|

Page 1 - Page 3

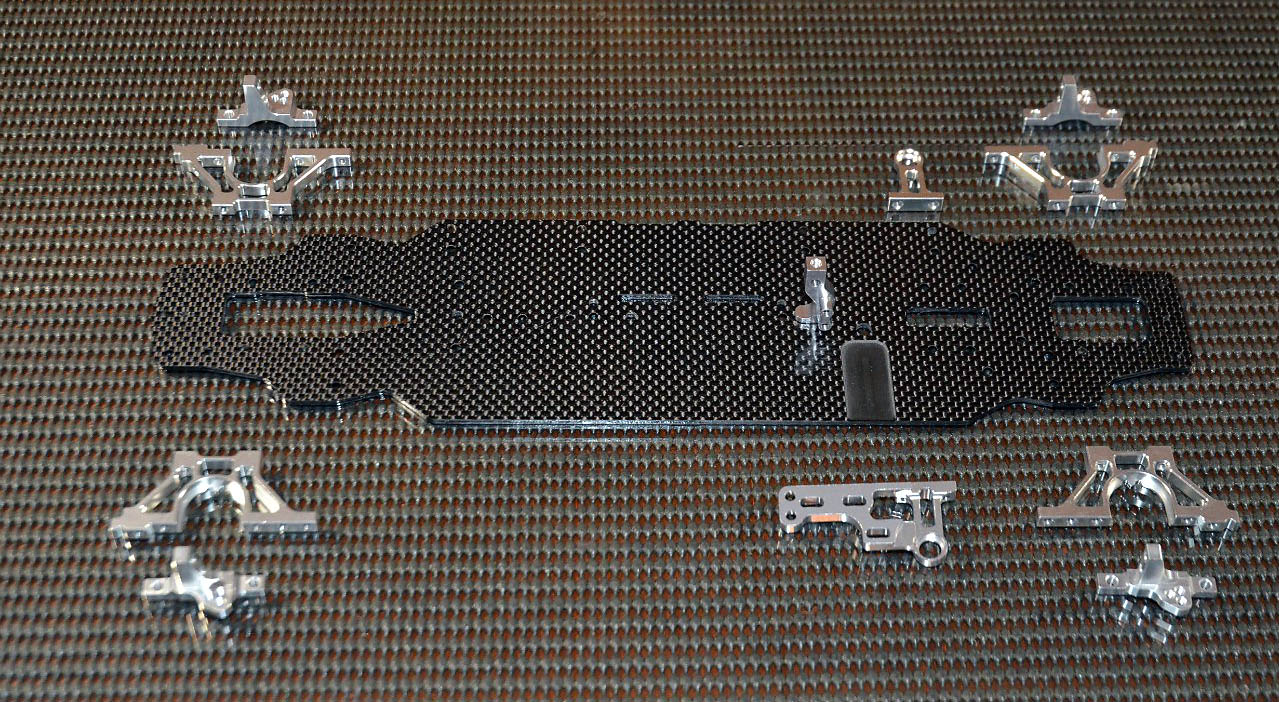

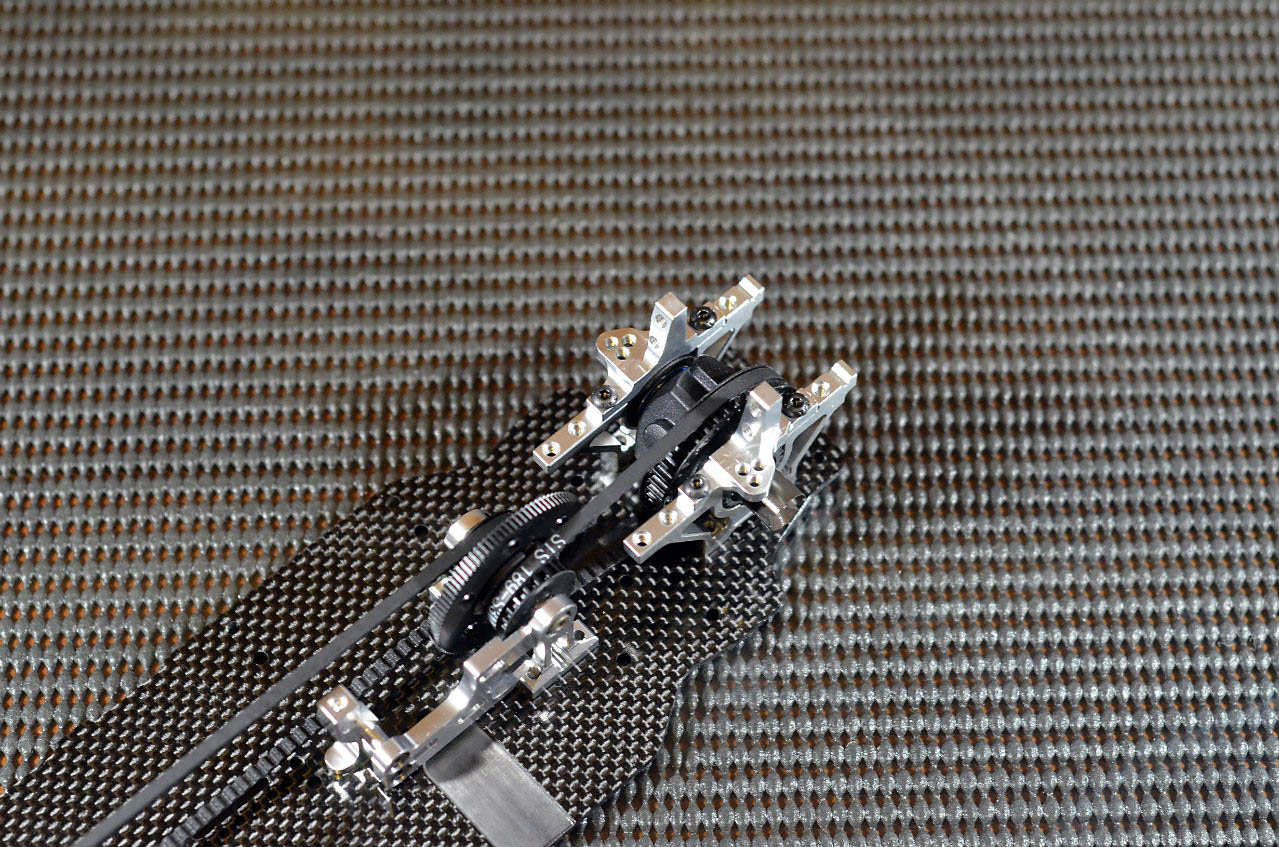

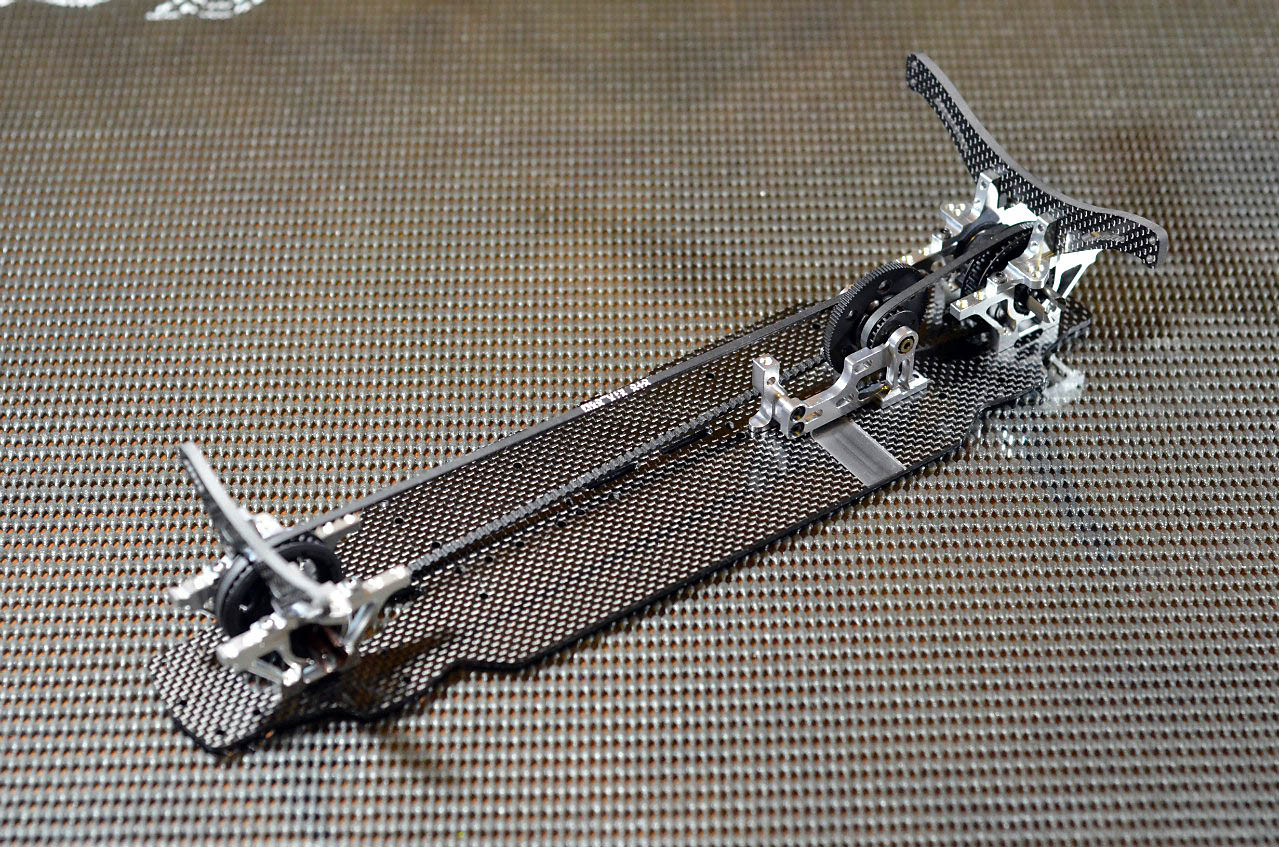

You can see lower and upper decks weighted as well. Lower deck is one of the narrowest on the market - only 82mm. Another interesting thing is an option to mount battery with transverse tape placing. In theory it increases chassis flex.

