|

- Team Durango DEX410V4 - Review -

1/10-SCALE ELECTRIC 4WD BUGGY | KIT

Durango sharpens their 4WD and attacks the competition

Text by ERICH REICHERT - Photos by PETER HALL

The original Team Durango DEX410 is among the new-age, off-road rockets responsible for the transformation of the 4WD buggy class over the last decade. In the early 2000s, when the class was still at a loss for viable options from major manufacturers, the Team Durango 4WD buggy project quickly became one of the most exotic and sought-after buggies in the world. It all started with Durango founder Gerd Strenge lending a handful of hand-built prototypes driven by the fastest racers in the world, like Mark Pavidis, Billy Easton, Travis Amezcua, and more, for just one race weekend at a time. After Team Durango was officially founded in 2009, the newly named DEX410 was released to the public to rave reviews – and an IFMAR World Championship in the hands of Martin Achter. The platform has been updated nearly every year since, leading up to the v4 edition shown here, which boasts improvements to the suspension, drivetrain, and all over to make this the most efficient, durable, and best-balanced DEX410 to date.

LIGHTWEIGHT GEAR DIFFS

Durango was the first to include gear differentials in their 4WD kits and they’ve made a name for themselves as some of the best in the hobby. Because they’re filled with oil and gears, a gear diff is more consistent and has more forward bite when exiting corners compared to a ball differential. For the DEX410v4, the fluid-filled diff gets upgraded with a set of lightweight cross-pins and internal gears. The weight reduction lowers the rotating mass of the assembly for better acceleration and consistency. Finally, the diffs are housed in newly designed gear cases that are easier to remove. Simply remove four screws and a plastic cover that holds them in place and you can rebuild the diffs without taking the rest of the car apart to get to them.

The DEX410 was one of the first cars to run gear differentials and they’ve been lightened for the v4 to lower rotating mass and improve acceleration. The diff cases are also now easier to remove for maintenance as well. Simply remove four screws from the end of the buggy and it pulls out without disassembling the rest of the drivetrain.

TWO-WAY SLIPPER CLUTCH

For the v4, the slipper has been upgraded to Durango’s new Two-Way Slipper Clutch that allows the front and rear wheels to have their own separate clutch. Because the wheels on either end of the buggy can slip on their own, the buggy can put the power down smoothly when two of the wheels are off the ground. The power from the clutch is transferred to the diffs through a set of high-strength universal driveshafts. The rear of the shaft enters the diff case at a steep angle to clear the batteries, which makes the smooth-operating universal joints essential to reduce heat and friction and get the power to the wheels efficiently.

The 410v4 features an all-new Two-Way Slipper Clutch that slips independently for the front and rear wheels which keeps power moving to the wheels on the ground at all times.

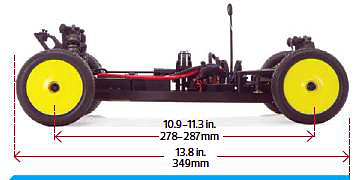

LOW CG CHASSIS LAYOUT

The key to the DEX410’s handling is its ultra-low center of gravity and centralized weight distribution. Rather than using a straight pack mounted to one side of the 2mm thick aluminum chassis and offsetting it with the motor on the other, or running a saddle pack with one half of the pack seated on each side of the center drive, the v4 tucks a saddle-style pack behind the slipper unit and directly underneath the driveshaft. In front of the slipper, the motor is mounted as close to the centerline as possible and the steering servo is directly below the front universal. Mounting the majority of the buggy’s running weight on or as close to the chassis’ centerline lowers its center of gravity and gives the buggy nimble handling. The trade off is that in order to remove the batteries you will have to remove the slipper and lift the rear driveshaft out of the way.

The center drivetrain is raised up on the DEX410v4 in order to place the buggy’s heaviest components like the motor and battery close to or right on the center of the chassis. Moving the majority of the vehicle’s weight to the centerline lowers the center of gravity and improves handling.

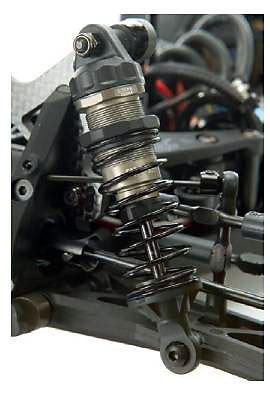

PRO SHOCK PACKAGE

Durango equips the v4 with a full set of 12.4mm big bore shocks that features hard coated threaded aluminum bodies and all new low stiction O-ring seals. The seals are made of a special low-friction material that’s very durable to maintain smooth shock movement under the toughest conditions. Inside the shocks, Durango gives you a full set of TiN coated shafts that are coated black rather than the traditional gold color and a choice of four different pistons as well as a full set of blank pistons that can be drilled to create optimal damping rates. Talk about tuning potential!

