So, the new season of TCS racing is fast

approaching and your looking to build a new car for the series. You've

decided to race the Mini class because it has always been a fun and

competitive class; the epitome of close racing, tight lines and car

setup. You've always had a soft spot for small British cars, and BMW's

nostalgic rendition of the Mini Cooper has stirred those old feelings.

Well Tamiya, once again, is on your side. This summer they released the

1/10th scale R/C version of your dream car, the BMW Mini Cooper on the

M03L chassis.

Building a BMW Mini Cooper for TCS

competition

The M03L chassis is the latest offering from Tamiya in their series of

M-chassis'. The new chassis is longer than the previous Mini's, hence

the L in it's designation. This equates to more stability for a

classically twitchy car. It also means more room for your electronic

equipment within the chassis. The best news is that since the chassis is

very similar to the M03, all of the Hop-ups for it will still work!

Tamiya offers a variety of Hop-Ups for the M03, which can turn your

street basher into a TCS winning screamer.

The M03L chassis is the latest offering from Tamiya in their series of

M-chassis'. The new chassis is longer than the previous Mini's, hence

the L in it's designation. This equates to more stability for a

classically twitchy car. It also means more room for your electronic

equipment within the chassis. The best news is that since the chassis is

very similar to the M03, all of the Hop-ups for it will still work!

Tamiya offers a variety of Hop-Ups for the M03, which can turn your

street basher into a TCS winning screamer.

Here's how:

Differential

Building a differential for the mini starts with a TA03 Ball

differential. The diff. parts should be assembled as per the Hop-up

instructions. The only deviation from this should be in your choice of

greases. Don't be afraid to experiment with different greases to tune

your car. Softer grease should help the car turn better on a tight

course, while thicker grease should help the car "bite" more

off the corners. For the M03L at the Tamiya America Test Track, I use

Tamiya's Anti-wear Grease, this provides a lot of lock-up for the

differential. Tighten the differential until it stops, but do not apply

excessive force. Make sure the diff. spins smoothly. A set of

lightweight diff. balls will improve your chances of achieving

smoothness. A differential that is set too loose will not only make the

car slow and difficult to drive, but eventually will come apart.

Parts:

53267 - TA03 Ball Differential Set

53379 - Light Weight Diff. Balls

53439 - Anti-Wear Grease

Drive Train

A free drive train on the M03L is critical because of the relatively low

power and restricted gearing (20T). Here are some important steps you

can take to ensure that your Mini rolls as free as possible.

Installing Tamiya's hollow carbon gear

shafts will help to reduce weight in your drive train, thereby improving

acceleration and handling.

Ball bearings: you must have these to race

competitively. The rolling resistance of the car will be greatly reduced

with a good set of bearings. Although Tamiya bearings are not required,

in my experience Tamiya sealed ball bearings are the highest quality and

will last much longer in your Mini. For an added performance advantage,

remove the seals from the bearings and clean out the factory grease,

then lube the bearings with light oil such as Tamiya's Metal Bearing

oil. Replace the seals. Periodically cleaning and re-oiling the bearings

will extend their life an improve performance.

Do not grease your gears. I know this is

contrary to Tamiya's instructions, but we're building a race car here,

right? Putting grease on the gear teeth in the Mini may make the gears

last longer, but it adds drag to the drive train. Wear is the price you

pay for speed. Be sure to replace the gears as soon as they become noisy

or start to show excessive wear. The use of a good quality pinion that

meshes well will make your gears last longer. Tamiya makes one for the

F201 that is light and hard.

A set of universals in the M03L will also

help drive line efficiency. This is especially true as you steer your

Mini. The angles that universal can achieve are better than the standard

dog bones and their use can reduce or eliminate dreaded wheel-hop in the

Mini. Wheels that don't stay in contact with road don't provide the best

acceleration. Lube the universals with light oil and be sure to keep

them clean!

Parts:

53509 - HFC 0.6 Aluminum Pinion (20T)

53348 - M03 Ball Bearing Set

53390 - M03 Hollow Carbon Gear Shaft

53508 - Metal Bearing Lubricating Oil

53205 - M-Chassis Universal Shaft Set

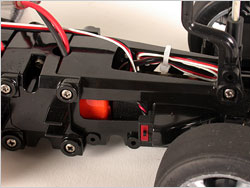

Low Center-of-Gravity (C.G.)

A nice thing about the new M03L is the middle chassis extension. It

provides some much needed room for electronics in the Mini. Previously

electronics either had to be placed on the top (high C.G.) or on the

sides (likely to be damaged) of the chassis. I can't stress enough how

important it is to keep the C.G. of the car low. A car with a low center

of gravity will have less body roll and will also be less likely to tip

over. This is very desirable! I managed to mount a Novak Cyclone TC and

Futaba FP-R113F receiver in my Mini. Shoe Goo is your best friend in

this endeavor. Double-sided tape is unlikely to work, because of the

unevenness in the bottom of the chassis. Be creative when mounting the

electronics, but keep in mind that you should be able to get to the

frequency crystal and be able to adjust your speed control.

