|

- Team Associated RC10T5M Team Kit - Review -

FIRST DRIVE

ASSOCIATED’S ALL-NEW STADIUM TRUCK SETS THE STANDARD FOR FACTORY TEAM PERFORMANCE

WORDS RC CAR ACTION TEAM

PHOTOS CARL HYNDMAN & JOEL NAVARRO

Loose dirt makes for great photos, but for actual testing we took the T5M to SDRC in San Diego, CA.

Predicting that a truck version will follow the release of a new Team Associated buggy platform doesn’t exactly require the skills of Nostradamus. Ever since Associated released the RC10T back in the early 1990s, we’ve come to rely on the latest RC10-series refinements to find their way into a new “T” model after the buggy hits the track. So, a stadium truck based on Associated’s fifth-gen buggy was a given, but which buggy would it be? With two flavors of B5—rear motor, plus the mid-motor B5M—there were two ways the truck could have gone, but as anyone who follows racing will tell you, mid-motor is the only way to fly as high-grip tracks are the norm. And so, the RC10T5M is here. Like the B5 buggies, the truck represents a clean-sheet design and is not a refit of the T4 series. RC Car Action is the first to drive the all-new mid-motor, aluminum-chassis truck (well, second if you include Associated’s team drivers) and we’ve got the exclusive review for you right here.

Aluminum Mid-Motor Chassis

Associated experimented with plastic chassis for the B5M, but discovered the mid-motor layout took up space needed for the molded-in reinforcements that a plastic chassis would require. As an inherently stiffer material, aluminum solved the packaging problem. With the truck chassis having to stretch farther between the front and rear suspensions, a plastic chassis would have required that much more reinforcement. An added benefit of aluminum is its greater density concentrates more mass lower in the truck, for a lower center of gravity and enhanced stability. While the T5M’s hard-anodized aluminum plate does most of the heavy lifting, additional bolstering comes from the plastic front chassis plate and “chassis cradle.” The cradle incorporates the battery tray, which can hold a 2S LiPo in “shorty” or “square” configurations, as well saddle packs. Square packs fit precisely, while others require the included foam spacer blocks to properly fill the tray.

The stamped and machined aluminum chassis has radiused sides to increase its stiffness. The center channel allows the motor’s sensor wire to route beneath the battery. There’s plenty of space for the speed control and receiver. We finished off the T5M with a Reedy Black Box, Futaba radio gear, and Reedy servo. The completed truck looks like a plastic-chassis design, but the backbone is aluminum.

