|

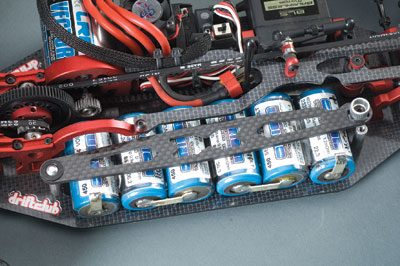

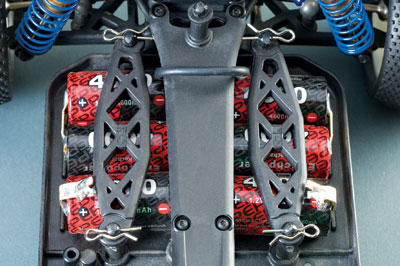

Today's cars

have a wide variety of battery layout and placement

options depending on class type. Some of the common

battery placement designs center all the batteries toward

the middle, use saddle pack configurations, or position

the battery to one side with electronics on the other.

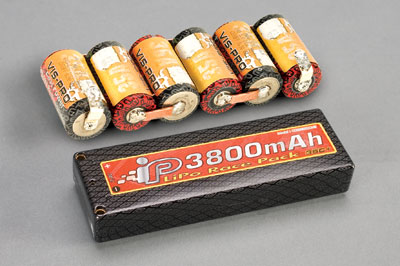

To give you an

idea of weight differences between the two battery

technologies, let's use some common packs. The weight

difference alone between 2-cell LiPo (Orion 3600 at 224

grams) and 6-cell NiMH (Orion 4200 SHO at 428 grams) is

quite significant. The difference (204 grams) needs to be

addressed (weight will vary depending on packs used).

For center

placed battery layouts like the ones in offroad 2wd

buggies and trucks, things tend to be slightly easier. It

can just be a matter of working on a new set-up that

reflects the new lighter weight, but as many of you know

finding that "magical" set-up isn't always that

easy. Almost everything is affected to some degree

including suspension, aerodynamics, tires and wheels,

acceleration, braking, etc.

A good example

of change is Ryan Cavalieri's AE B4 set-up. His buggy has

always been set up more or less the same with just a few

minor exceptions, and has always run with NiMH until

recently. As the rules for weight minimums change and his

choice of power shifts to LiPo, Ryan has made some unusual

changes to his buggy and will continue to make more. For

example, rear shock location has changed and there is an

inner hole drilled in the tower, and Ryan now uses a

spring that is lighter by one rate. Since the rear end of

the car is lighter and has less weight to stabilize it, he

also uses .5 degree hubs to compensate. Ryan still has to

add weight to meet the new rules, and the placement of the

weight is showing up in different areas, but overall his

buggy is lighter.

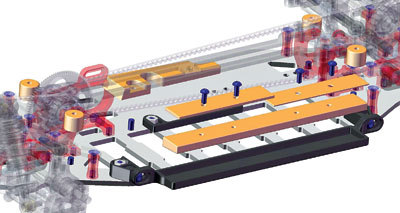

Today's

touring car chassis can be more of a challenge with most

designs sporting six rectangle spots (five in European

designs) all in line on one side of the car for your sub-c

cells (there are some exceptions, but for 99% this holds

true), with electronics and everything else on the other

side. There is a reason for this and you have to remember

that most touring cars were developed back when NiMh was

the standard. Now that LiPos are becoming standard, racers

have had to improvise to maintain the same balance. They

have used a wide variety of solutions to accomplish this.

It's not unusual to see weight added behind the battery,

in front of the battery, or directly to the battery with

double-stick tape or other fabricated piece (in this case

a scrap piece of lexan designed to work with the standard

strapping tape). One common and possibly easiest solution

is to add weight to the cut-outs in the chassis. This

keeps the center of gravity low and makes use of unused

space, but also has some limitations depending on car

design and clearance.

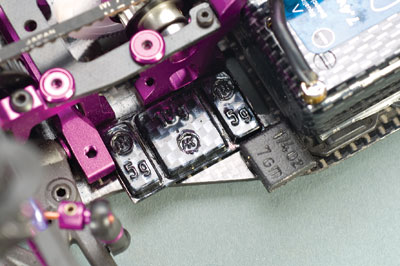

Some cars even

have specific places for adding weight to balance. The new

TOP Racing "Photon" takes this to another level

and incorporates the need to add weight by strategically

positioning chassis-specific weights in key areas. The

point is, you can't just switch batteries and run that way

and expect similar handling. Instead, plan your transition

to LiPo carefully and realize that the change will have

some side effects. You will also need to plan for a bit of

trial and error with your set-up since many of the factory

set-ups are based on the NiMH heavier cars.

Rules for

Weight

Rules for events and organizations often play a key role

in planning out your solution to the weight problem. If

you plan to do big races where rules dictate the direction

of your set-up, you may want to keep that in mind and

practice with the same restrictions you will encounter.

Most of our current rules are based on cars running with

NiMH, and only recently have the rules begun to change to

reflect the use of LiPos with only limited changes to

bridge that weight gap. Weight rules for electric are

changing fast and can be confusing with their variances.

Remember too, rules are constantly changing, so check

often and check with the governing body if you're unsure:

Example of Minimum Weights for ROAR 2009

Touring Car Foam 1418 grams

Touring Car Rubber 1500 grams

2wd Buggy 1499 grams

4wd Buggy 1613 grams

Power-To-Weight Ratio

Power-to-weight ratio (specific power) is a calculation

commonly applied to engines and mobile power sources to

enable the comparison of one unit or design to another.

Power-to-weight ratio is a measurement of actual

performance of any engine or power sources. It is also

used to measure performance of a vehicle as a whole, with

the engine's power output being divided by the curb weight

of the car to give an idea of the vehicle's acceleration.

The power-to-weight ratio (Specific Power) formula for an

engine (power plant) is the power generated by the engine

divided by weight of the engine as follows:

P-to-W = P/W

A typical turbocharged V-8 diesel engine might have an

engine power of 250 horsepower (190 kW) and a weight of

450 kilograms (1,000 lb), giving it a power to weight

ratio of 0.42 kW/kg (0.25 hp/lb).

Knowing this, if you were to take a 6-cell NiMH pack and a

2-cell LiPo pack with the same power output, considering

that a LiPo weighs significantly less, you would have a

big advantage bettering terms of power-to-weight ratio.

Ah, but this is where things can get even more interesting

since we all know the new LiPo technology means an

increase in power as well.

Hara's View

Recently I was able to catch up with Atsushi Hara and get

his thoughts about the state of touring car design. Over

the last few years, touring car design has started to

plateau with most designs seeing the battery and

electronics in basically the same configuration. With LiPo

battery technology, Hara feels that we are on the verge of

a big change in car design. With dropping weight minimums,

he feels we could see some pretty unusual stuff or may

even adopt some older designs that didn't work quite as

well with NiMH. As he points out, there really isn't a

reason why we should be carrying around so much "dead

weight" in order to balance out our cars. Will we see

touring cars with batteries in the center again, or even

have them running sideways? Time will tell, but it could

make for some interesting designs in the near future.

Conclusion

OK, now that you know a little bit about what to expect,

get to it. Yes, you will feel a difference, but you can

always start by trying to replicate the weight and

placement of your car in NiMH form and make the transition

to the lower weight through testing. Ask any engineer�he'll

tell you that light is faster on a track, so take

advantage of it. It's only a matter of time before minimum

weight rules drop and you'll be ready. |