The small company X-Factory has long been an integral part in the RC scene. True to the motto "Do the Math" included Charles "Chazz" and Paul Sinclair end of 2004, two and three X the Team Losi XX-4 buggies and XXX-4 together and created the X-5, which the excellent chassis of the XX 4 merged with the then-contemporary design of the level for routes built, unloved by many successor. The next major breakthrough came with the X-6, which, inter alia Hupo Hönigl and Ellis Stafford have won numerous championships. The X-6 made from the dominant buggy over the past decade, the Team Associated RC10B4, the first for the competition devised, mass-produced mid-engined Buggy. Unlike the younger Centro conversion of X-6 was not built primarily for systems with extremely much grip, but should also work on conventional Lehmstrecken. Slowly but surely, more and more drivers from the belief come from that on slippery ground only a rear-engined Buggy can function, which is without question one of the achievements of the Sinclair family. Not for nothing is the current slogan, "We made mid-engine work!" - We have managed to make mid-engined cars work !

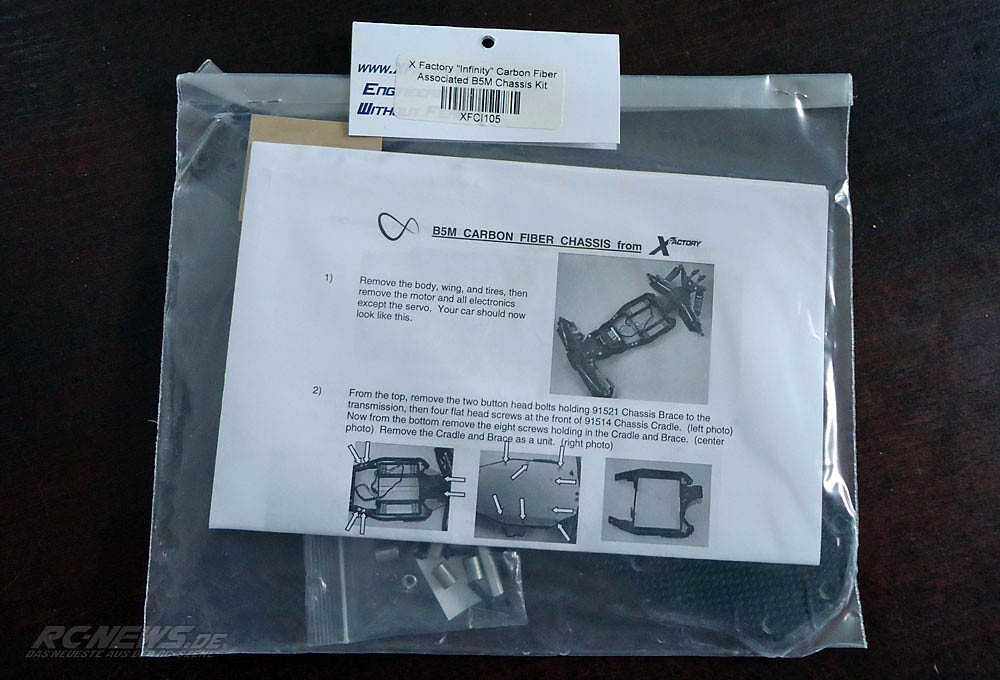

To ambitious, but economically less attractive projects such as the to 4WD Buggy X-7 continue to develop thiswas the product range by Infinity X-Factory introduced in the summer of 2014 to create the production of tuning parts for vehicles of other manufacturers another mainstay. Meanwhile, shock towers, battery holder, wishbone braces and just looked at the carbon fiber chassis are available.

If you look at the development in the 1/10-buggies, so many things seem to go round in circles: experienced with the introduction of the TLR 22 massive aluminum plates a Renaissance, so the opinions about their suitability often go apart. On the one hand bring these light metal plates the weight low, are robust, can be used in conjunction with a front panel made of plastic manufactured inexpensively and by appropriate cutouts not too rigid to work on Lehmstrecken, but then lies dormant, the risk that the plates permanently distort and affect driveability, without the driver the cause can recognize. In a plastic or carbon fiber chassis, this danger does not exist if broken, then broken.

