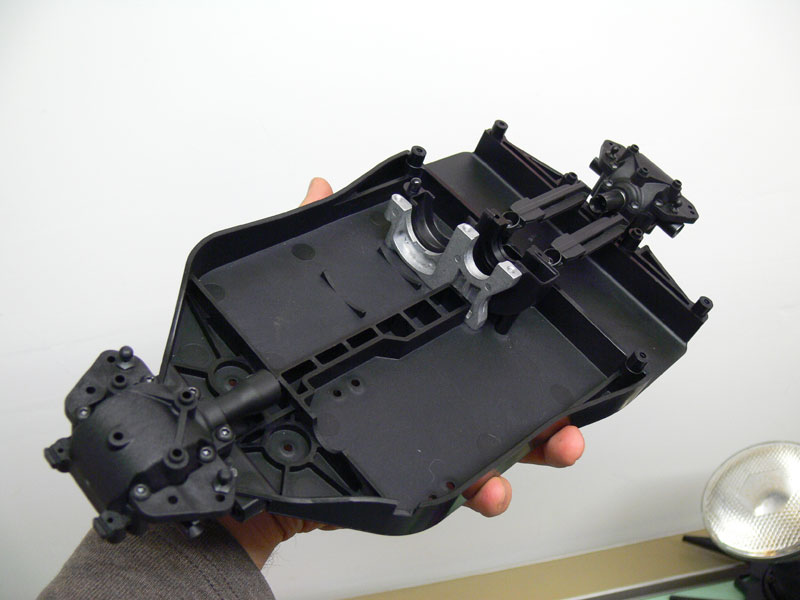

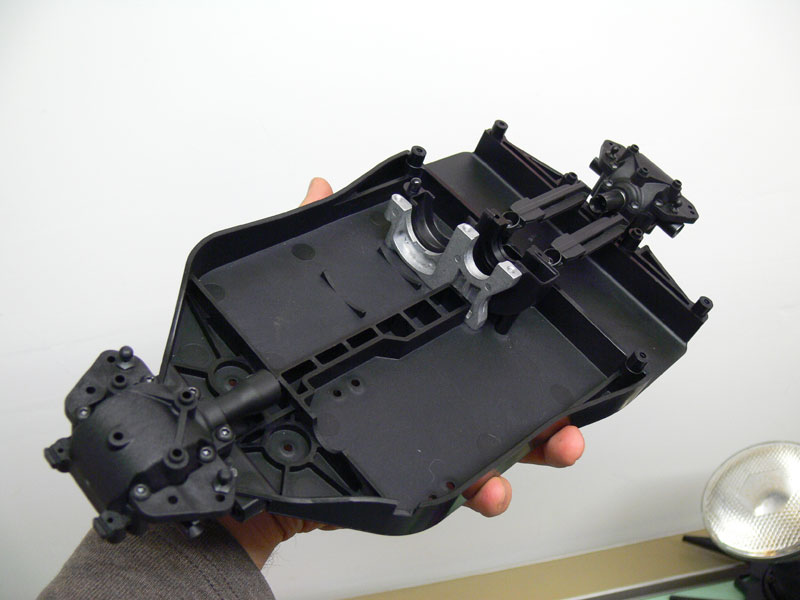

First impressions are the

plastic parts are of excellent quality. The chassis is well moulded,

very flat with no extreme flashing.

Can't really comment on how well it goes just yet. Need to build it

first.

In regards to cost, once you add a set of rear CVD's, slipper, titanium

turnbuckles and metal shocks, it's about the same cost as a B44.

In regards to building CVD's are there any tricks to stop the pins from

falling out? The manual suggests using rubber cement. Any other

solutions that have proven to work?

DAY 1

Up to page 17 now. Only one real surprise so far - no bearings were

included for the diffs, only bushings.

Also lost an e-clip while working on the front gearbox. Would've been

nice to have a spare or two.

Wondering whether I should apply diff lube to all the dogbones as per

the manual. In my experience, this just gathers dirt and causes more

damage.

Found a few good ideas on CVD's. Best solution I like so far is adding a

few layers of heatshrink over the CVDs. Thinking of doing this in

addition to threadlocking the pins in place.

DAY 2

Now up to page 21/34. Just finished building my first set of CVD's.

Fiddly little things.

