|

- C4.1 Centro mid-motor conversion - Tom Yardy - Advice & Tips - Jan 2012 -

Stuart Styles

PDF File

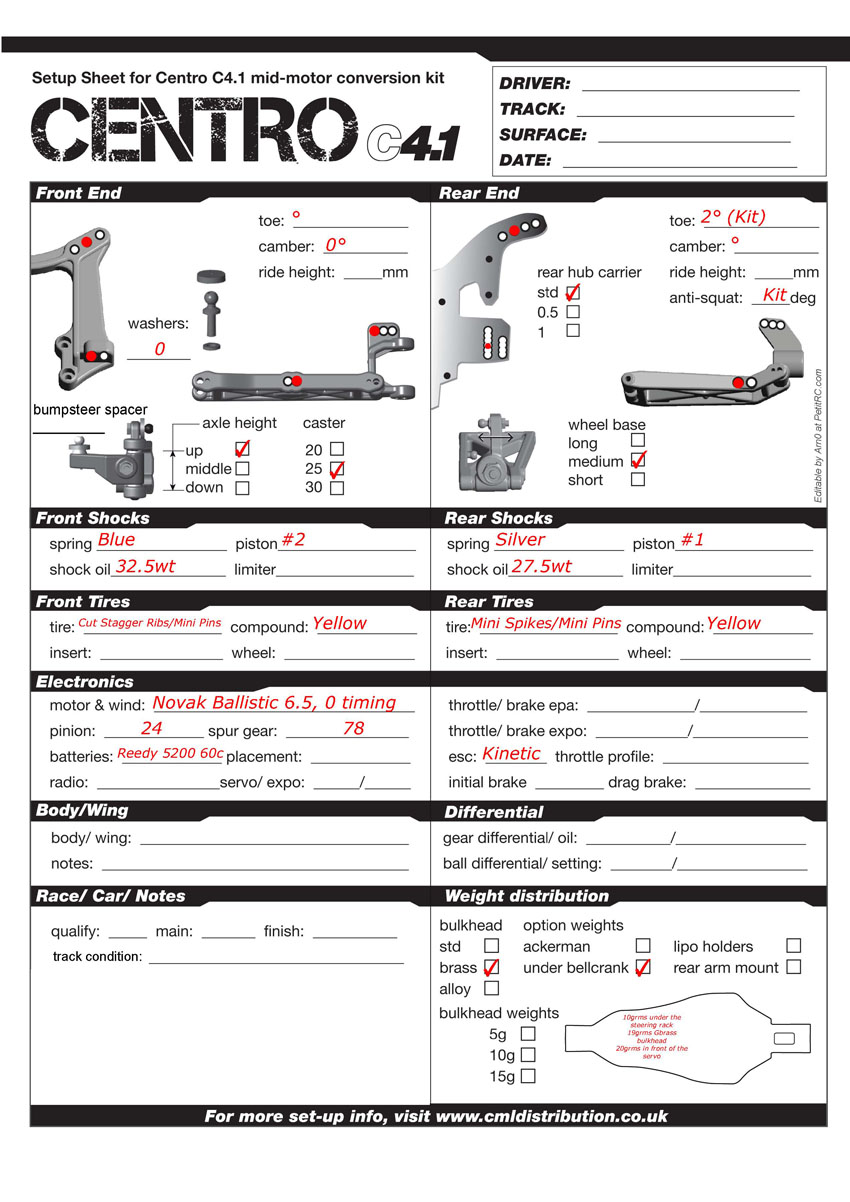

I'm really excited to bring you the first of the 2 part series where we get exclusive access to the Centro C4.1 of Midlands off-road race legend Tom Yardy. This feature is a step beyond a basic set-up sheet that a driver may release for other racers to try. Our goal here is to get some personal tips and tricks from Tom as he shows us around the buggy he trusts to perform every meeting.

Our first installment will see us delving into the basic set-up of Tom's buggy and also finding out in more detail what Tom uses as far as electrics and running gear. The second part of this mini series will give us a truly amazing look into the evolution of the C4.1 with special inside information from both Tom and CML top guy Jason Varley. We will learn how the chassis was developed, who the team behind the National winning platform are, and the exciting future developments that the guys have planned under the Centro brand.

