This is my review from the building of my WRC STX`015 Touring Car. It is the actual car from the WRC company which has its home in Brendola, Vicenza in the northern part of Italy. It is the second Touring car model from WRC and it is very unique compared to other cars on the market. WRC Cars and parts are distributed in my home country Germany and in Austria and other countries as well by MODELLSPORT TRINKO in Austria (www.modellsport-trinko.at). They offer a great support and fast shipping.

The car comes in a beautiful box with all parts are packed in groups and with a good structured manual and a decal sheet. As well included is a set of tires and a nice car stand with an included shock stands for easy maintenance.

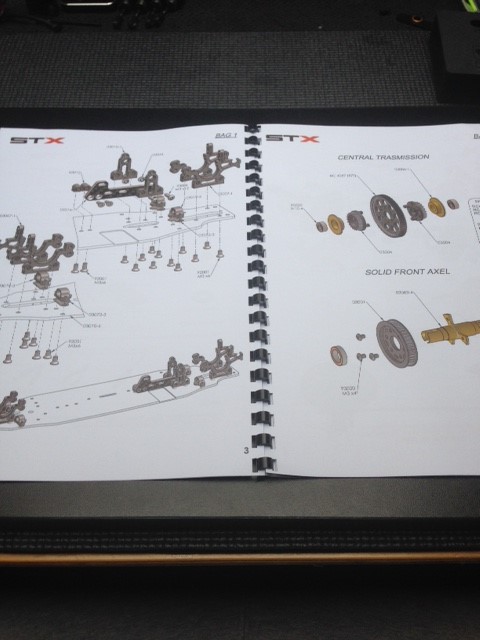

The manual is very detailed and all the drawings are easy to understand so the build of the car goes on very relaxed!

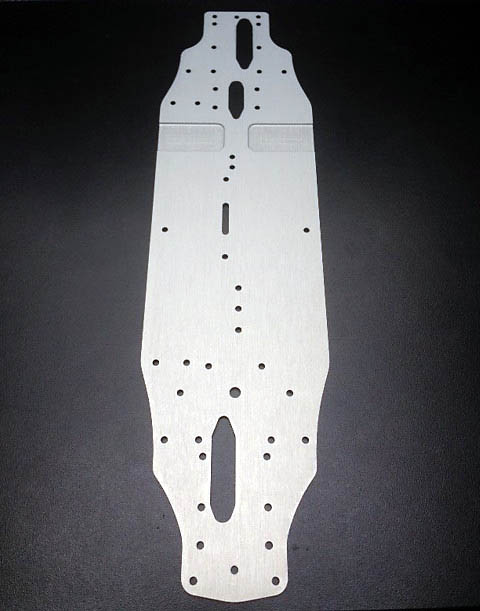

While I was building my car at the beginning of the indoor season I was choosing an optional WRC aluminum chassis for the base of the car because as most of you will know with an aluminum chassis on carpet the car is mostly more consistent and easy to drive and the aluminum plate avoids traction rolling as well when the traction gets very high on big events. The aluminum chassis from WRC is a very nice piece of art and comes in a silver grey colour which I must say looks very nice and cool! The standard carbon chassis which comes with the kit is also super nice and manufactured from a special non shining carbon fiber with 2.3mm thickness.