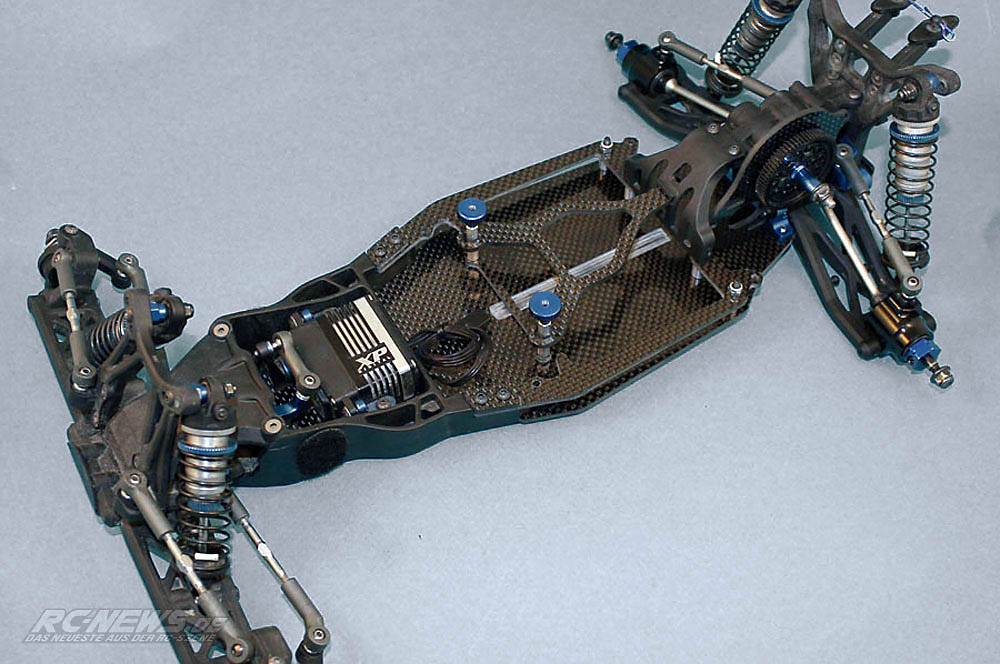

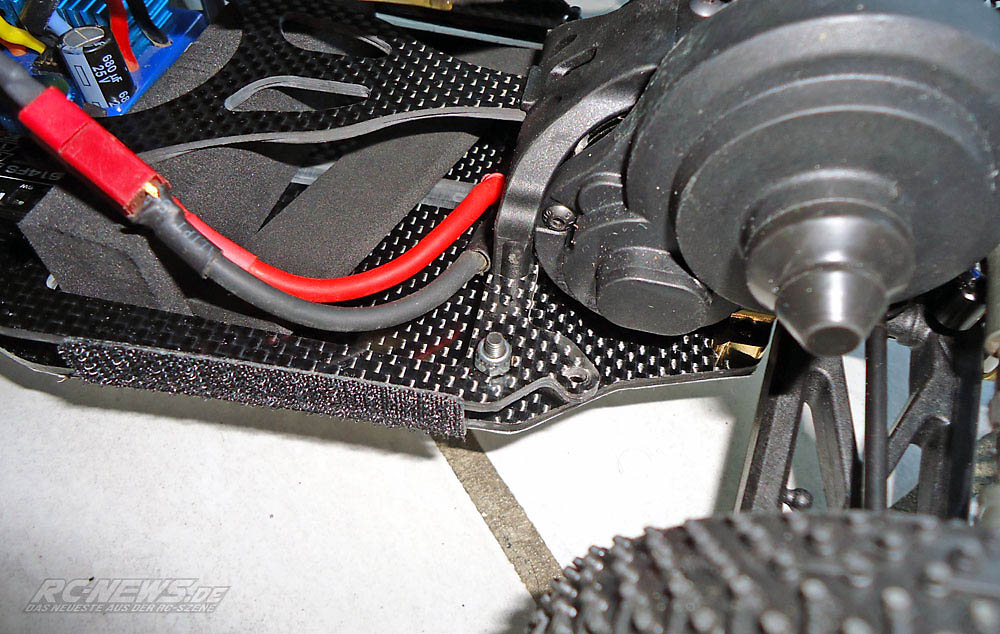

In accordance with this philosophy X-Factory has always used only plastic or carbon fiber chassis, lately, the focus is clearly placed on carbon. Similar to aluminum, this material offers the possibility of influencing the flexibility of the chassis by strategically selected cutouts. Even though, according to X-Factory is a by Infinity chassis equipped this B5M not to the fully-designed overall package of X6 Cubed approach, expected to lead to through the flexible material considerably more grip on slippery surfaces.