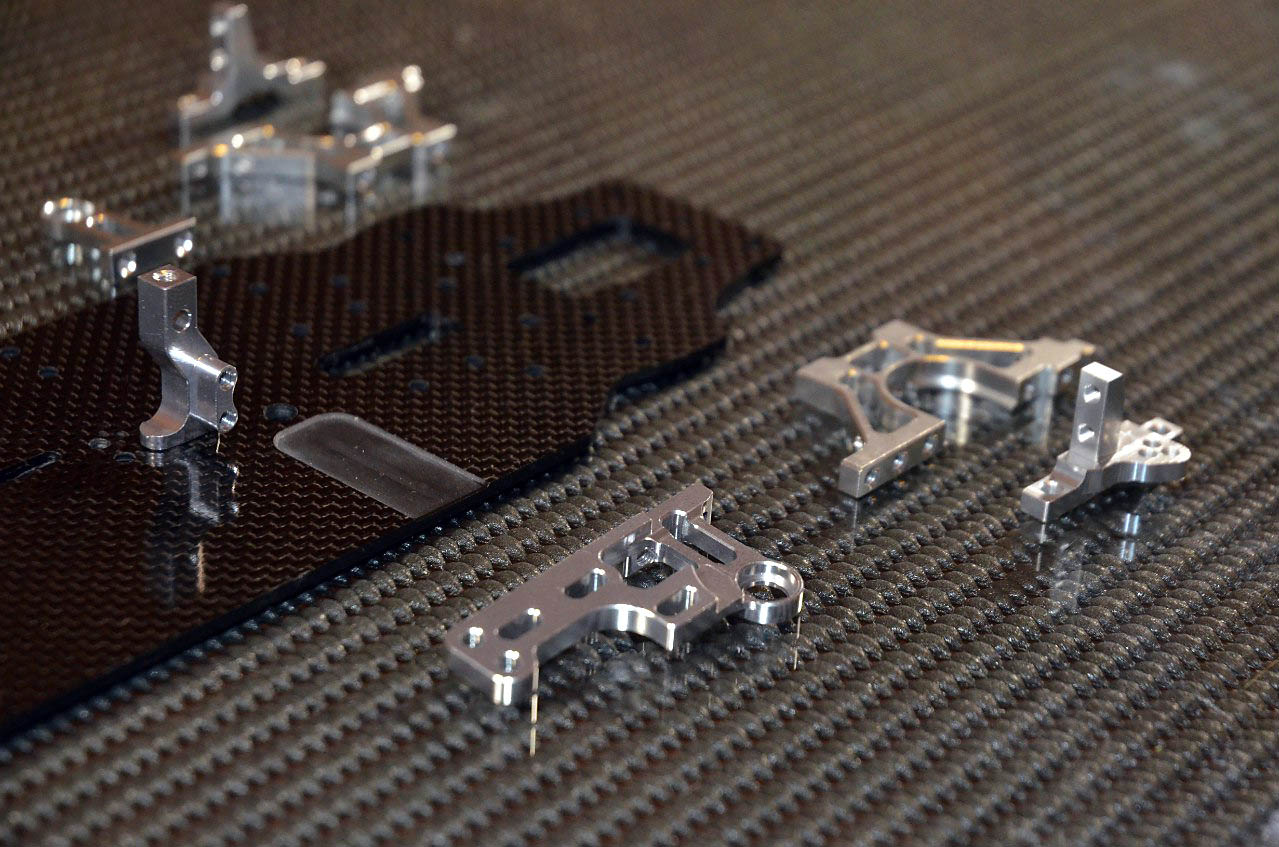

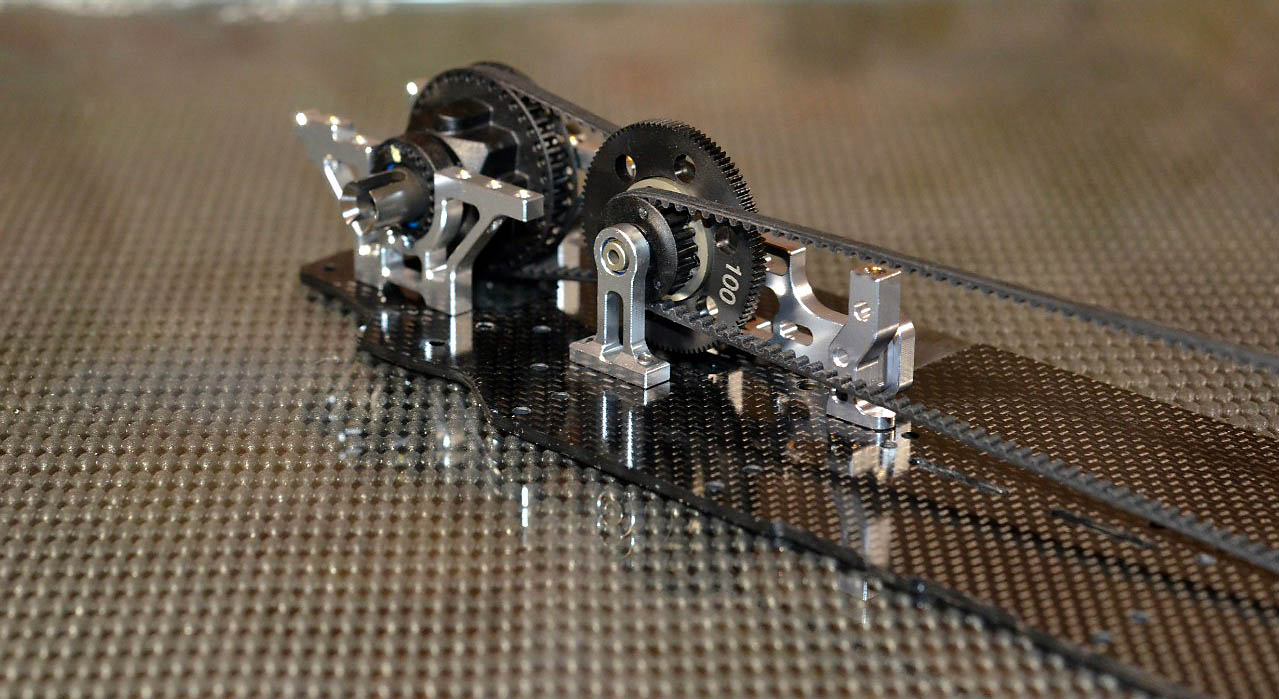

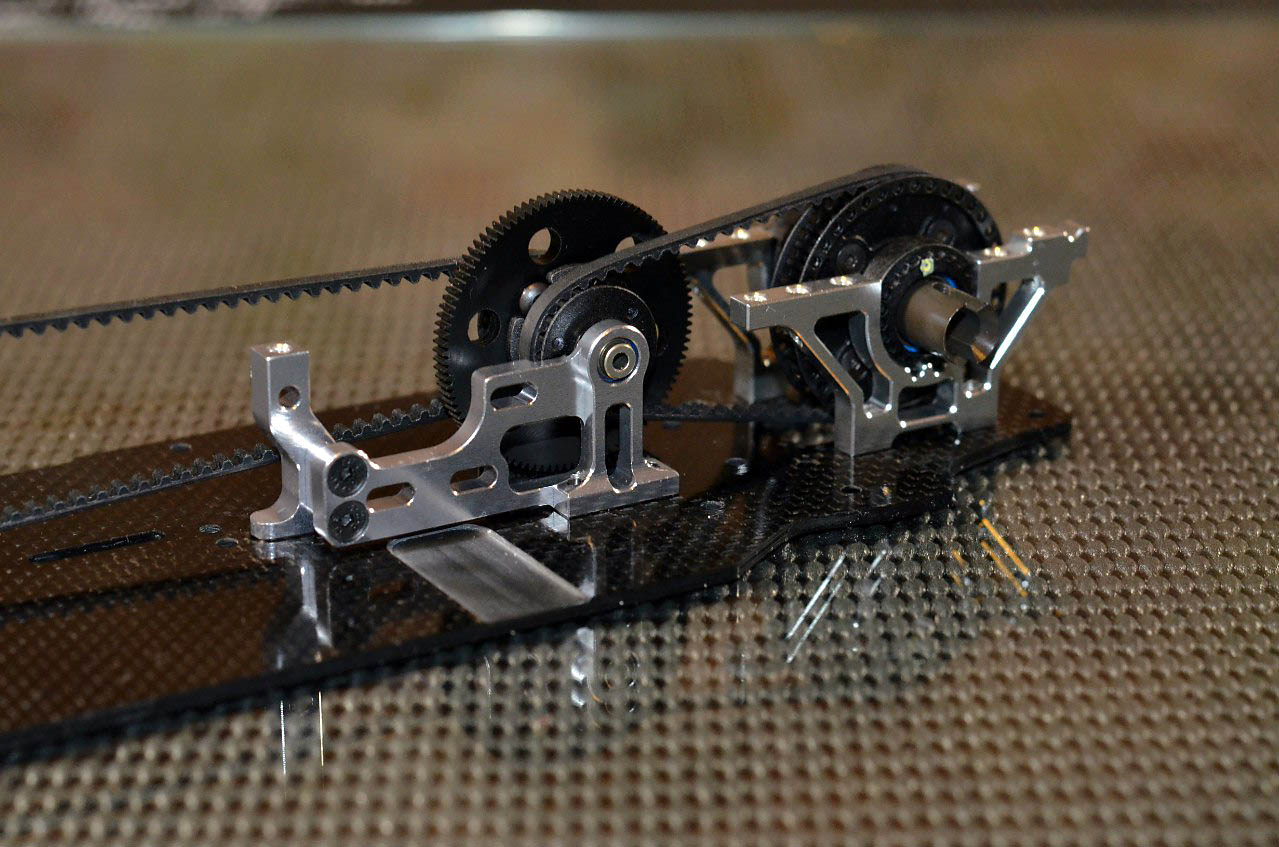

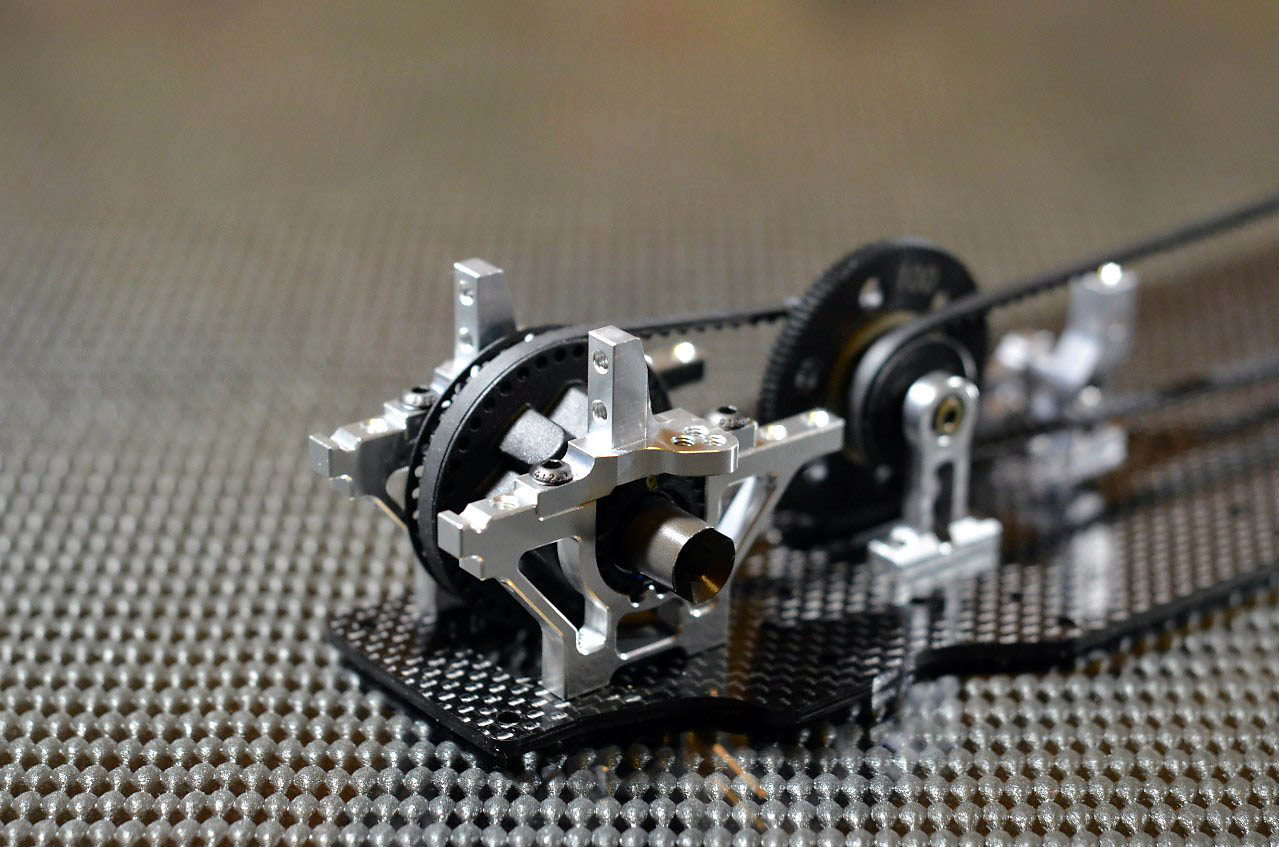

Now time for bulkheads and central pulley/motor mount.

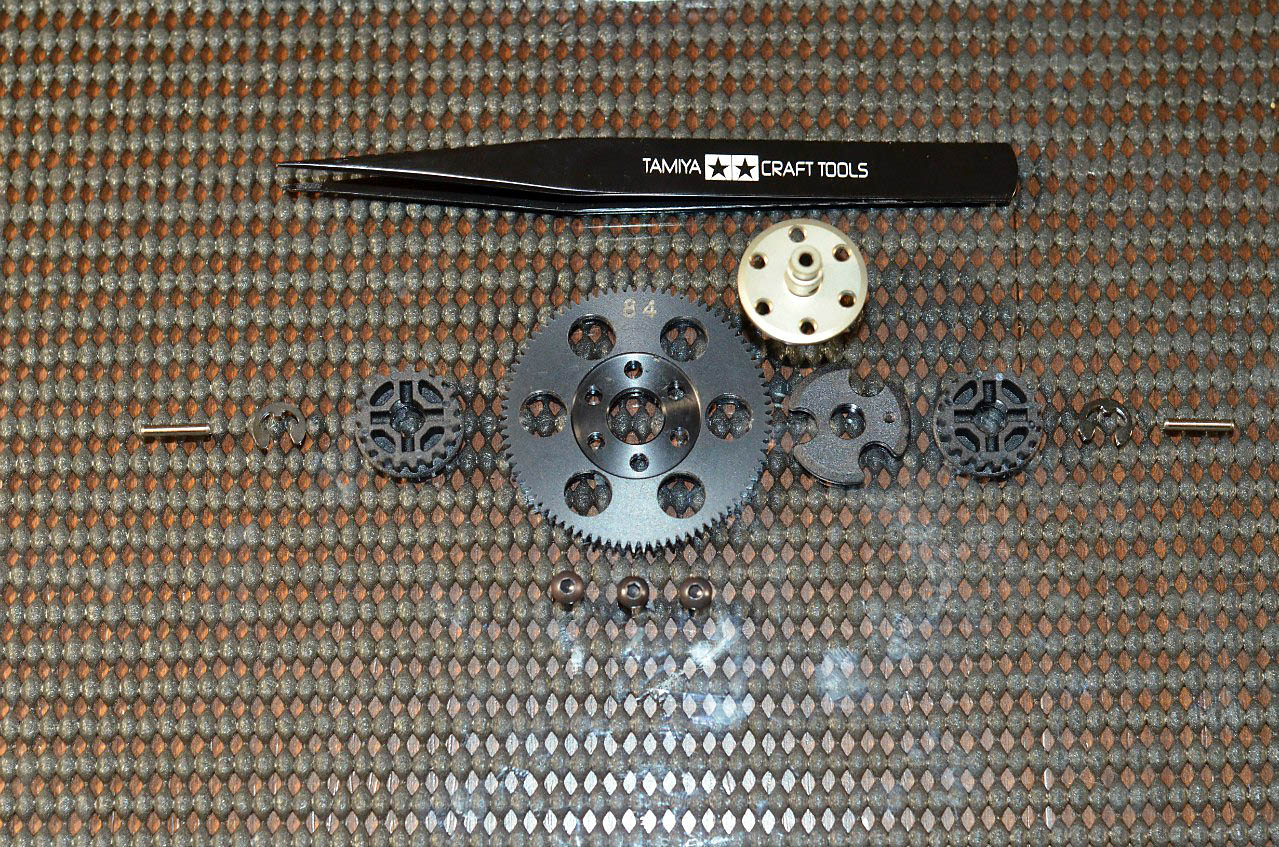

Central pulley assembly shows the classic construction: aluminum main shaft, two plastic pulleys, two steel pins, spur gear and spacer. You get full CNC machined 84T 48p spur gear straight from the box! Not a common thing. You need three screws for secure mount spur gear on main shaft and two large E-clips to hold pulleys.

