|

- Process to setup a car -

by Tony Newland

Here's how I go about setting a car up from the box through the process of getting it "dialed" for me... everyone has their own way but it has worked pretty good for 20+ yrs. Thought Id throw this out there

First off make sure everything on the car is free when you build the kit or go through a routine rebuild/freshen up... meaning the arms, hubs, steering knuckles, ball cups, anything that pivots is free/no drag. Now just because it flops on your bench without the shocks doesnt necessarily mean its "free" When the car is on the track and the drivetrain is accelerating and the shocks have loaded the arms you could still have something binding that causes tuning/handling issues. What I do is I have made a bunch of hinge pin reamers over the years to it everything Ive owned. I use old rounded hex drivers as they are usually made from either 1/8", 3mm or 4mm stock. I hit the shaft with a cutoff disc on my dremel and clean EVERY pivot pin hole several times to ensure the holes are straight and round. I also use a hinge pin grease made by Ultimate Racing. This might be impossible to find in the US, but Ive also used pledge as hinge pin grease and it works just as well but doesnt last as long. But use something, dry hinge pins on a dusty track will make the best car in the world suck balls in no time

I also build my shocks mythotical everytime. Make sure the orings are fresh and not swollen, life expectancy of the orings is about a month...silicone oil naturally makes them swell, I assemble the piston on the shaft, install it in the body without any orings, then slide the orings/spacers on the shaft by hand with just oil and then tighten the bottom retainer. You can tighten it by hand dry or use a tiny drop of loctite to keep it from loosening during a race. I use blue loctite... but just a TINY bit. By packing the orings this way you'll never tear or cut one. Most of the time the oring pack quality is determined only if it leaks or not. This is not the case, if the orings are leaking your adding a ton of air to the shock oil when pressures build inside the shock and the consistency is already long gone. I do my shocks when I start to feel air pockets when I hold my car upside down and slowly work the suspension. There should be NO airgap felt. If there is its time to freshen them up. When you freshen your shocks, feel all 4 without any oil and see if you can detect one thats not as smooth or "free" as the others. Replace all the orings if you feel any difference in the 4. Keep oring sets in your box, so you can pop them in anytime.

Also everytime I do my shocks its a good time to check all the hub bearings F&R. You would be surprised what a slightly bad bearing can do once its warmed up and under a load. keep the most common bearings in your box. Ive ran Avid revolutions since they came out, for $1 they cant be beat. Plus being that cheap just toss them and you wont feel bad.

Also a good time to check CVDs, spin the CVD with your fingers and rotate it through the angles like it would do during a race. any binding and immediately investigate the cause. I also keep CVD barrel kits in my parts box in case I find a bind I just replace them both and forget about it for another few months.

When I get the kit assembled and feel good about everything, I race the car with a 13.5 blinky for the first race. I dont care what class I sign up for, its always a 13.5. That way I can usually clear all the jumps and I can easily work on the setup and get it completely dialed before throwing the wood to it. Once I get the car fast AND consistent (take pics of your lap times to compare later at home and try to get them within .3-.4 before motoring up, any more variance and the additional power will make it alot worse) Also gearing up with a bigger pinion will increase the power and gearing lower will decrease the power the motor will produce. You can really tune in the powerband by changing the pinion up and down. This is a huge tuning aid when the bite changes from track to track. The size of the track might be the same but if its got alot less bite Ill drop my pinion a couple teeth to mellow out the hit of the motor.

I'll take some "mental" notes while Im driving and find my weak spots on the layout and how I want to go about fixing them. Marshaling the race after also gives you time between driving and wrenching to really figure out what your car needs. Good data would be "I need alittle more entry steering in that corner right there, but its good everywhere else" not "I need more steering" those are so far apart that there is no real solution other than throwing changes at it til you stumble upon something that works. Also always watch the fast guys and be attentive about the lines they take and when they use the throttle. New track/out of town tip: I always study the local fast guys at any track I go to before I even unload my stuff... I almost get the layout burnt into my mind before I even take a lap, you'll be one step ahead of the game by running mental laps and know what to expect when you run your first practice pack. After you do it a while you can tell what motor guys are running, what their driving style is and who is consistent and who might win the race.