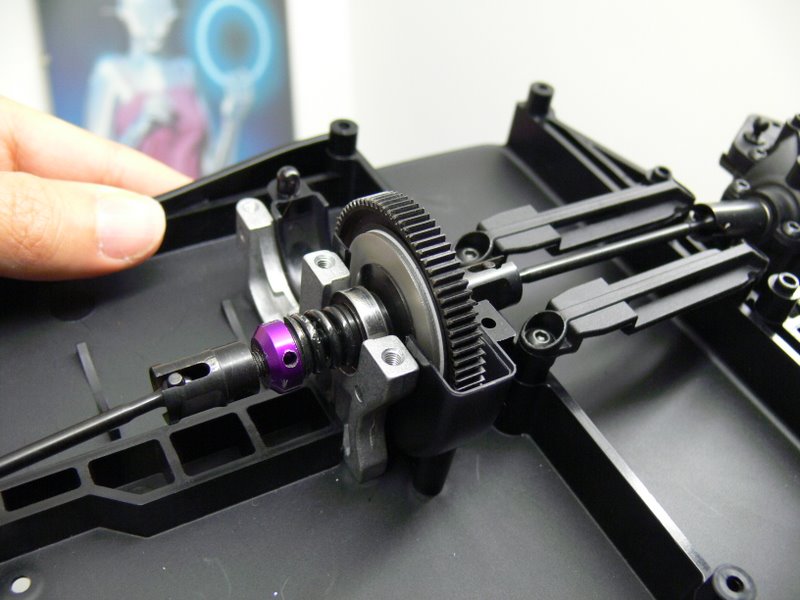

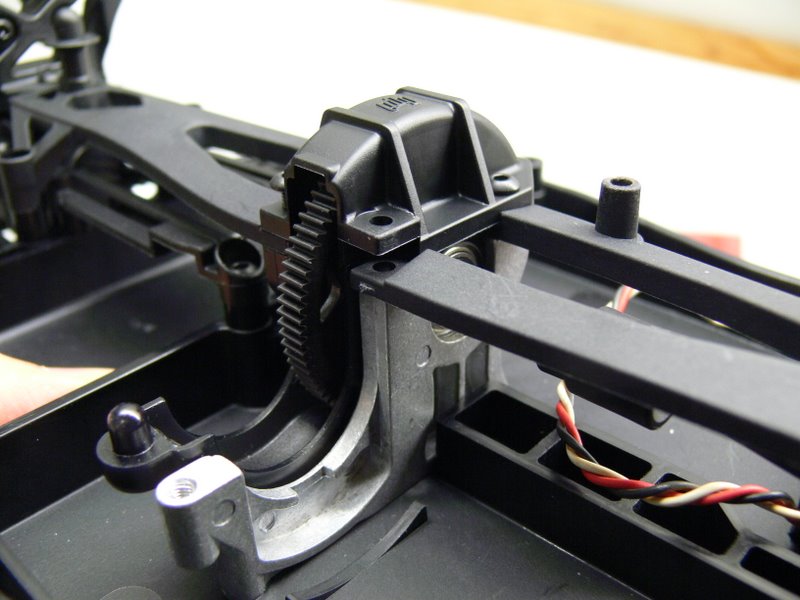

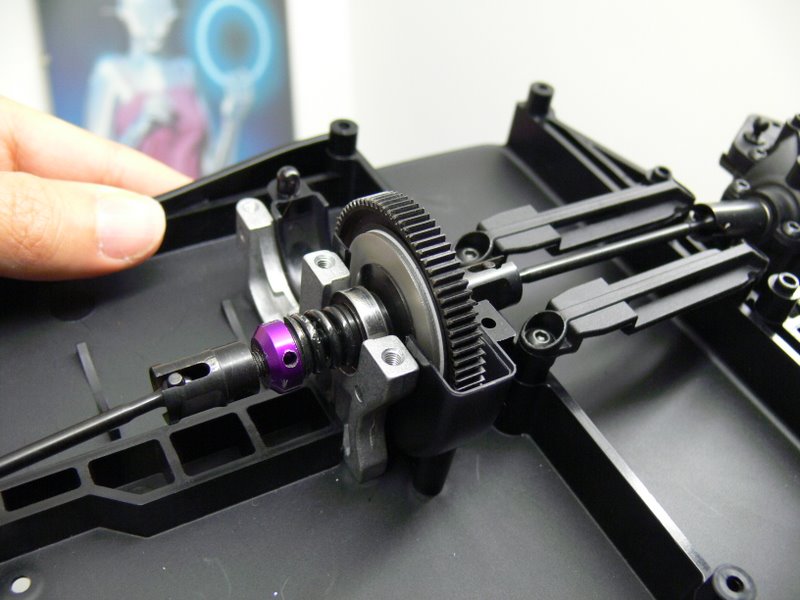

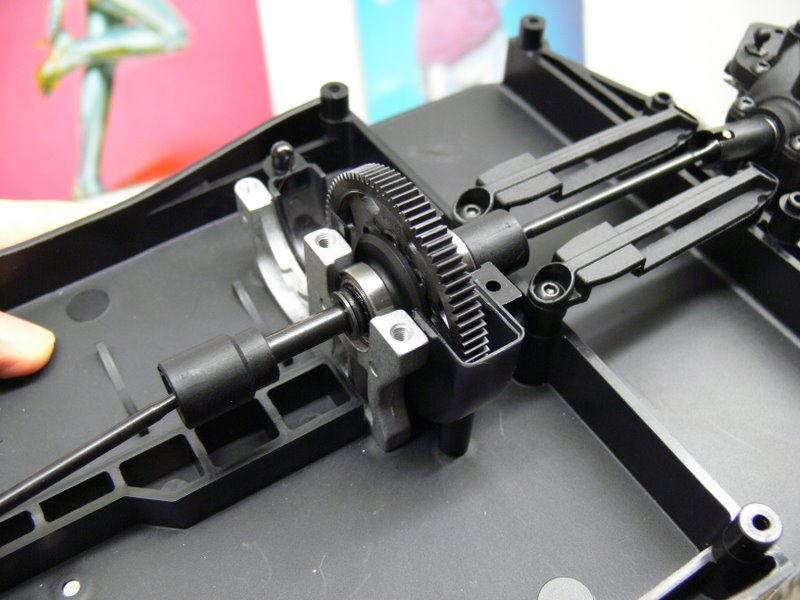

The buggy now has an enclosed spur gear cover, top deck, shock towers

and steering rack. Unlike the D4, there are no ball bearings in the

steering rack. Plastic spacers are used instead.

Also did a test fit of a D4 WCE slipper. Happy to confirm it is a drop

in replacement. Looks like the D4 aluminium CVD central drive shafts

from the D4 will also fit if you change the ends of the gearbox.

When building new CVD's, is it normal for them to 'catch' while rotating

by hand? Do they go through a break in period and eventually smooth out?

DAY 3

Midnight and my hands are raw from attaching turnbuckles to ball cups.

The turnbuckles themselves are the same thickness as their D4

counterpart, 3mm, but made of steel as opposed to titanium. They are

tastefully black in colour, much like the rest of the chassis.

A nice bonus was the inclusion of 1 degree rear hubs and 13 degree front

hubs. These are in addition to the 0 degree rear and 10 degree front

hubs which the manual suggests to use.

Hub pins are captured with a small screw on either side of the arm with

the top of the screw partially blocking the hole. Personally, I'd feel

more comfortable with a washer in there but it seems to do the job.