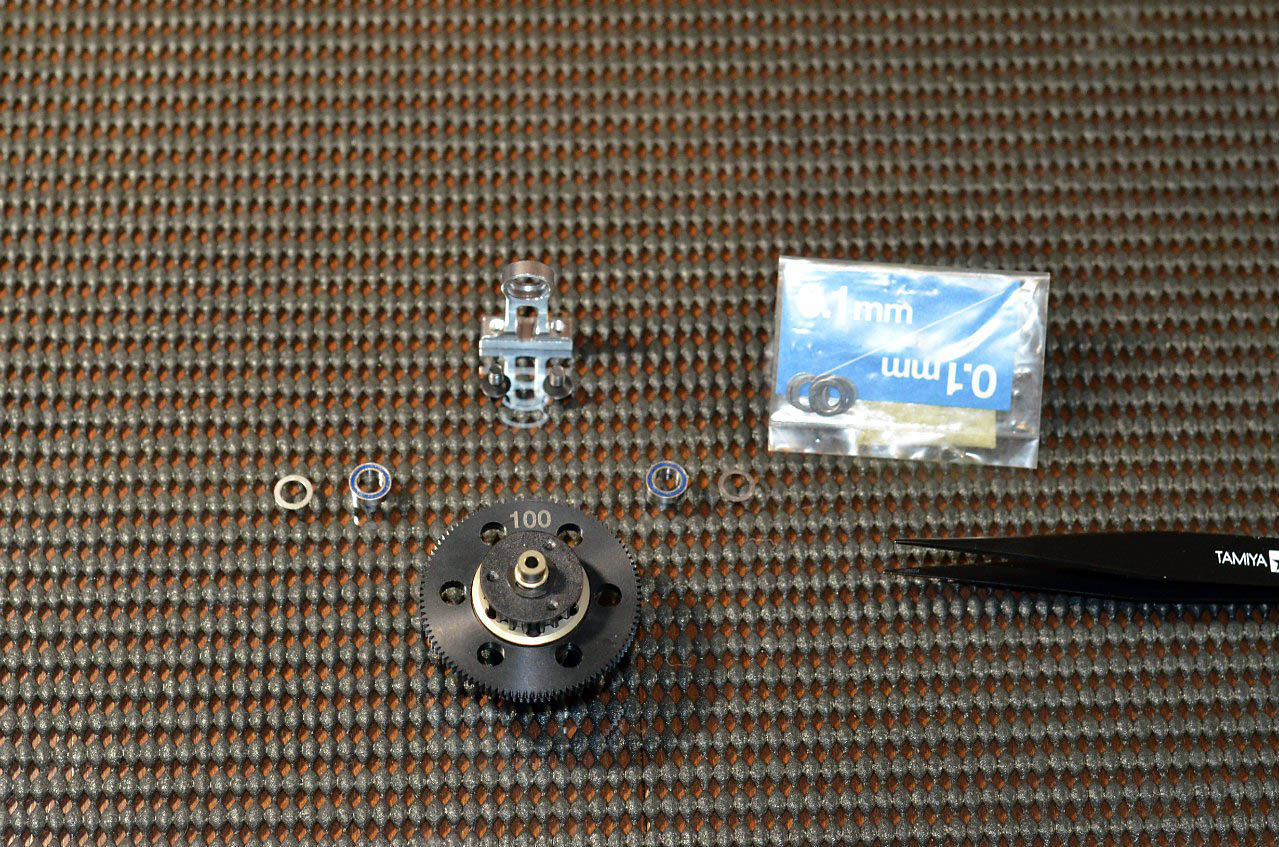

I use optional 100t 64p CNC Spur Gear, because I prefer 64p drivetrain for carpet for additional smoothness.

All parts fit perfectly to each other.