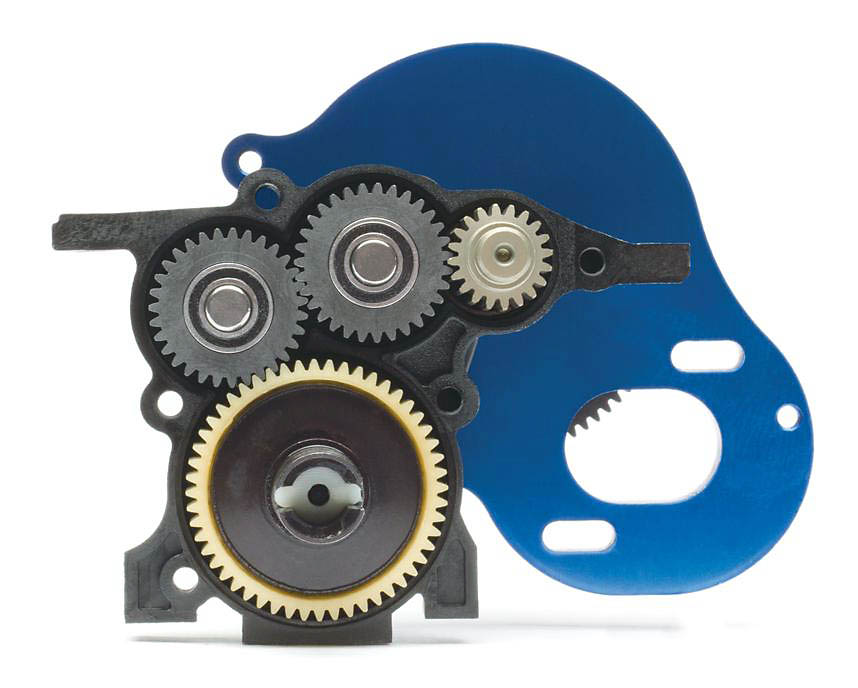

Mid-Motor 4-Gear Transmission

The T5M’s gearbox should look familiar to B5M drivers, since it’s essentially the same ‘box. The important differences are the top shaft, which is a new “V2” machined aluminum unit instead of the original B5M’s steel shaft, and the gearbox halves, which get a new part number and work with the V2 top shaft. Note that we said “original B5M;” the V2 top shaft and gearbox halves have been added to the B5M as a running change, so the B5M and T5M kits shipping now have the same transmission. Minus the spur gear, that is; the T5M gets an 84-tooth spur gear instead of the buggy’s 81-tooth gear. Other than an extra idler gear to make it a “4-gear” setup, the transmission is constructed like previous Associated T-models with an aluminum motor plate, dual-pad slipper clutch, and ball differential with steel outdrives. Steel CVA driveshafts are standard as expected, and 12mm hexes cap the stub axles to accept a variety of rims—which you’ll need to purchase separately, as wheels and tires are not included with the truck.

The T5M’s gearbox uses the same diff and idler gears as the B5M, but gets a new “V2” aluminum top shaft. Associated’s optional 3-gear transmission for the B5M will also fit the T5M.

Pro-Line supplies the T5M’s shell. It looks like a Bulldog, but the design is unique to the T5M. Tires and wheels are not included.

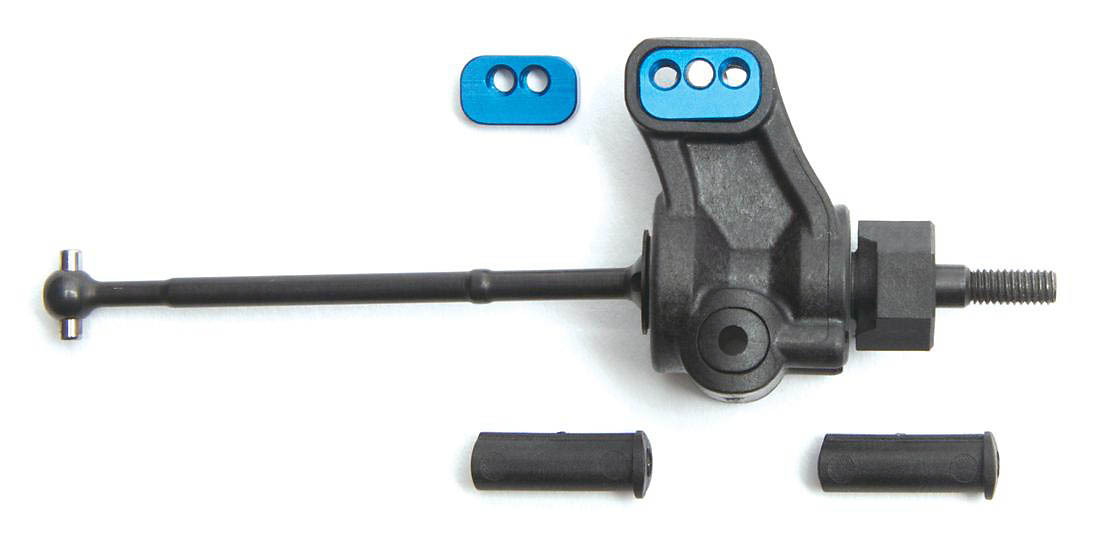

Factory Team Suspension

The T5M’s suspension and steering system is as notable for what it does have (excellent shocks and a load of adjustability) as for what it doesn’t—namely, a servo saver. The high-torque, metal-gear servos appropriate for T5M can survive happily without “saving,” and eliminating the servo-saver also eliminates slop, complexity, and a few grams. As for suspension adjustments, you get steel turnbuckles for camber and toe and a selection of shock and link positions—pretty standard stuff. The extra adjustability comes in the form of inserts that allow easy changes to caster, rear toe, and front axle configuration. Vertical inboard camber link ball studs and the steering rack’s front-facing ball studs let you set roll center and Ackerman with shims, allowing finer setting changes than moving the studs to new holes. In the rear, the ball studs mount to a new aluminum mount, the same part you’ll find on the new B5M “Factory Lite” kits.