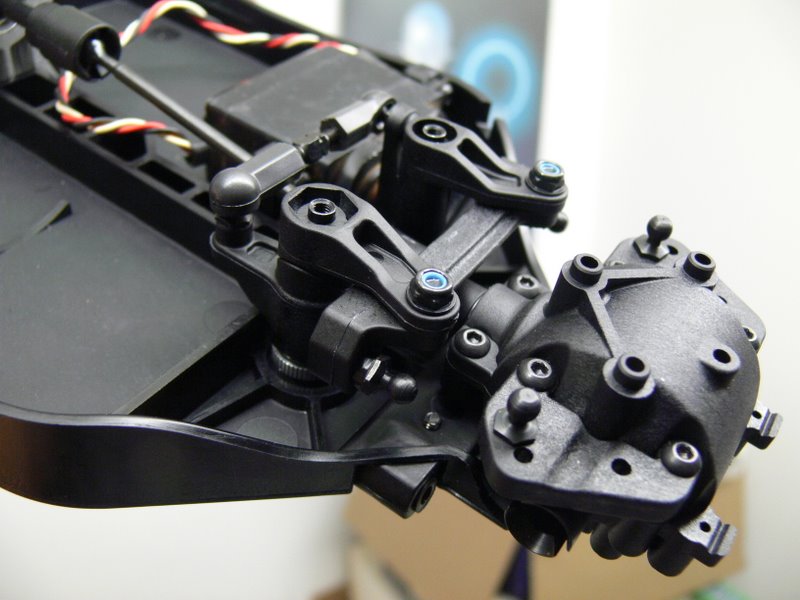

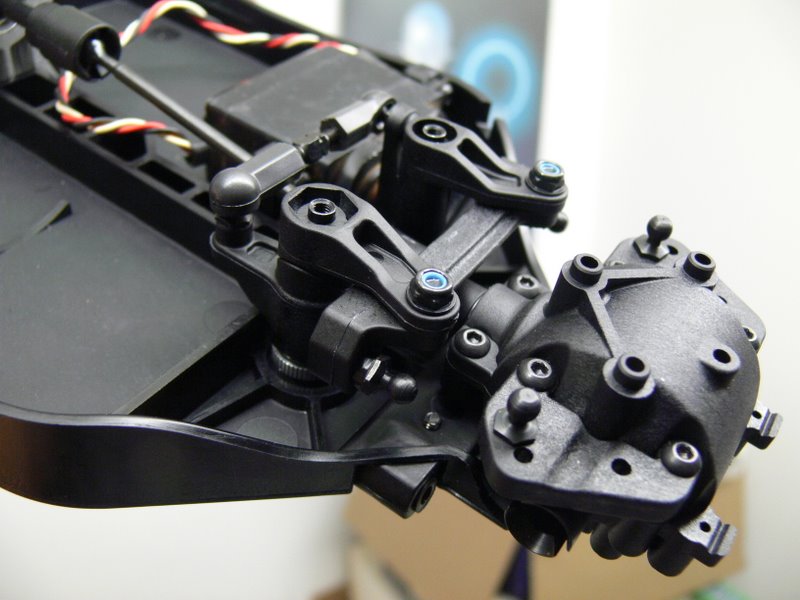

Would have been nice if the front bumper were slightly taller, similar

to the D4 WCE (which is not a direct fit to the Cyber 10b). There are

two points on the gearbox it could push against which I think would

better distribute the force of an impact a little better.

Tomorrow should be a productive day being the start of the weekend. High

on the agenda is to hunt down 'rubber cement'. I'm getting paranoid of

pins flying in all directions. If I can find some CVD rebuild kits

locally, might also have a stab at installing the D4 central drive

shafts along with the WCE slipper.

DAY 4

Completed the chassis this afternoon. I did cheat and used some metal

shocks from the D4. The Cyber shocks are indeed plastic replicas, right

down to the eyelets. The only noticeable different is the use of e-clips

to hold the piston as opposed to a small screw.

While I can understand the use of plastic shocks in an entry-level kit,

using plastic nuts to hold the shocks to the tower is disappointing.

They take the brunt of the impact when you land the car upside down and

I can imagine them quickly grinding away.

Now it's time for some upgrades. I dremelled a small pit in the CVD pins

as per the instructions

here in a bid to stop the pins from flying out. Also swapped the

stock rear dogbones for some D4 CVDs.