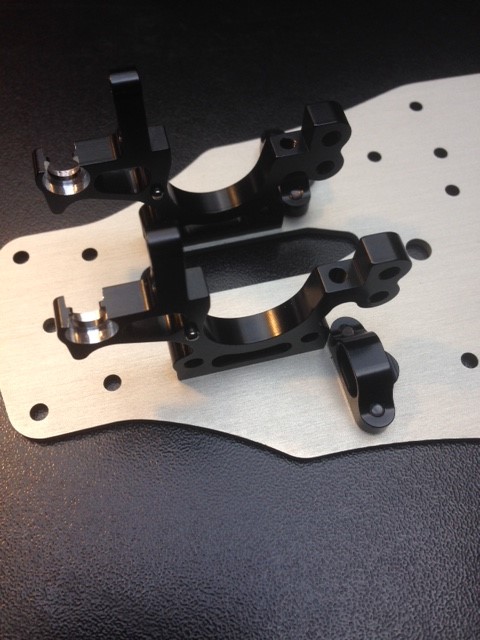

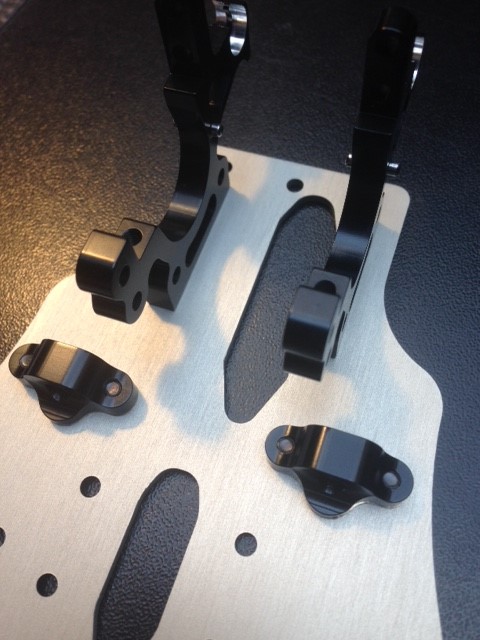

Now it is time to mount the suspension holders and the bulkheads to the chassis and the motor mount as well. All aluminum parts are black anodized and from high quality material and everything fits together very precise.

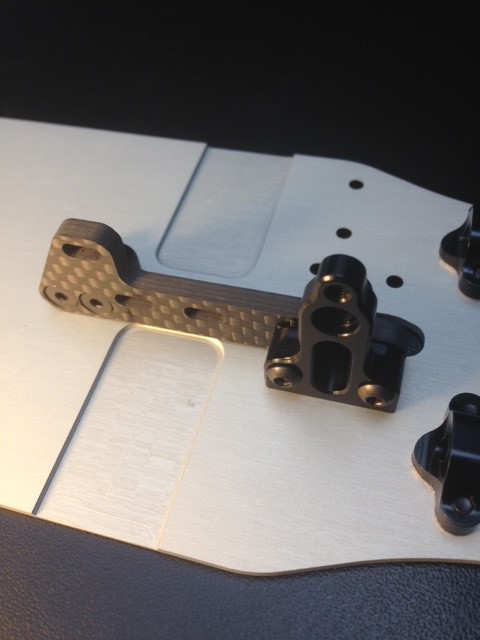

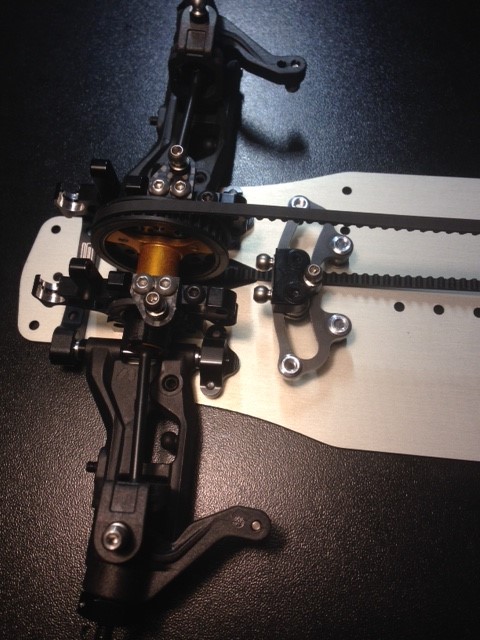

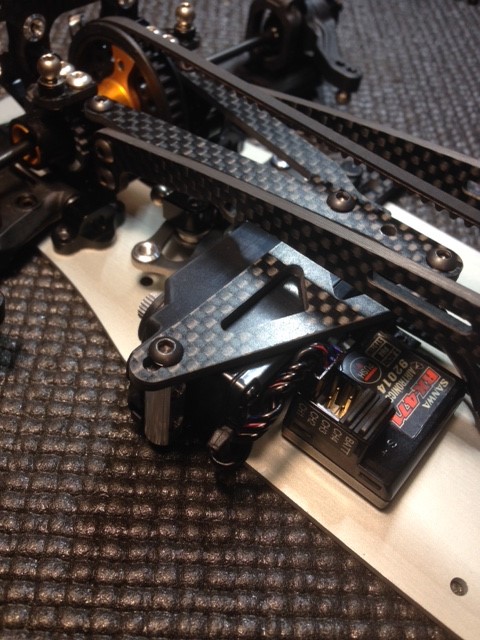

The motor mount is one unique highlight of the car. Comparing to other cars on the market the WRC STX`015 is equipped with a carbon fiber motor mounting plate which looks very nice and is maximum lightweight. The carbon plate is mounted to aluminum holders and the left layshaft holder and then directly to the chassis. Absolutely light, straight and beautiful!!!