Once I get the car maxed with the 13.5 Ill motor up, but when I motor up Ill also take the speedo and set it on the softest throttle setting and also back down the throttle expo on my radio. Basically what I want to do is make the power about the same as the 13.5 in the infield on the initial hit of the throttle but retain the top speed of the mod motor. I NEVER run any timing/boost/turbo/supercharger or whatever on a mod motor. If its not on pace your gearing or something else is wrong. Stock endbell timing is usually between 15-25deg. Less timing will give you more torque and more timing will give you more RPM. More timing also runs hotter almost always. Mod motors should never get over 120~ unless your on some super high bite stuff... more than here and we run slicks about 50% of the time. I cant remember the last time my speedo or motor was over 100deg and my stuff is right on pace with everyone else. Once you get the mod motor working good, then start creeping up on the expo and throttle curve in the speedo to a point that you think your consistency and speed is maxed out. The neodymium magnets in the rotors will start to degrade above 150deg. If your motor has been this hot, replace the rotor no questions asked.

At the end of the day if the hero lap in your class is .5 faster than you dont worry about it, consistently running within .5 of that and you will win the race. Consistency wins races, if you cant lay down consistent laps within 1 second for 6mins, motor down, you'll go faster trust me.

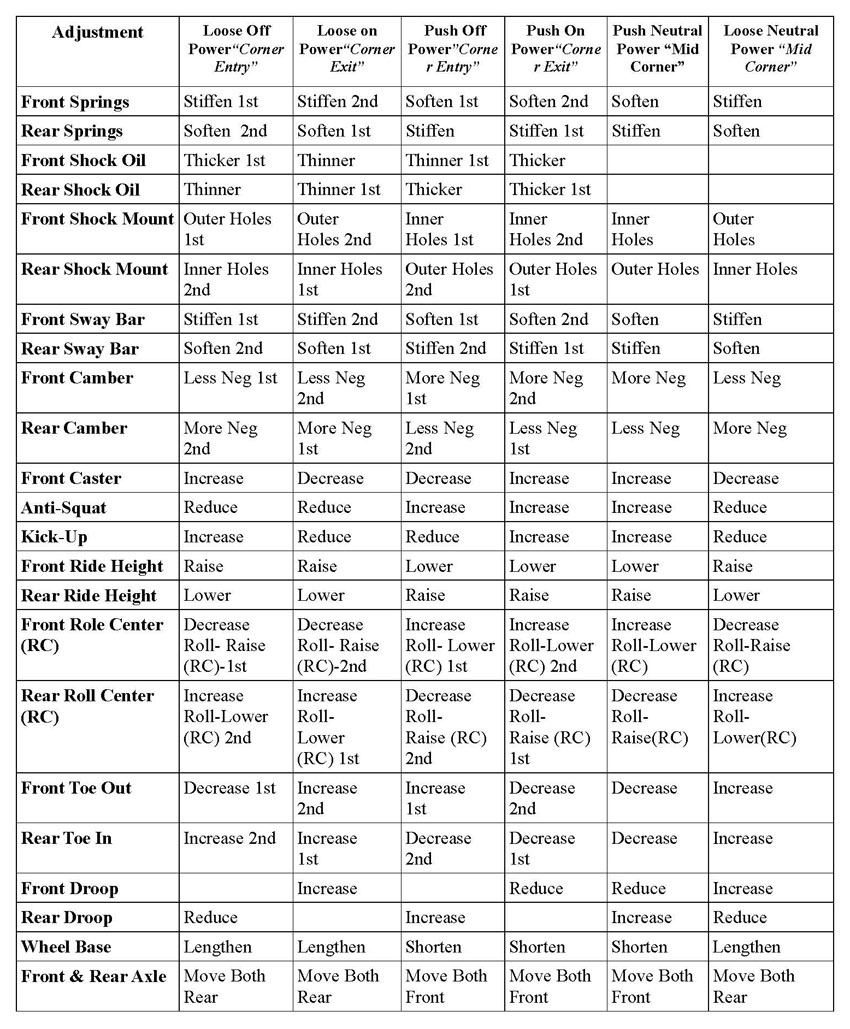

Those are the basics to getting on the right path to getting your car dialed. I posted a cheat sheet a while back on setup changes, tips etc. Ill post it again. Its handy to have in your box to quick reference no matter how long you've raced. I still look at it all the time after many years. Everything comes down to feel tho. Make changes and make notes, some of the changes wont be what your looking for next time at a different track, make notes and use your practice time efficiently and effectively and you'll go faster than your buddy and it will start to feel easy.

PDF File

Source:

T. Newland

|