Left: 12.4mm big bore shocks come standard on the v4 and are finished off with threaded aluminum bodies and black TiN shock shafts. The buggy also includes a full set of pistons including blanks that you can drill to your own specifications.

ENHANCED SUSPENSION TUNING

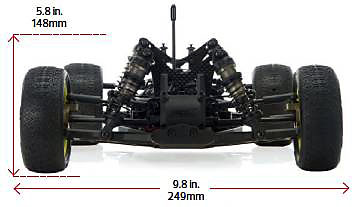

With today’s off-road races held on an increasing number of different tracks and surfaces, suspension adjustability is a must for any competitive buggy. Durango has outfitted their new buggy with front and rear arms that allow for nearly a half an inch of wheelbase adjustment. Up front, there are also new 19-degree aluminum caster blocks that provide tons of turn-in. Durango also includes their new DIMEC X ball cups that are specially shaped to provide an increased amount of articulation from top to bottom in the suspension travel. Being able to adjust the wheelbase gives the v4 more options for a wider variety of track conditions from loose to high-bite surfaces and from tight to sweeping turn designs.

Above: Both front and rear suspension assemblies have wheelbase adjustment built in to give you the ultimate in setup options and are finished off with DIMEC X ball cups for increased articulation.

BEHIND THE WHEEL

For power, I installed TrakPower’s MS-1 brushless speed control and 6.5T motor along with a their 6000mAh LiPo saddle pack battery. 4WD buggies are notorious not having a lot of room to run receiver and motor wires but the DEX410v4 takes this to a new level. All of the electronics are positioned next to each other on the chassis which means, and if your skill set allows, you’ll want to shorten up the leads on your speed control and servo and swap the stock sensor cable for a shorter one. Durango’s new cab forward body was sent to Larry at Kustom RC Graphics for a slick blue and yellow on carbon-fiber scheme that came out awesome and with a full set of super-soft compound Duratrax Persuader racing tires mounted up, the DEX410v4 was ready to hit the track. First at Wolcott Hobby’s indoor facility where grip is high and agile handling and quick response are a must to put down laps at speed. The manual’s box settings put the v4 in a “middle of the road” type of setup so I shortened the wheelbase on the front arms to get the car turning tighter and take advantage of its centrally mounted weight and put it closer to the front wheels. On the high-grip track, the buggy likes to be driven aggressively. Turn-in is instant and the balance of power and traction coming out of the turns leaves you pulling the trigger harder and sooner. Jumping is extremely controlled; steeper lift-offs result in a level flight in need of little to no throttle input to keep the car shiny side up. Over easier-graded jumps the v4 insists on a little extra gas to keep its nose in the air, but this type of attitude gets the car back on the ground and accelerating quickly. Wolcott’s outdoor track is an equally hard packed, but more sandy type of surface, for which the Persuader tires were better designed. With less traction and wider sweeping turns, I pushed the front wheelbase all the way forward, and actually tucked the rear end forward a bit to put a little more weight on the back wheels. I also backed out the rear arm’s droops screws to increase the amount of travel in the rear. On the looser surface, the rear bias wheelbase 410v4 handled takeoffs with ease, even considering the astounding amount of power the TrakPower 6.5 churned out. The slipper worked double time keeping the buggy tracking forward off the start line but quickly engages and launches the v4 to warp speed. Traction in a straight line is handled with ease by the full-time 4WD system and pitching the car into turns after a burst of speed, the buggy slid slightly but kept on line. Braking at the end of high-speed shoots settled the car in a more controlled manner that made the buggy easier to steer. The aggressiveness that the v4 insisted on indoors needs to be held back a bit when running outside but smooth tight lines and careful acceleration out of the corner resulted in a land missile of a buggy down the next shoot. Wolcott’s outdoor track is designed with 1/8-scale vehicles in mind, and as such the jumps are big. Undeterred by extended flight times, the 410v4 gives you time to adjust its attitude in the air, pitch the car down and get it back on the ground whenever you want. Even over the jumps I completely overshot, the buggy landed with poise and pressed on with no loss of control as the chassis slapped on the ground; whichever wheels hit first were powered forward by the two-way slipper and the buggy kept on its course.

