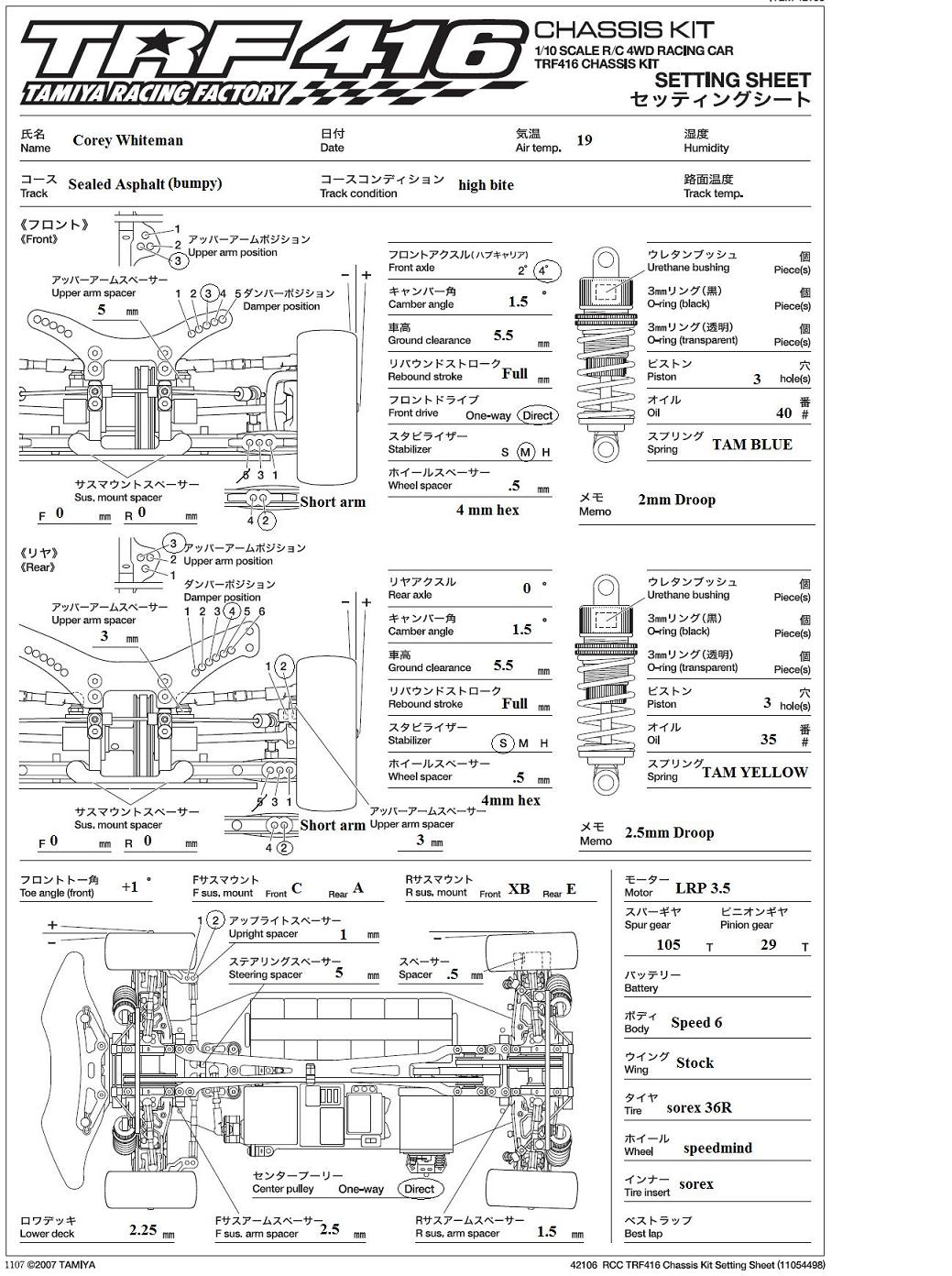

For the rear toe i made a little

error....should have been a XA block which equals 3 degrees. As for

droop, i measure it a different way the some people. The way i do

this is by measuring ride height, then i raise the chassis till the

tires barely touch and re-measure the ride height. The difference in

the measurements is my amount of droop. So if i have 5 mm ride

height and my second measurement is 7.5mm then i will have 2.5mm of

droop. Hope this clarifys things - Corey

Whiteman

Maybe I had some misunderstanding

between "rebound" and "droop".

So, the "rebound" which can measure by a guide like the

one in the HUDY set? I always use it to define the rebound bt the

end of the pin of arms.

And the "droop" which can measure by using a normal ruler

to check the high difference when the point of tire leaveing?

Because I always care about my rebound and leave droop behind...

Droop;

This is the term used for measuring the overall downwards travel of

the suspension. You set it by adjusting the set screws in the lower

arms. I tend to use a gauge to set (flat against the chassis, and

then read off the value underneath the outer hinge pin), although

there are other methods (at least two I can think of).

Rebound;

This is the term used for measuring how much rebound your shocks

have. To set this remove the shock from the car, take off the

springs, then push the shaft into the shock body. You'll see that

the shaft should move back out of it's own accord when you let go.

Thats rebound.

You can vary it by setting the piston to a certain position in the

shock when you build the shocks. To set rebound, leave the piston at

the bottom of the shock body, and pore the oil on top. Remove all

the air by gently pushing the piston up and down, then leave stand

for a while (or use a shock pump). When you can't see ay air bubbles

in the oil, Hold the shock body, and push the shaft in too your

required rebound level (Make sure that your pushing equal amounts of

shaft up per shock... there are a few tricks you can use here that

I'll mention later on with piccies). Then place the diaphram on top,

taking care not to a) adjust the piston position b) introduce air

into the shock. Carry on building the shock, and when you push the

piston in, you shoulc have your desired level of rebound.

For full rebound, just leave the piston at the bottom of the shock

body during building. - Ed

Clark