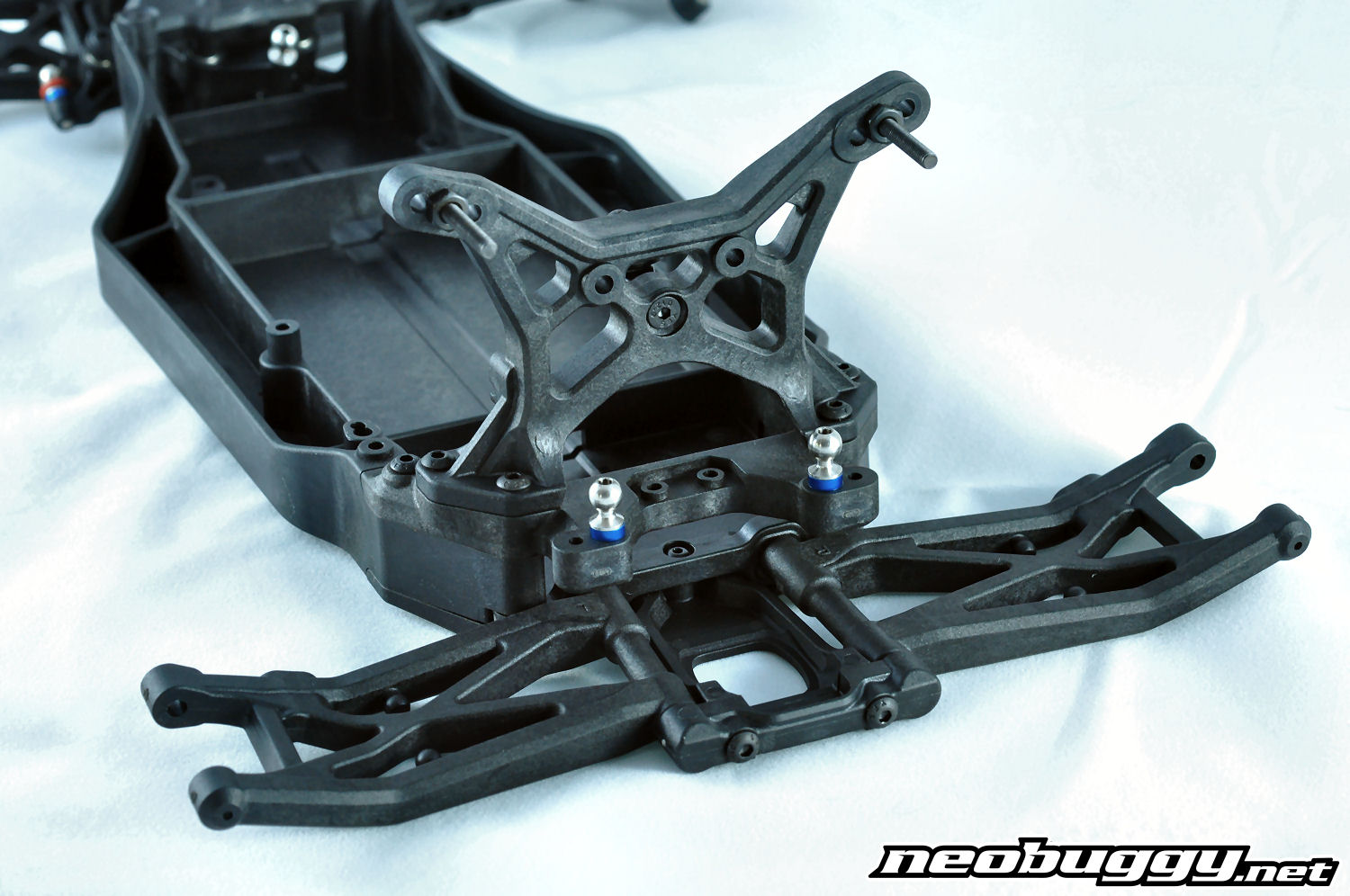

“The build has gone very well so far, no hand fitting necessary.”

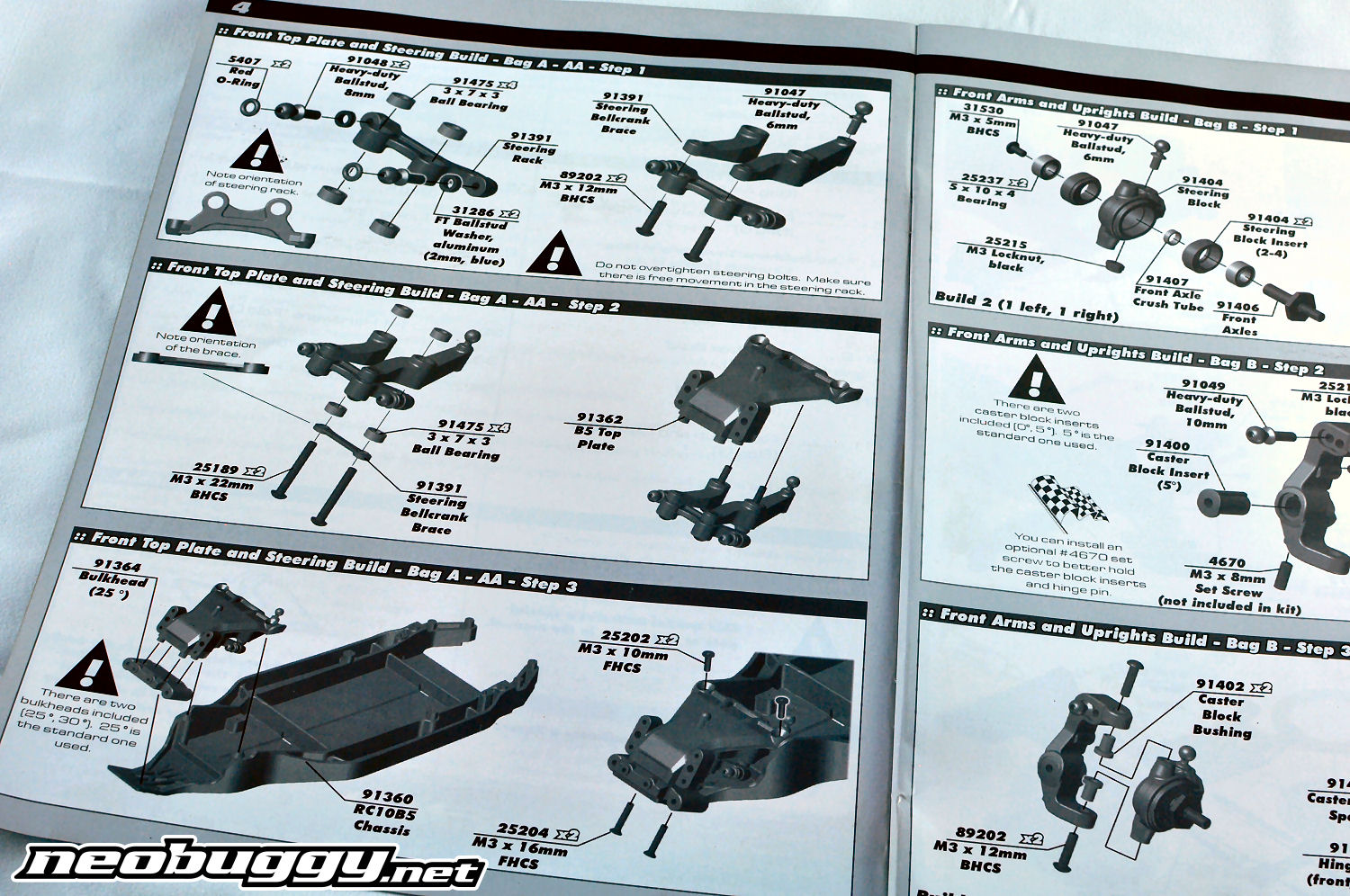

The manual could use a little more written guidance and is in need of a screw-size key to distinguish more easily between 3×10 and 3×12 (for example) without having to eyeball or compare.