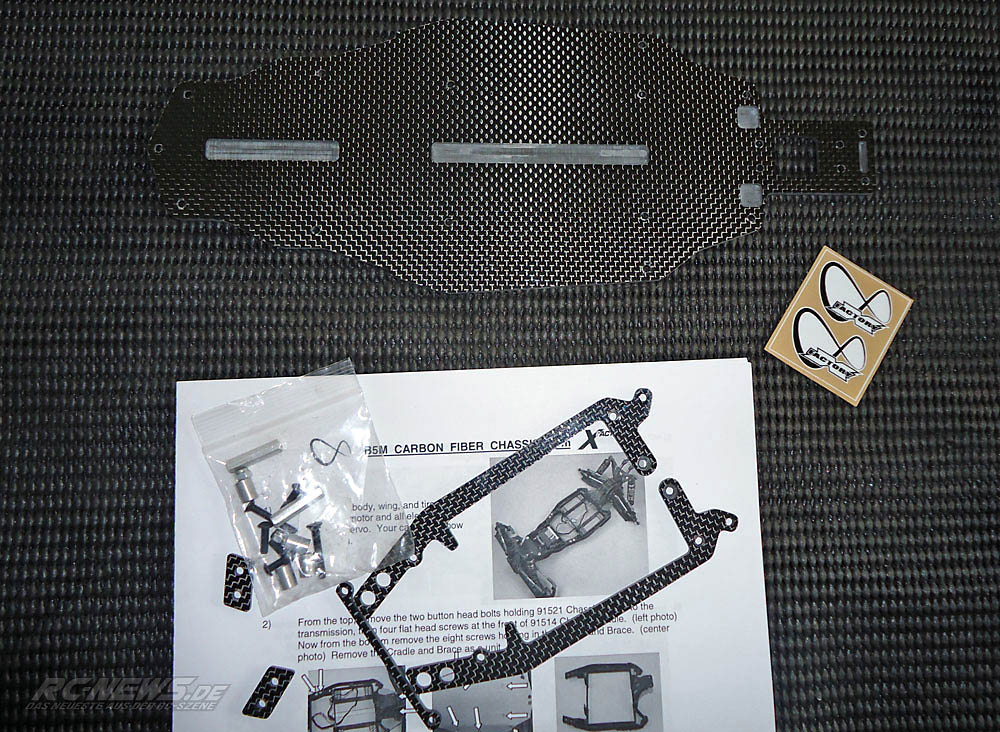

The package includes in addition to the chassis plate, a bag with nuts, bolts and metal sleeves, a brace for the front of the chassis, two large and small side panels, two X-Factory infinity stickers and a detailed conversion instructions in English. By adhering to the instructions, the conversion is extremely unspectacular vonstatten because all parts fit perfectly. Information on the effects of different settings in vain, as a rough estimate, however, be noted that one further achieved by loosening the rear screw or omission or mounting the front cross brace up more flexibility and therefore more grip.

