|

- Team Associated B5M Factory Lite - Review -

PERFORMANCE TEST 1/10-SCALE 2WD BUGGY | KIT

The B5M gets slimmed down and hopped up for 2WD Buggy supremacy

WORDS BY THE RC CAR ACTION TEAM - PHOTOS BY CARL HYNDMAN

The Team Associated B5Mhas become the weapon of choice for many racers since its debut just over a year ago. First offered in “Team Kit” spec, the car was well equipped, but left a few options on the shelf. In the past, Associated has followed up their “standard” race car releases with “Factory Team” versions that include all the hop-ups, but the Team has changed course with the B5M. The revised model is dubbed the RC10B5M Factory Lite, and as its name implies, many of its upgrades are aimed at trimming weight to “optimize the platform to excel in classes requiring spec motors,” to quote Team Associated. Here, in the states that means stock class racing, but the Factory Lite isn’t a one-class car—all of its upgrades benefit mod drivers too. In addition to a number of gram-shaving parts, the Factory Lite also includes a 3-gear transmission that reduces drivetrain drag, and swaps some suspension parts with the rear-motor B5. All the changes are based on feedback from B5M owners and Team drivers and make the B5M an even sharper tool for 2WD buggy racing in any class. Take a look at what makes the latest B5M “Factory Lite,” and put it to the test with Reedy 17.5 power.

