Author - Ben Panic

PDF in English - en Français

Tools required

· 3mm tap

· 3mm drill bit

· 2mm drill bit

· x acto knife

· 4 d-clamps

· Hand file

· Loctite 480 super glue

· Dremel with assorted bits

Parts Required

· Associated T4 Truck chassis (composite)

· Carbon Fiber Strip 2.5mm thick 175mm length 15mm height

· 8 x (3x6mm countersunk screws)

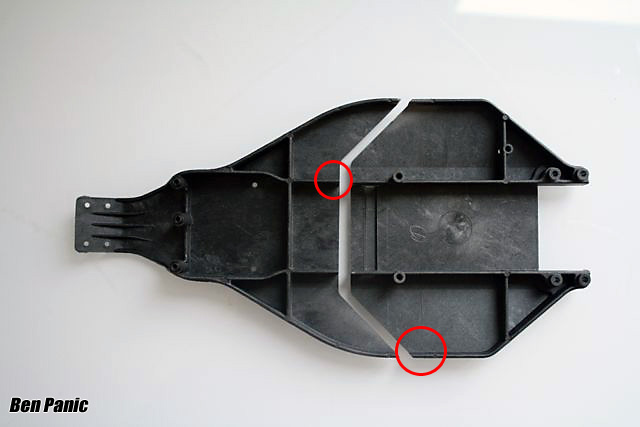

Step 1 - Cut 11mm out of length of chassis

· Remove 11mm of material from T4 chassis with dremel, hacksaw or CNC Waterjet or alike.

· If possible remove as per picture taking excess battery posts away

Step 2 - Cut 2 pieces of carbon 50mm x10mm for center rib strengtheners and set aside

Step 3 - Cut 2 pieces of carbon 25mm x 8mm for outer rib strengtheners and set aside

Step 4 – Chassis Prep

· Dremel or sand both carbon ribs and chassis where ribs will glue to. Ie inside of the outer rib on the chassis and outside of the battery ribs

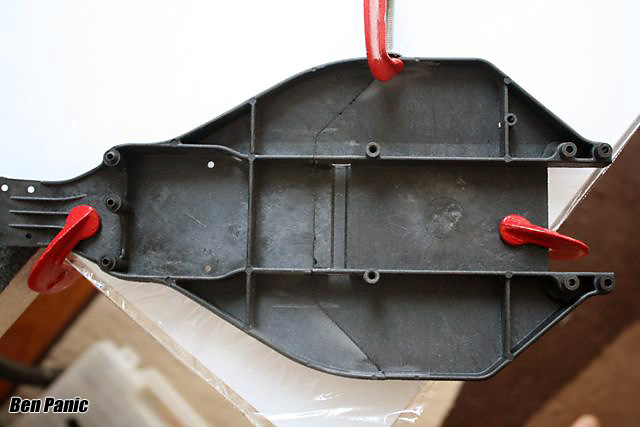

Step 5 – Chassis Gluing

· Check chassis alignment for level and make sure to get edges aligned for good gluing. Patience is required here and small amounts of material removed at a time. Use a hand file if required

· Place the chassis on a flat surface, ensure it all mates correctly and then clamp chassis to test fit

· Once you are comfortable with fit run a bead of Loctite 480 along the edge of one half of the chassis and join it up.

· Clamp it tight and ensure edges are butted up.

· Leave to dry

**Put some cling wrap on your flat surface so the chassis does not stick to it with excess glue.

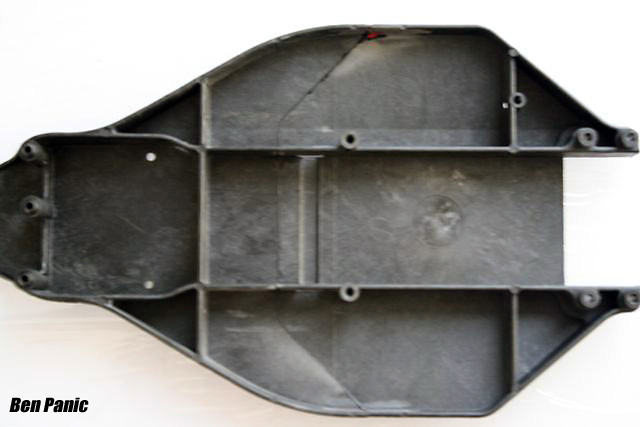

Glued Chassis

Step 7 – Outer Rib Carbon Strengtheners

· Locate 25mm outer carbon strengtheners and clamp in position on chassis. Place a clamp on one half of the strengthener leaving enough room to drill one hole

· Drill one 2mm hole through chassis and through carbon strengthener

· Place a second clamp over the hole you just drilled

· Remove first clamp

· Drill the second 2mm hole through chassis and through carbon strengthener

· With 3mm tap proceed to tap carbon strengtheners

· Take 3mm drill bit and enlarge chassis holes

· Take the dremel with a stone tip and countersink holes in chassis

Step 8 – Gluing Outer Rib Carbon Strengtheners

· Apply Loctite 480 to chassis and Outer Rib Carbon Strengtheners

· Screw Outer Rib Carbon Strengtheners to chassis tightly with 3x6mm c/s screws

· Let glue dry

Step 9 - Inner Rib Carbon Strengtheners

· Locate 50mm inner carbon strengtheners and place in chassis – mark holes to drill.

· Clamp to chassis

· Drill 2mm holes in inner carbon strengtheners where marked through carbon and through chassis. Keep as straight as possible

· Clamp inner carbon strengtheners to chassis rib

· Remove inner carbon strengtheners

· With 3mm drill bit finish hole on inner rib

· Place inner carbon strengtheners against rib and check alignment of holes

· Tap inner carbon strengtheners with 3mm drill bit

· Take the dremel with a stone tip and countersink holes in chassis inside ribs in battery compartment

· Locate esc rx slot in chassis and dremel carbon inner carbon strengthener to match

Step 10 – Gluing Inner Rib Carbon Strengtheners

· Apply Loctite 480 to chassis and inner Rib Carbon Strengtheners

· Screw inner Rib Carbon Strengtheners to chassis tightly with 3x6mm c/s screws

· Let glue dry

Completed Chassis