Tom was really welcoming with sharing how his buggy is set-up and was very keen to stress that he has found that simplicity in both weight distribution and electrical install are the key to his super reliable C4.1 racer. Lets get into the real science as we look Under The Lid for the first time.....

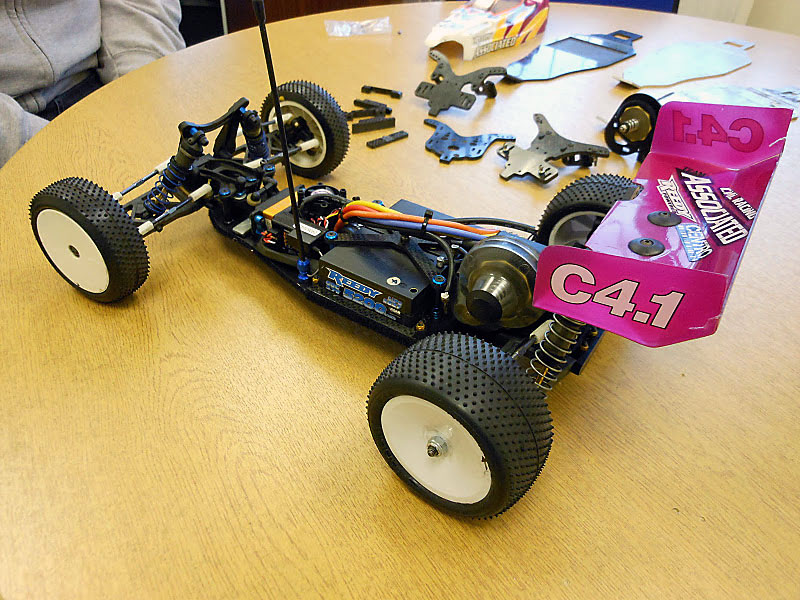

The C4.1 conversion benefits from a beautifully machined chassis deck. Tom was excited to share with us how the production cars genetics are a strong reference to the super classic Atomic Carbon mid-motor beast the S2. As we move through Tom's set-up choices I'm sure those of you who owned an S2 will feel the strong heritage link. We will look deeper into the connection between CML's new creation and Jonathan Clarke's cult classic later in the series.