LOW-DRAG 3-GEAR TRANSMISSION

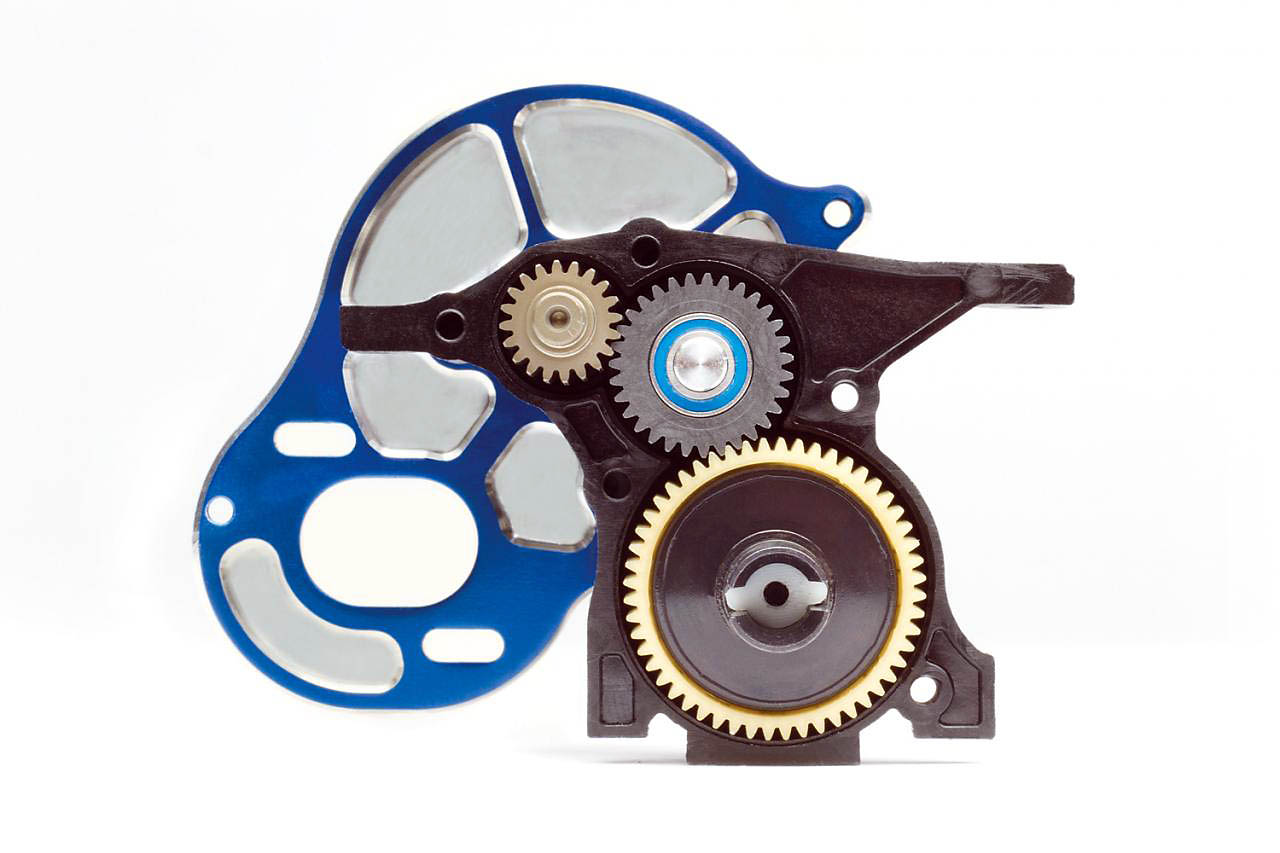

When racing in classes where you can’t just bolt in more horsepower than the other guy, the only way to eke out a power advantage is to give the motor less work to do—less weight to accelerate and decelerate, less friction to overcome. The Factory Lite replaces the original B5M’s 4-gear transmission with a 3-gear version to achieve both ends. On the weight-savings front, the mass of an idler gear, shaft, and two bearings are eliminated. Removing the idler also takes a mesh point out of the gearbox, so there’s less rolling resistance. More weight is shaved by replacing the Team Kit’s steel top shaft with Associated’s aluminum V2 version, and the shaft spins on smaller-diameter bearings to trim a few more grams and reduce friction. The most visually noticeable weight-saving measure is the motor plate, which shows off heavy machining to remove noncritical material.

In addition to its weight- and friction-reducing benefits, the 3-gear transmission also has an effect on chassis tuning. To achieve the proper rotation direction, the motor is mounted with its output shaft pointing to the car’s right side, instead of to the left as in the B5M Team Kit. This means the force of the motor’s torque is applied in the opposite direction of the 4-gear setup. Instead of contributing to chassis squat like the 4-gear transmission, the 3-gear setup counteracts the tendency for the chassis to squat under acceleration and dive when decelerating or braking. That leads to a “flatter” chassis, and can make for faster laps on high-grip tracks. |

A milled motor plate, aluminum top shaft, and one less idler gear highlight the Factory Lite’s new gearbox.

|

B5 SUSPENSION SWAPS

In its original Team Kit spec, the B5M wore “gullwing” front arms and the rear-motor B5 got conventional “flat” arms, each with a front shock tower specific to the arm configuration. For the Factory Lite, the B5’s flat arms and their narrower shock tower are fitted. The Factory Lite also gets the B5’s rear arms, but flips them so the “left” arms are mounted on the right side of the car and vice-versa. The flipped B5 arms give more forward sweep than the B5M arms, and Associated’s Team drivers preferred this setup along with the flat front arms.

The Factory Lite improves on Team Kit spec by trading steel turnbuckles for Factory Team blue titanium links, and the ball cup tooling has been improved so the cups move freely as soon as you snap them on (the first batches fit too tightly). The Team Kit’s notoriously fragile plastic rear ball stud mount has been replaced with a machined aluminum version, which adds adjustability as well—by flipping the part, you can raise or lower the ball stud height by 2mm.

There are no changes to the excellent V2 12mm big-bore shocks other than updated o-rings (which are a running change for all V2 shocks). The Factory Lite has the same hubs and camber link locations as he Team Kit, but the bearings pressed into those hubs are improved with Associated’s higher-tolerance, lower-friction Factory Team units. The adjustability of the B5M is unchanged; roll center can be tuned by changing ball stud location and installing spacers under the studs, and inserts set caster, rear toe, and front axle trail.

|

Titanium turnbuckles, aluminum front axles, and the B5’s “flat” arms and narrower shock tower outfit the Factory Lite.

|

The Factory Lite doesn’t look very different than the Team kit, until you notice the glints of blue anodized parts and the flipped motor orientation.

Other than improved o-rings, there are no changes to Associated’s V2 dampers. The 12mm big-bores were already dialed.

The Factory Lite replaces the original plastic ball stud mount with a much stronger aluminum version. The part can be flipped to raise or lower the ball studs.

MILLED AND HARD ANODIZED CHASSIS

This is one of the Factory Lite’s most anticipated changes. The standard B5M chassis had minimal milling and was fairly heavy as a result. That’s good for lowering the car’s CG and not a bad thing when you’ve got plenty of mod-motor horsepower to carry the weight, but not ideal for Stock class racing where power is at a premium. The Factory Lite chassis starts with the same aluminum stamping as the Team Kit, but is much more aggressively milled to remove unnecessary material. The plastic parts that bolt to the aluminum chassis are unchanged, so there’s room for a shorty or square/saddle pack LiPo battery. Foam inserts and a thumbscrew-secured plastic battery strap make it easy to position the chosen battery for better weight bias tuning. |

No changes to geometry, but the Factory Lite chassis is extensively milled compared to the Team Kit version (inset).

|

Factory Lite vs. Team Kit

What does the Factory Lite give you that the Team Kit doesn’t? Here’s the breakdown and the benefits in chart form. For an extra $20, the Factory Lite packs in a lot of upgrades. The chassis alone would set you back $70 if purchased separately.