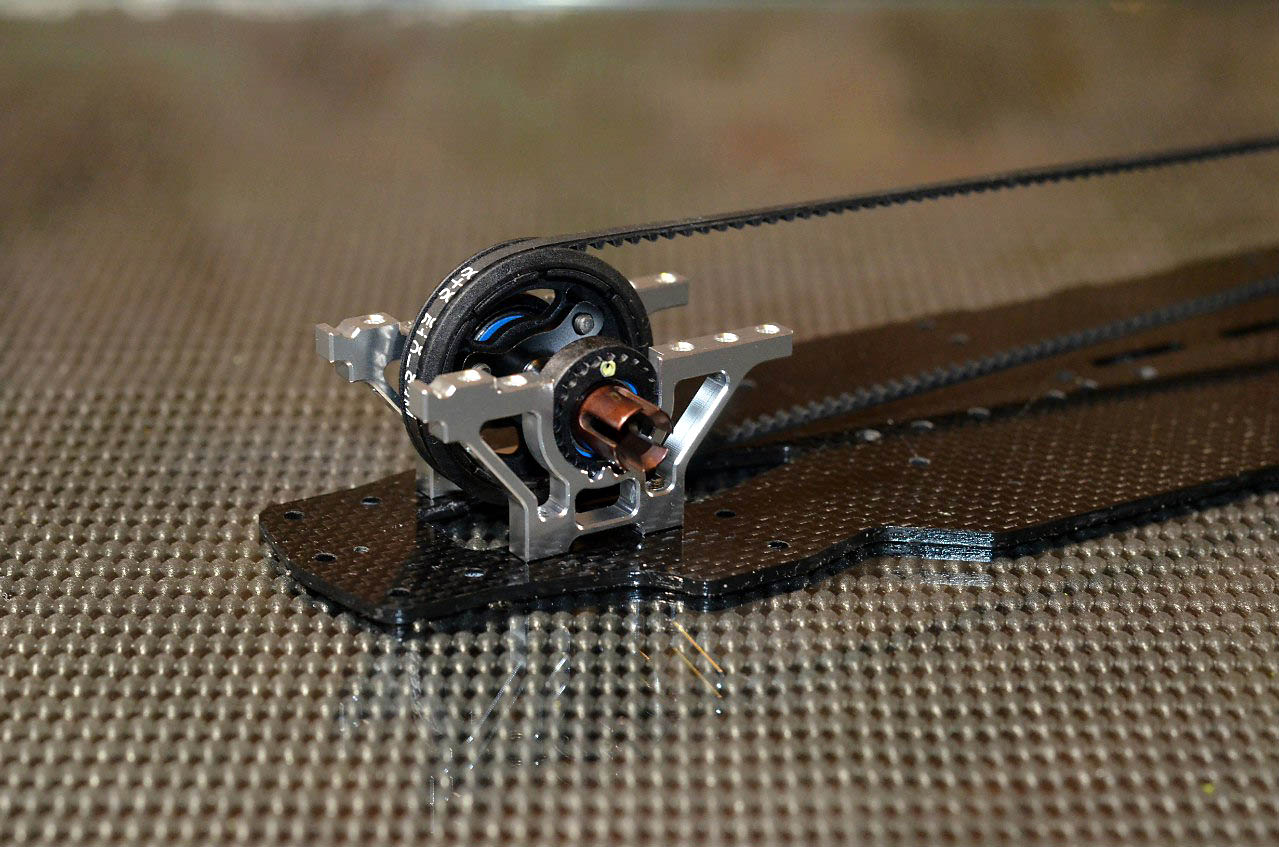

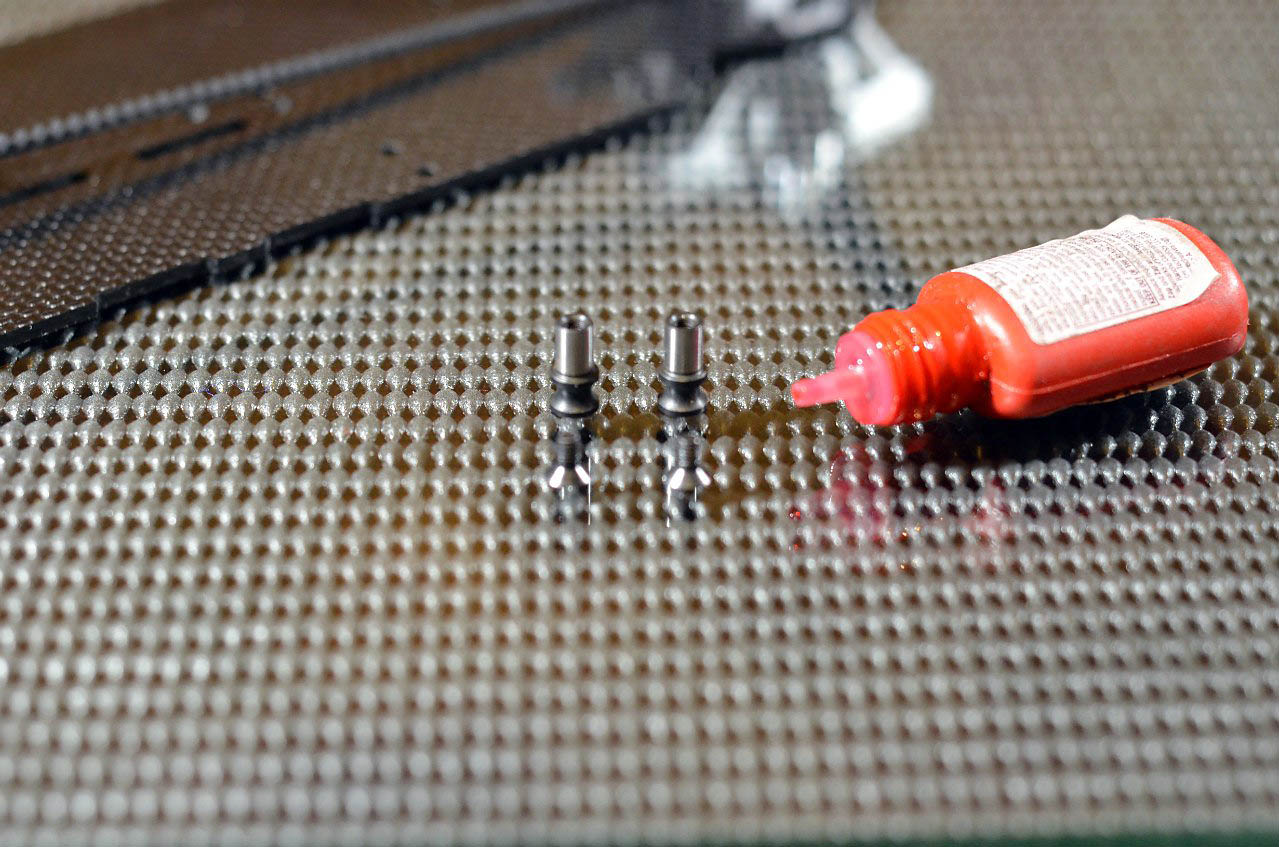

I prefer to mark the eccentrics with color dots. It just makes it easier to make adjustments when you donít have enough light etc.

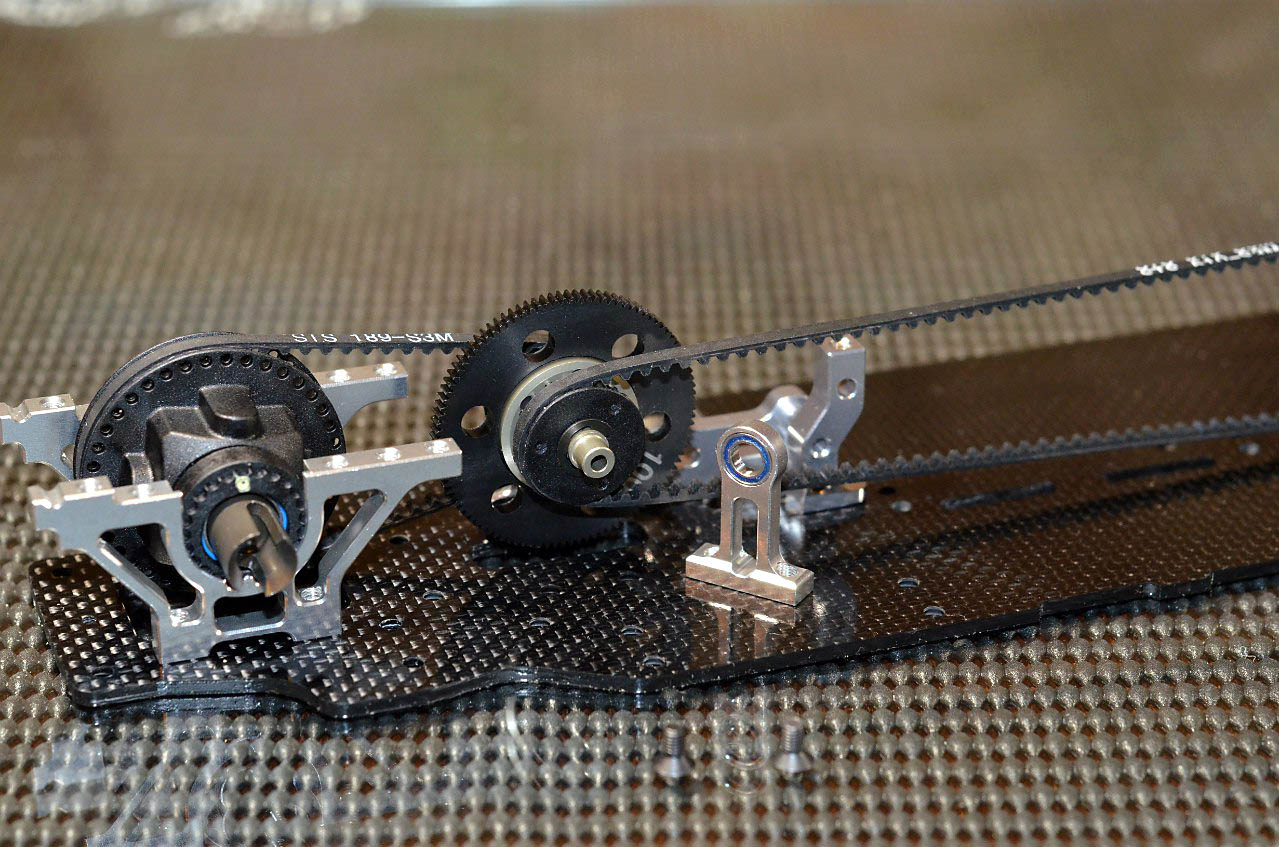

Final assembling of drivetrain. First, you need to install Spur Gear unit with belts. To adjust fitment to perfection I use two 0.1mm shims (one to each side of main shaft). Rotation is flawless! Thanks for ideally balanced and centered CNC Spur Gear.