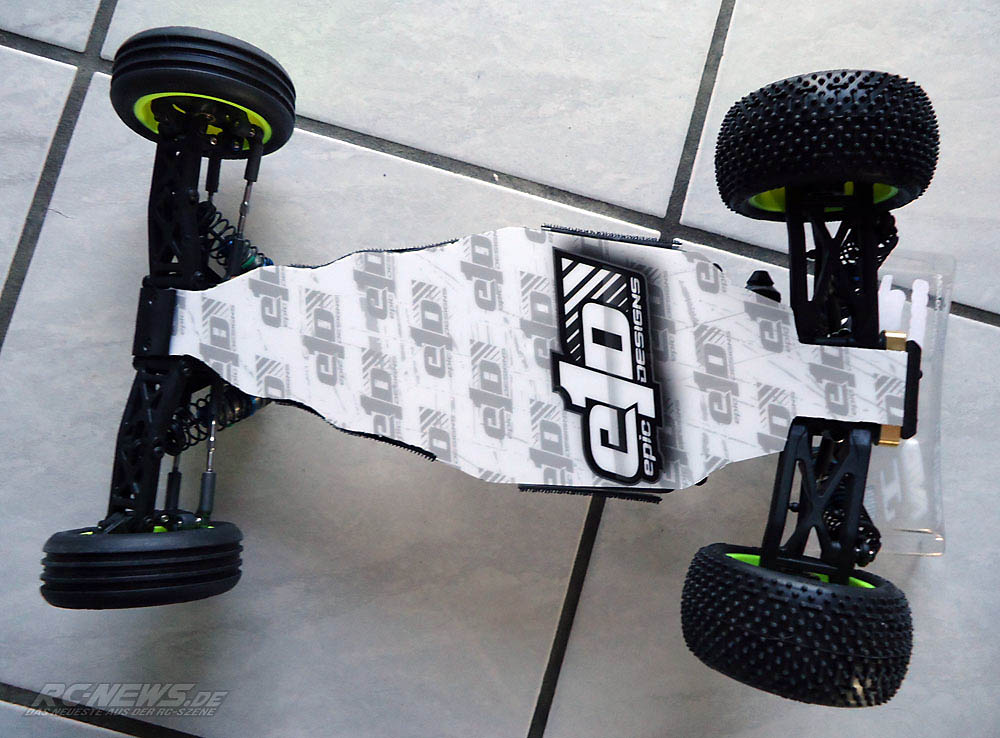

At the end of the manual to indicate to a weight saving of about 70 grams, which I have not checked. In race trim for the LRP Offroad Challenge my car commuting with the lightweight team Azarashi-body, low-profile power, LRP Spin Super, Shorty battery, V2 slipper and two heavy wishbone holders made of brass on the rear axle at 1512 grams a, by no means to be despised. If, in addition, titanium bolts, an aluminum main shaft and the MIP Puck Drive differential, should be able to fall below the official weight specifications effortlessly.

Since I've never been a weight fanatics, I lower the torsional rigidity and the resulting handling on slippery tracks was much more excited. The Südring is still under reconstruction would provide ideal conditions for a corresponding test drive, and so it went on 14 May to RCRT Duisburg eV, the organizers of this year's LOC-DM. For the basic setup I oriented myself this code to the recommendations for slippery tracks from the Australian Team Associated-driver Ray Munday Set-up Guide which was specially developed for the B5M. Since the Australian routes to Europe more similar than the ironed and treated down to the last US-tracks should be to use the drawn up on the other side of the planet during our latitudes well.

According to the area of use, the rear part of the chassis was built as flexible as possible at the beginning. In order to keep the adjustment even when loosened nuts to stress, I put at the top with a pair of used O-rings from the junk box. The underside of the chassis has been protected by the proven chassis Armor of epic1Designs against deceitful stones. On the chassis top, I mounted with double-sided tape a few Lexanwinkel with Velcro as a provisional body mounts to secure the various bodies set up during the race day safely. At the back of the carbon frame while loops are provided for attachment, but these fit not to the existing holes in my cars.

The route presented itself objectively from a less beautiful side. As the weather had not always played, the team of RCRT Duisburg eV the extensive construction work was not able to finish in time for the race, and so the ground was extremely uneven and covered with a layer of dust and stones. That the planned jumps were missing, was the pilot of 2WD vehicles have the slightest problem, the short-course racer with the conditions prescribed in the LRP Offroad Challenge tires were even more shaken than the slightly more motorized buggy drivers who with the JConcepts Goosebumps in the green mixture had a proper basis is available. However, the fun layout knew to convince, and so prevailed in the driver's cab, the good mood -. Except, a car was once again placed on the roof of an invisible stone

(© Photo: Anja Fuhrmann/Flubber Digital Collection)

After from the different also tested that day the bodies Azarashi team had emerged Lepter than ideal, it went to the fine-tuning. Even though I had deliberately chosen the most good-natured body, I wanted a little more steering. Fortunately, agreed theory and practice, and I was by removing the front strut under the small battery holder post a good deal closer to the best possible driveability. A trial basis built Saddle Pack had to give way again, because although the car felt more comfortable, the two runs total half a minute each were slower than the ones I with Shorty battery graduated hatte.Nachdem changes to the damper oil, the suspension travel and the springs more had brought improvements, I put the chassis behind a little stiff, and was given the track conditions more than satisfied. Although I would not call myself a really fast driver, jumped at the end of the day, a second place for me out with the VBC Racing Firebolt DM before me is a mid-engined Buggy went into goal.

Conclusion

With the chassis from the Infinity range X-Factory is the experimental B5M owners a successful tuning possibility of the hand in order to adapt the car even on very slippery surfaces can. To get the most out of the chassis, should certainly some battery charges be necessary, but already in a relatively short time I was able to customize the vehicle perceptible to my needs. For drivers who can not adapt to the driving characteristics of a mid-engined Buggy their gas finger, also the excellent crafted carbon fiber chassis will not overturn the laws of physics, all others who do not shy away from the investment of just under $ 100, should definitely risk one way or another test drive .