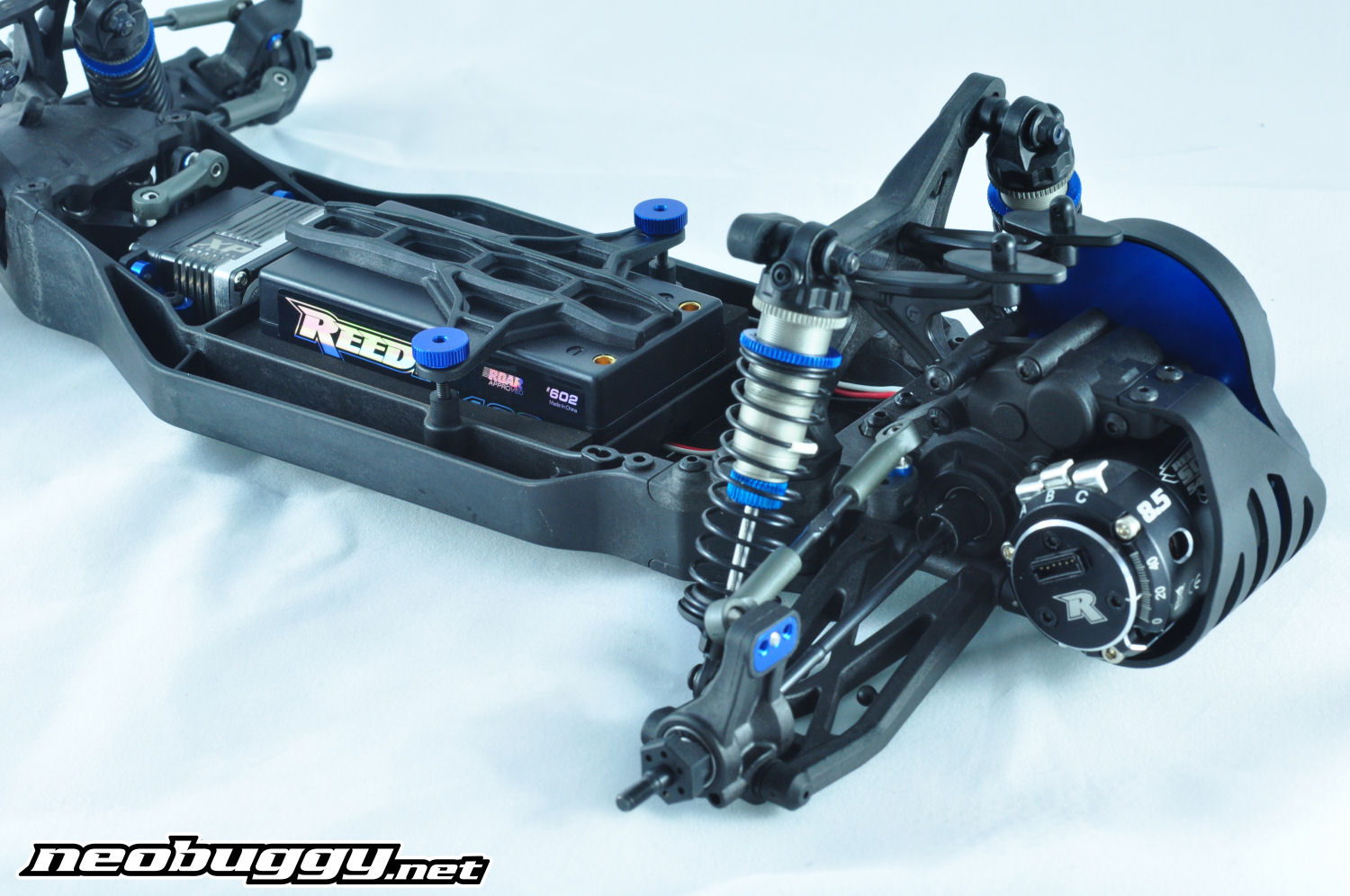

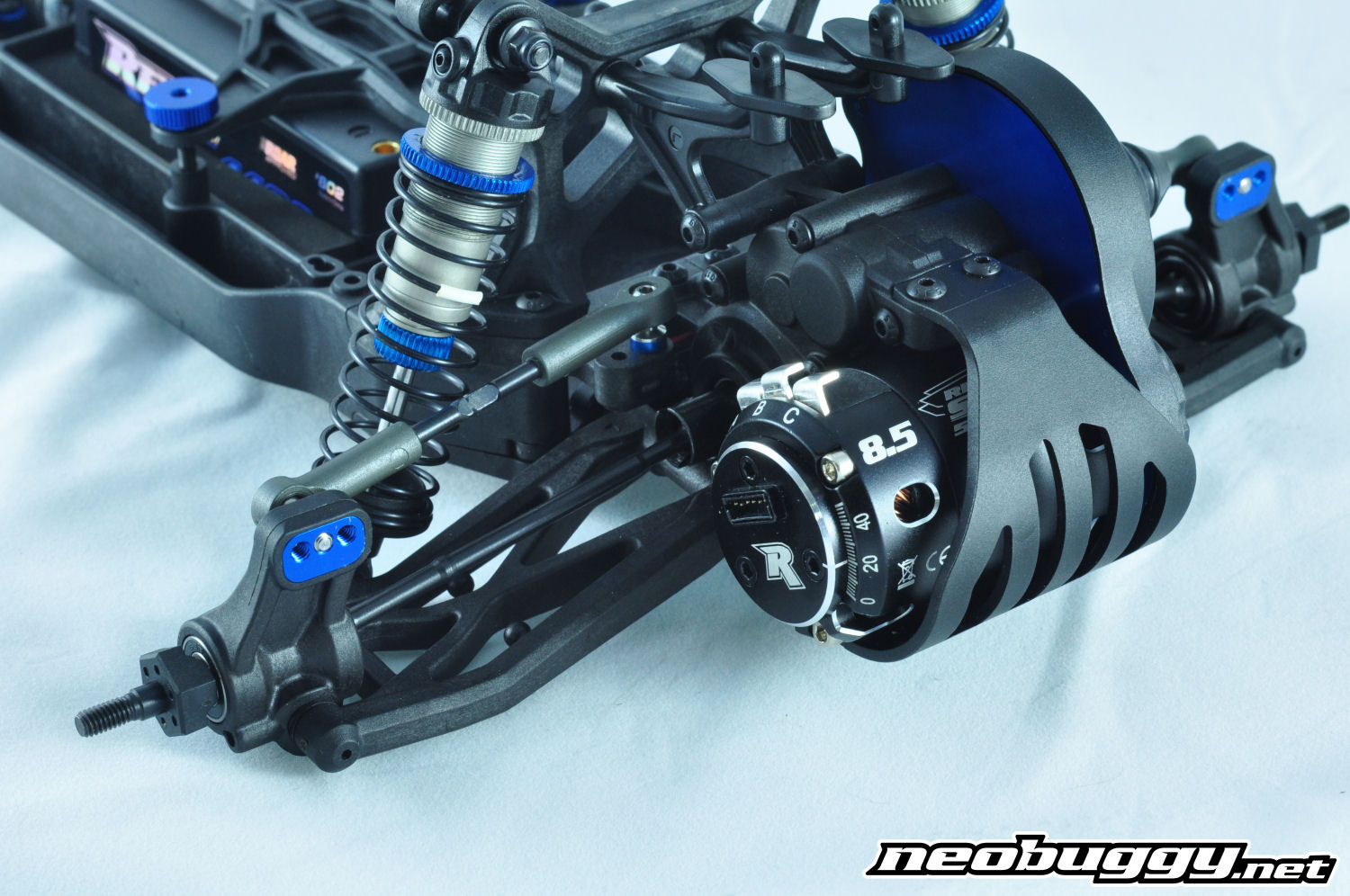

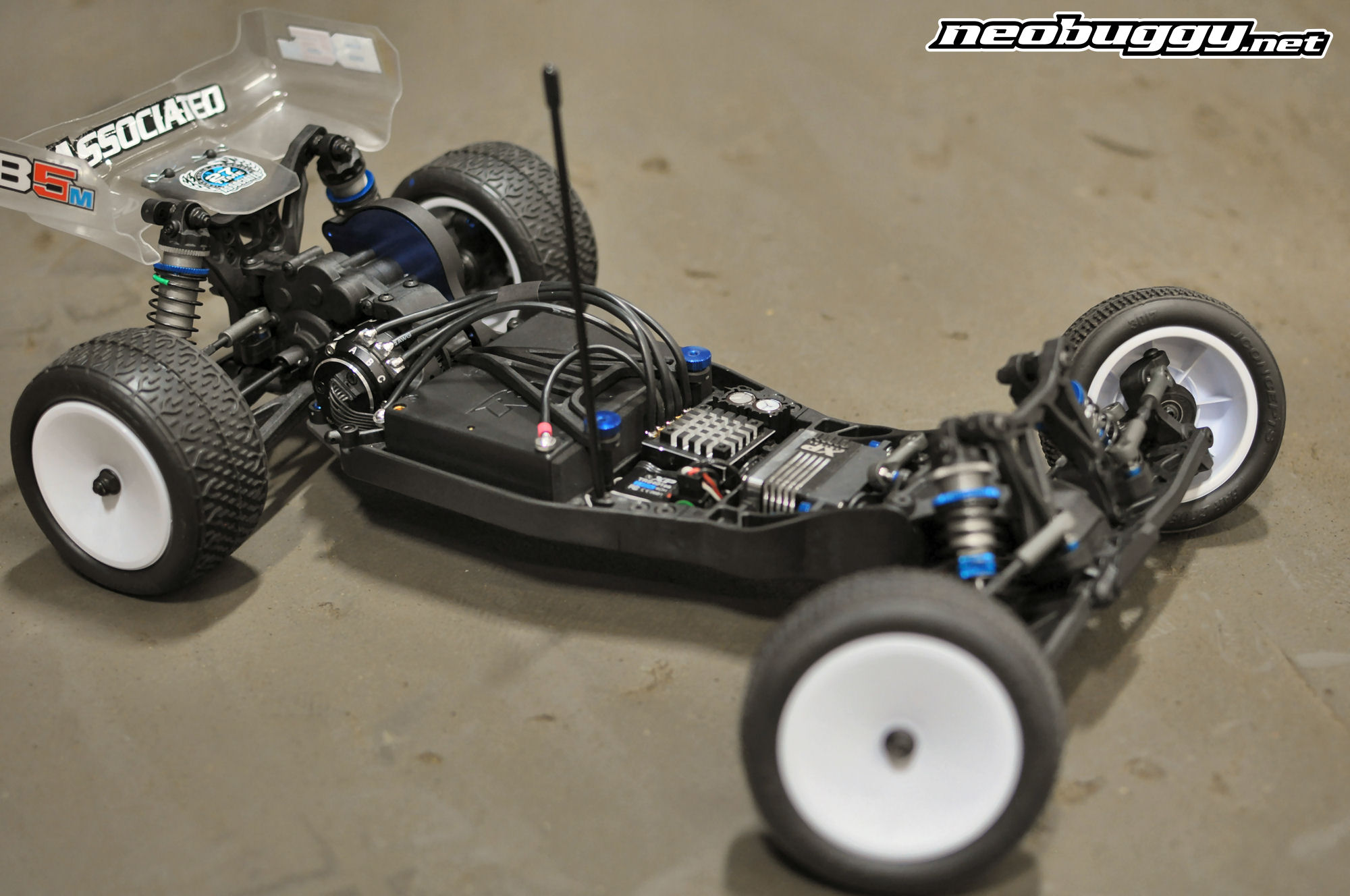

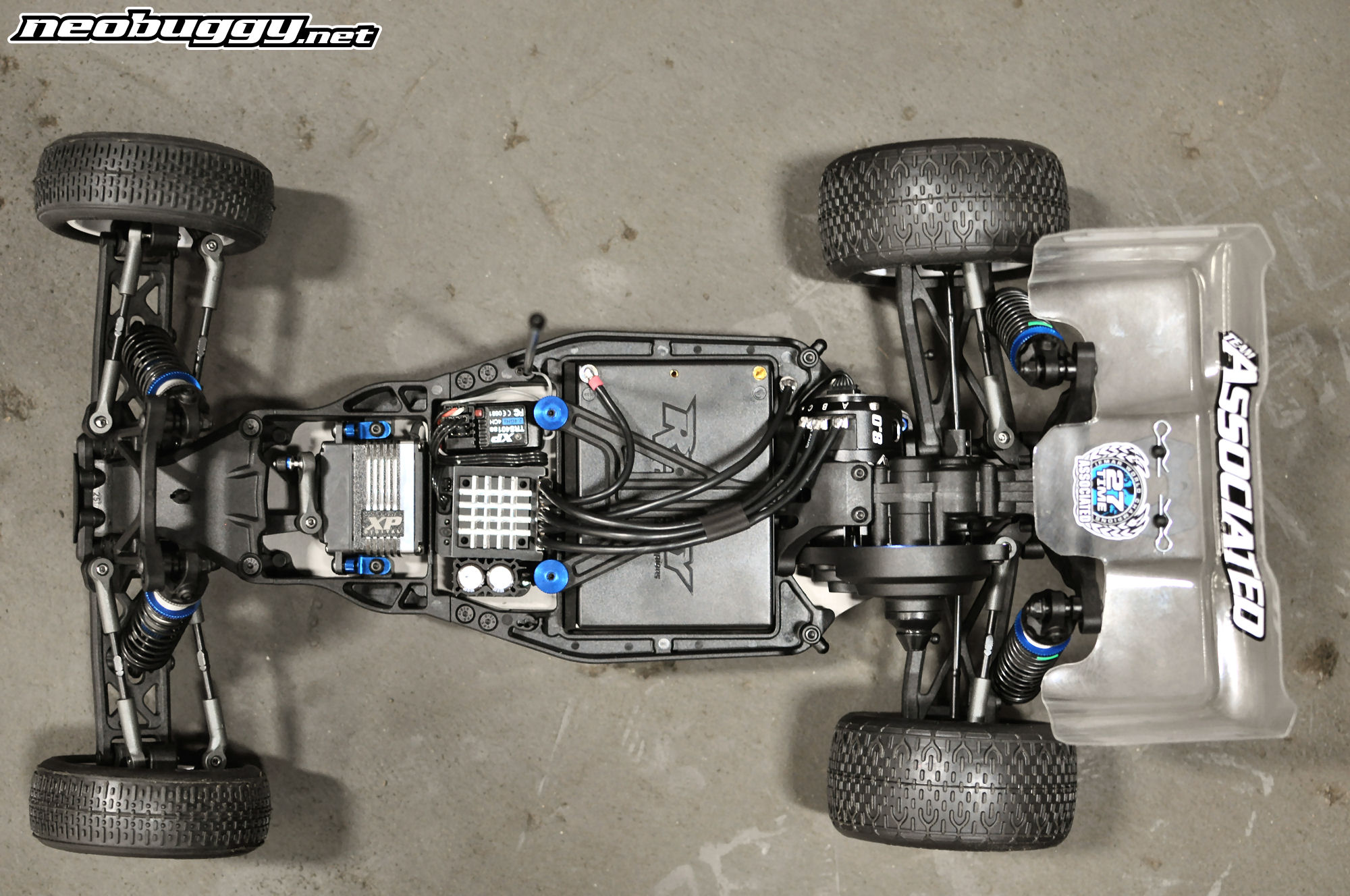

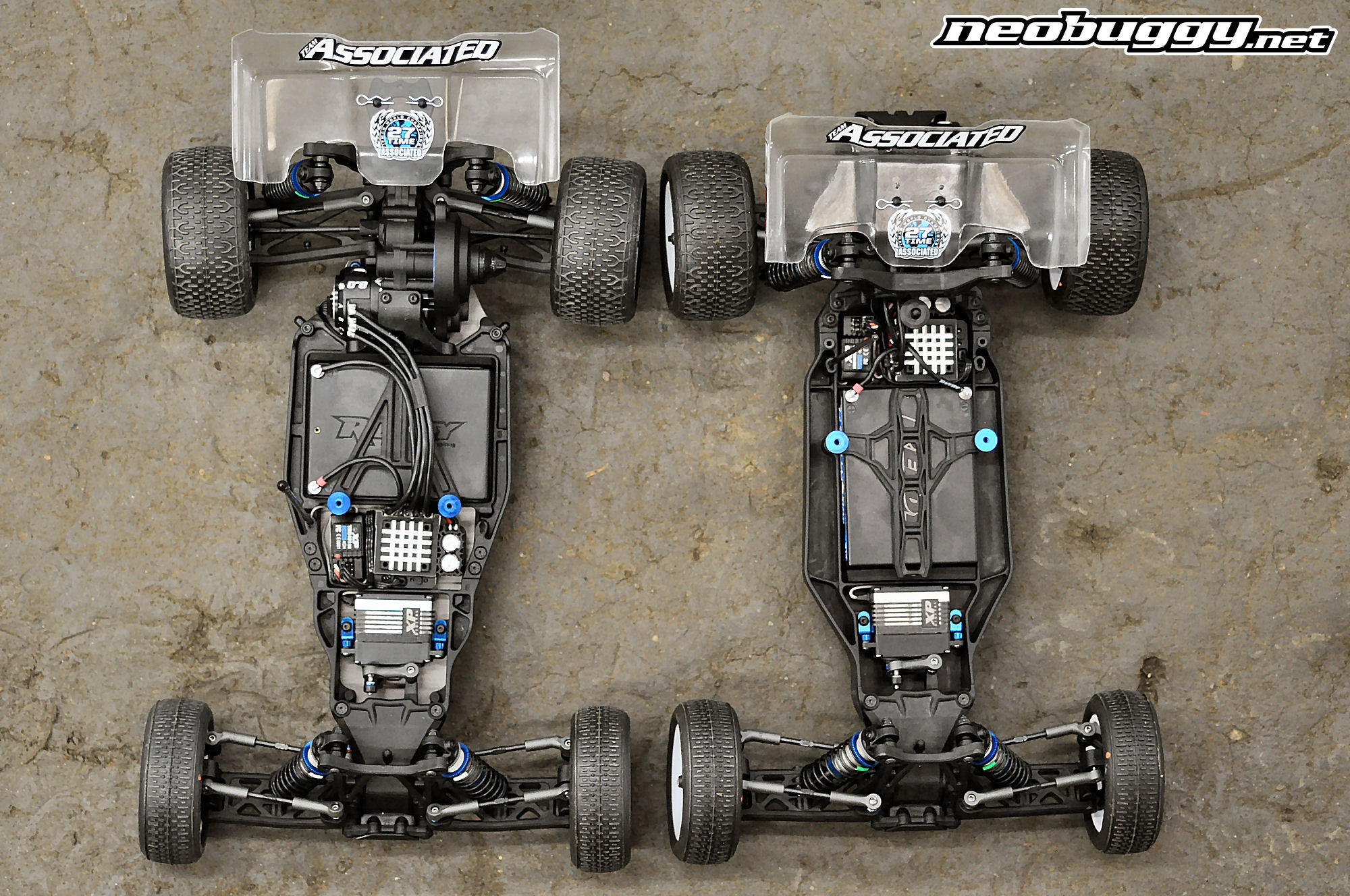

Assembly with Reedy 8.5 modified motor and “shorty” LiPo should equal similar handling and performance to the B5 I drove at the AE press event. AE provided a rear motor car because I will run this buggy mostly outdoors and occasionally indoors, where I will benefit from the added predictability and neutral handling. Stay tuned…

While I’m admittedly not a professional 2wd electric buggy racer, I have logged plenty of wheel time with the previous generation AE B4.2 at my local outdoor track and several of SoCal’s indoor tracks. What’s immediately noticeable about the B5 platform’s on-track handling characteristics is its stability.

“the B5M is incredibly quick. It’s the 2wd expert driver’s car for indoor…”

The B4 platform was always fast—who can argue with multiple IFMAR Worlds wins?—but in the hands of a club racer like me, it felt nervous and sketchy at times. For more talented drivers, the B4 was all the buggy they needed. At the wheel of the new B5 buggy, I felt more confident and considerably faster.

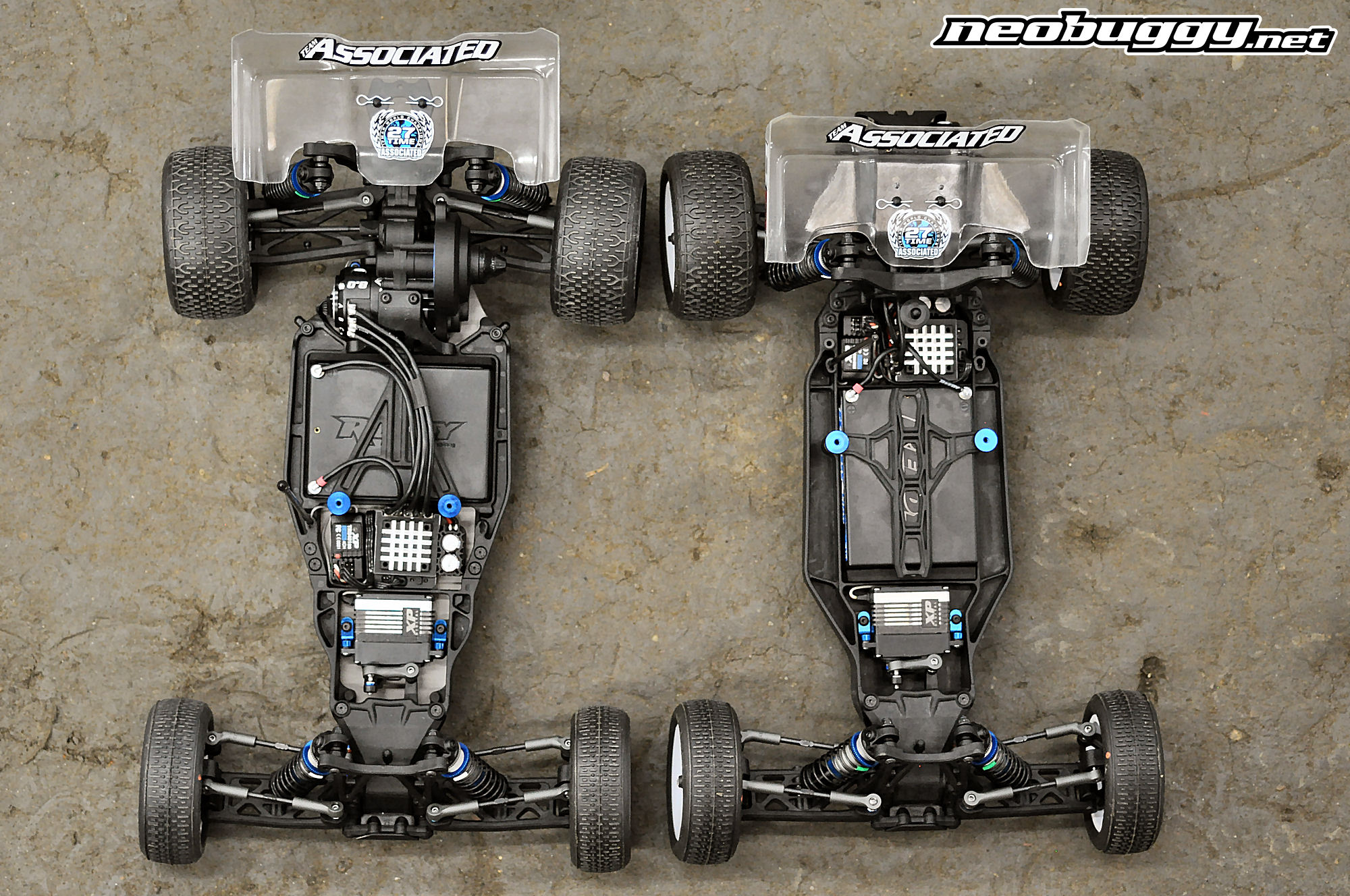

The rear motor car felt best to me during our limited track time, although one of my good friends and fellow journalist in attendance preferred the mid-motor car—and yes, we both drove the B5s on the same day, in spite of their silly claim of having an ‘exclusive first drive’ at SDRC. The rear motor B5 car transitioned through corners more progressively, with the rear end sliding predictably and smoothly as traction decreased and speeds increased. I never felt like the B5 wanted to bite back; it simply rotated, steered and accelerated on its way.

Such handling traits are more difficult to create than they sound. Designer Bob Stellflue (Mr. Stealth Lube, as the AE guys call him) reinforced multiple times that his design objectives were to maintain the best parts of the B4 while improving the platform. Predictable handling, increased steering and jumping ability were all addressed. We should note that the rear motor car also had the B5’s flat front arms installed, which as Stellflue remarked, would give the car a more forgiving handling feel.

The mid-motor car was also impressive. Though not as forgiving as my nitro-soaked throttle finger would have preferred, the B5M is incredibly quick. It’s the 2wd expert driver’s car for indoor, high traction racing–a buggy that can be pushed hard, rotated hard, and flung around the track in a way that rewards precision and confidence. On the indoor SDRC high traction track, the B5M felt right at home.