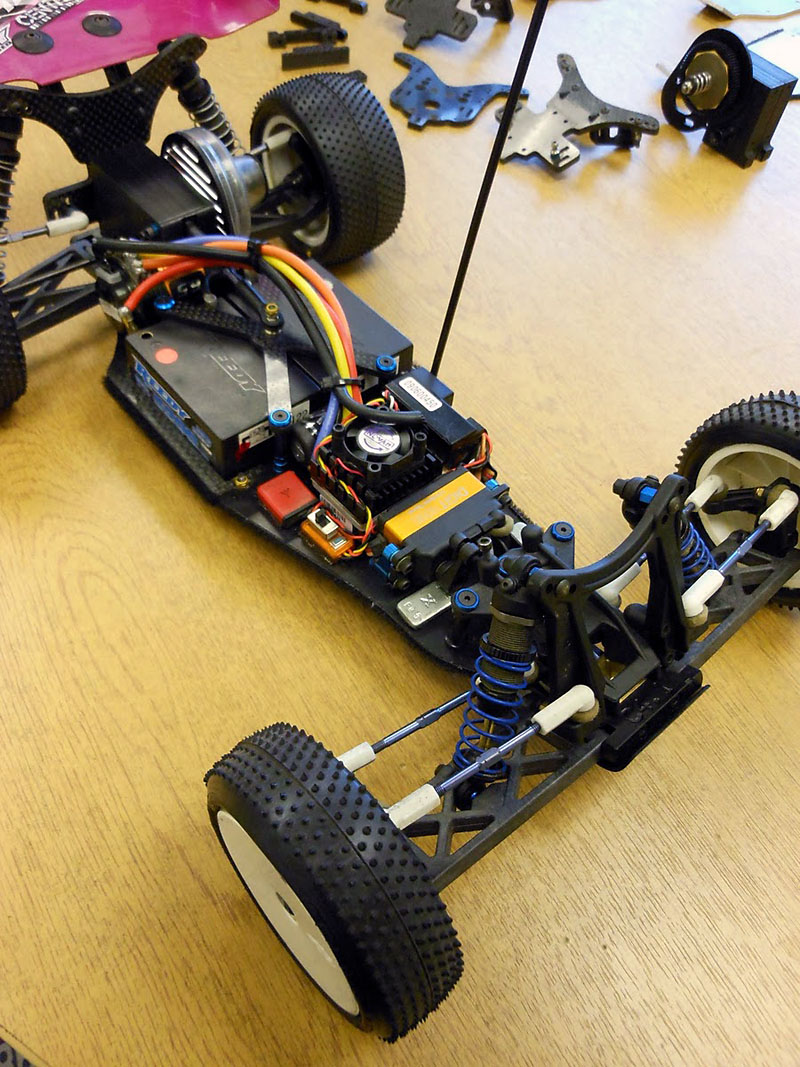

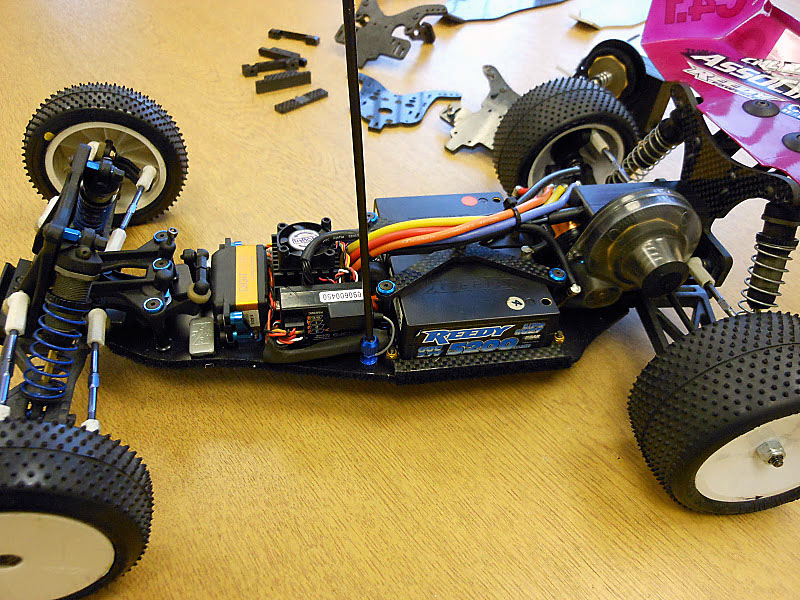

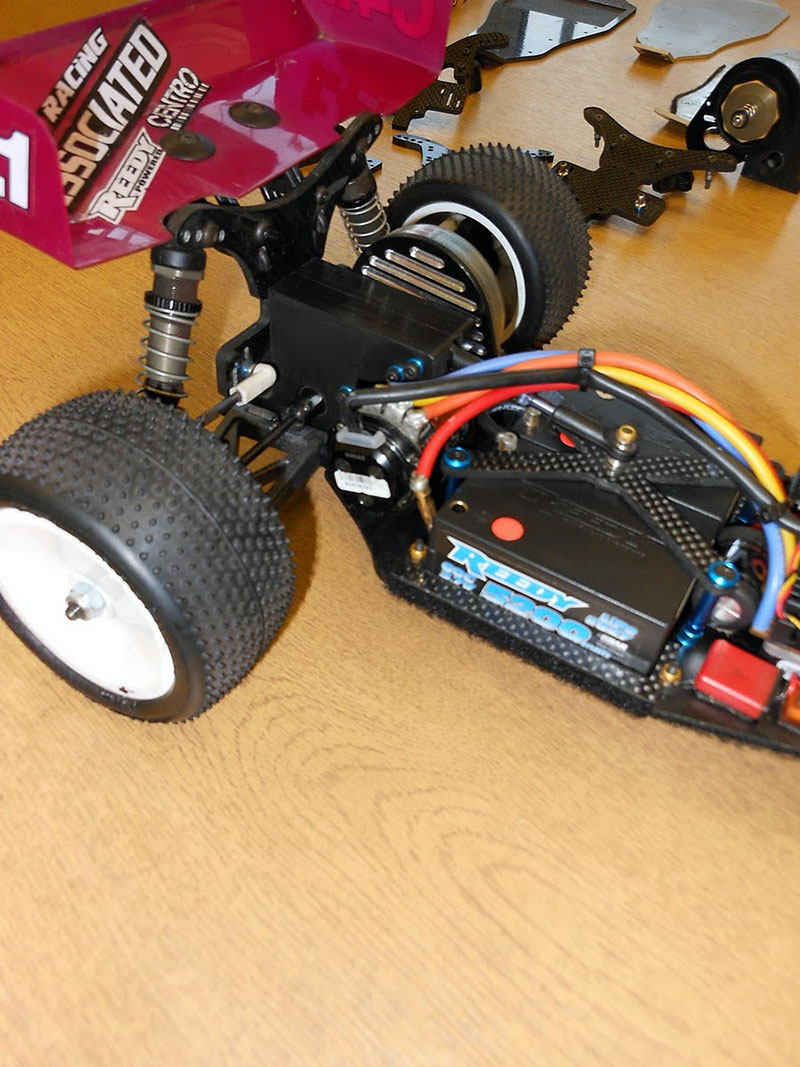

Whipping the shell off Tom's C4.1 reveals the following electrical install:

- Savox 1251MG low profile steering servo fixed with Associated FT mounts

- Futaba receiver unit

- Novak Kinetic ESC

- Novak Ballistic 6.5T motor set on zero timing

- Reedy hard case saddle batteries - 5200 mah 60c Burst

- Harry PT unit

Tom commented that this simple but efficient electrical install has allowed him to focus on trouble free and reliable performance during both domestic and European meetings. He added that he has also ran the Novak Ballistic motor in the 7.5T flavour on some occasions with up to level 4 timing.

As we investigated further into Tom's choice of tuning aids and set-up preferences we found the following items of interest:

- RPM rod ends on all Associated FT turn buckles

- Vented Associated slipper plates

- 10grms of added weight under the steering rack assembly stuck directly to chassis

- 19grms Ghea brass bulkhead

- 20grms of added weight in front of the servo

Tom showed us around his basic geometry choices and once again stressed that simplicity is a real key element with his C4.1 set-up.

"Early testing showed us that we had a potentially fast platform, and we knew as soon as we ran our first prototype chassis that the B4 front end would need very little improvement"

Tom agreed that the C4.1 front end needs very little variation from previously successful B4 or B4.1 set-ups that racers will have experienced on their chosen track surface. Just so we are fully aware of how Tom rides in the front third of his buggy here are the specifications for reference:

Shocks: Associated V2 units with 32.5 WT oil - 2 hole piston - positioned middle mounting hole at the top end and outside hole at the lower end

Wishbones: Associated B4 graphite

Caster: 25 degrees with the linkages in the high position

Camber: 0 degrees

Tyres: Schumacher Cut Stagger Ribs in yellow compound or Schumacher Mini Pins

Closer inspection of the front end of Tom's C4.1 shows that it really is that simple. No wild weight distribution, no unusual alignment settings, Tom commented - "I get a lot of questions from racers wanting to know how I manage to get so much steering during mid corner on my C4.1. I simply reply show them that my weight added is fairly modest, there is no need to load the front end and unbalance your weight transfer under braking conditions and during cornering...simple"

Moving around to the rear of Tom's buggy we were met with a similar simple, no nonsense set-up, Tom added - "The whole team have found that during the development of the rear shock tower, the extra roll centre options we wanted to add became redundant as we sought to alter the rear shock tower design for increased strength"

The rear end set-up was as follows:

Shocks: Associated V2 units with 27.5 WT oil - 1 hole piston - positioned second mounting hole from inside at the top end and inside hole at the lower end

Wishbones: Associated B4 graphite

Toe Block: Stock C4.1 kit block at 2 degree

Anti-squat: Stock C4.1 kit plate

Tyres: Schumacher Mini Spikes in yellow compound or Schumacher Mini Pins

Roll centre: 3rd hole from the bottom of the centre row of stock tower settings

Tom added that he is currently running 1 washer on the inside end of his camber linkages at the rear end.