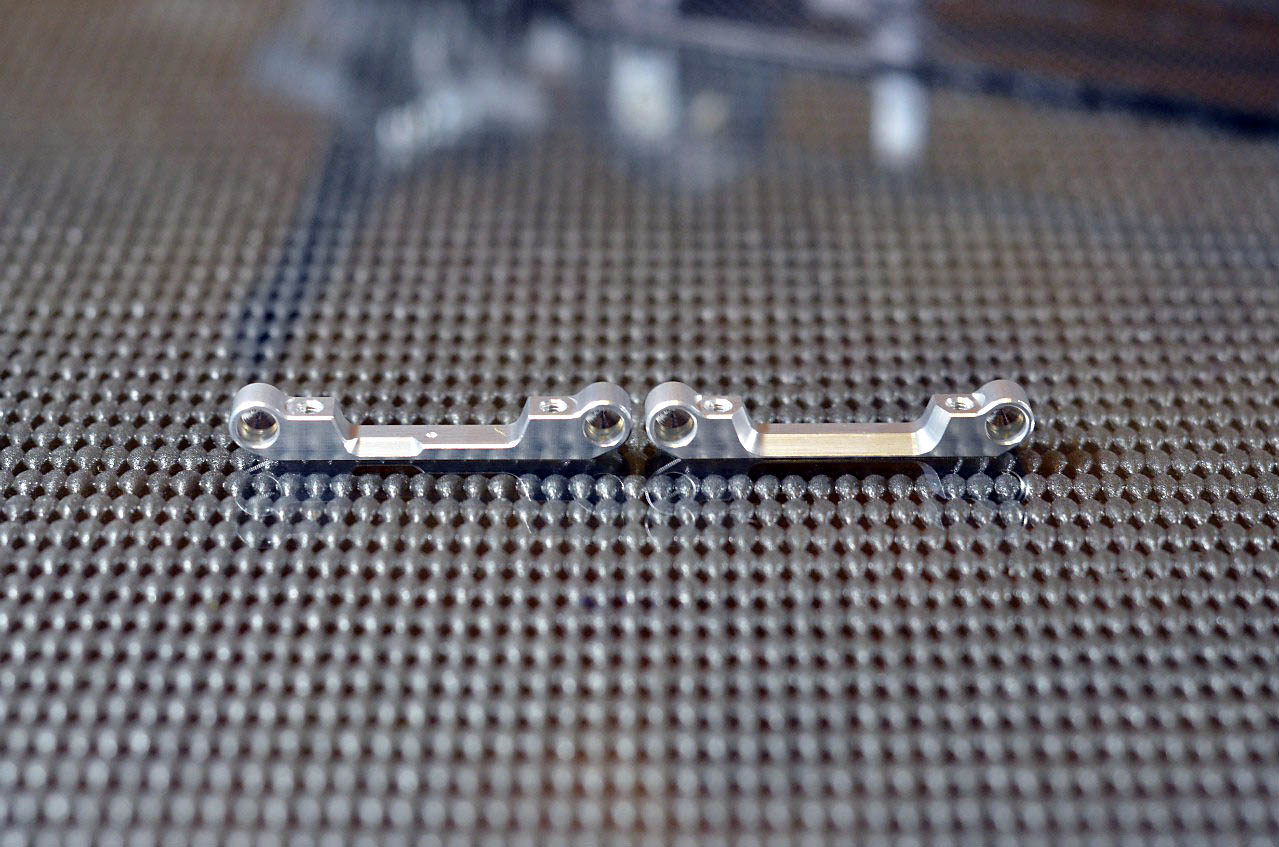

Before mounting upper bulkheads I install upper deck to make sure, that eccentric position is right for good belts tension. It shows, that initial position (dots centered up both front and rear) is what I need.

Full CNC silver aluminum parts everywhere - pure pleasure to look and to assemble.

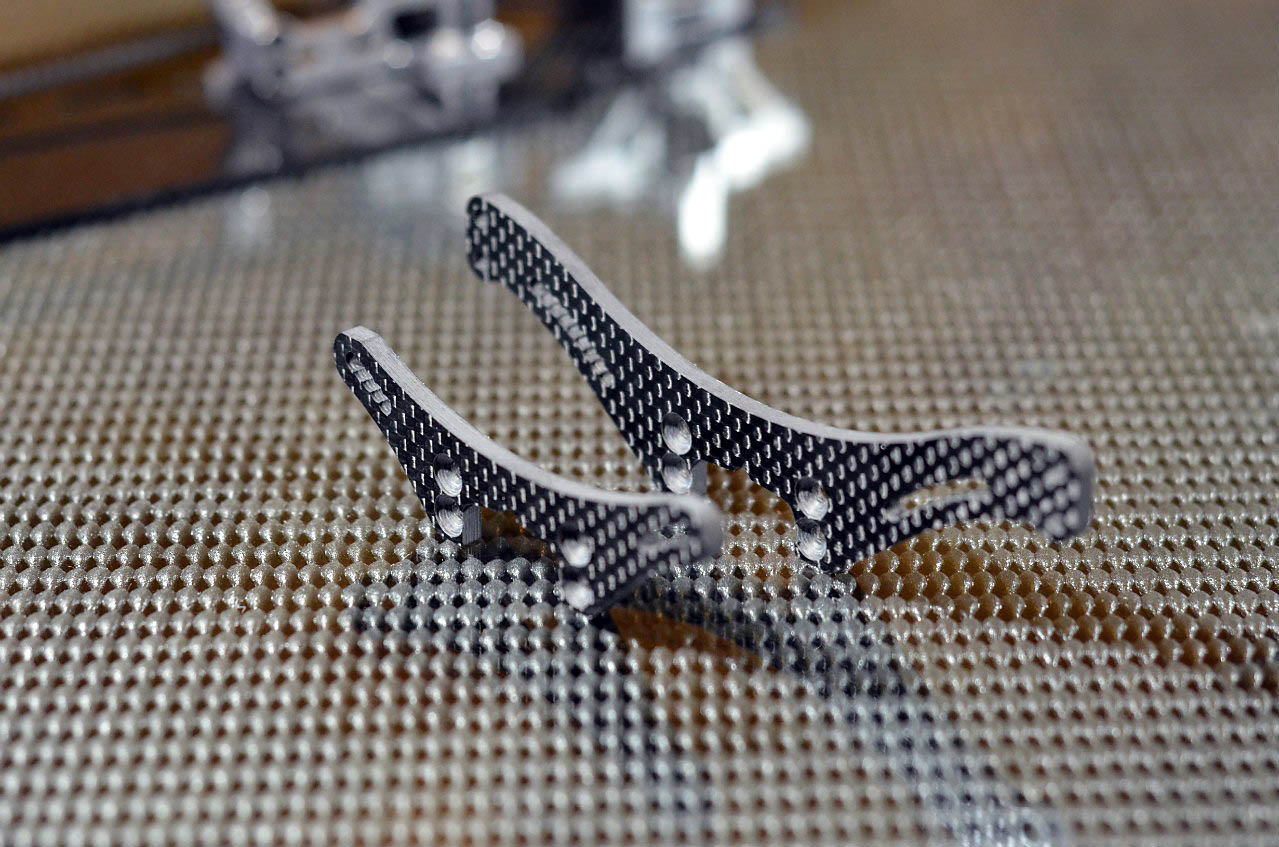

Shock towers. 3mm thickness, machined holes, smooth shape with a lot of shock mounting holes. You have 5 in front tower and 9 in rear - good space for tuning. Hard as a rock.