Upgrading a B5M Team Kit with these parts would set you back over $150!

|

|

ON THE BENCH

SLOP-FREE STEERING BLOCKS

Once you’ve decided which steering insert to use in the steering block, place a drop of CA glue to bind them together. This will help to eliminate slop and extend the life of the bearing.

DIFF SPRING SET

Before installing the differential thrust spring, use a pair of pliers to compress it completely a couple of times so it takes a “set.” This will speed up differential break-in and help the diff hold its setting longer.

RIGHT IS LEFT

When assembling the rear suspension, note that the arm marked “R” actually goes on the left side of the car, and vice-versa.

EASY PISTON ID

The molded markings on the shock pistons can be hard to see, but if you use a Sharpie marker on the number and wipe away the excess, it will leave just enough black to make the numbers visible and permanent.

SLICKER O-RINGS

When building shocks, put a dab of Associated’s Green Slime (sold separately) in an empty parts bag along with all the o-rings. Massage the o-rings in the Green Slime till they have a light coating, then install them as you normally would. The lube provides the smoothest possible action, improves the o-ring seal, and helps reduce o-ring swell.

PRELOAD COLLAR MOD

Scribe or file a mark on the shocks’ preload collars so you can easily count the number of turns you give them as you make adjustments. This makes it much easier to set preload equally from shock to shock.

SLIPPER LOCK-DOWN

If you race stock class on high-bite surfaces and need a bit more acceleration, try tightening the slipper clutch all the way down. Assuming your car is geared correctly, the power of the stock motor isn’t enough to break the tires free and you’ll gain some punch. Experiment.

TEST GEAR Reedy Sonic Mach 2 17.5T Spec

The Factory Lite isn’t just for horsepower-limited racing, but since its weight-savings measures make it particularly well suited to stock and spec classes, it made sense to test it with a 17.5 motor. The Reedy Sonic Mach 2 is a first-class mill with all-aluminum construction, including the end cap, for precise timing adjustment and bearing alignment. Bearing size is optimized for peak RPM, and the machined can is heavily vented for cooling. As expected, Reedy’s competition motor had no trouble matching delivering A-Main worthy power.

The Factory Lite isn’t just for horsepower-limited racing, but since its weight-savings measures make it particularly well suited to stock and spec classes, it made sense to test it with a 17.5 motor. The Reedy Sonic Mach 2 is a first-class mill with all-aluminum construction, including the end cap, for precise timing adjustment and bearing alignment. Bearing size is optimized for peak RPM, and the machined can is heavily vented for cooling. As expected, Reedy’s competition motor had no trouble matching delivering A-Main worthy power.

|

BEHIND THE WHEEL

OCRC Raceway in Huntington Beach, California is my home track and I’m pretty familiar with its characteristics. The latest layout is a good test for stock racers and has some of the most competitive racers in the class, and it provided me with a benchmark to compare the new Factory Lite to other racers with speeds I know quite well. Before cutting loose at race pace, I put in laps to break in the tires, set the slipper and differential properly, and fine tuned the chassis. With the ride height set at 24mm and the camber set at negative one all around, it was time to see what the buggy could do. I immediately noticed the Factory Lite’s increased corner speed. Out of the box, the buggy is much closer to what most stock racers will use for a final setup than the previous B5M. The flat front arms give a more consistent steering over the gullwing style, while the flipped B5 rear arms provide extra traction and a shorter wheelbase that rotates faster. However, the 3-gear transmission has a feel that is unusual and took some getting used to, as it doesn’t respond the way a 4-gear transmission does. Acceleration squat and braking dive are less pronounced than the 4-gear setup. Also, the 3-gear transmission, milled motor plate and lightened chassis remove some of the weight over the back wheels. This lightened feeling required me to be smoother on the wheel and trigger, but a few tuning tweaks back in the pits including moving the battery all the way back and swapping 32.5w oil for 27.5w resolved that. With the manual-suggested setup, the buggy is fairly aggressive and requires a good level of traction to settle it down, but is easy to tune and familiar to those who already have experience with the B5M Team Kit. A lot of people expected the 3-gear transmission would be more efficient and would really help in stock racing, and yes it does feel like some friction is lost, but there were a couple of unexpected side effects as well. Less weight means the Factory Lite accelerates faster, but with less mass to fuel inertia, it also slows more quickly. The drag-brake setting that feels right in a heavier car will probably feel like too much in the Factory Lite. In fact, I found the fastest lap times often meant running almost no drag brake at all. I was able to focus on things like this because the shocks were doing such a good job of giving the buggy that pillow-like feeling, and the new o-rings are noticeably smoother. –Carl Hyndman