I’m confident that a full afternoon testing with this version of the B5 would result in faster laps than the rear motor car, but again we had limited time with both. The B5M I drove was equipped with the gullwing arms, providing it with increased steering sensitivity and an athletic, sharp reaction time to inputs.

Both cars felt planted, and both cars also jumped incredibly well. If I had to summarise the cars’ handling in one word, it would be “neutral.” This is a wonderful adjective to attribute to ANY 2wd buggy, considering they are challenging to drive and often like to oversteer or understeer without an expert set up. Having raced 2wd buggy in the past, I’ve always felt like each large jump could become the death of my buggy if jumped/landed incorrectly.

Occasionally a 2wd buggy will fly nose high or kick up the rear end without notice or reason. With the B5 and B5M, both buggies jumped predictably, with level flight and a minimum of driver input required to land smoothly. When the B5 cars land, they soak up the landings and are ready for throttle application immediately. My B4 buggy never quite felt like that. A definite improvement and one that drivers of all skill levels will appreciate.

I am eager to build a B5 and report on it here at NeoBuggy when I am able to get more track time under its wheels.

My initial impressions are that this will be a highly popular car, and that having two different optimized kits—the B5M for indoor and high traction surfaces, and the B5 for outdoor and lower traction surfaces—will be a successful venture for Associated.

Most club racers tend to spend a great majority of time at their local tracks, meaning they will set up one car and run it an entire season that way with only minimal changes. Associated believes that few racers want or need a “convertible” rear motor/mid-motor car in one box, and after driving both versions, I tend to agree.

Pick one, build it, and hit your local track. Associated did its homework with this car, and if initial impressions mean anything, the B5 and B5M have quite the bright future.

Feature: Associated B5 on Track

After giving Associated’s new B5 a thorough shakedown at SDRC earlier this winter, I eagerly anticipated the arrival of our test B5 rear motor kit for full testing.

Rather than bore you with a generic “review” which would insult your intelligence, or show you photos of suspension components you’ve undoubtedly seen a thousand times already, I’ve kept this article as a focus on the car’s handling traits.

I’ve raced the B5 buggy weekly for the last several months, often twice per week, here in Southern California with some of the fastest club racers around. I’ve won a few, I’ve lost plenty, but through it all the B5 has performed like a champ. Here are some thoughts about the car and my experience with it thus far.