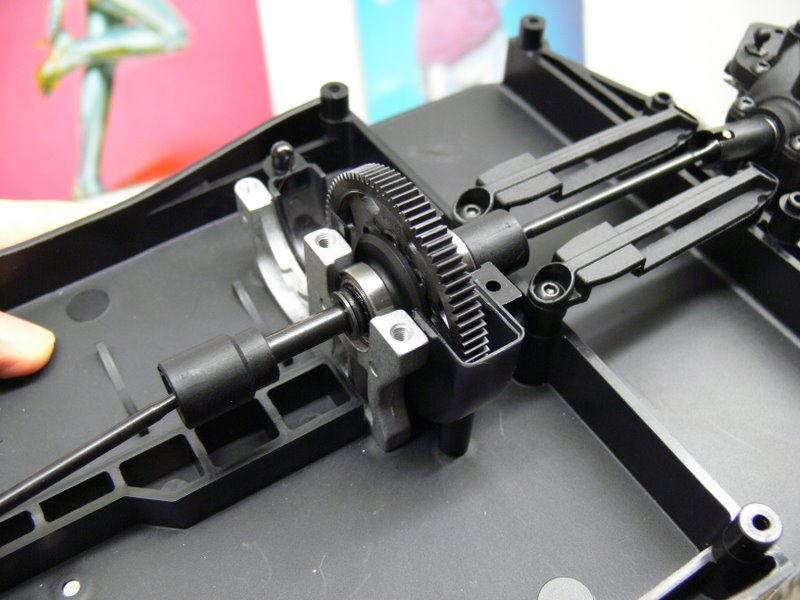

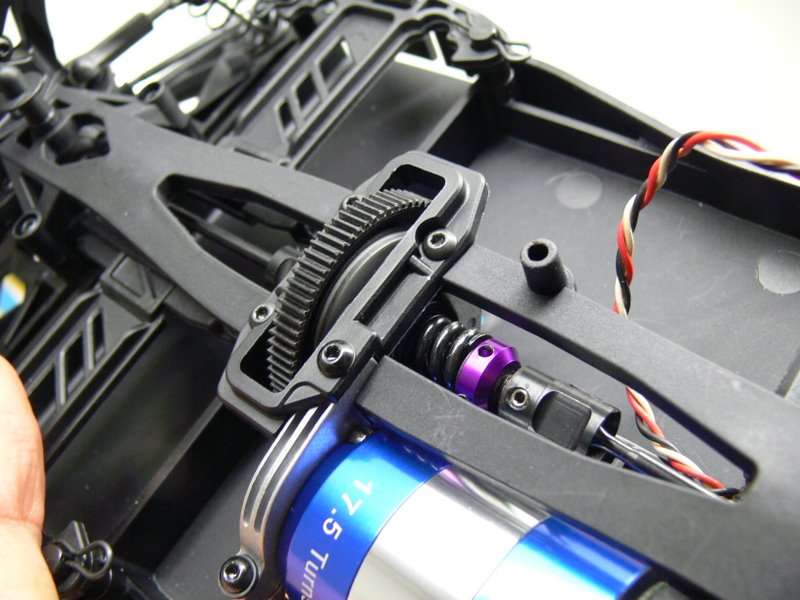

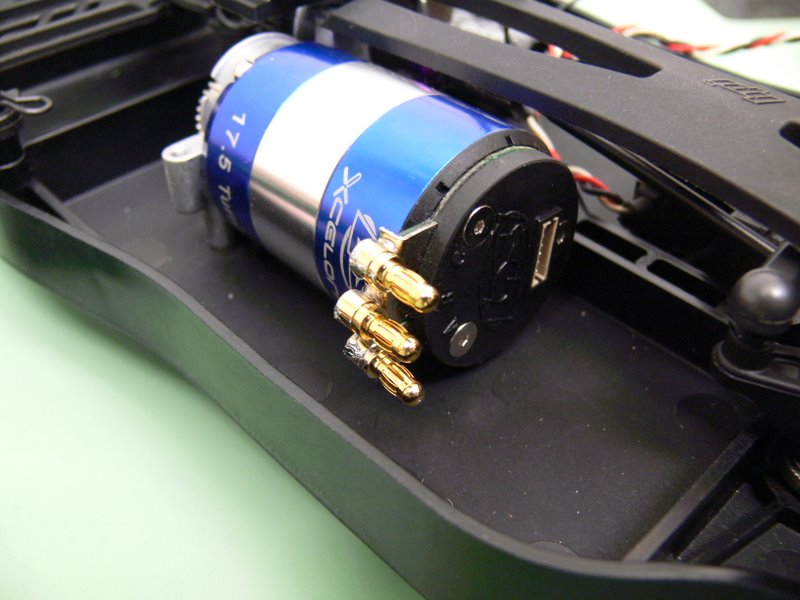

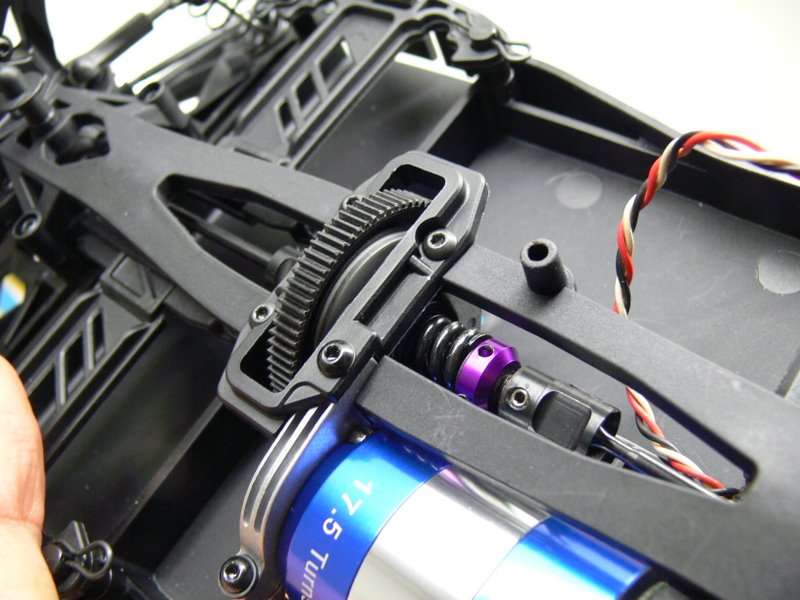

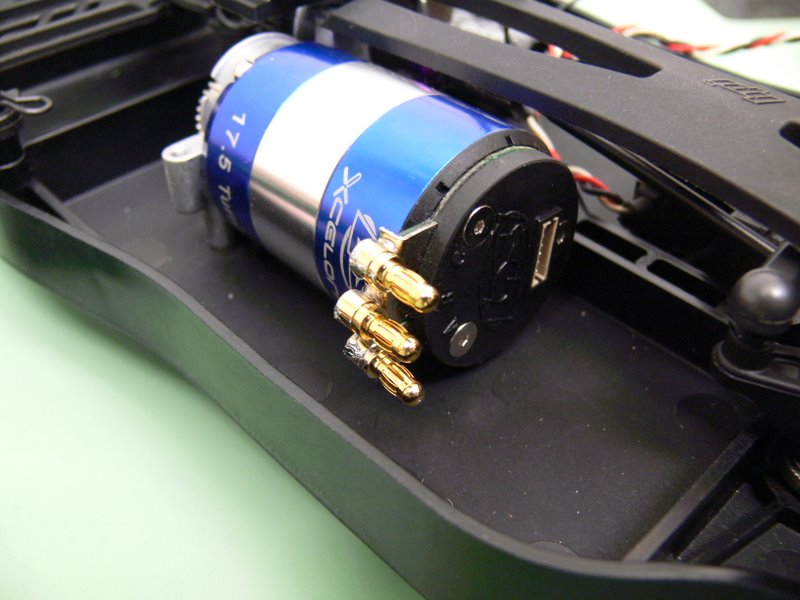

I intend to race in 4wd stock so changed the spur to 80t. Powering the

car is a Losi Xcelorin 17.5 which I have been very happy with in 2wd

stock. I also added in a D4 WCE slipper which is an easy drop in

replacement. After much though, I removed the enclosed gear cover and

opted to leave everything exposed for easier inspection. I found the

inspection hatch to difficult to open and close. Since the car will only

be used on the track, I figured debris would not be a large issue for

me.

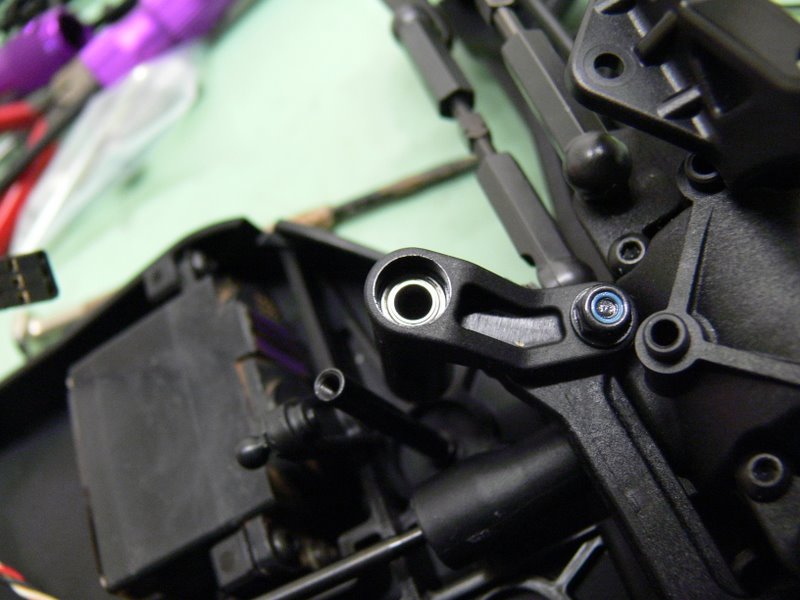

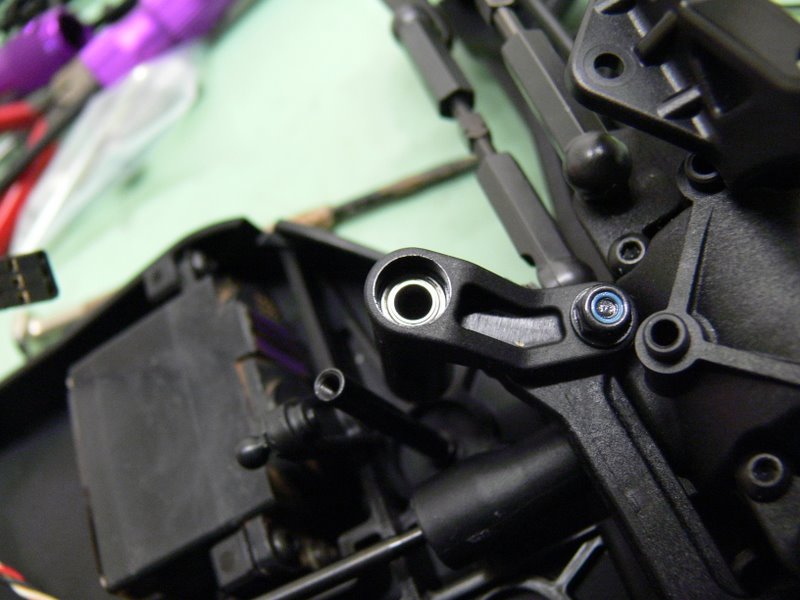

Finally added 4x ball bearings to the steering rack, replacing the stock

plastic bushings. To be honest, it doesn't feel any different. I think

everything is still a little stiff because it's new.