The buggy is currently set-up with a medium wheelbase and Tom has found little need to run longer since first tests at this length.

During testing the C4.1 was piloted by some very esteemed members of the racing scene. We asked Tom a few fact finding questions that will help us all understand why his current set-up works for him.

Why do you choose to run 25 degrees caster up front Tom?

Some of the other members of the team swear by 30 degrees. Every driver is different and I just find that both my C4.1 and my original B4.1 feel less 'vague' with 25 degrees during on power steering.

Can you explain your choice not to run any added weight in the mid section of the buggy? Many racers are still adjusting to the lightness of lipo batteries and will be surprised there is no added weight in this area?

During the evolution of the first proto chassis we found that we were filling the milled saddle recess with weight to get the cars CG down lower. As soon as we made the decision to move from the proto 1 carbon chassis to the proto 2 aluminum chassis, we found that the added weight in chassis material negated the need for adding extra weight under the batteries. The C4.1 does not suffer from lack of forwards traction or stability.

Gearing is a hot topic (no pun intended) these days as we all have access to such powerful motor and ESC combinations. Gear box evolution has come on a long way since the first mid-motor cars that required an ESC capable of running the racers selected motor in the opposite direction due to the motor being flipped in front of the rear axle line. The C4.1 boasts the beautifully created 4 gear transmission case that racers have seen before on the Atomic Carbon S2 a few years ago. A few minor tweaks were required during the development of the C4.1 to aid performance, but more of that during part 2.

Tom is running 24T Pinion with a 78T Spur gear

For those readers with eagle eyes, you will notice a selection of proto parts and spares in the background of some of this features images. We will explore these exclusive pictures during part 2 of this series and we have some real juicy information with regards to how Tom and the dedicated CML team developed the items we find in the kit version of the C4.1 conversion that is on general release.

So as Tom has shown us, there is no black magic or super secrets under the lid of his C4.1. Tom relies on a super simple, easy maintenance, versatile set-up that allows him a proven basis to make adjustments from. Tom concluded our meeting with these words "Stick to basic and reliable set-up choices with the C4.1. I have found no need for complicated weight additions and the buggy is fast all over the track"

You just can not argue with Tom's performance on the rostrum. His car mirrors his driving style, clean, organised, and definitely focused on fast laps race after race.

So our journey into the greater detail of CML and Associated race star Tom Yardy's C4.1 now takes us into an exclusive first time look at the evolution of the chassis. We will learn just who has been involved with CML's first 2wd 1/10th project, from the origin of the design, to the track testing that resulted in an amazing 1,2,3 top National positions for the Centro team last year.

I recently visited CML to meet with Tom and some other members of the crew that are behind the new Centro C4.1 conversion for the Associated B4 & 4.1 platform. I was especially interested in delving a little deeper into the history of the kit, and also speaking with one of CML's owners Jason Varley, about how they have contributed to this wonderful new release. Tom gave me an amazing insight into how it all started:

"I'm really proud to say that I was involved in the Centro project right from the beginning. At the end of the 2010 season I was pretty deflated with 2wd, the pace of the class was moving on due to mid motor cars' reaction to LiPo batteries - the B4 isn't and never will be a bad car but on the UK tracks it certainly wasn't quick enough any more"

"I decided to take my concerns for me and the rest of the team to CML and between myself; Craig Drescher and Jason Varley we began to consider what options were available. I suggested talking to Jonathan Clark of Atomic Carbon as I recalled his conversion he had previously produced for the B4 called the S2. He very kindly lent me his S2 and I and my Dad put in a lot of time in the evenings and weekends privately testing it - from the moment I drove it I knew it was something we should pursue"