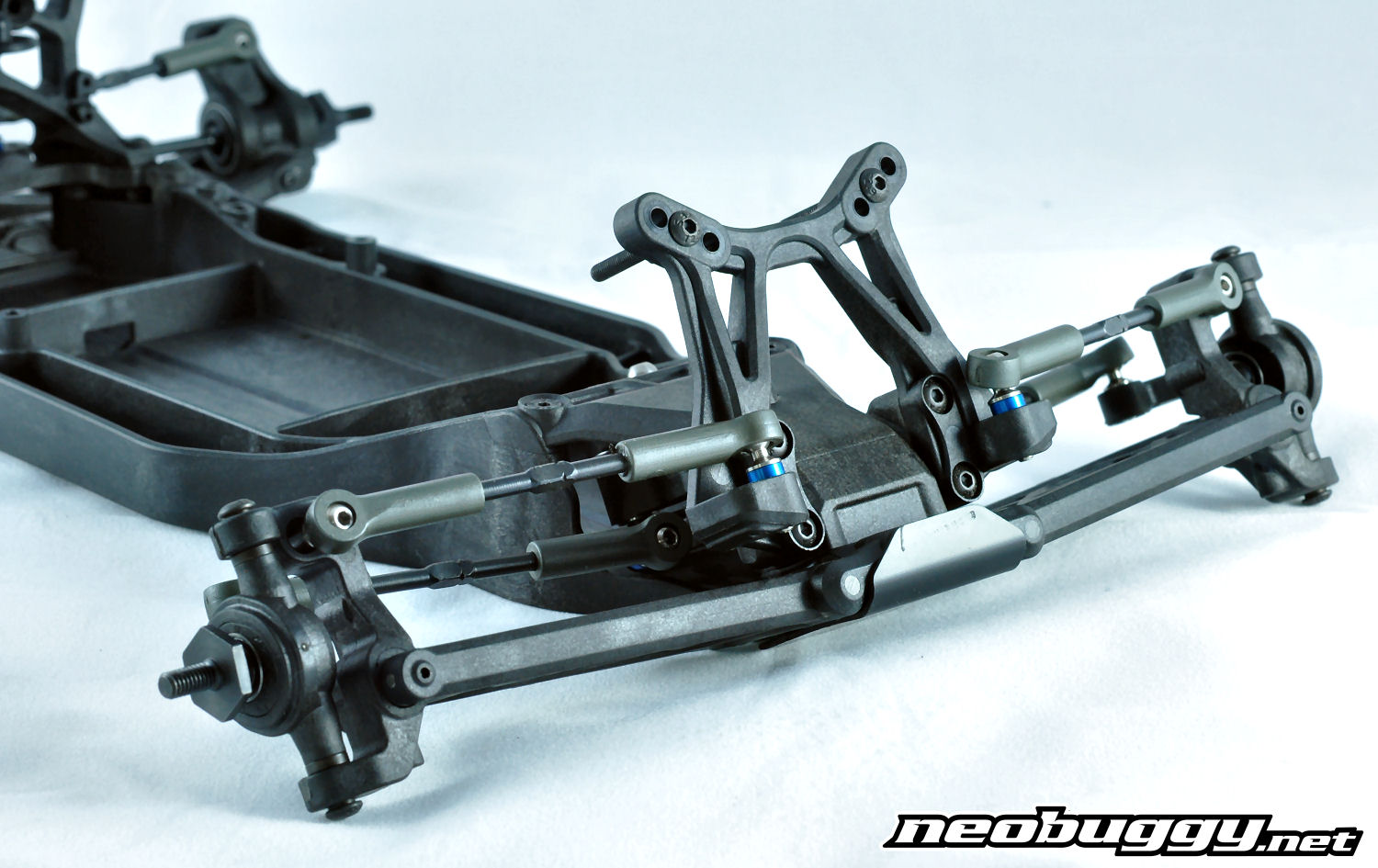

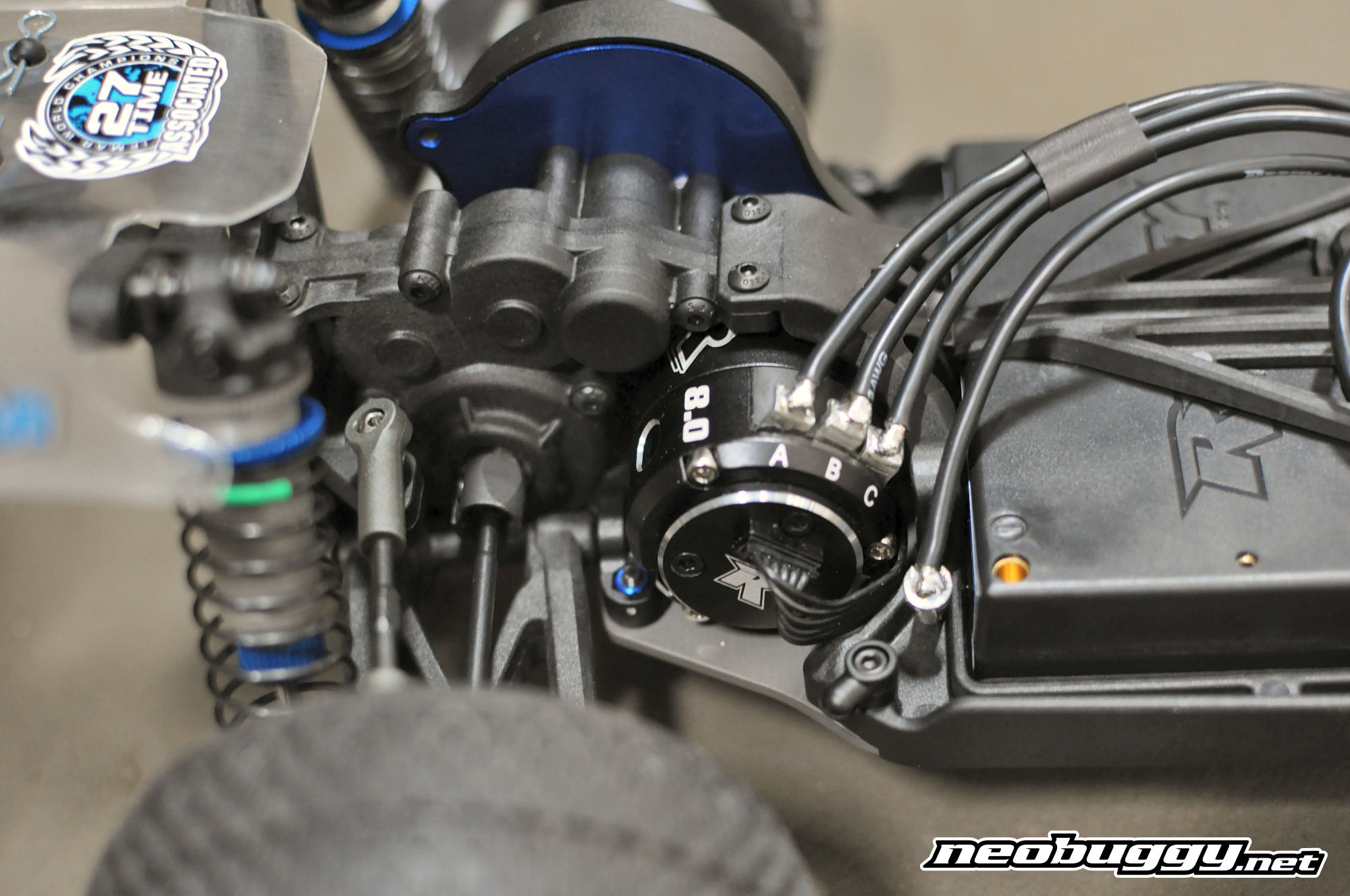

On the Bench

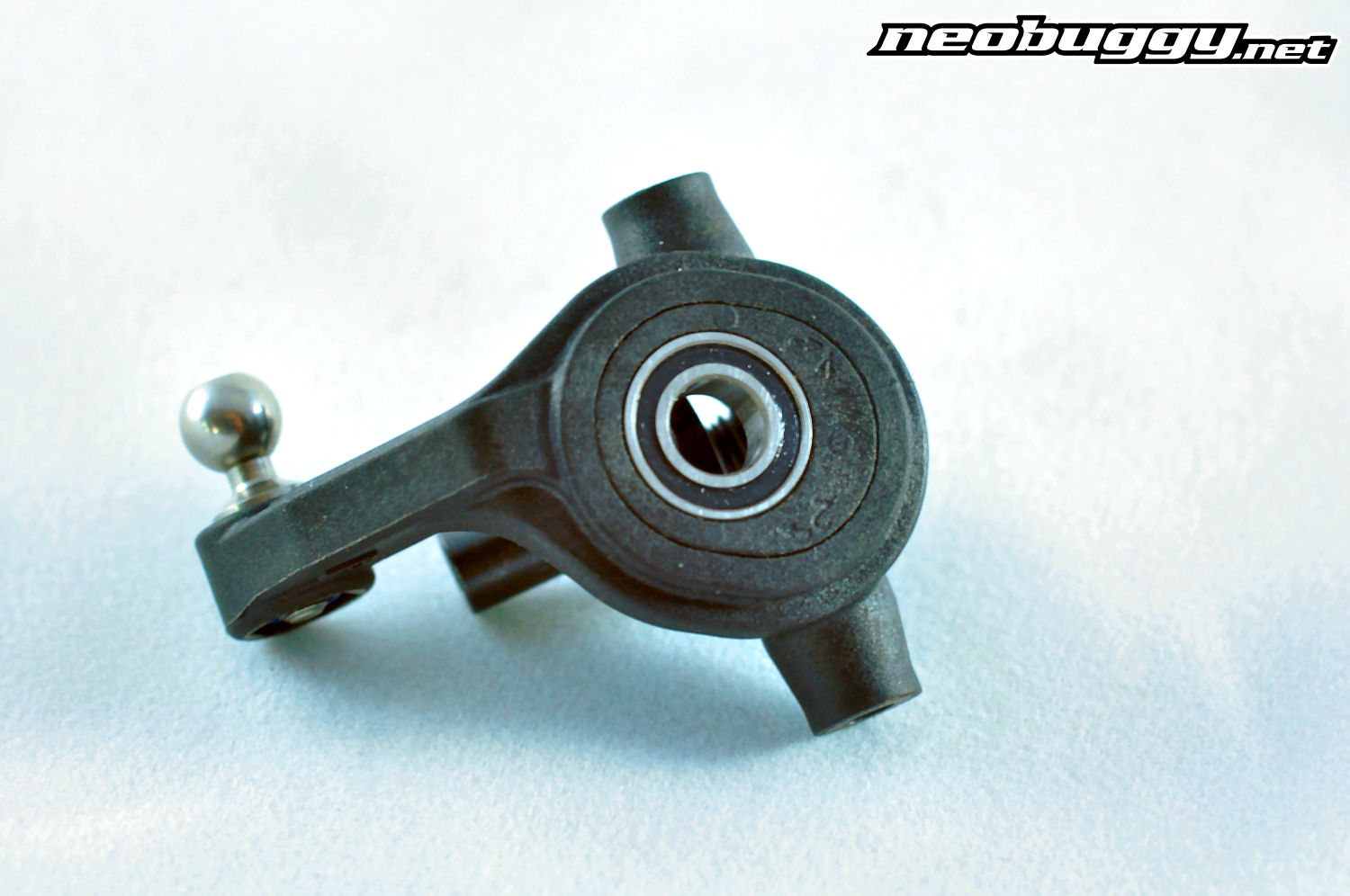

First off, my B5 kit built as well or better than any Associated kit I’ve ever assembled. And I’ve had some good ones, and some really not so good ones over the years. AE nailed the mouldings, fitments and clearances with this car. I’ll usually spend an extra hour or two on any kit I build from any brand to eliminate binding in the suspension and transmission.

Minus a quick pass with my Hudy push/pull reamers through the suspension arms.

I didn’t have to spend an extra moment freeing anything up on the buggy. The B5 was a great build.

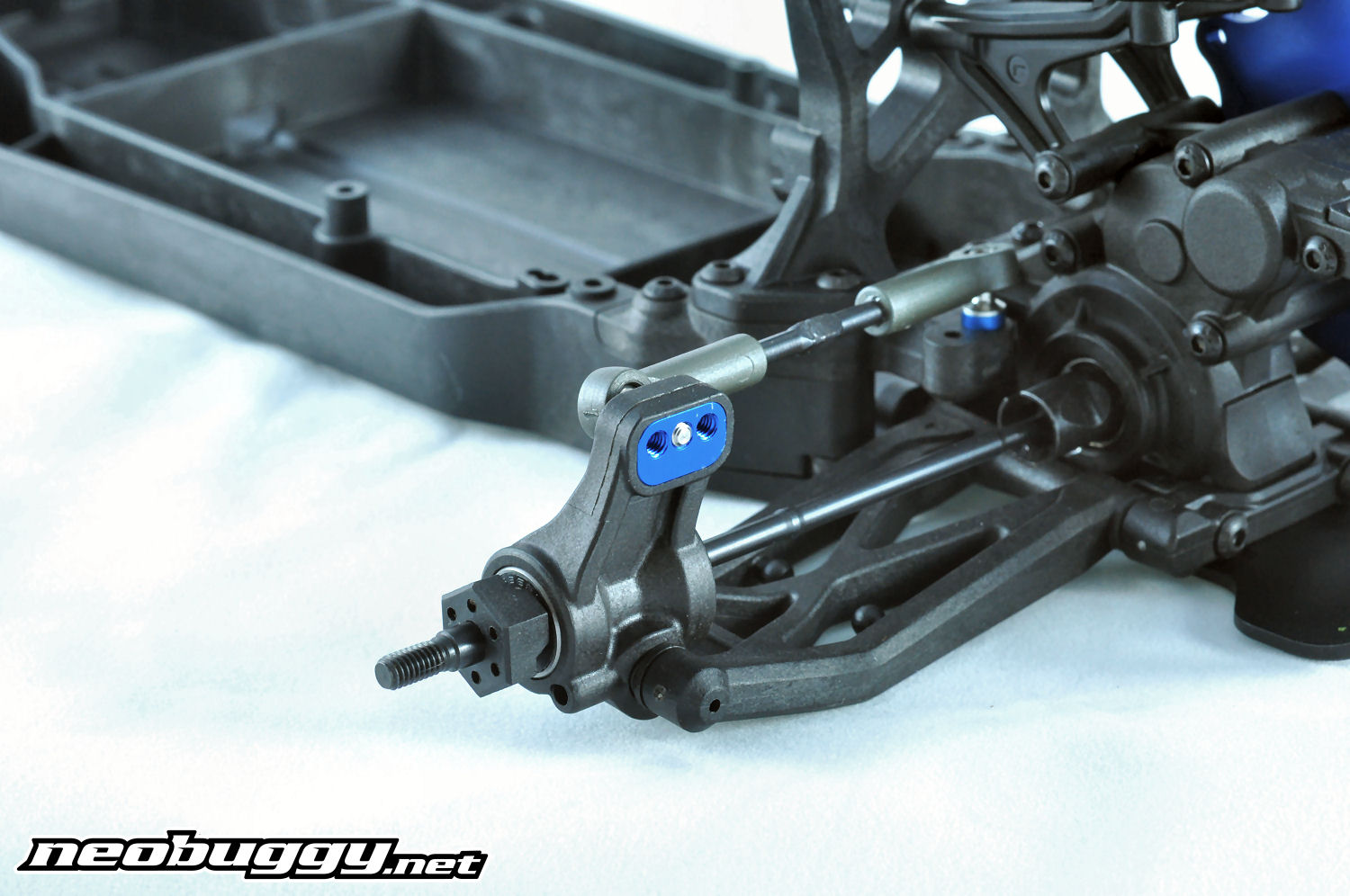

Once I began dialing the car in for the track, I did discover a few little things. First, those cool new heavy duty ball cups are nice, but they grip the turnbuckles so tightly that I had trouble adjusting camber without one of the ends popping off a ball stud.