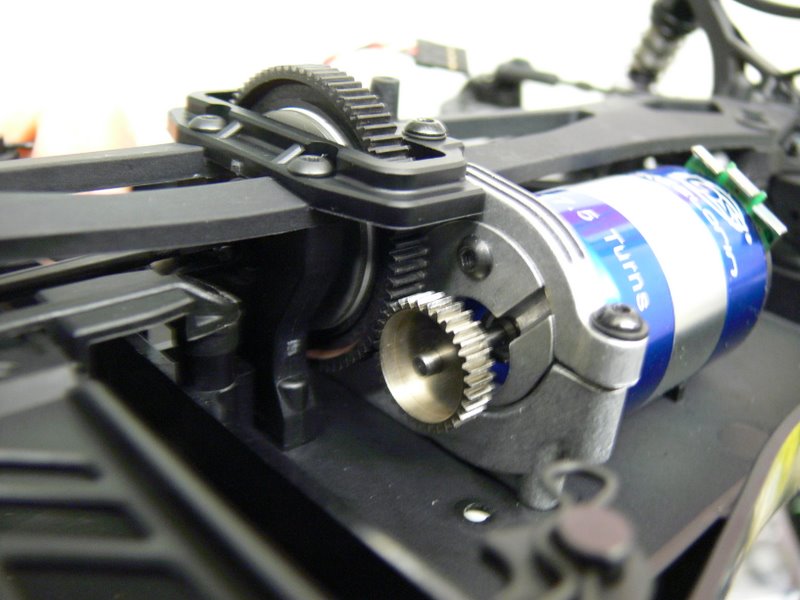

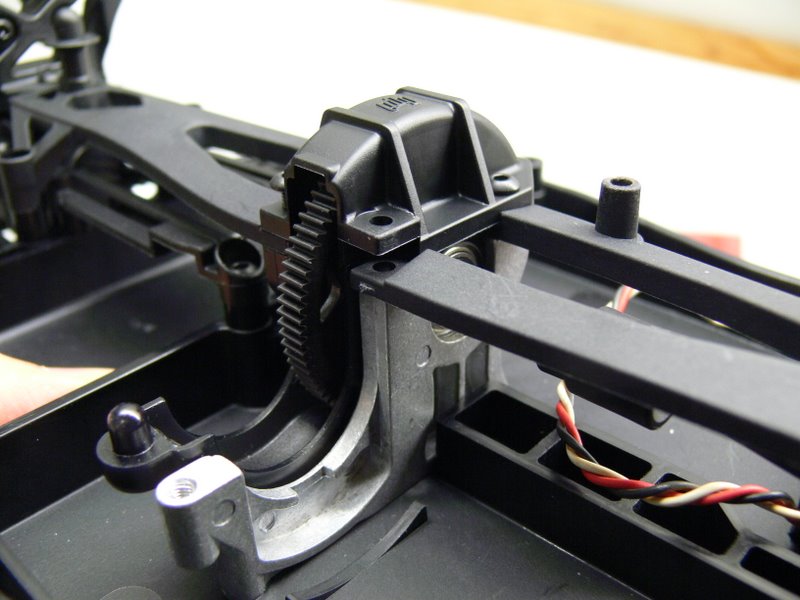

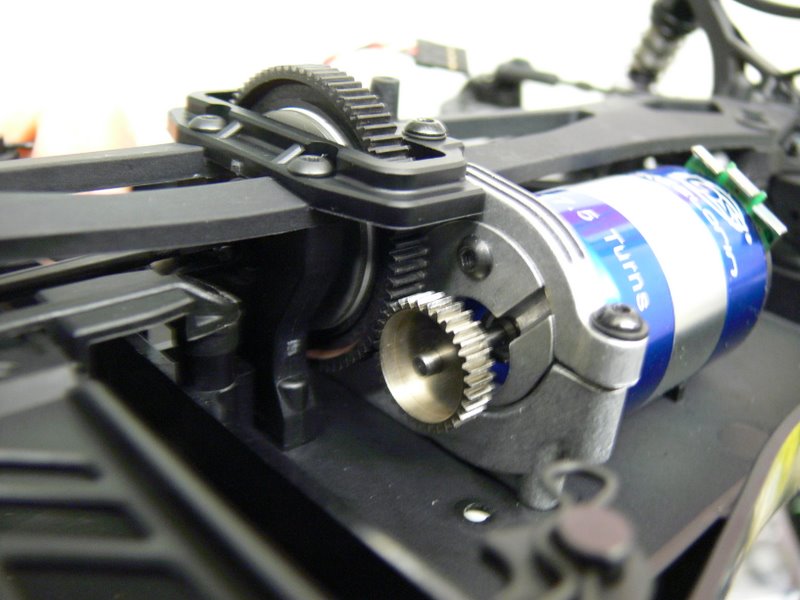

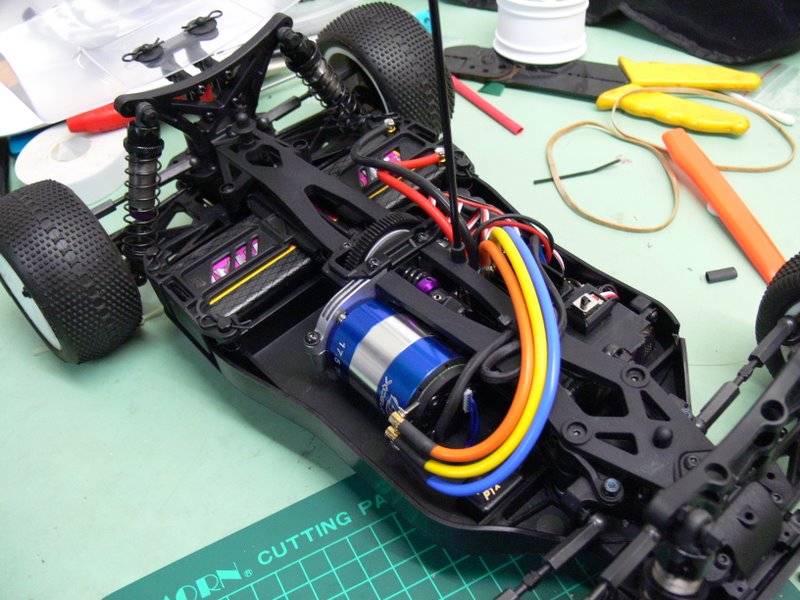

The motor mount mechanism is simply brilliant. The motor sits inside a

bracket which swivels to adjust the distance between the pinion and the

spur. All you need to do is loosen a screw to get very fine and accurate

motor distance adjustment. Once you're happy, simply tighten the screw.

No need to remove battery posts or poke a long hex driver from the back

of the car.