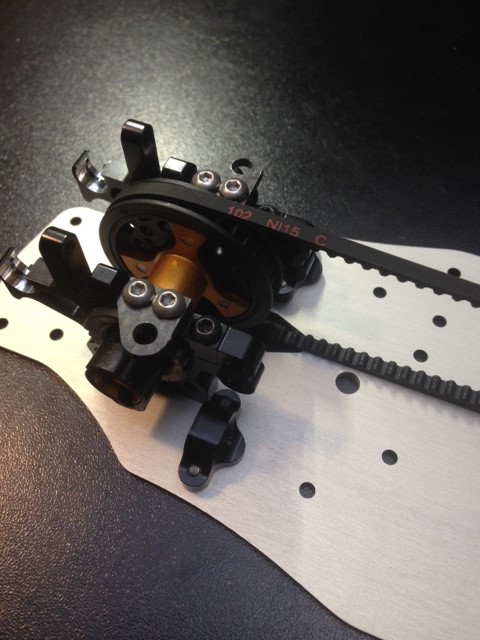

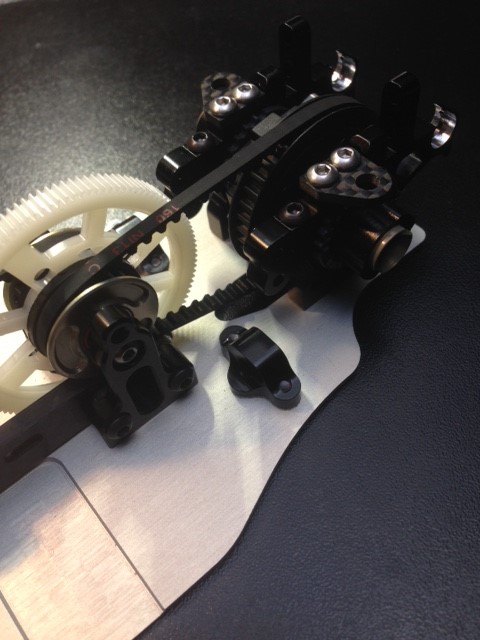

The next step in the manual is the drivetrain. So I had to build up the spool, the gear diff and the pulleys with the Spur gear. The spool is an ultra-light piece of aluminum which is fitted with replaceable plastic blades directly on the spool for a minimum of wearout on the driveshafts. The gear diff goes together very easy and is sealed with a gasket and a big o-ring so it should be absolutely close with no loss of oil. As the internal gear ratio of the car is 1.9 the spool and diff comes with 38 teeth and the pulleys with 20 teeth. The main gear layshaft is also very easy to build and so the drive train was ready very quickly.

After I finished the drivetrain I mounted the wishbones and the c-hubs, uprights and steering knuckles. The toe on the wishbones can be adjusted via plastic inserts and the customer does not have to buy several aluminum parts to change the toe - very nice in my opinion. The turnbuckles are also industry standard with right-left screw thread and nice WRC ball cups. Everything goes together very well as in the steps before and I was very satisfied how it goes so far.

Another special feature of the WRC STX`015 is the steering system for sure. The car uses a so called dynamic steering rail which I have never seen before in an rc car. The steering is guided in a rail and the steering sled moves there from left to right. The sled is guided by ball bearings and the system has almost no slope when it is built and adjusted correctly. The system promises a very smooth and direct feeling for the driver and I was very excited how it would work on the track.

To adjust the play in the steering sled I used 2 small grub screws in the top of the holes to counter the flanged screws which are tightened from the bottom of the sled to holt the bearings in place. For me this small modification is important to hold everything safe on its position.

Then I mounted the Servo into the car and the small front topdeck as well. This topdeck connects the servo mount with the front upper bulkheads to create more stiffness in the front area of the car. The two long carbon fiber topdecks were mounted in the next step and they are connecting the front with the rear bulkheads for a very good and linear flex characteristic of the car. The flex can also be changed very simple by adding or removing aluminum shafts between the two topdecks.