Multiple friends of mine who built B5s also had the same issue.

I had to hold one of the ball cups with pliers to adjust the tie rods, at least until they had been adjusted many times. I also found that some of the ball cups began binding once dirt entered the picture, and no amount of crushing with pliers helped free them up. Unfortunately, I couldn’t find extra ball cups anywhere (both locally and online), so I’m running the car as free as possible while I wait on new ball cups.

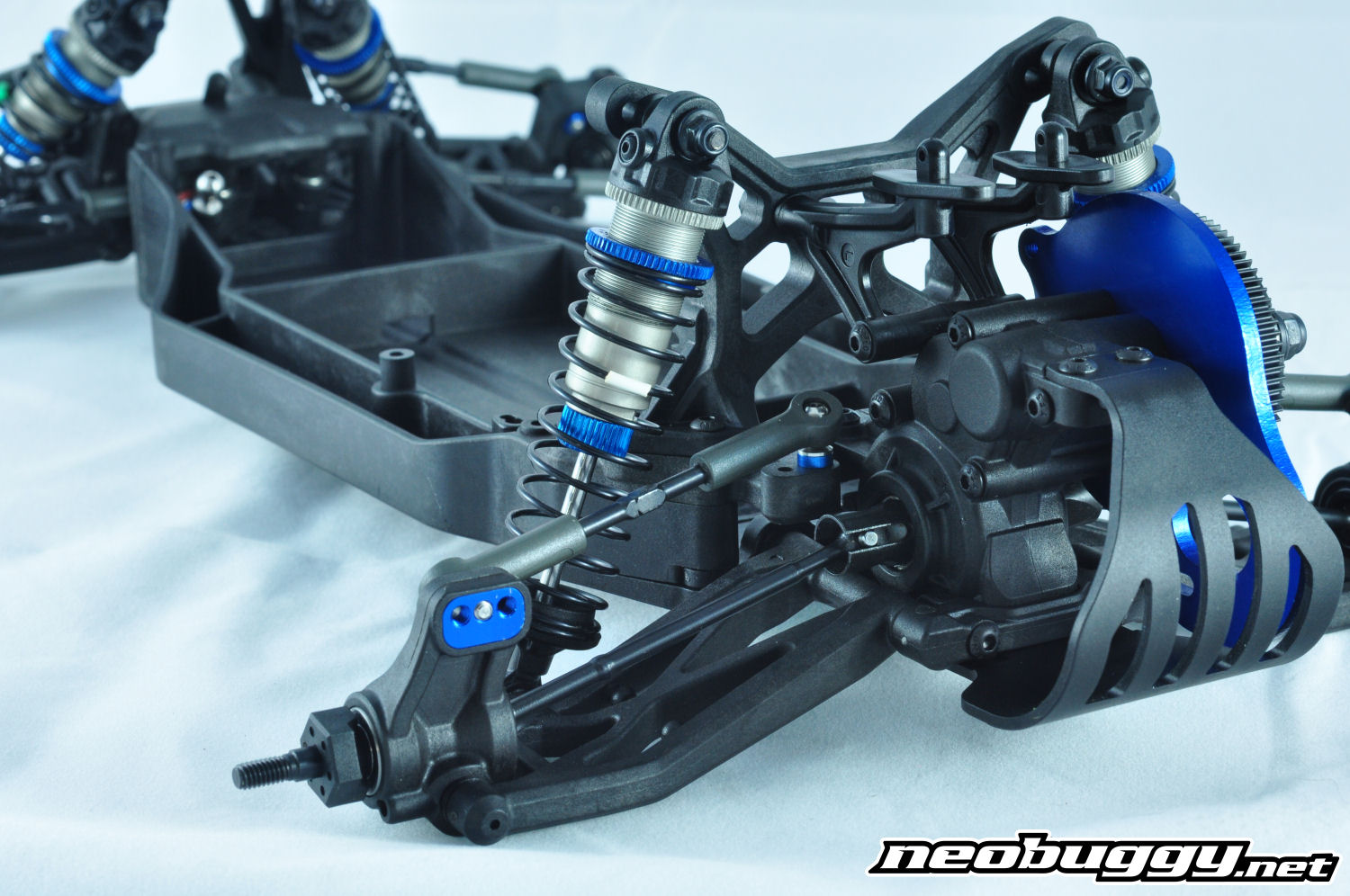

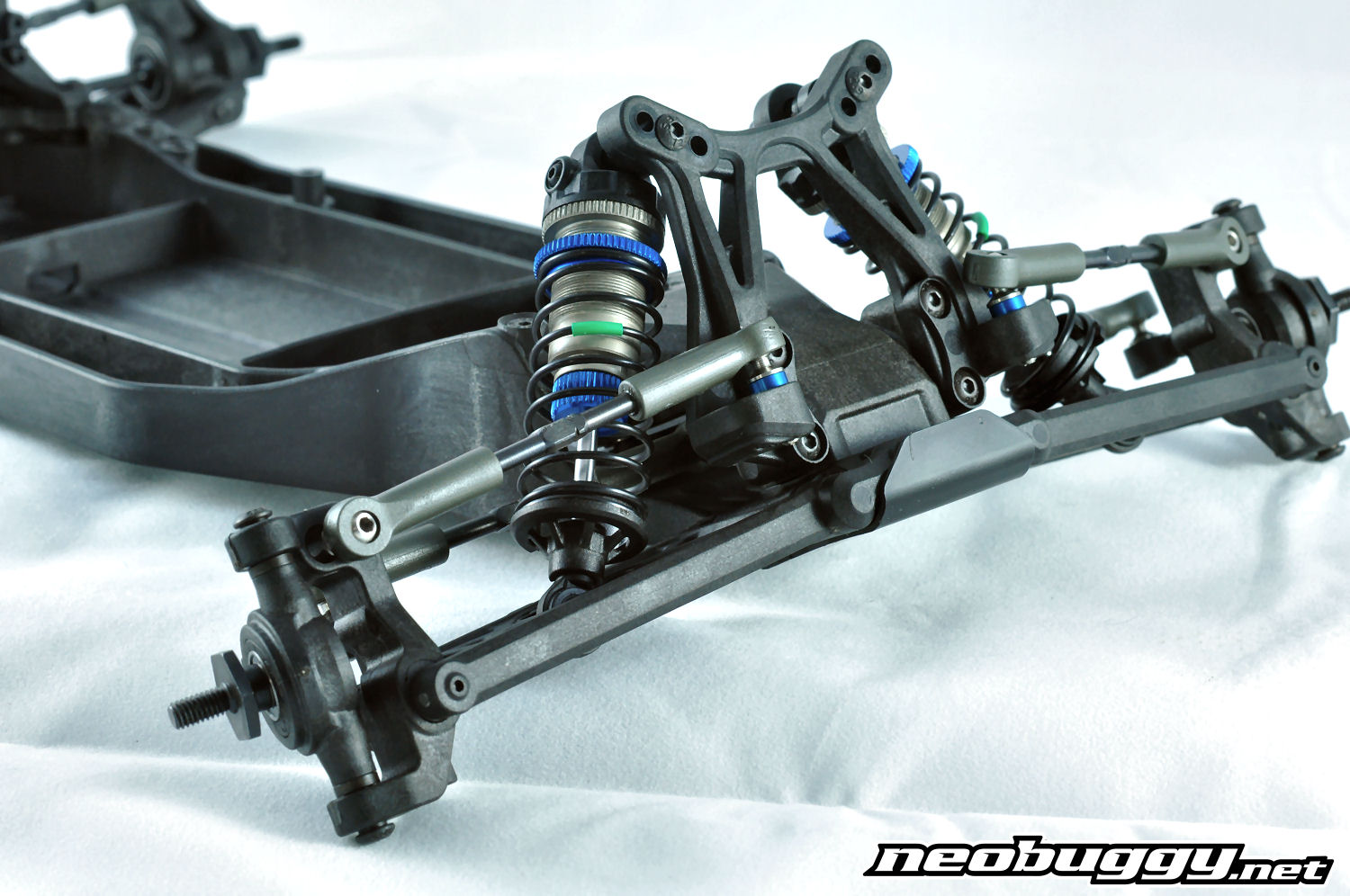

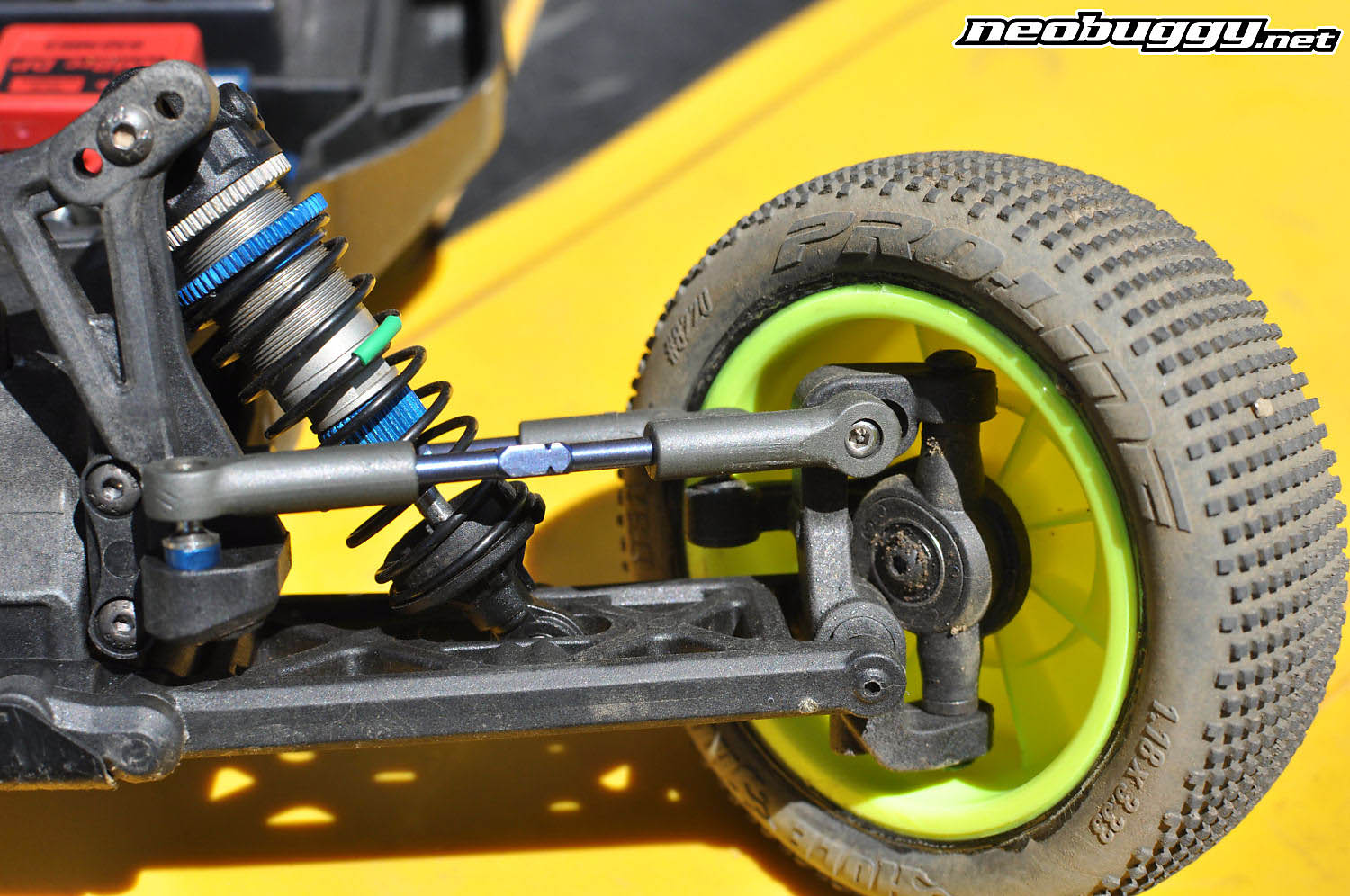

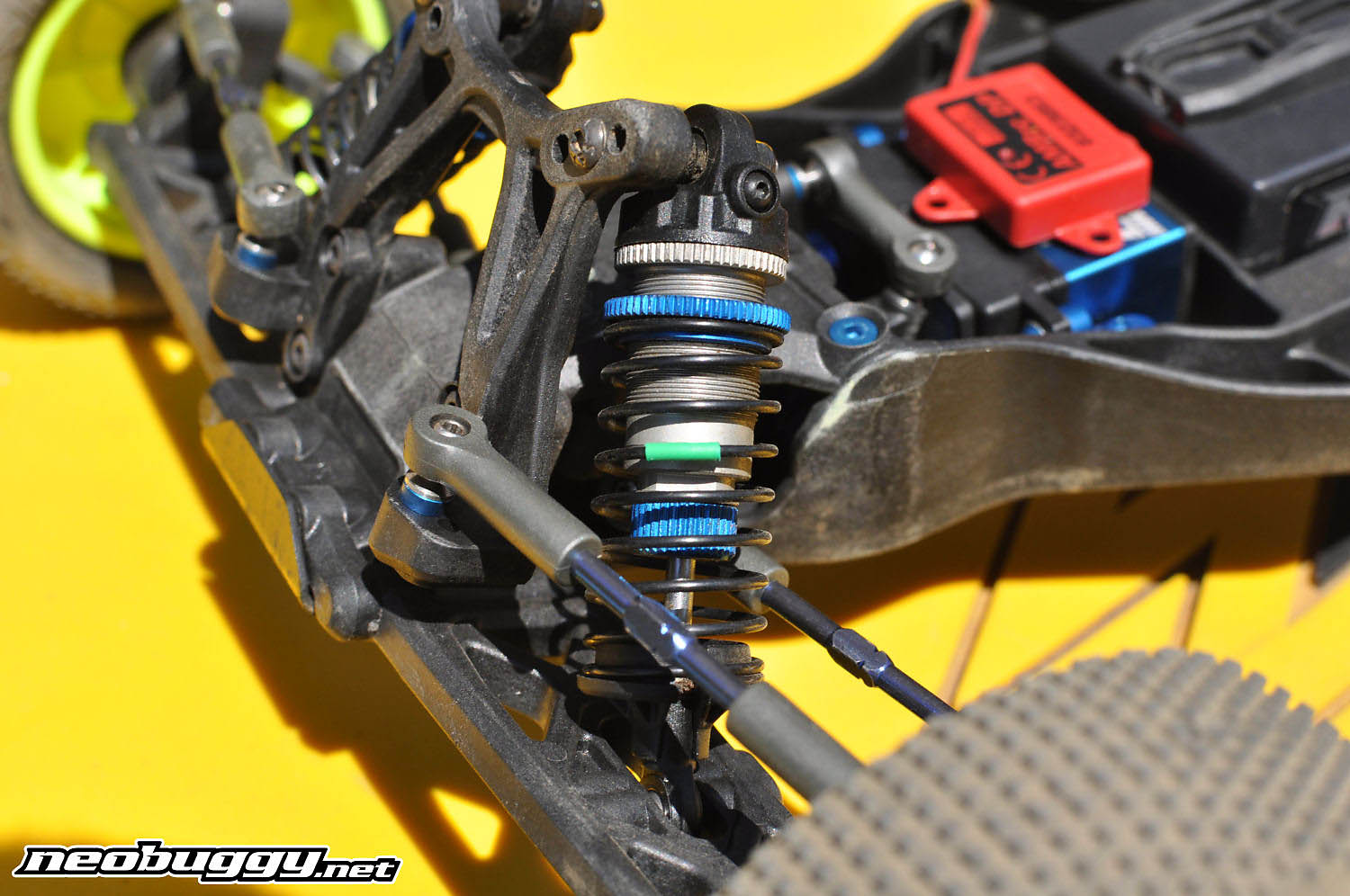

Building the B5’s shocks are a walk in the park, at least in my opinion, when compared to building the older style AE emulsion shocks. Before you cry foul, understand that I am a perfectionist. I like all of the shocks to work properly and evenly, and no matter how precisely I built the old emulsion shocks, they never seemed “right.”

The B5’s big bore shocks, with the bleed screw cap, assemble nearly perfectly every time. I topped the shock off, capped it, pushed the shock shaft in to bleed the air and extra oil, and tightened the bleed screw. Booyah, perfectly bled shocks. Nicely done, AE.

Editor:We lost Stephen for a while as he celebrated his shock build by obsessively pressing the suspension up and down about 576 times. Buttery smooth baby.

On the Dirt – “calm and collected”

AE’s engineer Bob Stellflue (listen to Stellflue’s audio interview about the B5 here) was quick to tell me at the first Associated test session that the AE team spent lots of time on the B5 and B5M’s baseline set up. Knowing that the team gets exponentially more hours on the track with their cars than a club racer ever could, I built the B5 exactly to the manual’s suggested set up.

I requested the rear-motor B5 because my local track, Hot Rod Hobbies in Southern California, is an outdoor track. Not only is the traction relatively low when the track isn’t grooved (it grooves once per year for the Hot Rod Shootout), but on club racing nights, the track is also watered. You’ll get low traction when the sun is up, and medium traction at night once the moisture comes up. In other words, Hot Rod is a rear-motor type of track and similar to most other outdoor club tracks I’ve visited. A B5M would be a waste of time here.