Next step is to cut out the body and plan the electronics layout.

I must admit I might be

wrong about the shock nuts. At the club day yesterday, I noticed all the

FT B44's used plastic nuts. The theory goes that if the shock tower

breaks, the nuts strip right off, minimising damage to the shocks.

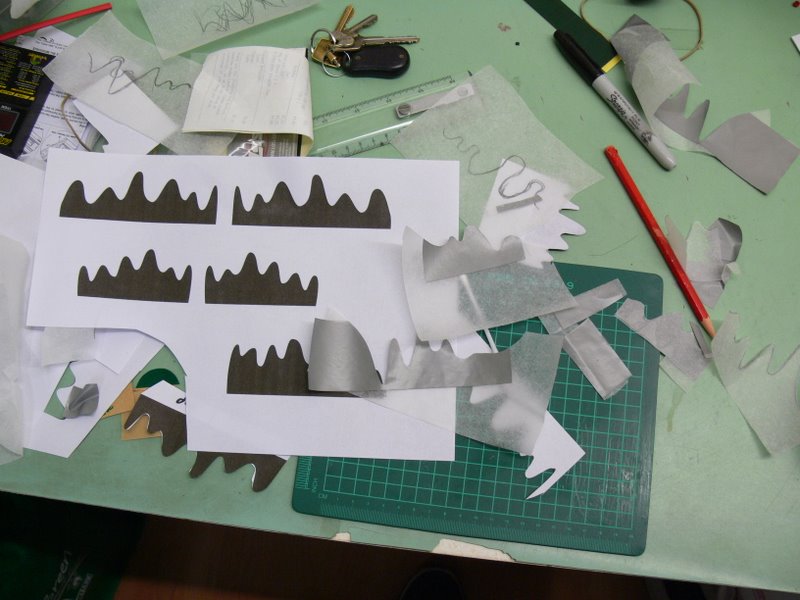

DAY 5

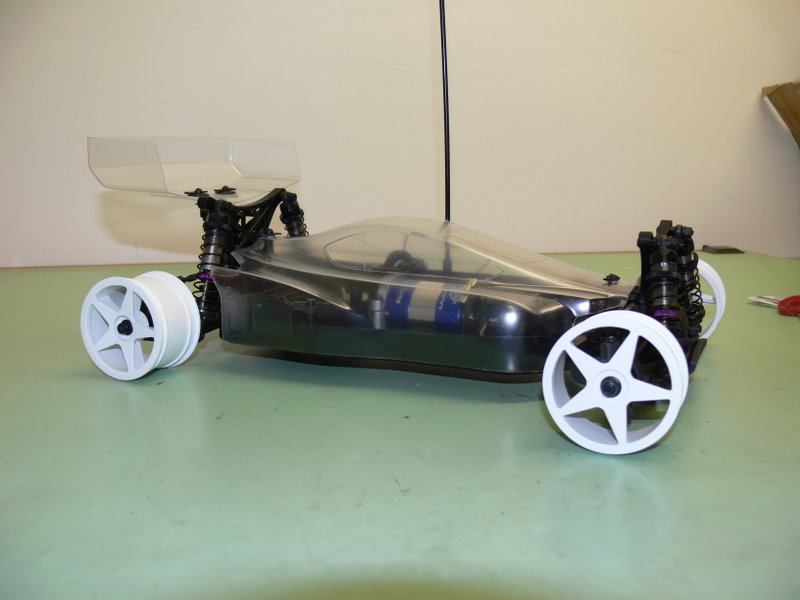

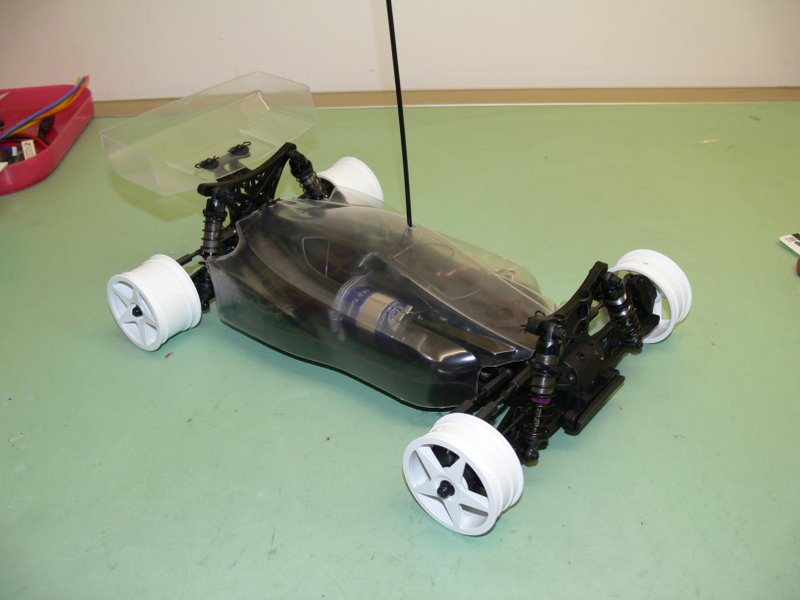

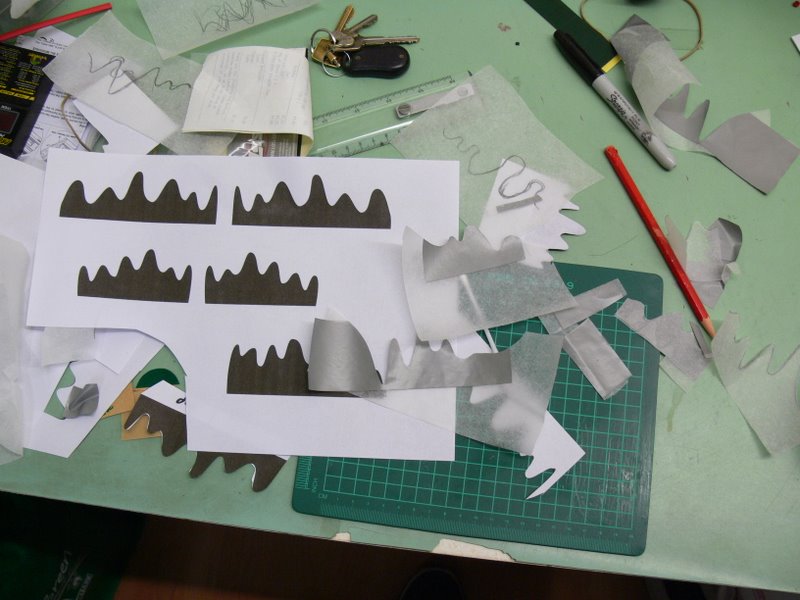

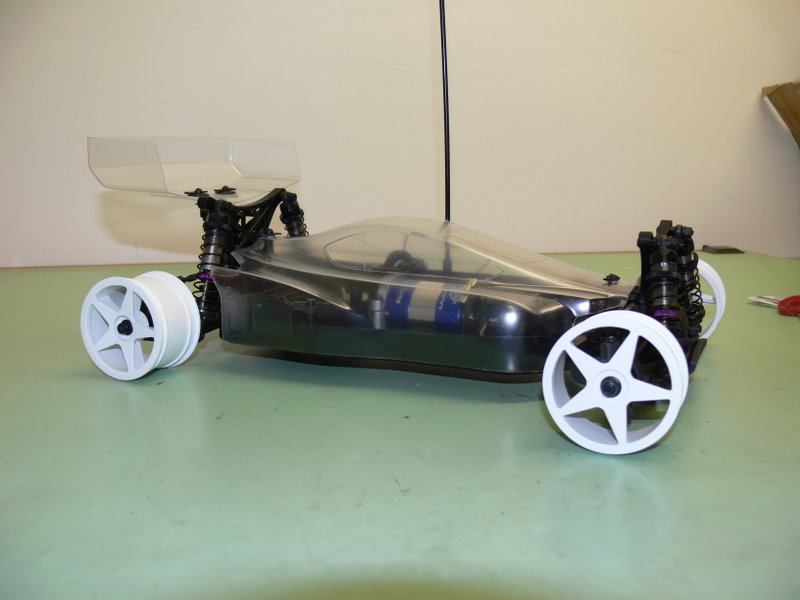

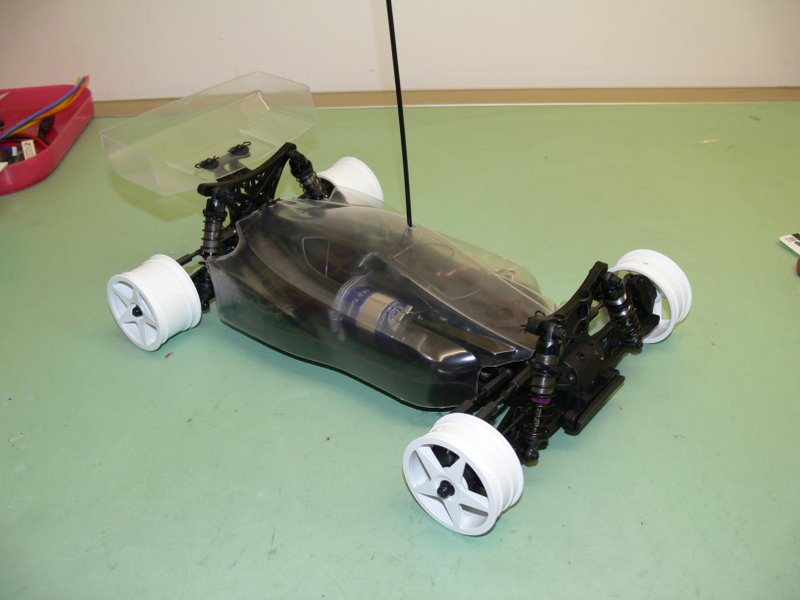

Cut out of the body and wing on Sunday night while watching Eurovision.

HPI must have intentionally designed the body to be easy and straight

forward for a beginner to cut out. Lots of straight lines with all

corners long and smooth. There are no tricky tight corners at all to