"So between me, my Dad, Jonathan and CML we began refining the design, tweaking little elements here and there, some changes to materials on the chassis etc. and as a group we created the C4.1. Centro was actually a name me and my dad came up with, so it's really cool that CML have kept it. A few months later, Neil Cragg and Paul Bradby got cars and for the 3 of us to finish 1-2-3 in the national series in our debut season was a great reward for everyone’s hard work. I'd like to publicly thank Jonathan, Craig, CML and of course my Dad for making the Centro project happen"

Speaking with Tom and Jason firstly helped me to begin to understand just how much time, work, and ultimately money has been invested into the development of this new conversion kit. Upon news of the potential release of this chassis, well before the guys had won at top level with the buggy, the forum boards buzzed with eager anticipation. During this period, as Tom has eluded towards, the team were super busy testing chassis materials. Tom gave me this super secret insight into how this process developed:

"Our first attempt at running the early proto-type chassis was a really sharp learning curve. We had used Jonathan's original design from the S2 to craft our own carbon chassis deck. We all found that due to the lightness of the carbon fibre, we were filling the saddle battery recess with up to 90grms of lead!. We also had concerns that the production cost of a carbon chassis would only result in the end user having to pay more for a conversion kit. Both these elements took us back to the drawing board to explore potentially making an aluminium chassis"

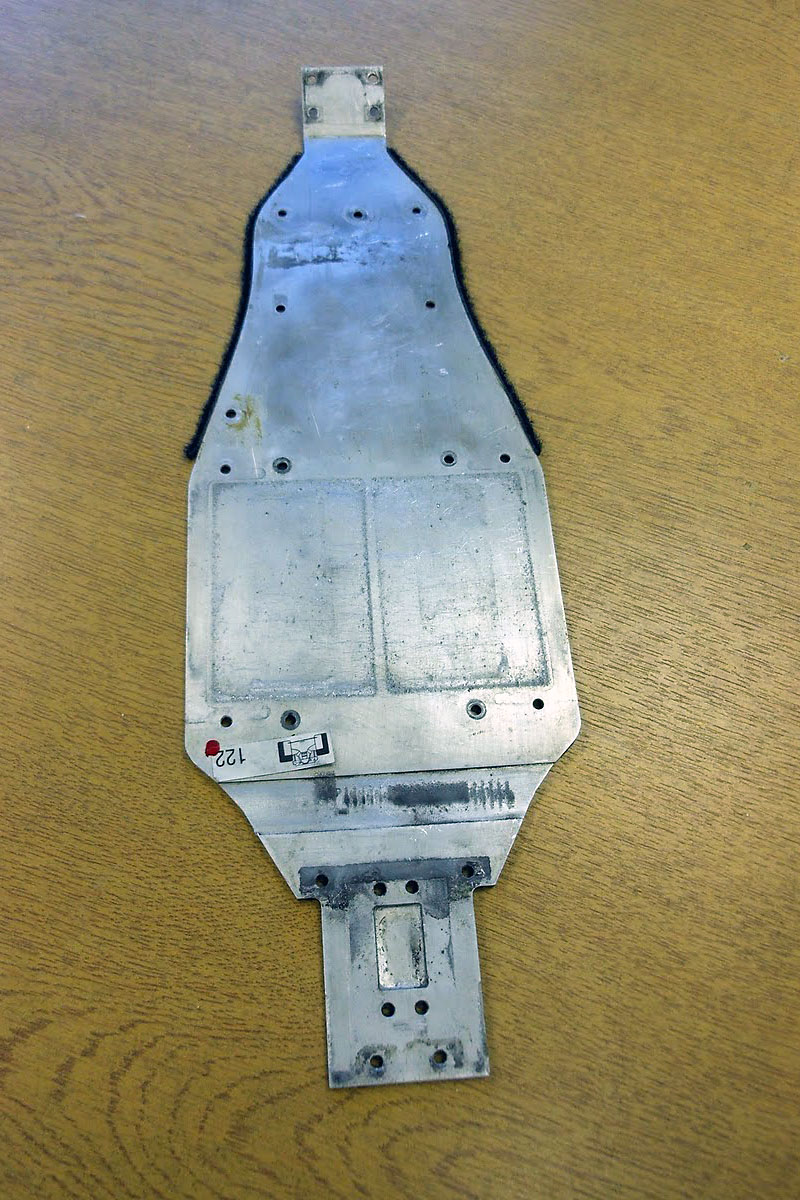

Mark 1 Proto-type carbon chassis for the C4.1:

"We knew aluminium was going to bring the cars CG instantly lower due to the extra weight throughout the machined chassis. We also knew that gaining extra strength was a key area we wanted to explore during development. We already understood that racers want durable cars without sacrificing performance. Ali was the ONLY way for us to progress this stage of development”

Mark 2 Proto-type aluminium chassis for the C4.1:

As Tom showed me the first 2 proto-type chassis decks we discussed how the existing Atomic Carbon platform had further contributed to the core genetics of the new Centro buggy. The original S2 conversion used to allow the gearbox to be mounted directly to the rear of the chassis with the rear toe blocks in turn bolting onto the gearbox casing. Tom explained how the team wanted to revise this detail and why.

"We really wanted to gain even more strength in this area whilst also allowing for easy changing of the rear toe block adjustments. During the development of the first carbon deck chassis, we revised this mounting method and solved our concerns with strength and ease of use in this area. The first ali chassis proto-type gave us an opportunity to allow some lower ability racers a chance to test the conversion. The reason we did this was to attempt to gain a wider level of feedback on the new chassis from as many different driving styles as we could access at this early stage"

Tom explained that one instance occurred where a racer 'tweaked' the rear end of the chassis after a collision. The chassis had bent slightly on its access near the rear gearbox cut-out. The team knew that the grade of aluminium they had chosen was correct, but this slight twist caused them to begin thinking about how they could eradicate any potential weak spots under the now revised gearbox mounting area of the chassis. Tom continued:

"We decided that we had to revise both the rear gearbox slot on the chassis and potentially the lower half of the S2 gearbox housing. The bottom of the gearbox had previously protruded through the mounting hole at the rear of the chassis. If we filled this hole we had no space for the diff gear to sit. After a few drawings back and forth with Jonathan at Atomic Carbon, we came up with the idea that we could fill the existing hole, but, leave a shallow recess for the diff gear to sit in and run free. In turn we also decided to cut a slot in the bottom of the gearbox case to allow for this modification. This now gave both chassis and gearbox a solid, strong seating position. Our 3rd aluminium proto-type chassis was perfect!"

The final chassis pictured below was much quicker on the track than the carbon fibre version, stronger, and also incorporated the previously mentioned refinements with gearbox housing that the team wanted to refine....time for action!

3rd Proto-type chassis for the C4.1:

It seems at this stage the team had really begun to understand what it was going to take to create a fast, well balanced, and cost effective conversion kit. Tom is always keen to point out that Jonathan Clarke's original S2 was, and in fact still is, a truly awesome conversion. He just knew that if this new project was going to be made commercially available to the masses it would need certain revisions to realise its top potential.

As our conversation developed Tom explained just how much input Jonathan Clark had during the testing stage of the Centro C4.1 project.

"Every single technical drawing was constructed by Jonathan. His expertise were fundamental in the CML team making progress on this project"

With the chassis looking and feeling the best they had found so far the team began work on developing other parts of the kit. As previously mentioned in Part 1 of this feature, the donor B4 front end was already extremely well suited for this conversion. It therefore received almost no modifications and the teams focus was now on the rear shock tower, anti-squat block, and toe-in fitments. Tom expanded on how the rear shock tower developed during this stage:

"We all agreed that we would like to offer the racers who would invest in this kit an opportunity to gain more adjustment at the rear end than previous conversions have allowed. We decided to test several shock tower configurations that had extra role centre holes added"

The original S2 rear shock tower before any adjustments:

Tom explained how the balance between refining the adjustment options and keeping solid strength was a real challenge. If the team wanted to alter the shape of the tower, they also had to 'build in' to their plans areas of material that would create extra impact strength.