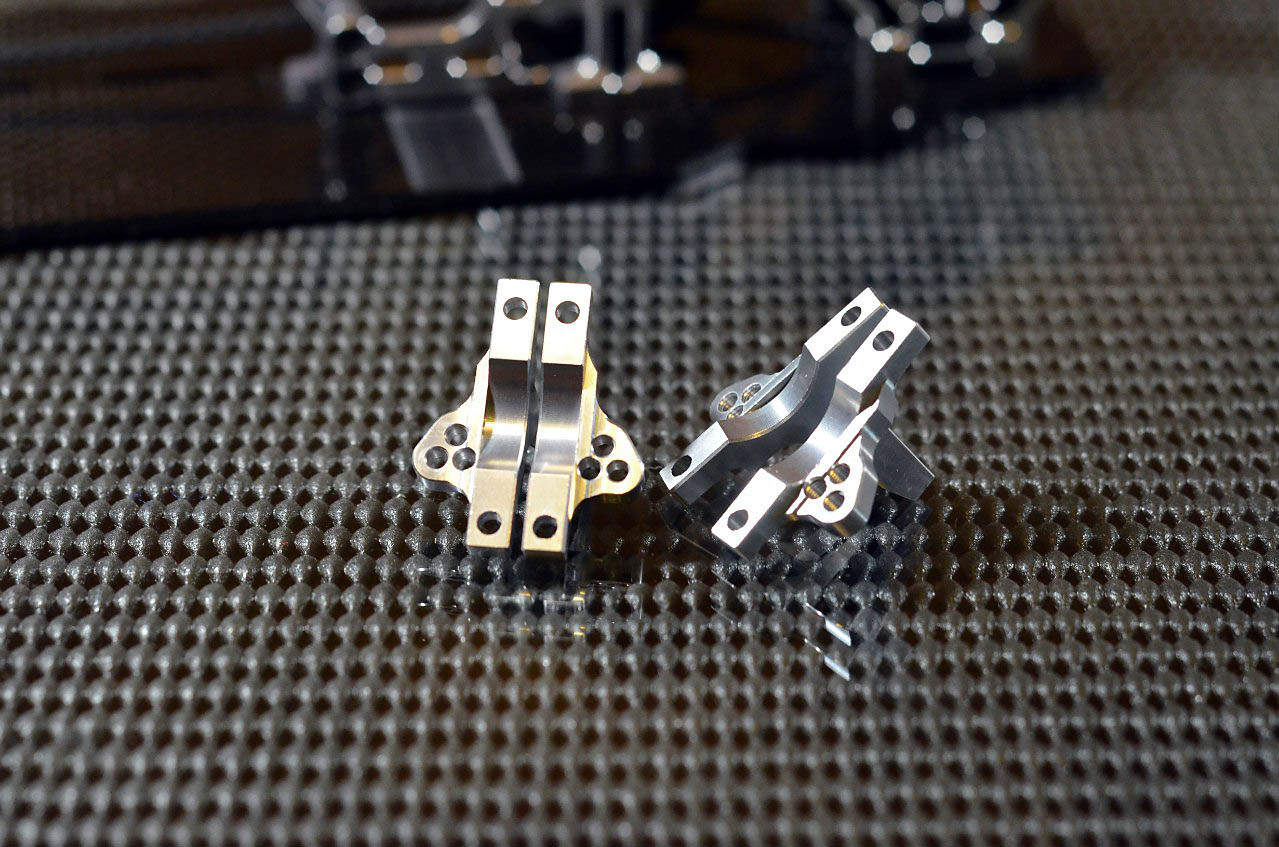

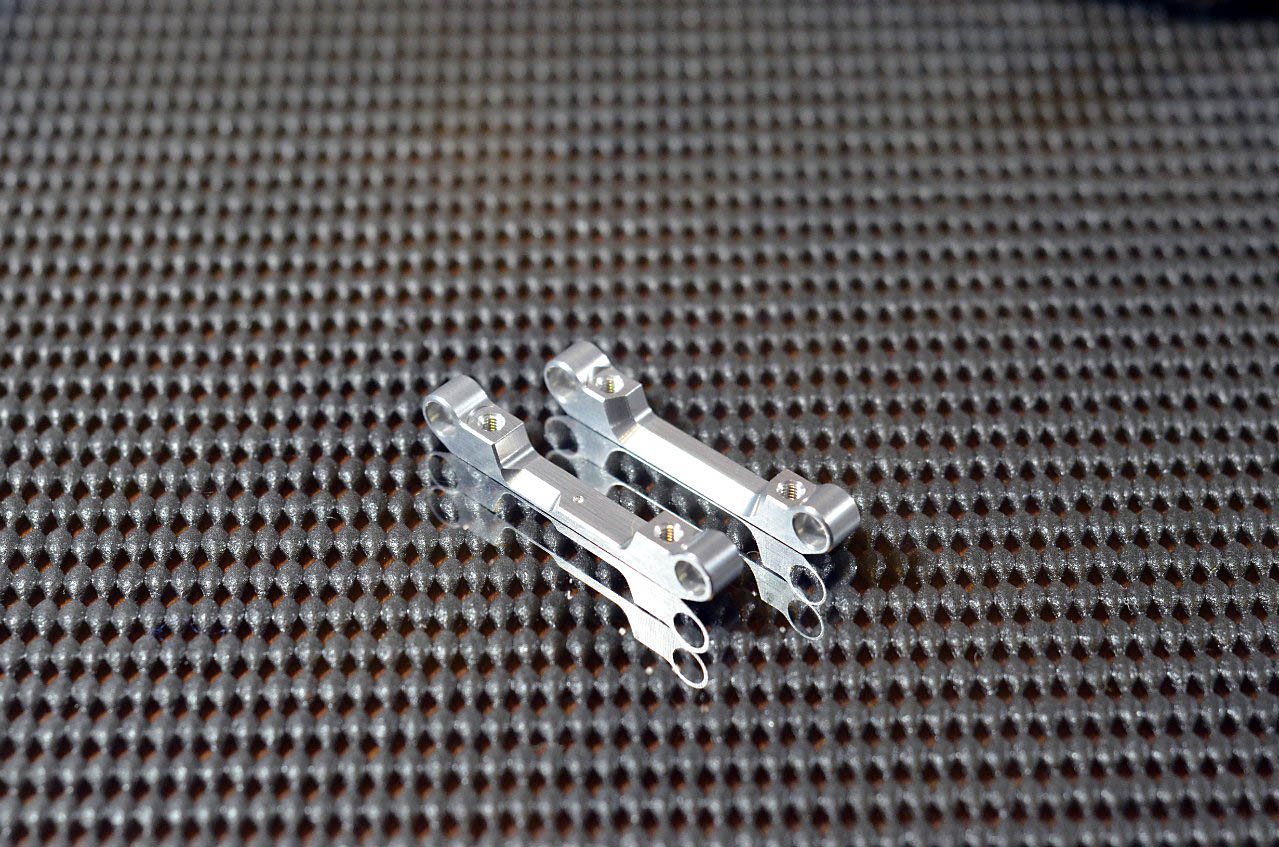

Pivot blocks. All unnecessary material removed, good shape with additional space for belt.

Steel steering posts. I use red loctite here to be sure, that mounting screws will not be loose during race.

Page 1 - Page 3

|