+ Extremely adjustable chassis and suspension

+ Two-way slipper clutch really works!

+ Easy access diff design

- Battery removal requires removing center drivetrain

- So little chassis space, so much wire to tuck away

The Durango Buggy Story

When it was first designed at the turn of the millennium, the car referred to simply as “the Durango buggy” was something of RC folklore here in the U.S. Original designer Gerd Strenge had produced a handful of these prototype cars for himself and a few select pro drivers and they were nearly impossible to get your hands on. What set this buggy apart from the rest of the pack was its wild chassis layout: the steering servo was tucked up inside the nose of the car, with the speed control, receiver, and motor all in front of the middle of the car. Placing all of this up front left room for the battery pack to be positioned behind the center where it was put on the centerline with the driveshaft over it. This layout placed the majority of the car’s weight down the middle of the car, and kept its center of gravity was massively low. Without all that weight to pitch side to side, the Durango buggies were fast, nimble and had consistent traction no matter where it was raced. Gerd worked with Serpent to put the car, to be named the S500, into mass production but the project was put on hold early in 2008 in response to a decline in the global economy. By the end of 2008, Gerd and designer Michael Vollmer formed “Team Durango” as its own brand and launched the car as we know it today, the DEX410. In 2009, the 410 took top honors in the IFMAR World Championship backed it up with a runner-up finish in 2011 at the hands of team driver Jörn Neumann. The DEX410 has lived on to see its all new fourth generation but has really changed very little over the years. Considering that the buggy pictured is a nearly 10-year-old prototype, the v4’s lineage is apparent and the Durango way of doing things has been established as one of refinement and small changes to a revolutionary design that was clearly ahead of its time.

Durango’s original hand-built prototypes, with a polished aluminum chassis and gearboxes, were the most sought-after race cars of the early 2000s. (Photo by Sebastian Suerstedt)

FINAL WORD

Team Durango doesn’t make wholesale changes to their cars. When compared to the v3, you’d be hard pressed to identify a lot of what makes the v4 that much better of a buggy even though they’re in there. As is often the case in life, the finer things are in the details; things like adjustable wheelbase front and rear, droop screw-limited rear arms, fine materials and well-thought-out, unique designs make this buggy even better than it already was. The DEX410’s life story, at times, seemed impossible but its innovative layout and design won the hearts of racers instantly, and kept life behind the buggy until it finally came to be. When invention meets revolution, the combination results in success and with the finely tuned changes made to the v4 paired with all -new components like a two-way slipper and high- strength universal joints, the DEX410v4 is a champion in the making. The only question left is if you can handle it.

SOURCES

Duratrax duratrax.com

Futaba futaba-rc.com

Kustom RC Graphics kustomrcgraphics.com

Team Durango team-durango.com

TrakPower trakpowerusa.com

Wolcott Hobby & Raceway wolcotthobby.com

VEHICLE SPECS

Item no.: TD102030

Scale: 1/10

Price: $400

Weight, as tested: 4 lb. (1,817g)

CHASSIS

Material: 2mm aluminum

Type: Machined plate with plastic side guards

SUSPENSION

Type: Lower A-arm with adjustable upper link

Inboard camber link positions (F/R): 6/12

Outboard camber-link positions (F/R): 2/3

Shock positions, towers (F/R): 4/4

Shock positions, arms (F/R): 2/3

SHOCKS

Bodies: Threaded aluminum, 12.4mm bore

Shafts: Black titanium nitride-coated steel, 3mm

Volume compensation: Bladder

DRIVETRAIN

Type/ratio: Shaft-driven 4WD, 2.47:1

Spur gear/pinion: 87T/21T

Differential F/R: Sealed bevel gear, silicone filled

Driveshafts: Steel CV-style

Bearings: Rubber sealed

WHEELS & TIRES

Wheels: Yellow dish wheels, 14mm hex

TEST GEAR (NOT INCLUDED)

Tires: Duratrax Persuader C3 Super-soft compound

Transmitter: Futaba 4PKS Super R

Receiver: Futaba R614FF-E

Speed Control: TrakPower MS-1

Motor: TrakPower 6.5T

Steering servo: Futaba S9155

Battery: TrakPower 6000mAh 80C 7.4V LiPo

Source:

|