The first revised C4.1 rear shock tower with an added row of role centre holes and new swept shape:

The thinner areas on the first revision where found to be too thin, and the team set about really 'beefing up' that area whilst keeping the new swept look of the first proto-type tower.

The final version that we all see in the kit release of the C4.1:

Tom was keen to point out that during the total schedule of testing, the team of drivers and designers behind the project had really begun to get very high performance out of the first proto-type vehicles. As the rest of the race community watched Tom, Paul Bradby and of course Neil Cragg dominates the 1/10th National off-road series, the team at CML and Jonathan Clark were busy making fine adjustments. The whole development machine was now some 15 people deep and the key to getting the most from track testing and design sessions was for all members to communicate their findings quickly and clearly to the rest of the team.

Tom and his father spent large amounts of their personal time on this project, and along with Jason and Craig at CML, Jonathan at Atomic Carbon, the rest of the racers involved in development testing, hundreds of man hours went into developing a product that would be ready for general release. They all knew that the conversion was fast. They knew that their revisions in materials and design shapes had added strength. But would the final kit be good enough for the broad spectrum of racer who would like to own this 3rd party conversion....the answer were soon to come.

During my visit to CML I had the amazing opportunity to also grab some valuable time with Jason Varley. Jason was really keen to share some of the more business related facts about the Centro project.

“We became aware that if we were going to allow our team drivers the very best chance to represent our brand at the highest level, we had to explore how we could give them a buggy platform that helped them compete. Mid-motor 2wd platforms have been proven to be the faster format on European high grip tracks. It was time to investigate how we could give our team drivers a buggy that would mix it up with the very best mid-motor chassis’ out there”

Jason went on to explain the commercial aspects of the project, and was really keen to allow more of an insight into the large commitment that the CML team have put into producing the C4.1.

“The cost of creating custom tooling and the subsequent parts for any RC vehicle can be astronomical!. For the Centro project to be both high quality and financially viable we had to really ‘crunch the numbers’ so to speak. Our main agenda was to develop a really high quality, fast, and easy to use platform, but also not put ourselves in a situation where the cost to the end user was not in keeping with other manufacturers equivalent kits. This balancing act is the very essence of car development as far as the RC business is concerned. We have produced a fairly low number of kits in comparison to what we perceive other manufacturers would release, and no matter how good your product is, there is always a element of ‘educated gamble’ involved with producing anything new”

Jason is a really inspirational person to talk with. He seems to evoke a strong feeling of optimism and forward thinking without ever losing his solid vision for the success of his products. He also was very keen for the public to be aware that the Centro project was never intended to be created as a massive commercial tool, but was originally developed out of the desire to give racers another lovingly developed and created product from an already respected British company.

The Centro brand has a really exciting future planned, and Jason gave me a sneak insight into how this will develop over the next 12 months.

“As soon as we created the Centro brand, a name that was originally conceived by Tom and his Father during the development of the C4.1, we knew that we would love to create a complete race oriented brand around the name and newly created graphics. We are really please to announce that we will soon be expanding the Centro range to incorporate several other high quality products. The first of these new developments will be a beautifully manufactured ride height gauge with a super unique design”

After leaving the exciting company I had kept for the afternoon, I couldn’t help thinking that I had not just witnessed the beginnings of a new off-road super brand, but I had also managed to get much more deeply acquainted with a 2wd buggy that we are all going to be seeing a lot more of during the 2012 season. It will be driven by some of the very best racers in the country, developed and manufactured by a real British family run company, and supported by a massively committed and passionate team. Surely this is the perfect recipe for truly wonderful success. Keep your eyes on the Centro C4.1.....it WILL be winning at a track near you very soon!

My sincere thanks go out to Tom Yardy and Jason Varley for their brilliant input during creating this feature. I would like to wish the whole CML team the very best of luck for the 2012 season.

To learn more about how you can own a Centro C4.1 visit http://www.cmldistribution.co.uk/

|