The B5M Mid Motor – No good at Stephen’s local track

With the stock set up, the B5 impresses immediately with tons of rear traction…even on a slippery surface. Initially, I couldn’t believe how planted the B5 felt under acceleration out of corners; rather than looping out or pushing into a gradual over steer, the B5 felt calm and collected.

After several club outings, I grew accustomed to the B5’s slight push and started looking for more steering (more on that in a minute). With the stock set up, AE uses the 4mm trailing front axle insert for maximum stability. That stability never goes away even as the tires wear, and for most racers, this is a great thing. 2wd buggy tends to be very difficult to drive on an outdoor track with unpredictable traction. The B5 feels dialed in even right out of the box; even when it isn’t the absolute fastest thing on the track, it’s stable and consistent. I’ll take it!

You’ll immediately notice the B5’s improved jumping and landing characteristics. Jumps don’t upset the car. Landings are smooth and predictable. Yes, you can wad it up, but you really have to screw things up to do so. The car’s stability continues in bumpy sections. Through a particular whoops section at our local track, B5s charge through the bumps, floating over the bumps at three-quarters throttle. Sections like this tend to cause a 2wd buggy to get “assy,” swapping the rear end left and right until things slow down. The B5 is just locked in.

All of this stability means that the car occasionally is too locked-in for its own good. Experienced racers will likely wish for more steering than the stock set-up provides, which is always better than wishing for more traction. Read below to check out some of the changes I made.

Dialing it in

So I’ve gushed a bit about the B5’s out-of-the-box handling, but I’m not the only one. Check the forums and ask at your local tracks. The rear-motor car works really well out of the box, but like any race car, it can get better with some tuning to your own preferences.

