|

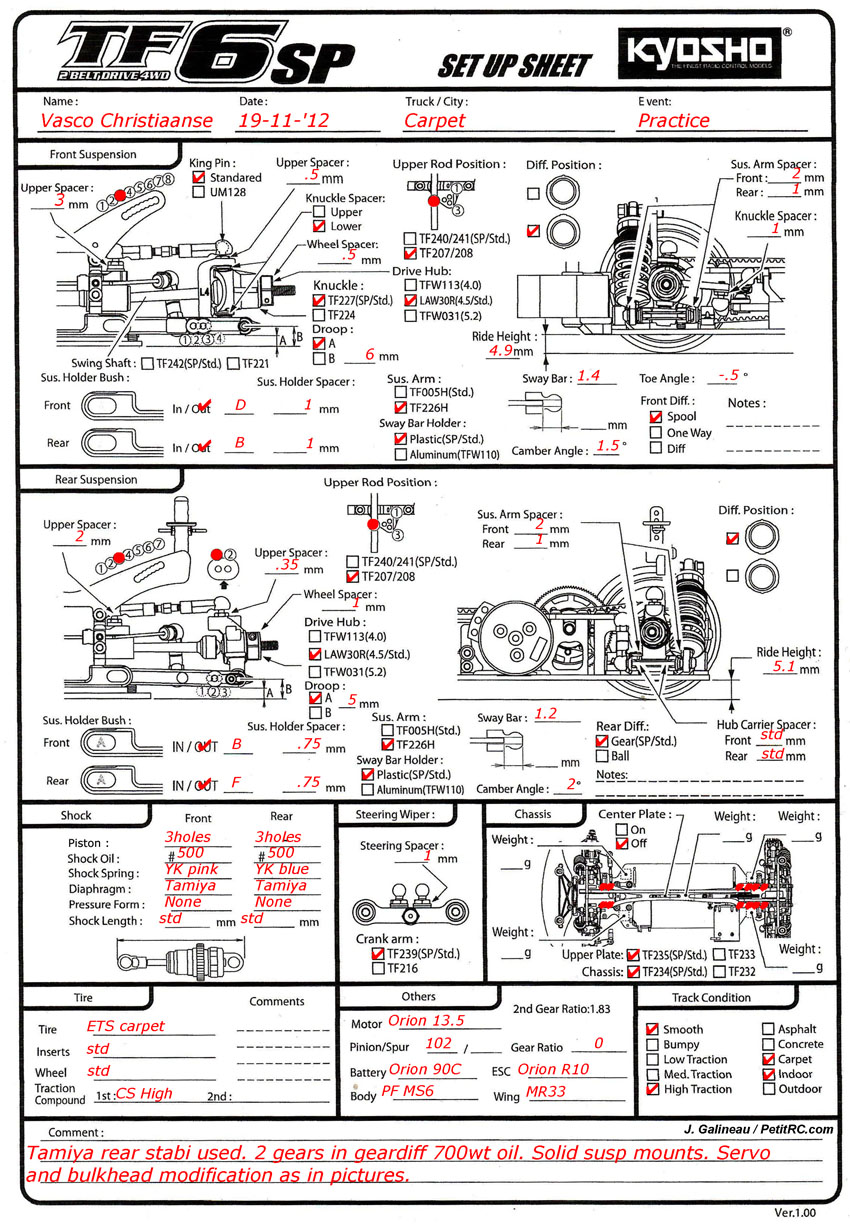

- Kyosho TF6SP - Vasco Christicone - Carpet Track - 19.11.2012 -

This setup suffer improvement, here is the replacing one

I went practicing with John yesterday and we really made a big step. The car is far less twitchy now due to running the rear diff in high position which keeps the rear from pushing and the much wider suspension setup with the B-F blocks in rear. Please give the setup posted below a chance next time you go out, I'm very certain this will make the car much better to drive.

PDF File

What does "pushing from the rear" mean?

The 'pushing' rear gives you the feeling that the rear end of the car wants to overtake the front causing the car to feel twitchy to drive. It has something to do with the rather big angle the rear driveshafts are making from the hub to the diff side.