A nice thing about the new M03L is the middle chassis extension. It

provides some much needed room for electronics in the Mini. Previously

electronics either had to be placed on the top (high C.G.) or on the

sides (likely to be damaged) of the chassis. I can't stress enough how

important it is to keep the C.G. of the car low. A car with a low center

of gravity will have less body roll and will also be less likely to tip

over. This is very desirable! I managed to mount a Novak Cyclone TC and

Futaba FP-R113F receiver in my Mini. Shoe Goo is your best friend in

this endeavor. Double-sided tape is unlikely to work, because of the

unevenness in the bottom of the chassis. Be creative when mounting the

electronics, but keep in mind that you should be able to get to the

frequency crystal and be able to adjust your speed control.

Electronics

The electronics that you choose for your Mini are a matter of personal

preference and I will list the electronics that I used for comparison

purposes only.

- Servo: Futaba S9404

- ESC: Novak Cyclone TC

- Receiver: Futaba FP-R113F

Keep in mind that the Mini uses a direct

link between the Servo and the steering. This means that the Mini's

servo does not have the leverage that can be achieved by other cars with

bell-crank steering. It is therefore very important, for racing

purposes, that the servo you choose has plenty of torque and speed.

To be competitive in a TCS race you must

use and electronic speed control (ESC). Put simply; buy the best one you

can afford. Size, weight, on resistance (low), ruggedness and smoothness

are key features to look for.

I highly recommend running a good quality FM

radio system. Most racers quickly find out how good their radio

equipment is at a major race. Lots of transmitters means lots of radio

noise and there is absolutely nothing worse than having radio problems

at a race. Read your radio's instruction manual carefully; most contain

excellent tips for routing the wiring on your car to avoid interference.

Chassis Tuning

Before you begin tuning your chassis, be sure that all the parts on your

car are in good condition. No parts on the car should be broken or

binding (especially suspension arms). It's amazing how many handling

problems can be solved, simply replacing a bent suspension pin! Also, be

sure that no parts on the car are excessively worn. Sloppy steering and

suspension arms are typical trouble spots. Fortunately the M03L is well

setup to begin with but there are a few chassis adjustments that can

considerably improve the cars handling.

Steering

Use a high-torque servo saver to protect the investment you made in that

expensive servo. If you choose the Tamiya unit install the longer of the

two servo horns that are included in the kit. This most closely matches

the length of the kit servo horn and reduces bump steer as much as

possible. I installed Tamiya's new Front Upright Set on my car for

strength and steering response. These new uprights include two mounting

holes for your tie-rods. The forward most holes provide quicker and

tighter steering. Another nice feature to have on the steering are

turnbuckles, which Tamiya has now made available in Titanium. These are

stronger and lighter than the stock pieces and allow front toe to be

adjusted quickly and easily. My car is set with a static front toe of 2

degree out. This setting allows the wheels to pull themselves to 0

degrees of toe under acceleration. Your car may differ, so to check this

adjustment, set the toe and push inward on the forward most part of both

front tires. With moderate pressure the wheels should both point

straight ahead (0 toe). On the back of the car I use toe-in rear

uprights for stability and control. The 2 degrees of toe-in that these

provide make the car track straighter and keep the back end in line on

turn-in.

Parts:

50473 - Hi-Torque Servo Saver

53523 - M03 Aluminum Front Upright Set

53527 - 3x32mm Titanium Turnbuckles

53345 - M03 Toe-In Rear Upright

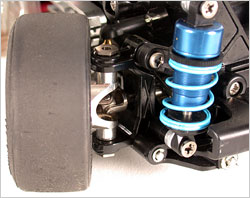

Dampers

Dampers, the heart of your suspension and handling, are often over

looked. Correctly building and adjusting your dampers can turn a good

car into a great car. For the M03L, I recommend using the TRF Super Low

Friction Damper Set. For clearance purposes these dampers must be used

with the Adjustable ball end connectors. The 2mm spacer is required in

this kit to provide the necessary clearances for the adjustable spring

perch. Follow the damper directions, but when installing the internal

spacers use four 3mm o-rings in each damper (front and rear). This will

restrict excessive droop or down-travel in the suspension. I have found

that this makes the car less sensitive to movements on and off the

throttle making it easier to drive. Use the 3 hole Teflon pistons that

come with the kit. The front dampers I filled with 600# Tamiya Silicone

Damper Oil (approx. 60wt) and the rear dampers with 400# (approx. 40wt).

Be sure to remove as many air bubbles as possible from the dampers

before screwing down the cap. Measure the extended lengths of the shocks

and thread the eyelets on until they are all equal lengths. My set-up is

based on a damper length of 56.5mm (measured end-to-end).