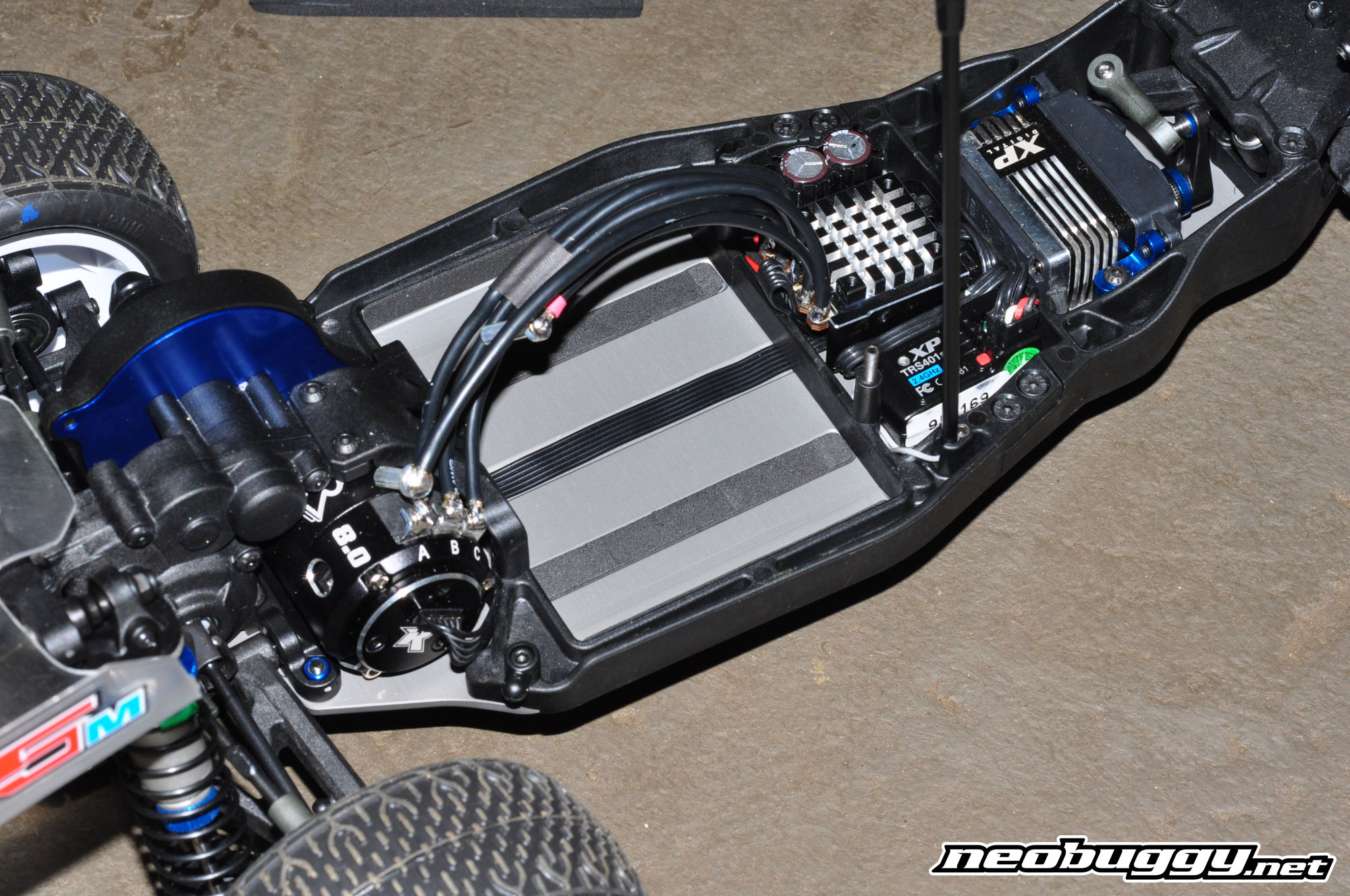

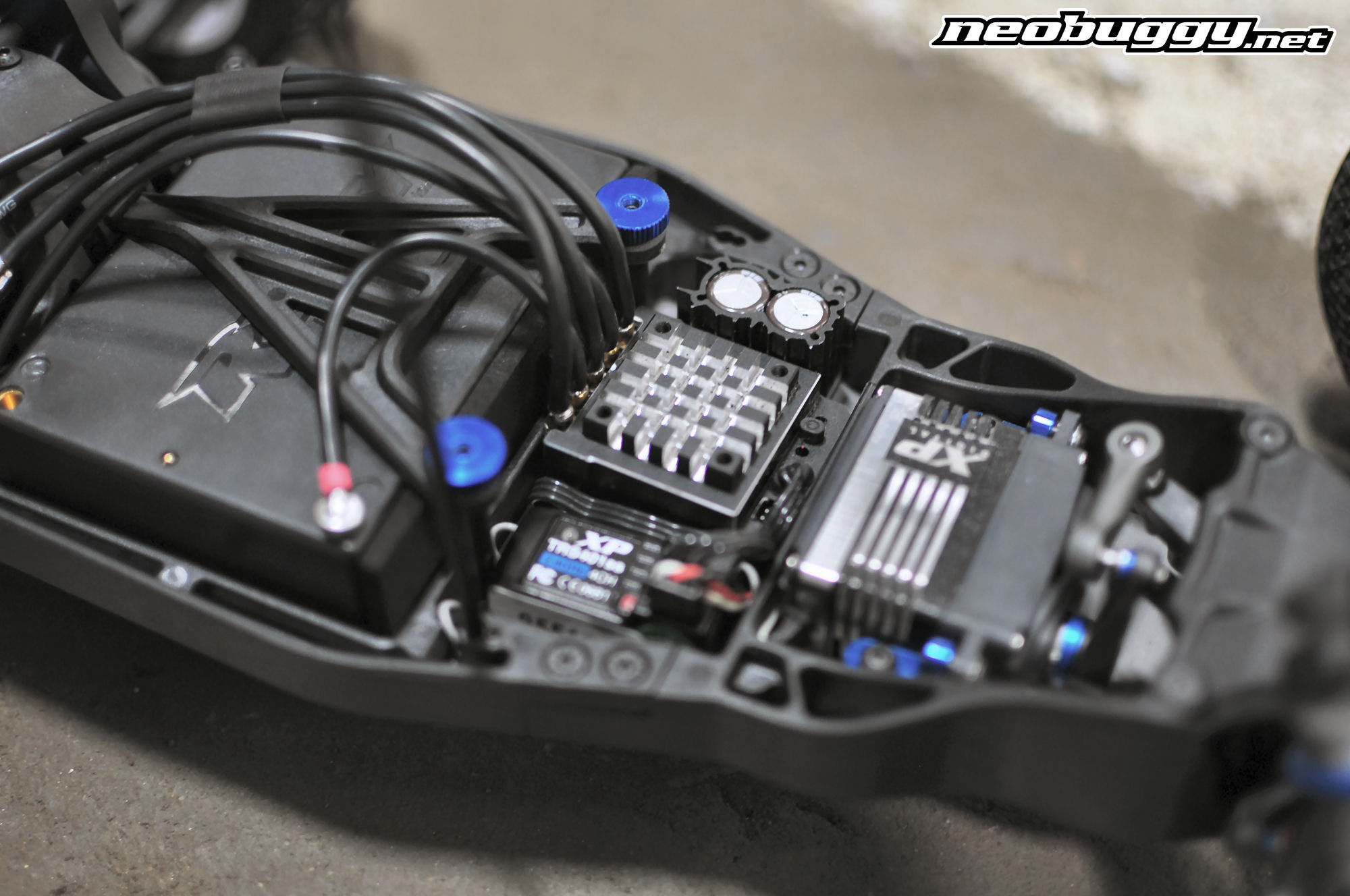

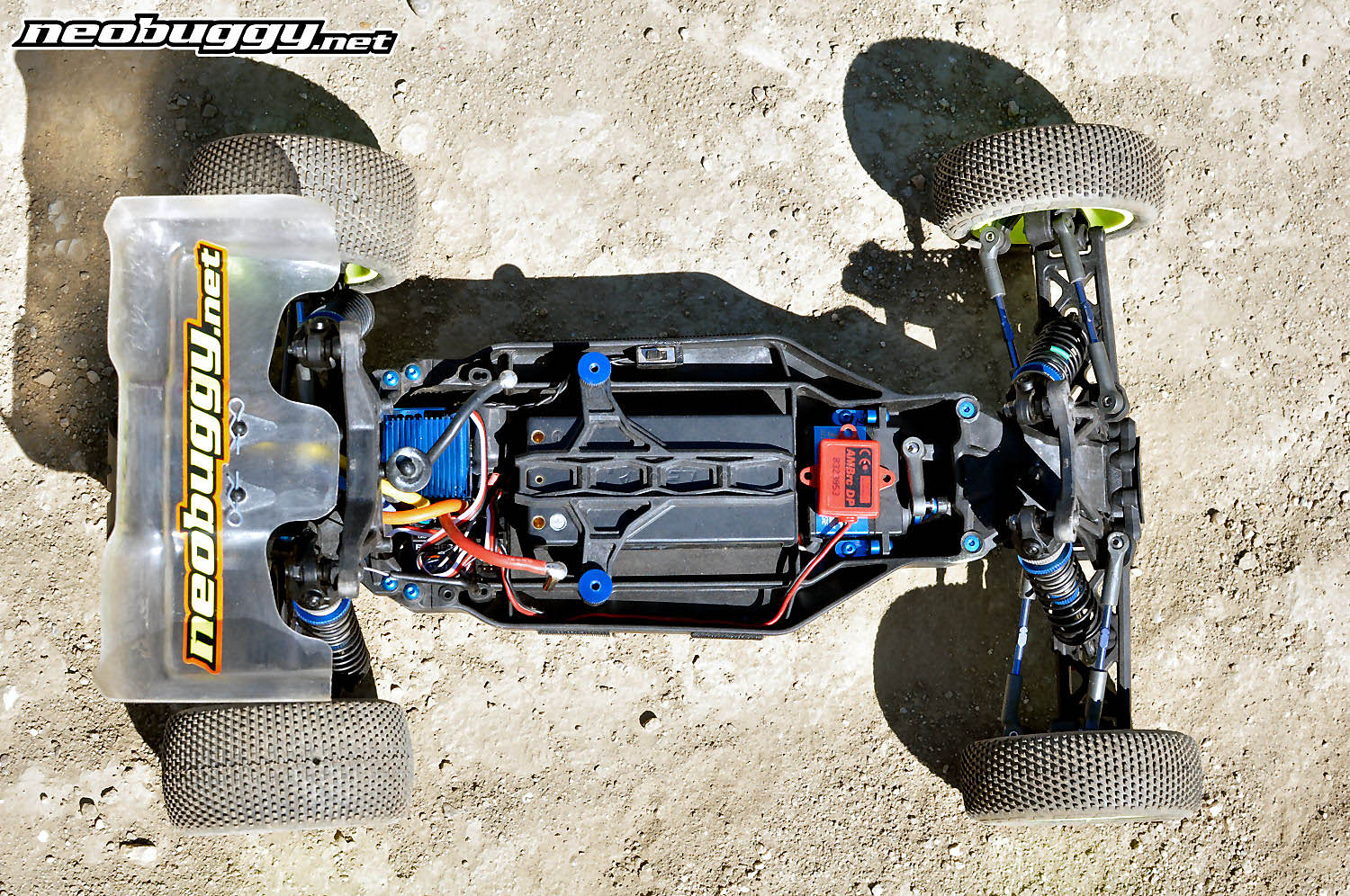

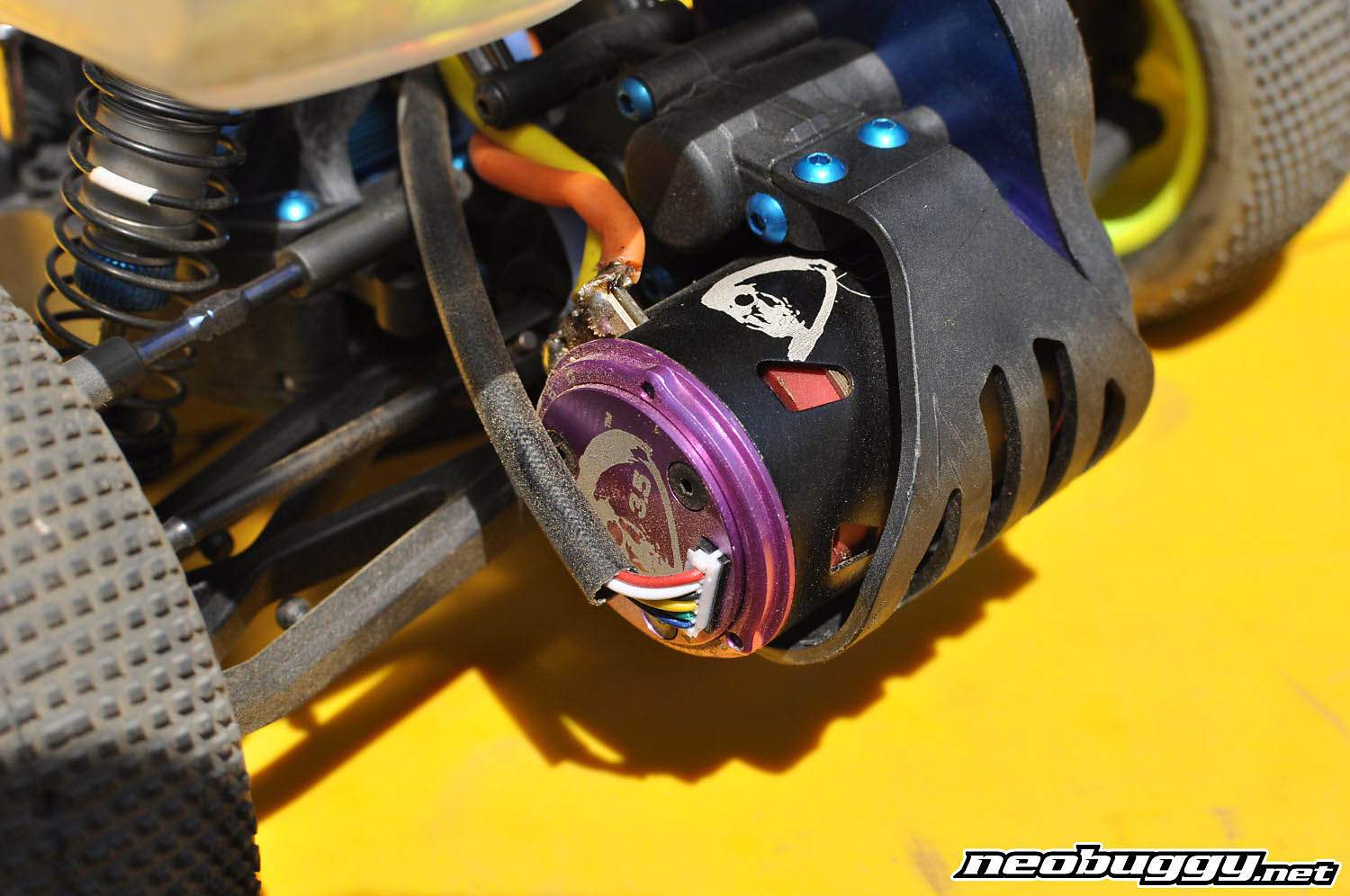

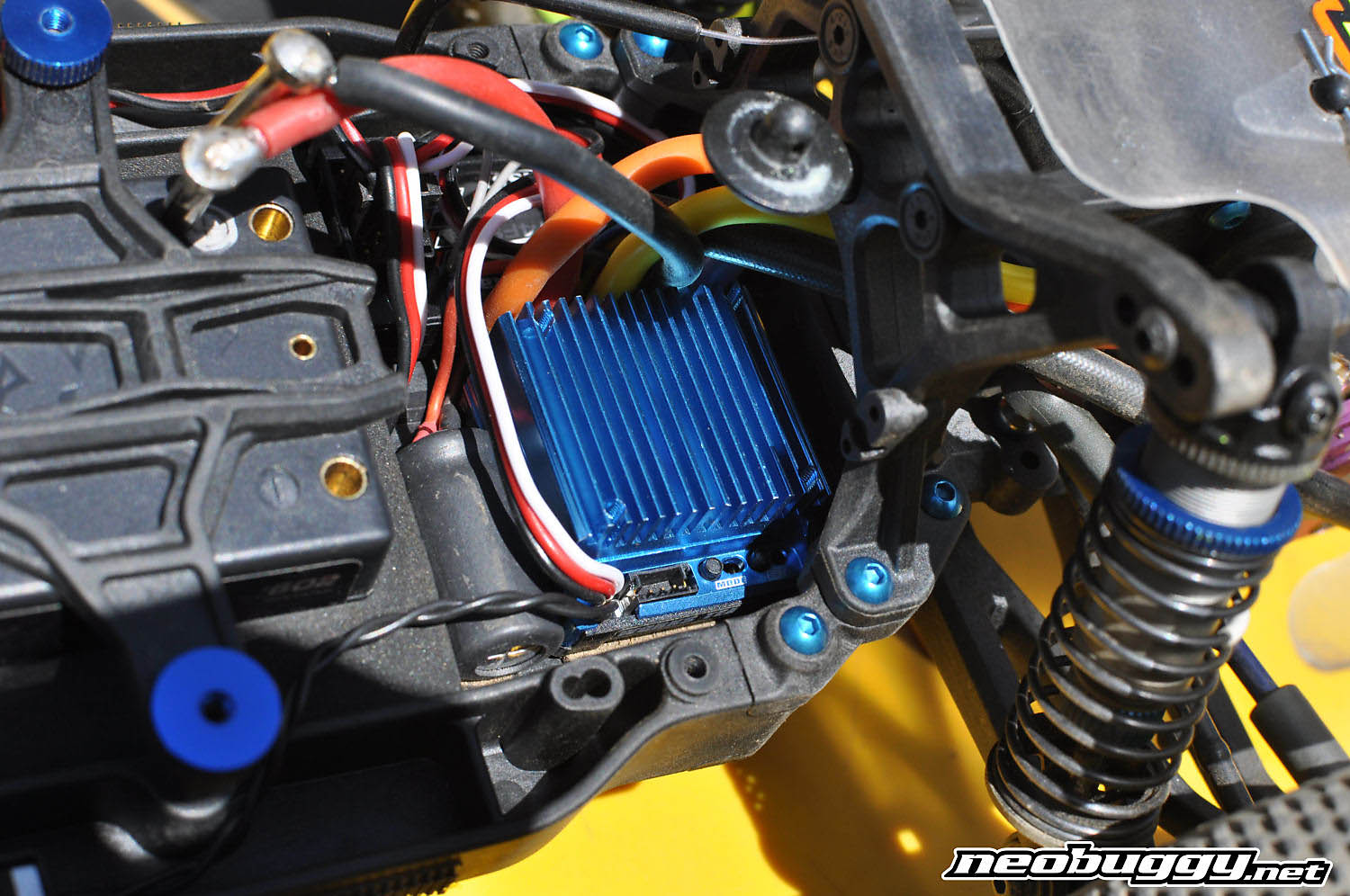

By far the most popular class at our track and throughout SoCal is the rapidly growing 17.5 “blinky” class, which is a no-timing, no-boost class. The focus is on chassis tuning and driving rather than overpowering the car with a 6.5-turn modified. For 17.5-turn racing, I set my LRP ESC to the “blinky” mode (one slowly flashing blue light), and installed the most popular 17.5 brushless motor at our track, the Trinity D3.5

To help reduce rotating mass and improve acceleration, I removed the robust but overkill-for-17.5 racing VTS triple slipper assembly and replaced it with AE’s lightweight standard V2 2-pad slipper clutch (#9603 pads, #7495 vented plates). This is a great tuning option for stock racing, but for modified I would stick with the VTS triple set up.

I also installed a Robinson Racing lightweight aluminum pinion gear, and set the slipper to raise the front end slowly under full throttle. Next, I installed a set of AE’s Factory Team titanium turnbuckles (#1282), and I installed a set of AE’s aluminum screws (#91543) to shave just a bit more weight…and to look super factory dialed, since I don’t have the driving talent to wear oversize sunglasses and a flat bill hat without looking silly.

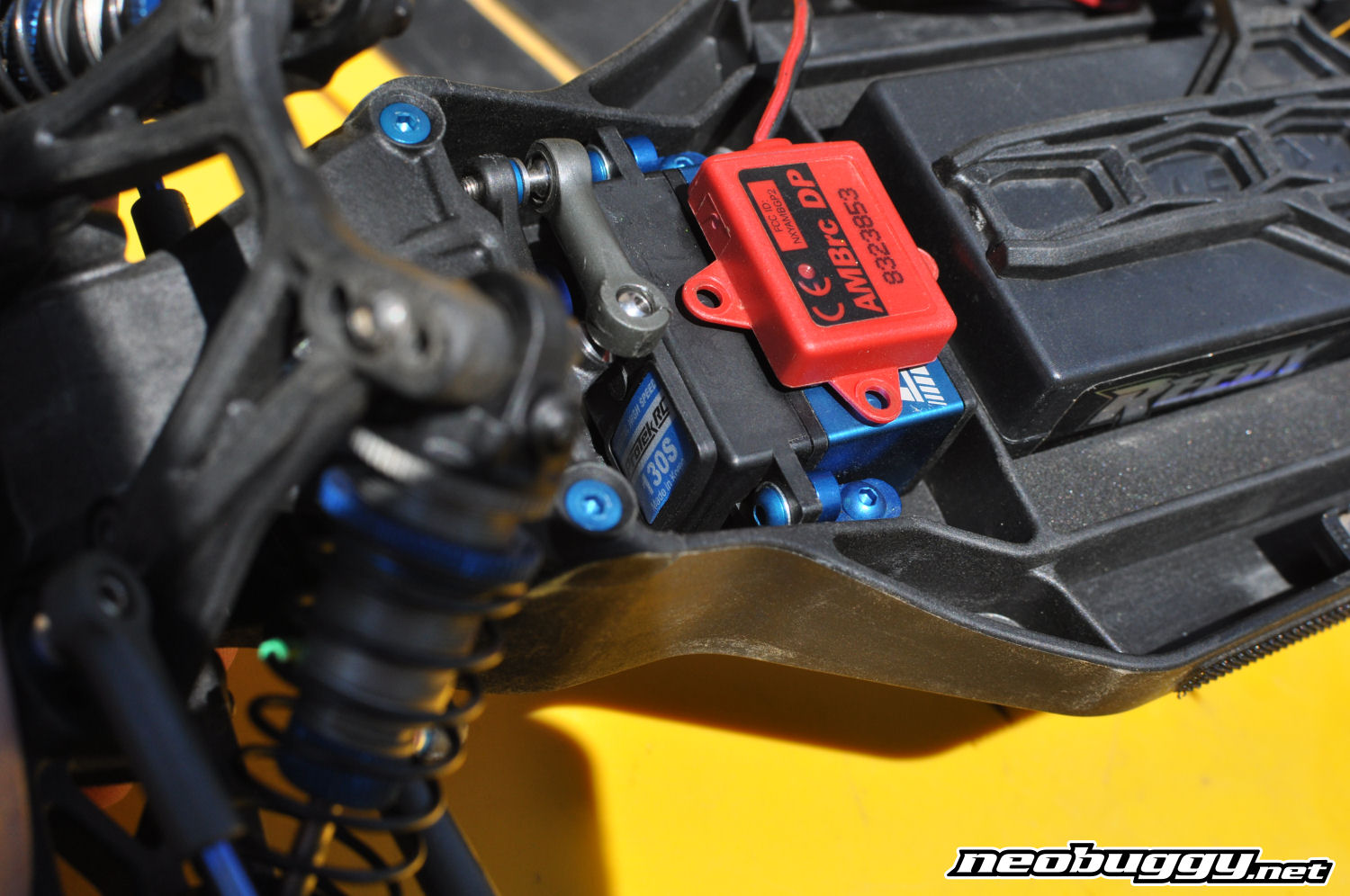

On the bench, I swapped out the stock #4 front trailing axle inserts for the #3 inserts, which move the axle forward slightly for increased steering. Following the manual’s instructions, I altered the Ackerman shims and front castor hub position to match the #3 trailing insert.