I went practicing with John yesterday and we really made a big step. The car is far less twitchy now due to running the rear diff in high position which keeps the rear from pushing and the much wider suspension setup with the B-F blocks in rear. Please give the setup posted below a chance next time you go out, I'm very certain this will make the car much better to drive.

Using 'old' TF6 upperbulkheads since they're a tiny bit lower then the SP ones.

Solid suspension arms holders used front and rear.

Made a couple of changes to the chassis itself:

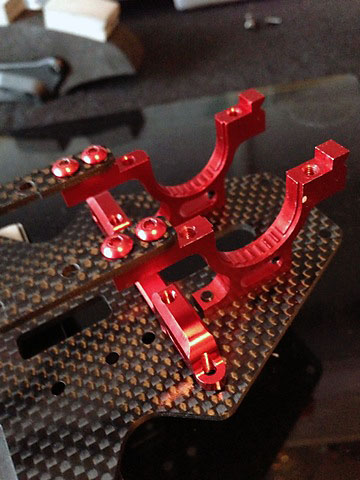

I fitted front bulkheads in the rear of the car for more even flex. This requires two extra holes in the chassis to mount them the right way. Just mounted an old chassis backwards on my current chassis and drilled the holes:

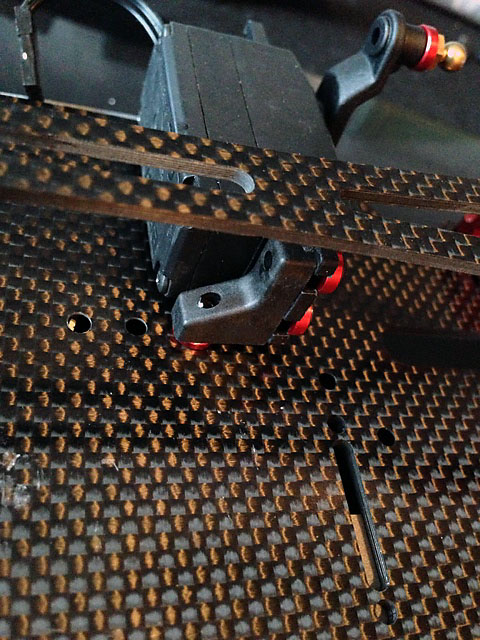

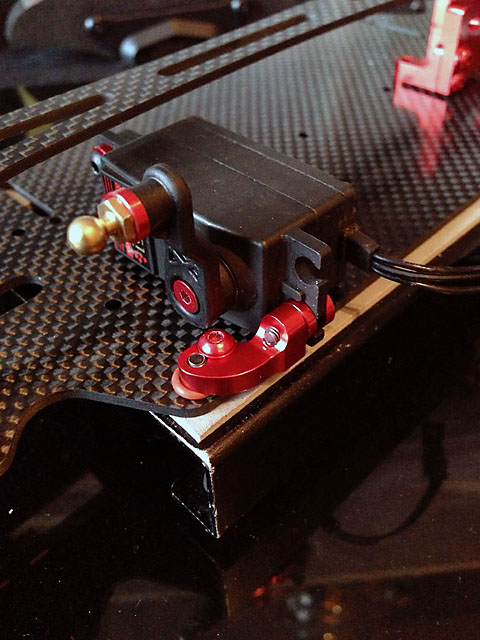

Another idea I'm going to try is a different way of mounting the servo to 'copy' the current Yokomo, Tamiya, Xray etc. servo mount idea. Since we have no such part (yet) available I worked on a sort of similar solution while using the regular inner and outer servo mount. I've raisen the inner mount 1mm just by adding a shimm underneath, then on the outer mount I justed a rubber shimm instead so the servo can not move back and fort, but chassis is able to flex. To keep the servo from beeing pressed down I use a screw in the other hole of the mount that is very close to touching the chassis. When I flex the chassis now it seems to work really well and the desired movement of the chassis underneath the servo (which was previously impossible) is clearly noticeable. My solution:

Some other things I'm going to try is a gear diff with just two gears in it. Matthijs came up with this idea for a smoother operating diff which could be benifitial when racing pro-stock. John has been testing with the gear diff running in high position to keep the rear of the car from pushing as the car tends to do this on carpet tracks.

Source:

|