Parts:

49198 - TRF Damper Set (Blue/4pcs.)

53488 - Adjustable Ball Connectors (*2 required)

53443 - Silicone Damper Oil Soft Set (#200,#300,#400)

53444 - Silicone Damper Oil Medium Set (#500,#600,#700)

Springs/Ride Height

The Short Tuned Spring set is the best choice to setup the M03L. It

allows the ride height to be lowered with out the need to excessively

preload the springs. My setup uses the blue springs up front and the

yellow springs in the rear. The threaded spring perches on the dampers

should be adjusted to give you a ride height of approximately 3mm in the

front and 6.5mm in the rear. Set-up should be performed with a battery,

a motor and all electronics in the car. Use the lowest points on the

front (just behind the axle) and the rear (very back) of the chassis to

obtain correct measurements.

The Short Tuned Spring set is the best choice to setup the M03L. It

allows the ride height to be lowered with out the need to excessively

preload the springs. My setup uses the blue springs up front and the

yellow springs in the rear. The threaded spring perches on the dampers

should be adjusted to give you a ride height of approximately 3mm in the

front and 6.5mm in the rear. Set-up should be performed with a battery,

a motor and all electronics in the car. Use the lowest points on the

front (just behind the axle) and the rear (very back) of the chassis to

obtain correct measurements.

Parts:

53333 - Touring Car tuned Spring Set (Short)

Anti-roll Bars

Some people use them some don't. In my opinion this is one of the best

and easiest ways to tune your car. These can be quickly changed or

removed to improve an ill-handling car. If the car pushes, try adding a

stiffer rear bar and/or remove the front bar. If the car is loose, a

stiffer front bar and/or remove the rear bar may be called for. My car

has medium bars installed on the front and rear. In general the M03L is

inherently more stable that the old M03, so you can run the car quite a

bit stiffer in the rear (spring, shocks damping), without making the car

loose.

Tires/Inserts

With out a doubt 60D Type-A tires provide the maximum grip for the M03L

on a prepared surface such as Tamiya America, and these are the tires I

use there. Your track may not provide as much grip or may be dustier. If

this is the case the 60D Super Grip Radial Tires may be more

appropriate, these tires are generally more forgiving than slick tires.

Some people even mix the tires front to rear to tune the car. Only

testing and personal preference can determine your tire choice.

With out a doubt 60D Type-A tires provide the maximum grip for the M03L

on a prepared surface such as Tamiya America, and these are the tires I

use there. Your track may not provide as much grip or may be dustier. If

this is the case the 60D Super Grip Radial Tires may be more

appropriate, these tires are generally more forgiving than slick tires.

Some people even mix the tires front to rear to tune the car. Only

testing and personal preference can determine your tire choice.

TCS National rules changed last year to

allow any tire insert in competition. This makes choosing a tire insert

an expensive and time consuming proposition. David Jun has written an

article on this topic that is posted on the Tamiya America site and I

recommend reading it. The only additional factor to consider when

selecting inserts is rollout. Since the M03L has limited gearing (20

tooth pinion is basically the only choice for most tracks) it is to your

benefit to make the front tires as hard as possible. This is equivalent

to inflating a tire to its maximum pressure. Anyone who has ridden a

bicycle knows that its easier to peddle a bike when the tires are pumped

up. In addition the diameter of the tire is maximized; a bigger tire

improves the overall gear ratio. All this means your Mini will be faster

on those long straights. To achieve this I used a 24mm insert cut and

taped to fit the diameter of the mini wheels and I also stuffed a foam

insert in to the tire. It can be quite difficult to get all this

material in the tire without bulges so practice it a few times before

you glue the tire. Keep in mind this is only for the front tires. For

the rear tires I mounted them more conventionally with just a foam

insert. It should be pretty easy to tell which are fronts and which are

rears by squeezing them but I recommend labeling them anyway.

Parts:

53340 - M Chassis 60D Reinforce Tires Type-A (*2 required)

53254 - 60D Super Grip Radial Tire (*Optional, 2 required)

50686 - 60D Inner Sponge Tire Set (Soft)

53435 - Medium Narrow (24mm) Shaper Insert (Hard)

Testing

The setup that I have provided here is a result of testing at the Tamiya

America facility under specific track conditions. It is a good basic

setup that has proven competitive with other Mini chassis. Don't be

afraid to make adjustments to the car and to try different options. I

found that through out the day, small changes to car improved its

performance. Remember that out door tracks are very dynamic and require

constant changes to get the most out of a car.

Conclusion

With the right Hop-Ups and careful construction, this is

definitely a car that can win races. Drive train, chassis tuning, tires

electronics are all important factors in making a well-rounded racecar.

The M03L simple construction and fundamentally good handling are a good

platform for this. Additionally, the Mini is a relatively cheap class to

run and even a well hop-up car wont break the bank. I consider my Tamiya

BMW Mini Cooper a great addition to my RC car stable.