I’ve found that the B5 is, like all 2wd buggies, sensitive to ride height adjustments. For some reason, ride height is one of the last adjustments a racer will think to check, if at all. Spend some extra time before your first run, and every few runs after, to make sure ride height is set properly as the springs settle in. Even a few millimeters can make or break the car’s handling. Use a perfectly flat surface (your warped wood pit table probably isn’t a good idea), and set the car’s ride height first, then set camber and toe. Your B5 will thank you on the track.

For a bit more steering, I also unthreaded the front shock ends 2-turns for extra down travel. Finally, keep an eye on the rear ball diff—keep it on the tight side rather than too loose, to improve longevity and overall performance. After nearly 2 months of racing weekly (or more), my car’s ball diff is still very smooth. So far, it is wearing well.

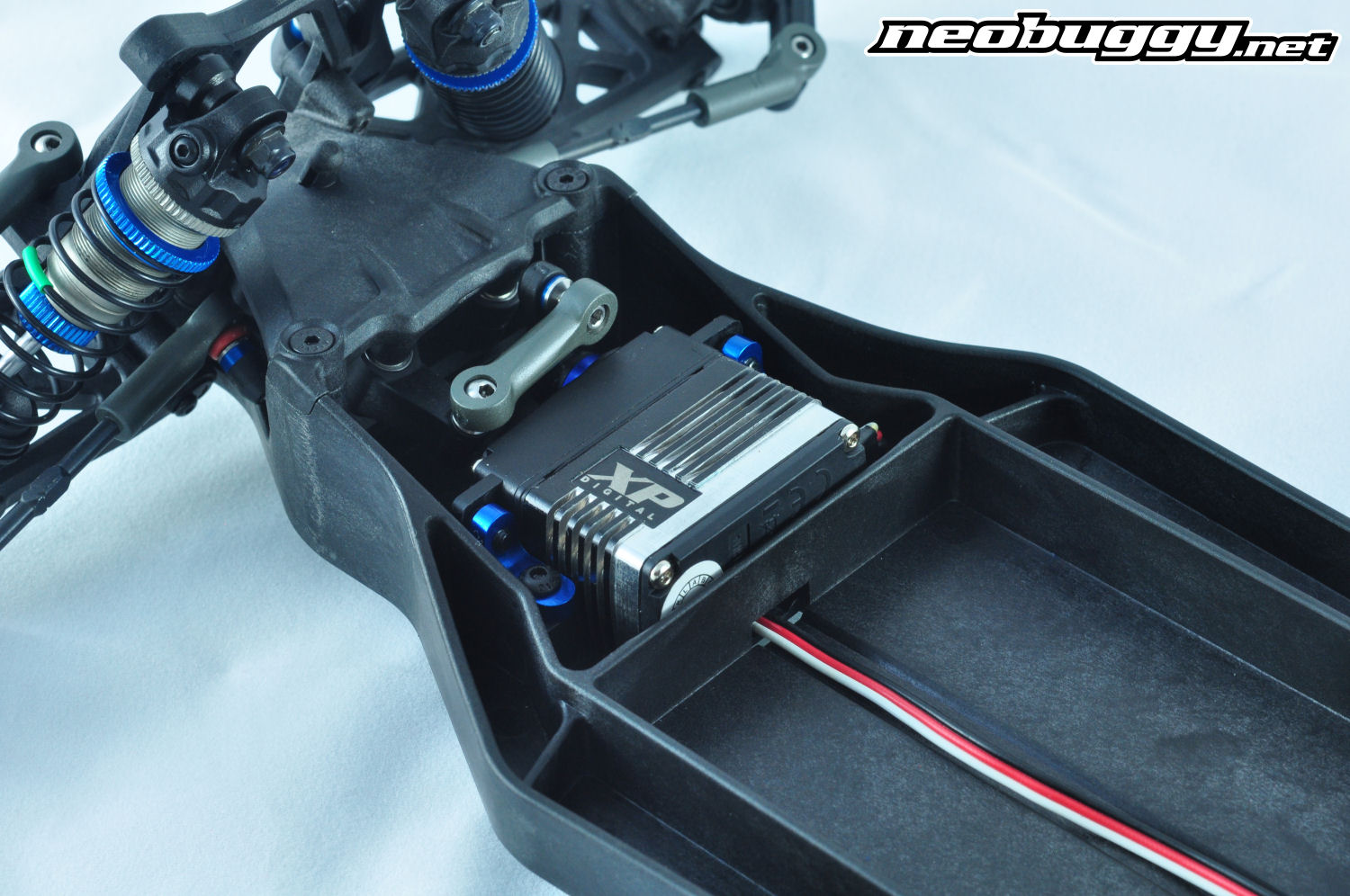

With these adjustments and parts additions, my 17.5-class B5 is a rocket with excellent performance on our local outdoor track. I typically run Pro-Line M4 Holeshots front and rear (holeshotM4.jpg) and I installed a super fast ProTek RC 130S speed servo for quick handling and turning in tight sections. Small adjustments work on the B5, and you can tune in more or less steering easily with the front trailing axle system.

I am not a professional driver, so the fact that the B5 works so well in my hands should be encouraging. If you’ve considered trying a 2wd buggy but were unsure of which car to try, the B5 is an excellent choice. It’s easy to drive, the stock set up works better than any other stock AE set up that I can think of, and the car is durable…which is a good thing, because as of this article, the only flaw in AE’s nearly perfect B5 armour is parts support.

It’s nearly impossible to find suspension arms and suspension parts, even online. Everyone is backordered, which is surely a sign of the car’s popularity. Grab spares when you find them, at least until AE catches up with demand.