FINAL WORD

With the RC10B5M Factory Lite, Team Associated has done an effective job in their mission to “optimize the platform to excel in classes requiring spec motors.” The many upgrade parts trim over two and a half ounces from the car, and some have the added benefit of increasing adjustability and durability. And it’s a great buy; for an extra $20, the car is loaded with upgrades that would cost far more if purchased separately. The Factory Lite is ready to rule stock racing out of the box, but it’s not a “stock only” machine. The benefits of a lighter buggy and quicker corner speed can be utilized by modified drivers as well, and the weight savings gives racers the ability to add weight back to the car strategically as a tuning aid. The Factory Lite really is the next evolution of the B5M and its features deliver enhanced value and higher performance.

+

New 3-gear transmission with lightweight V2 aluminum top shaft

Milled, hard-anodized aluminum chassis

Costs only $20 more than B5M Team Kit

-

Wheels and tires not included

3-gear transmission may reduce traction on low-grip tracks when racing Mod

SOURCES

Team Associated teamassociated.com

Reedy reedypower.com

Pro-Line prolineracing.com

Futaba futaba-rc.com

Stiky Liks facebook.com/stikyliks

|

|

VEHICLE SPECS

Item no. 90000 Scale: 1/10

Price: $280

Weight (shorty configuration): 3 lb., 7.4 oz, (1570g)

Height: 5.5 in. (140mm)

Length: 15.2 in. (385mm)

Width: 9.8 in. (250mm)

Wheelbase: 11 in. (280mm)

CHASSIS

Material: Hard-anodized Aluminum

Type: Machined plate

SUSPENSION

Type: H-arm with titanium turnbuckle camber link

Inboard camber link positions (F/R): 2/2

Outboard camber link positions (F/R): 2/10 (w/ 2 inserts)

Shock positions, towers (F/R): 3/3

Shock positions, arms (F/R): 2/2

SHOCKS

Bodies: Threaded Aluminum big-bore

Bore: 12mm

Shafts: 3mm Steel

Volume compensation: Emulsion-style

DRIVETRAIN<

Type: 2WD enclosed gearbox

Spur gear/pinion: 69 (78 also included)/not included

Slipper Clutch: Dual-pad

Differential: Ball-type

Driveshafts: Steel CV type

Bearings: Rubber and metal-sealed ball

TEST GEAR (NOT INCLUDED)

Transmitter/receiver: Futaba 4PX / Futaba R3045B 4-Channel

Servo: Reedy RT1508 HV Digital Competition Servo

Speed Control: Reedy Black Box 410R Sensored Brushless Competition

Motor: Reedy Sonic Mach 2 17.5T Spec

Battery: Reedy 4100mAh 65C Competition 7.4V Shorty LiPo

Tires (F/R): Pro-Line Ion 2.2” MC/ Pro-Line Ion 2.2” MC

Pinion: Robinson Racing 31-tooth, 48 pitch aluminum pinion |

STOCK RACERS GET CREATIVE TO SHAVE GRAMS AND LAP TIMES

Arizona is a hotbed for stock racing, and racers work hard to push the limits of engineering to get the most performance from the fixed horsepower of the class. Working within the rules, racers modified and optimized their batteries, motors, drivetrains, and suspensions in order to gain an edge. It’s so intense, it’s almost become a hobby on its own. Steel parts are replaced by aluminum or titanium, then milled to lighten them further; ceramic bearings replace steel, and are lubed with oil instead of grease to banish friction; gears are slimmed to reduce drag … the list goes on

To make sure they get peak power, drivers dyno motors to measure watts, rpm, and efficiency and cherry pick the best performers. Cars are set up to minimize the need for braking, because braking builds heat and reduces efficiency. Batteries are cycled to reduce resistance and activate their chemistry, discharged and charged hard, timed to peak just before the car is placed on the grid.

|

3-gear transmissions, profiled idler gears, ceramic bearings, milled aluminum top shafts, and carbon fiber idler gear shafts are just some of the things stock racers are doing for small gains. These parts belong to Jeff Kulp, an SRS local.

Creative milling on the outdrive areas.

|

|

|