Above: The latest B5-spec caster and steering blocks are fitted to longer arms for truck duty. The front wheel hexes are integrated with the axles to trim weight and the truck’s part’s count.

Left: Associated’s Factory Team V2 shocks build easily and offer exceptionally smooth damping. Spring cups of varying heights are supplied to provide a wide range preload and sag adjustment, and bleed screws in the caps make setup easy.

Right: The rear uprights carry large 6x13mm bearings and have 2-hole and 3-hole inserts for camber link positions. Hingepin inserts set toe-in relative to the arms at at 0, 0.5, or 1 degree.

The 3-Gear Option

If you’re racing in 17.5 class, you already know that eliminating drag and weight is an important part of getting the most from the limited horsepower the class allows. With that in mind, Associated offers a 3-gear mid-motor transmission to fit the B5M and T5M. Eliminating an idler gear means there’s one less gear mesh applying drag to the drivetrain, and the weight of a gear, two bearings, and a shaft are trimmed from the truck.

The optional 3-gear transmission trims weight and drag for top stock performance, but can benefit mod drivers too.

There’s also another effect; the 3-gear transmission holds the motor so its output shaft points to the right side of the car, instead of to the left as with the 4-gear transmission. This means the force of the motor’s torque is applied in the opposite direction of the four-gear setup. In the case of the 3-gear transmission, motor torque counteracts the tendency for the chassis to squat under acceleration and dive when decelerating or braking. That leads to a “flatter” chassis, and can make for faster laps on high-grip tracks. So even if you’re racing mod, the 3-gear transmission is worth a look as a tuning aid—and reduced weight and drag never hurts.

Hammer down at SDRC. The T5M was flying with Reedy power.

On Track With The RC10T5M

The perfect opportunity to test the T5M came in Round 6 of the SoCal Top Notch Series, held at my home track of SDRC Raceway in San Diego. I hit the track on a practice night to get the truck dialed in, and instantly noticed how sure-footed the T5M was as I burned off hot laps. As the tires wore in and my lap times decreased, I started to concentrate on fine-tuning the well-sorted stock settings. I have a ton of track time under my belt with the B5M, and the stadium truck version of the race-proven platform was quickly feeling as easy to drive at race-pace as my buggy. The T5M accelerated like a missile as it turned the Reedy 7.0 motor’s considerable power into velocity, wheelying on command as the Pro-Line lons adhered to the clay. I did hear some diff bark indicating I had set the slipper clutch a little too tight. With a quick adjustment of the slipper, the T5M delivered consistent launches out of turns with predictable and fast power delivery. Mid-motor vehicles are designed to be aggressive and the T5M exhibited this with every lap. With the weight of major components in the center of the truck, corner entry was quicker than the older T4.2’s ever was. With endless corner speed to spare, I found myself pushing the T5M through SDRC’s short chute and 180 degree turns harder and more confidently, quickly leaving anyone following me in the infield behind. When it came time to get airborne, the T5M almost jumped itself. A level attitude was easy to achieve and the combination of a plush suspension and fat tires saved the chassis from smacking on the clay if I overshot a jump. I also tested the T5M with a 17.5 motor and appropriate gearing. The truck was even easier to drive with less power to wrangle, but top speed and acceleration was a tick behind other trucks on the track that had been modified with lightened drivetrain parts and slimmed to reach minimum weight. Associated has its own bag of tricks to race-prep the T5M for stock class (as used on the new B5M “Factory Lite” buggy) including a 3-gear transmission. Stock or mod, expect the T5M to be a formidable track weapon. – Joel Navarro

THE VERDICT Is anyone actually surprised the RC10T5M is a hot truck? Team Associated’s 27 IFMAR World Championships weren’t flukes, they’ve got this racin’ stuff down. Straight out of the box, the T5M is as competition-ready as you would expect an Associated machine to be, and its deep adjustability makes it unlikely you’ll find a track it can’t handle. While it’s nice to have all that tweakability at the ready, don’t be surprised if there’s not a lot of wrenching left to do once you hit the track with the right tires. The manual-suggested settings had the T5M well sorted out at SDRC, and the truck is easy to drive fast—even easier if you’re already wheeling a B5M, as the T5M will feel familiar from the first lap. Just ask Associated pilot Ryan Cavalieri; as we go to press, he’s Top Qualifier at the Cactus Classic with his T5M.