worry about.

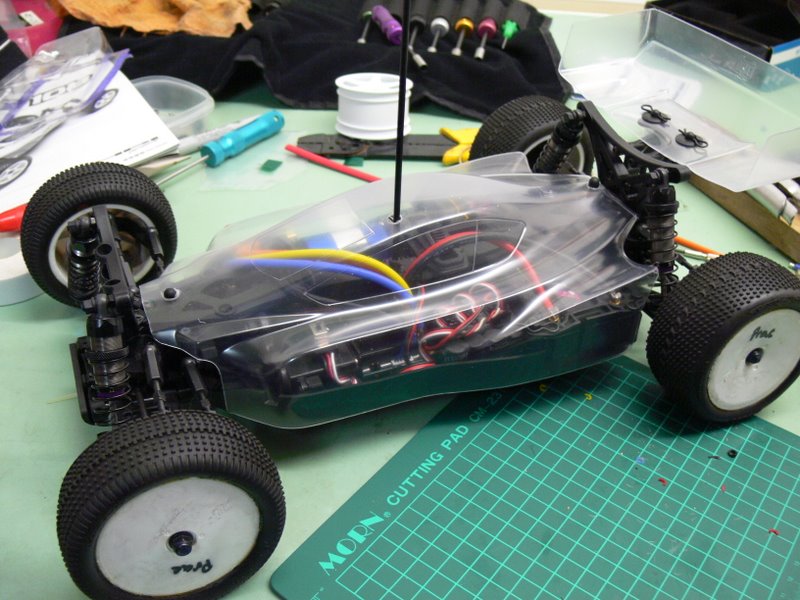

With the body now fitted, I've started planning the layout of the

electronics. Compared to the D4, the chassis is roomy which is not

surprising. The cyber 10b chassis is wider and requires less space for

the battery because most of it is under the shaft. I think fitting a

motor heatsink is going to be a challenge. The body kind of wraps around

the motor leaving little room.

My receiver is too tall to fit in front of the motor (it interferes with

the steering rack) so it looks like it'll be position either behind the

servo or behind the lipo.

I have always liked to have a completely detachable motor and

traditionall used deans plugs. Trying something different this time

round and soldering 3.5mm bullet connectors directly to the motor's

solder tabs.