SOURCES

Futaba futaba-rc.com

JConcepts jconcepts.net

Pro-Line prolineracing.com

Reedy reedypower.com

Team Associated teamassociated.com

|

|

VEHICLE SPECS

- Item no.: 70001

- Scale: 1/10

- Price: $280

- Height: 5.5 in. 140mm)

- Length: 16 in. (406mm)

- Width: 9.8 in. (250mm)

- Wheelbase: 11.4 in. (289mm)

- Weight as tested: 4 lb., 2.4 oz, (1885g)

CHASSIS

- Material: Hard-anodized aluminum

- Type: Machined plate

SUSPENSION

- Type: H-arm with steel turnbuckle camber link

- Inboard camber link positions (F/R): 2/2

- Outboard camber link positions (F/R): 2/3

- Shock positions, towers (F/R): 3/3

- Shock positions, arms (F/R): 2/3

SHOCKS

- Bodies: Threaded aluminum

- Bore: 12mm

- Shafts: 3mm Steel

- Volume compensation: Emulsion

DRIVETRAIN

- Type: 2WD enclosed gearbox

- Spur gear/pinion: 84T/not included

- Slipper Clutch: Dual-pad

- Differential: Ball type

- Driveshafts: Steel CV type

- Bearings: Sealed ball

TEST GEAR (NOT INCLUDED)

- Transmitter/receiver: Futaba 4PX / R614FS 4-Channel FASST

- Steering servo: Reedy RT1508 HV Digital, 212 oz.-in.

- Speed Control: Reedy Black Box 410R

- Motor: Reedy Sonic 540 Mach 2, 7T

- Battery: Reedy 2S 7.4V 5800mAh 65C “square” LiPo

- Wheels: JConcepts Mono 2.2”

- Tires: Pro-Line Ion 2.2” MC compound

|

Kody Numedahl Talks T5M Tech

Kody Numedahl is a top-level racer and an engineer for Team Associated. He was involved in the development and design of the Team Associated B5M 2WD buggy, and has been instrumental in developing T5M stadium truck. We spoke with Kody at the Cactus Classic to gain his insights on the development of Team Associated’s latest racing truck.

You were involved with the development of the B5M buggy. What did you learn in the process of developing the B5M that you could apply to the T5M? A lot of tuning between the cars. We rarely ran mid-motor cars before the B5M other than a couple of carpet races. We learned how to tune a mid-motor car since it is different than a rear-motor car. You start to think about that stuff while you design a new car like the T5M and it makes the process easier.

What are the biggest differences and similarities between buggy and stadium truck? As far as assembly, it’s all the same, but for geometry you have to make some adjustments due to the differences in tire size. We also took what we knew from the T4 and improved on that as well. I think we should be able to run on a bigger variety of tracks. You can still run on the loose tracks, but obviously it works better on the high-bite tracks.

Are there any plans for a rear-motor version? Not yet. We are going to see how it plays out. We have both for the buggy and we look at sales from that and the trends in racing. We are at the Cactus Classic right now and it’s really high grip and I doubt there are any rear-motors here.

Do you think the mid-motor trend will continue and become the future? Yes, I think so. I’ve said this before, but I don’t think mid-motor is worse than rear-motor on low-bite. I think it is just a different feel to it and now that we’ve got more knowledge with the mid-motor cars, I think we’ve made them just as good, if not better, on low-bite tracks. It just lets you have a bigger tuning window. I think the T5M will be fine with just a mid-motor version.

Did you make any running changes to the buggy that you applied and now share with the stadium truck? The bearings on the layshaft have been updated to match the other bearings in the transmission, and the buggy now has that change and the stadium truck and the new B5M Lite coming out will have that change. We also retooled the ball cups. Originally the ball cups were coming in tight and it was frustrating, but it happens when you are dealing with plastic molded parts. Now the ball cups are better and move freely. They are good from the get-go. The Factory B5M Lite buggy and any new kits from here on out will also have the new ball cups. It was a running change, so any spare parts have already been switched over.

|