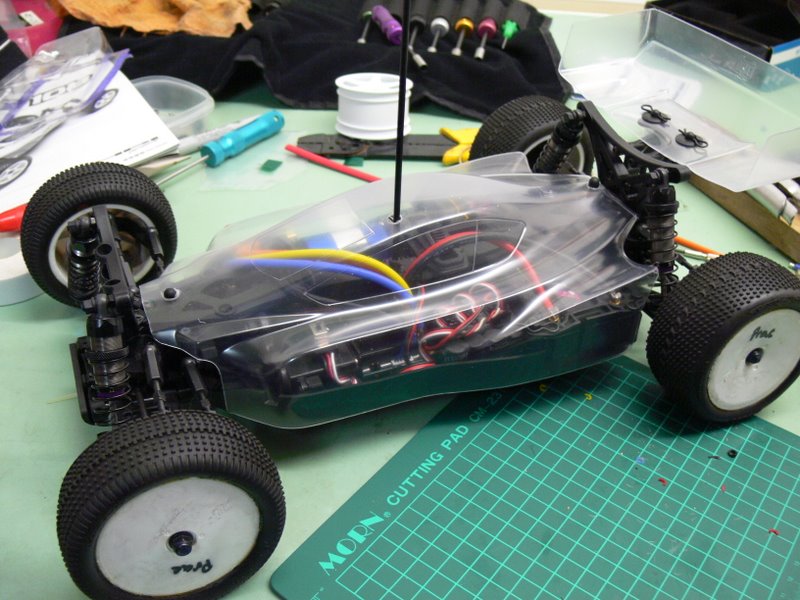

DAY 6

It's alive

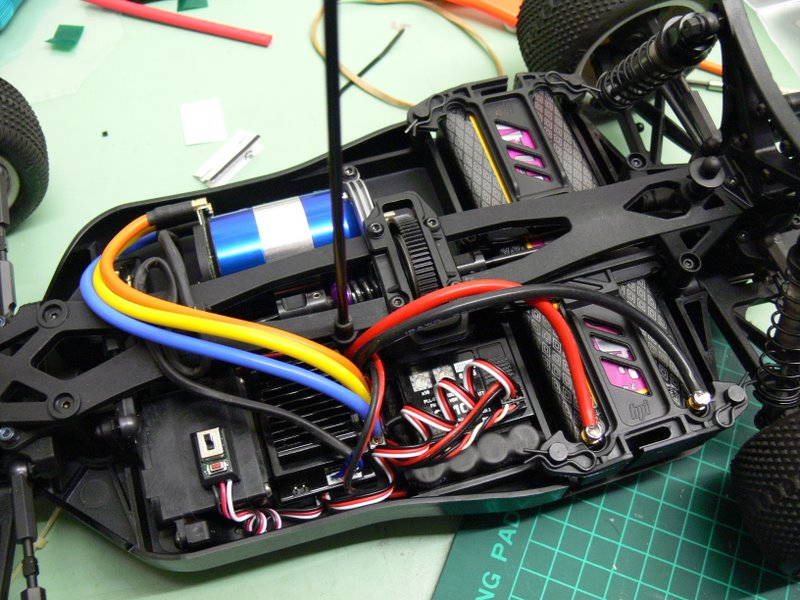

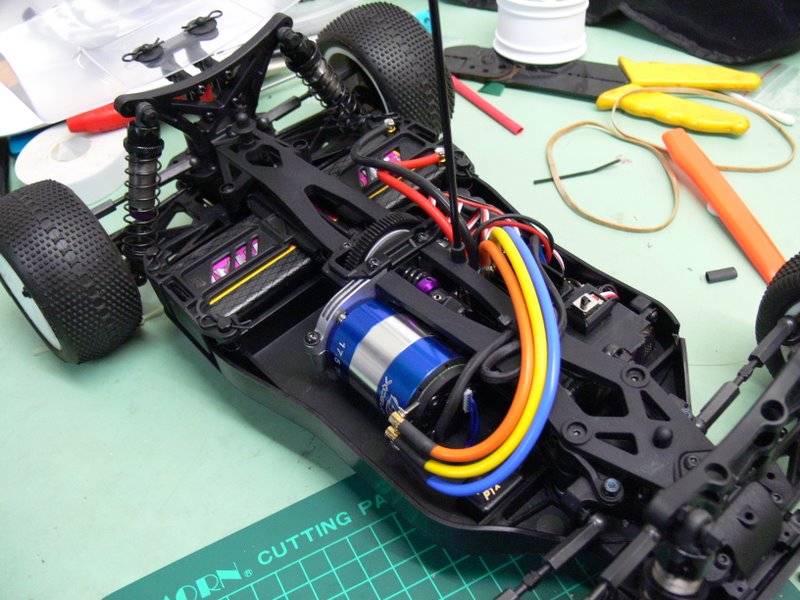

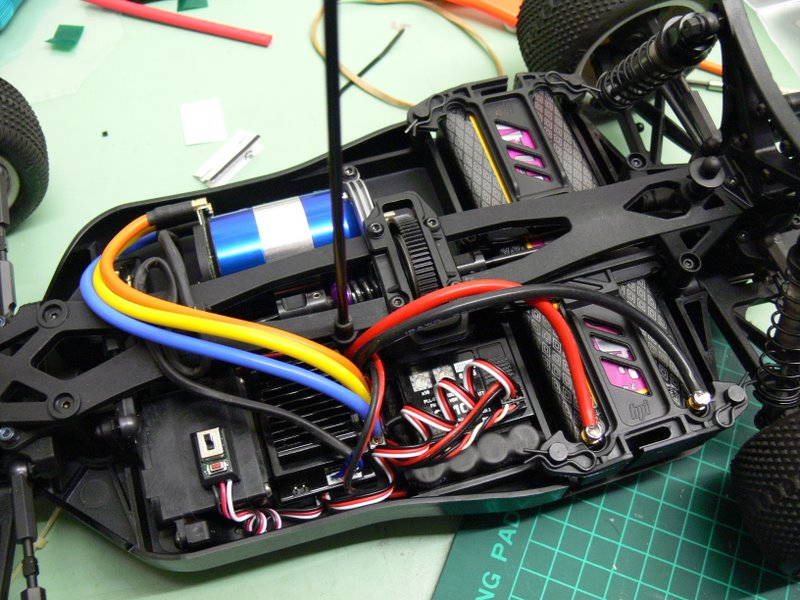

Electronics are now in place. Kitted out with a Hobbywing Xerun v2.0, JR

RS-310 receiver, KO-Propo digital FET servo, Intellect IP3800 25C lipo,

MRT transponder and Losi Xcelorin 17.5t motor.

Chassis is indeed very roomy. Spent most of the evening trying out

different ways to route the cables and position the components. Decided

on bringing the ESC up front directly behind the servo to balance out

the weight of the motor.

I did try to position the receiver in front of the motor (B44 style) but

it interfered with the steering rack.

Now comes the fun part - designing a new paint scheme. Meanwhile, I'm

going driving.

DAY 7

Just some minor stuff today. Applied some JConcept chassis protector

(it's actually just 2 sheets of 3M PFTE adhesive plastic). Never used

the the stuff before, not sure if it's worth the effort to protect a

plastic chassis.

Also had to push the battery forward to stop it from touching the rear

gearbox shaft outdrive. I used some furniture adhesive feet to fill the

space. This in turn caused the battery holder to interfere with the

battery terminals. Only solution was to shave a bit off. End result is

the battery clears the outdrive by around 1-2mm.

Also managed to put the car on the kitchen scales. 1680g all up,

including Intellect 3800 lipo.

DAYS 8 & 9

Attached tyres and spent the weekend painting.

DAY 10

Attached a few stickers and peeled off the paint mask.

That's about it. All in all a very satisfying experience. Only thing

left is to take it to the track and see how it runs. Have to wait for

the weather to clear up a bit before that happens.

My Cyber-10B finally had its

maiden run today and subsequently doesn't look as shiny as it used to.

Verdict? Easier to drive than a 2wd being my first 4wd, I don't have a

lot to compare it with. The shock towers are tougher than I previously

gave credit for. The car landed on it's lid plenty enough times to prove

that.

The antenna has a rather large kink in it now, I imagine it'll snap

after a couple more upside down landings.

After chatting with some of the more experienced stock drivers, think I

might go back to the non-slipper arrangement. Save a bit of weight and

reduce the rotational mass. |